MARKET OVERVIEW

The global nano thin film coating service market will be in a singular and expanding role in the surface engineering and advanced materials industry. The business revolves around the coating of ultra-thin layers of functional material onto a wide range of substrates, often no more than a few nanometers thick. The coatings are produced to give the substrate specific physical, chemical, or biological characteristics that cannot be obtained using ordinary coatings at this microscopic scale. The global nano thin film coating service market will address industries that need extremely high levels of performance improvement, product durability, and reliability requiring very high levels of surface modification accuracy. The market will be defined by services offering nanometer-level thickness, composition, and uniformity control of films.

Services provided by atomic layer deposition (ALD), molecular layer deposition (MLD), chemical vapor deposition (CVD), and physical vapor deposition (PVD) technologies will be the leaders in services. These processes will allow the development of corrosion-resistant surfaces, friction-reducing surfaces, optically clearer surfaces, or even biocompatible surfaces for medical devices. Customization will be a cornerstone in the global nano thin film coating service market because customers from the electronics, energy, automotive, and healthcare sectors will need coatings that are very specific to functional requirements. Nano-scale coatings usage will not only be limited to enhancing product durability or esthetics. In the case of high-performance electronics, for instance, nano coatings will be utilized for insulation and temperature control without decreasing component size or efficiency.

The Global Nano Thin Film Coating Service industry will have crucial roles in the production of compact high-performance semiconductors and sensor technologies requiring high precision as well as minimum material waste. In medical devices, these services will be utilized for designing surfaces to be antimicrobial, hem compatible, or tailored for drug delivery functions and will play increasingly important roles in personalized medicine as well as in implantable devices. Optical uses will continue searching for nano thin film coatings which manage light transmission, reflection, and absorption at specific wavelengths. The global nano thin film coating service market will meet this need with coatings used in high-end lenses, solar cells, and display technology. Nano-level uniformity and adhesion will be essential, particularly where optical performance must be preserved over complex geometries or sensitive substrates.

As design requirements increase, service providers will be focusing on maximizing process parameters that ensure repeatability and quality. In aerospace and defense uses, where weight, strength, and resistance to harsh environments cannot be compromised, nano thin film coatings will be a viable solution to protect components without adding bulk. The global nano thin film coating service market will answer this need by offering solutions that maximize performance without compromising structural integrity. Service providers will also continue to make investments in equipment supporting precision deposition within highly controlled conditions. With the continuous transformation in the market, the global nano thin film coating service market will no longer be limited to technical details but also on compliance requirements and environmental issues. Coating services will be increasingly about integrating green practices, material as well as energy, in order to meet worldwide compliance regimes as well as customer demands. This market will offer a revolutionary overlap of industrial practice and material science discovery, whose relevance will grow in direct proportion to progress within nano-scale technology.

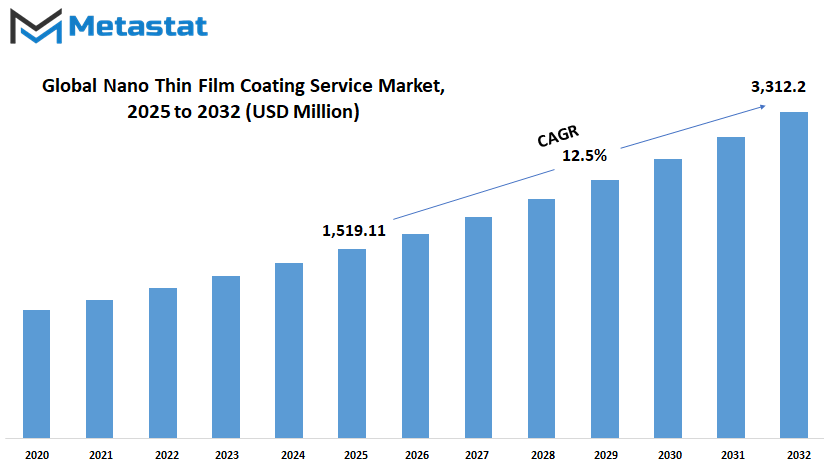

Global nano thin film coating service market is estimated to reach $3,312.27 Million by 2032; growing at a CAGR of 12.5% from 2025 to 2032.

GROWTH FACTORS

The global nano thin film coating service market will continue to increase steadily over the next few years as industries in various sectors search for more advanced means of protecting surfaces and promoting functionality. The market will be driven by high momentum as higher demand is developed for coatings that are extremely thin but highly functional in terms of delivering benefits such as durability, anti-reflection, and resistance to wear. As industries look for materials and technologies that improve product performance with lower energy consumption and material loss, the worth of nano thin film coatings is increasingly evident. Among the major reasons for the potential of the market is the growth of markets like electronics, automotive, medical devices, and renewable energy.

These sectors need coatings that are deposited with precision, have lasting effects, and perform best under fluctuating conditions in the environment. The need for miniaturized and high-performance electronic equipment, for instance, will fuel the application of such coatings. The need for light materials with strong protective capacities, especially in the automotive and aircraft industries, will also be a major factor. These coatings enhance product lifespan and reduce maintenance costs, which generates massive value for businesses. Environmental awareness and stricter regulations on material consumption are also shaping the future of this sector. Nano coatings can reduce the amount of thicker protective coatings used, which decreases the overall resources utilized. They also enable the shift to energy-efficient technologies, especially in solar panels and other clean energy devices.

This will also fuel demand in the global nano thin film coating service market. However, some of the above challenges might impede the advancement. Technical know-how and high production cost might limit small companies and make it difficult for them to access the market. In addition, there may be concerns over the long-term stability and safety of some nano materials, which could lead to greater regulations or reluctance to adopt.

On the other hand, continued investment in research and development will provide new opportunities for this market. Increasing numbers of businesses will be able to utilize these coatings in their products as methods become less expensive and simpler to apply.

Technological advances allowing greater customization and greater performance will also provide new opportunities. With these types of advancements continuing, the Global Nano Thin Film Coating Service industry will expand further into new regions, delivering above-and-beyond benefits.

MARKET SEGMENTATION

By Type

The global nano thin film coating service market is bound to leave a noteworthy influence on the manner in which industries prepare for the future. As technology advances and industries look for more efficient and durable materials, thin film coatings are becoming more prominent. With the purpose of making products perform better in areas such as electronics, healthcare, automobiles, and energy, thin film coatings have been developed. They work by leaving a highly thin layer on surfaces, which strengthens their wear resistance, moisture resistance, light reflectance, and other resistances in the environment. This technology is not only beneficial but also essential in facilitating innovation across many sectors. By the year 2025, this market is anticipated to demonstrate extraordinary growth, especially when segmented based on coating type.

For example, Anti-reflective Coatings are expected to be valued at USD 447.09 million. They are used to remove glare on lenses and screens and are thus valuable for application in optical instruments and electronics. Anti-corrosion Coatings, valued at USD 463.78 million, are useful in preventing corrosion on surfaces from exposure to chemicals and moisture. This is particularly useful for application in industrial and construction use. Anti-fingerprint Coatings, anticipated to reach USD 282.85 million, are increasingly being utilized in smartphones, tablets, and other hand-held devices that are commonly handled. The coatings keep surfaces clean and improve the experience of users. Hydrophobic Coatings, anticipated to be valued at USD 325.39 million, make water non-adhesive and maintain surfaces dry. These are being used increasingly in cars, medical equipment, and even apparel. In the years to come, demand for nano thin film coatings will only increase as increasingly more industries recognize the advantage of improved product quality at reduced maintenance. As production methods continue to advance, these coatings are going to be increasingly cost-effective and feasible.

Companies will be all the keener to adopt this technology not just for its performance benefit, but for maximum cost savings as well. Greater emphasis on sustainability will also make manufacturers choose coatings that extend the life of their products and conserve waste. Overall, the global nano thin film coating service market is replete with potential. It is remodeling how products in the future will be produced and serviced. More companies coming into the industry means that the use of advanced coatings will become the norm in production and design. The transformation not only will change how things operate but also make it possible for smarter and more efficient ways to produce and protect materials.

By Coating Material

The global nano thin film coating service market is slowly creating the future for many industries. The coatings are put on surfaces to protect them, improve their performance, and in other instances, change how materials behave altogether. What is so special about this technology is that the coating is so thin—nearly invisible to the naked eye, but powerful in its use. As demand for lighter, smaller, more efficient products grows in industries like electronics, healthcare, and energy, this market will continue to be in the limelight. The coatings are not just for protection anymore. They also make products more durable, reduce friction, and allow products to operate under more adverse conditions without being broken. This value creates opportunities for innovation in products that need to perform reliably over time. By the coating material, the global nano thin film coating service market is easier to comprehend.

Metal oxides are typically used as they have greater resistance to heat and corrosion. They may be applied to surfaces that have to withstand severe environments. Nitrides are another alternative, often used where hardness and strength are of primary importance and employed within high-performance machinery. They make machines last longer without needing to be repaired or replaced. Metals are used when electrical conductivity is important. They can make circuits or sensors work better where current must flow with ease. Polymers, while being light and elastic, provide a surface that resists wear and tear in moving parts. Diamond-Like Carbon, or DLC, offers a combination of hardness and smoothness that is distinct. This material is friction-reducing and offers a hard shield against damage. In the future, this market will grow as more industries employ nanotechnology. More people and businesses are seeking lightweight materials but want them to stay strong.

Nano thin film coatings offer them a way to achieve this balance. They don't add bulk but also offer protection and improve how a product performs. Over the next few years, the application is likely to grow in wearable electronics, solar power systems, and medical devices. As products are miniaturizing and increasing in complexity, these coatings will be needed more than ever before. The ability to control materials at this infinitesimal level will unlock doors and shatter records for smart and durable products. This is a sign of things to come where surface coating is not something added as an afterthought but an integral part of product design from the beginning.

By Application Method

The global nano thin film coating service market will experience stable growth with the increasing demand for enhanced surface properties in various industries. These thin films are used to enhance durability, increase wear resistance, and create protective barriers on a wide range of materials. As industries continue to require greater performance at lower material consumption, the need for nano thin film coatings will continue to rise. What is most notable about this market is that it applies leading-edge material science to real-world applications. Future industries will tap into these coatings as they are looking to drive performance and sustainability goals at the same time. Looking at where these coatings are applied, we can observe in which directions the market will progress.

Physical Vapor Deposition, or PVD, is evaporating a solid material and subsequently depositing onto a surface. It gives a clean, even layer and is applied in electronics, optics, and medical devices. Chemical Vapor Deposition, or CVD, relies on the use of gases that react on the surface of a material to form a coating. CVD is ideal when high adhesion and quality finishes are needed. Then there is Atomic Layer Deposition, or ALD, which builds films one atomic layer at a time. This provides unprecedented control of thickness and uniformity, which is crucial in high-tech electronics and nanotechnology. With advancing technology, the demand for more efficient and accurate means will propel the market. Products will be faster, smaller, and more powerful.

This will subsequently fuel an even greater demand for ultra-thin and reliable coatings. Companies who can provide services through PVD, CVD, or ALD in less stringent and cost-effective ways will have a better opportunity to meet future needs. This growth will be fueled by electronics and optics, but also by industries like healthcare, energy, and aerospace that are increasingly finding the benefits of such coatings. The future global nano thin film coating service market will be central in the development of materials that are not only functional but more sustainable. Focus on innovation and better use techniques, this market will be even more critical in helping businesses cross the hurdles of the future.

By End-user Industry

The global nano thin film coating service market is also gaining attention for the role it plays in boosting the performance and longevity of different industries. The market is likely to witness uniform growth as more and more companies learn about the long-term benefits of thin film coatings. The coatings, even though they have an extremely thin thickness, are very resistant to water, scratches, and even corrosion. Over time, this protection will extend the life of products and make them better in terms of appearance and performance. As companies try to stay competitive, they are likely to implement this technology to a larger degree. In the electronics sector, thin film coatings are already making it simpler for manufacturers to develop products that are more durable and have a longer lifespan.

These coatings are capable of protecting sensitive components from dust and moisture, which will become even more important as devices shrink and become more advanced. In the short term, we can expect these coatings to become standard across a majority of electronic devices, from smartphones to advanced computing systems. This will reduce damage and improve performance, making devices more appealing to buyers. The automotive industry will also stand to benefit. Vehicles are becoming smarter and more dependent on electronic systems, which require more protection. Nano coatings offer a light, efficient way of coating surfaces without adding weight. With the growing demand for electric and autonomous cars, the need to protect sensors and circuits will also grow. Nano coatings will play a growing part in meeting these needs. In aerospace, every gram matters, and these coatings deliver strong performance without weight. They shield against wear and tear due to harsh conditions, which is crucial for safety and longevity. As new aircraft models are developed, the use of advanced coatings will make them more efficient and safer.

Healthcare is yet another sector where these coatings are becoming important. They are used on medical devices and implants to prevent bacterial growth and increase longevity. As the focus remains on cleanliness and safety, especially in laboratories and hospitals, this trend will only gain momentum.

The renewable energy industry will also be impacted. Wind turbines and solar panels have to endure extreme weather, and thin-film coatings can protect them from devastation. As clean energy has a greater place in the world's plans, the coatings will help maintain systems running longer and more effectively. Other industries are starting to realize the benefit too, and it is not surprising that in the years to come, the Global Nano Thin Film Coating Service business is used increasingly.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,519.11 million |

|

Market Size by 2032 |

$3,312.27 Million |

|

Growth Rate from 2025 to 2032 |

12.5% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global nano thin film coating service market is poised to be one of the biggest breakthroughs in contemporary technology services. With demand increasing in different sectors, ranging from electronics to solar power, the market is likely to be adopted far and wide in the near term. The process itself involves depositing an ultra-thin coating of material onto a surface, which adds such properties as durability, wear resistance, and even electrical conductivity. The technology itself is not new, but it is picking up steam because it can be customized for very specific applications, which makes it viable for everything from consumer electronics to industrial machinery on a massive scale. In the future, research and development will dominate this market.

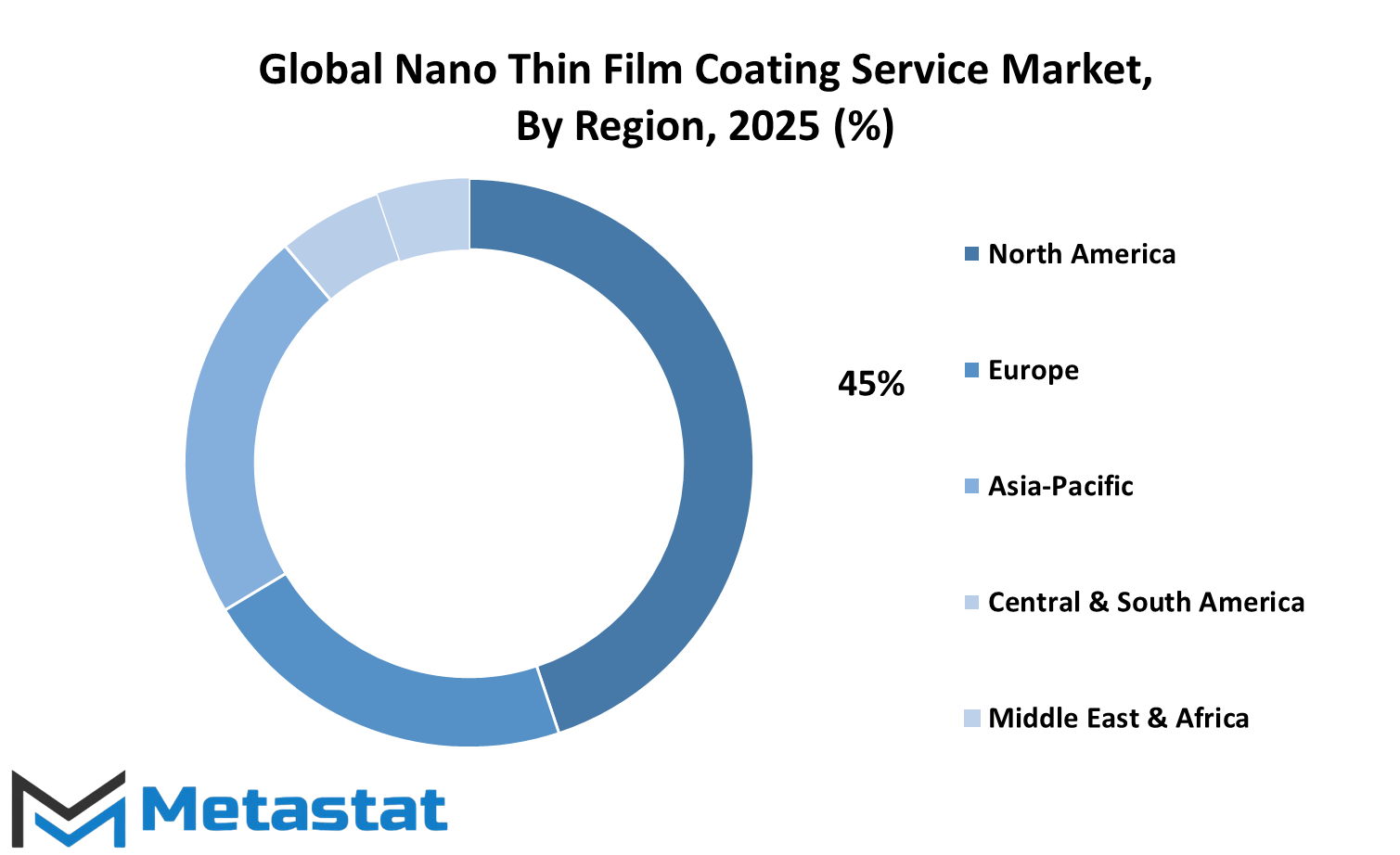

More companies are discovering how these coatings can make their products more durable and perform better, particularly in harsh environments. As production methods are improved, businesses will seek means to lower the cost of production without compromising product quality. That is where nano thin film coatings fit in. By providing protective and performance-enhancing films, these coatings are no longer a feature but rather an absolute requirement in industries that require precision and reliability. Globally, the global nano thin film coating service market is spread over a number of significant regions. North America, with the U.S., Canada, and Mexico included, is likely to experience growing interest because of a focus on the earliest adoption of new technologies.

Europe, which includes the UK, Germany, France, Italy, and so on, also demonstrates strong potential, mainly in automotive and renewable energy. In Asia-Pacific, countries like India, China, Japan, and South Korea are gaining significantly on account of higher manufacturing activity and increasing interest for energy-efficient solutions. South America, particularly Brazil and Argentina, will progressively increase utilization of this technology, particularly in the industrial and agricultural equipment sector. The Middle East and Africa, including GCC Countries, Egypt, and South Africa, will experience growth in this area as infrastructure projects and technology programs keep expanding. As more companies see the benefits of advanced surface technology, the global nano thin film coating service market is expected to be a major influencer in shaping next-generation product development. It will not only provide protective functions but also assist companies in achieving increased consumer expectations of quality, efficiency, and sustainability.

COMPETITIVE PLAYERS

The Global Nano Thin Film Coating Service industry will become more prominent as technology continues to shape the manner in which industries operate and deliver results. The industry, which consists of applying very thin layers of material onto surfaces to enhance performance, is getting more and more attention from companies seeking to increase durability, resistance, and efficiency in a number of applications. From electronics to medical devices and even automobile components, these coatings improve performance while reducing wear and tear. With industries calling for smaller, lighter, and more efficient products, the demand for such coatings will keep increasing. What makes this market even more fascinating is the way companies are positioning themselves to meet these increasing demands. A number of key players are already leading the way with innovative solutions which cater both to current needs and future possibilities.

P2i Limited and Nanofilm Ltd. are some of the businesses which have clearly made efforts to offer water-repellent and protective coating services that are effective and reliable. Their focus on adapting their technology to suit diverse industries has put them ahead of the competition. Modumetal Inc. and Nanoslic Protective Nano Coatings also have their part to play with their capacity to make coatings that have excellent corrosion and friction resistance. With sectors like aerospace and healthcare searching for materials that are not merely durable but light weight as well as safe, the service of such coatings becomes even more valuable. Buhler AG and SilcoTek Corporation both specialize in advanced methods, looking to improve the way nano coatings bind to different surfaces. This can open up new uses in sectors that previously did not utilize such technology.

Kurt J Lesker Company and Nanocare Technologies have also focused on customization and adaptability, making their services more attractive for clients with specific needs. Meanwhile, companies like Nanophase Technologies Corporation and Advanced Nano-Coatings, Inc. are researching newer types of coatings that respond to a change in temperature or chemical exposure. These smart functions could redefine industries' perceptions of maintenance and product lifespan. Veeco Instruments Inc., Evaporative Technologies Inc., Intlvac Thin Film Corporation, and Leybold GmbH are introducing a lot of support in equipment and machinery, making the service aspect of the industry more precise and reliable. In the future, their technical support in high-tech equipment will play an important part in making coating services universally accessible, efficient, and of good quality. Together, these players are building a future where the global nano thin film coating service market plays an increasing role in how products are made, consumed, and changed over time.

Nano Thin Film Coating Service Market Key Segments:

By Type of Coating

- Anti-reflective Coatings

- Anti-corrosion Coatings

- Anti-fingerprint Coatings

- Hydrophobic Coatings

By Coating Material

- Metal Oxides

- Nitrides

- Metals

- Polymers

- Diamond-Like Carbon (DLC)

- Other

By Application Method

- Physical Vapor Deposition (PVD)

- Chemical Vapor Deposition (CVD)

- Atomic Layer Deposition (ALD)

By End-user Industry

- Electronics

- Automotive

- Aerospace

- Healthcare

- Renewable Energy

- Other

Key Global Nano Thin Film Coating Service Industry Players

- P2i Limited

- Nanofilm Ltd.

- Modumetal Inc.

- Nanoslic Protective Nano Coatings

- Buhler AG

- SilcoTek Corporation

- Kurt J Lesker Company

- Nanocare Technologies

- Nanophase Technologies Corporation

- Advanced Nano-Coatings, Inc.

- Veeco Instruments Inc.

- Evaporative Technologies Inc.

- Intlvac Thin Film Corporation

- Leybold GmbH

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252