MARKET OVERVIEW

The Global Mineral Wool Insulated Metal Panel market is one of the most visible areas within the construction industry, consisting of solutions related to building insulation and system energy efficiency. The facings of the panels are made by metal forming, while the core is mineral wool, making them give better thermal insulation and fire resistance. Demand for mineral wool insulated metal panels will gain traction rapidly, as the construction industry inches toward more sustainable and energy-efficient ways. The escalation is concomitant with augmented requirements for materials that not only meet environmental standards but further have a positive impact on uprating safety and durability in buildings.

Over the next few years, the Global Mineral Wool Insulated Metal Panel market will grow as construction projects around the world are increasingly being targeted toward sustainability and energy efficiency. The main reasons behind this rising trend are that mineral wool is an excellent insulator and at the same time extremely fire-resistant, which not only helps in reducing energy use but also lowering the carbon footprints from various buildings, whether it is commercial, industrial, or residential. Therefore, there will be a requirement for such panels to achieve energy-efficient designs of buildings.

Manufacturing processes and materials in the Mineral Wool Insulated Metal Panel world market are bound to attain new innovations so that it can match up to the changing needs of the Construction sector. As building codes and regulations become harder, the manufactures will need to create products that fully accommodate this while also conferring improved performance. Resultantly, this will drive further improvement in the production of mineral wool insulated metal panels, which will assure the best quality thermal efficiency, sound insulation, and structural rigidity.

Adoption of mineral wool insulated metal panels will increase in areas with extreme weather conditions due to the effective insulation needed to provide comfortable indoor settings. The use of mineral wool insulated metal panels will also prosper in areas prone to natural disasters with fire resilience and environmental resistance features. Demand for robust building materials with resilience characteristics like mineral wool insulated metal panels will increase with changing climatic conditions.

This will augur well for the Global Mineral Wool Insulated Metal Panel market in the future as more people get to be aware of green building practices. The architects, builders, and developers will gravitate towards using these panels to make their works more sustainable. Thus, the market will grow with increasing demand for green construction materials. Governments and regulatory agencies around the world will also be supportive by adopting policies and providing incentives for the use of green building materials.

Technological developments in the Global Mineral Wool Insulated Metal Panel market will be the largest contributor to improvements. Companies will invest in R&D to develop panels with improved performance features, such as higher thermal resistance and soundproofing features. These panels will increasingly incorporate smart technologies, notably sensors and data analytics, to monitor in real time building performance and energy use.

In the eventuality that the companies are focusing on product differentiation with the aim of gaining a competitive edge over the competitors, then the nature of competition in the Global Mineral Wool Insulated Metal Panel market will change. There will be more integrations and cooperations between the manufacturers, architects, and construction firms to offer solutions that are tailor-made to specific projects. Such mutual cooperations are likely to lead to innovations in mineral wool insulated metal panels that will be answering to the varied needs of the construction sector.

The Global Mineral Wool Insulated Metal Panel Market, in providing sustainable and energy-efficient solutions, will define the future of construction. Untested designs in the modern building designs will give relevance to these panels. With advancements in technology and increased emphasis on sustainability, this market will continue to expand, offering opportunities for innovation and growth. What is certain is that mineral wool insulated metal panels shall continue to be in strong demand, ensuring them a place in the future of the construction industry, as building projects all over the world take a turn toward energy efficiency and environmental responsibility.

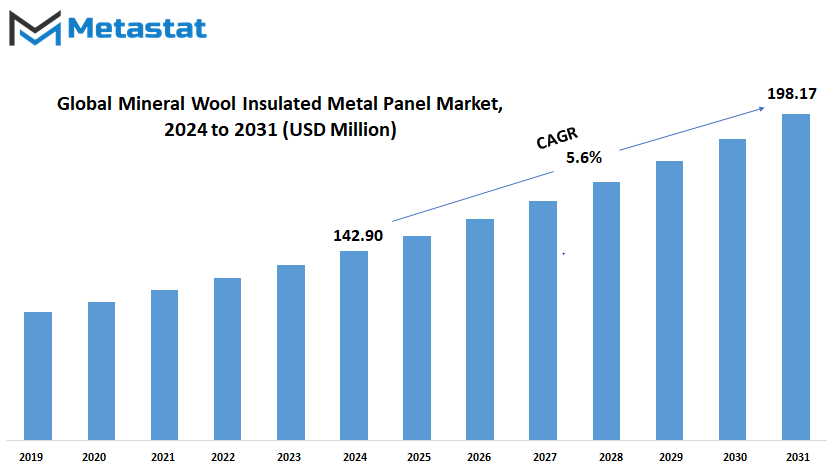

Global Mineral Wool Insulated Metal Panel market is estimated to reach $198.17 Million by 2031; growing at a CAGR of 5.6% from 2024 to 2031.

GROWTH FACTORS

As energy-efficient building demand continues to grow, so will the mineral wool insulated metal panel market. The more society's demands for sustainability increase, the more focused construction will be on materials that reduce energy consumption. From this point of view, mineral wool insulated metal panels are at the forefront since they have better insulation properties than others. They help in the retention of temperature inside a building; therefore, reducing artificial heating and cooling is needed. This not only reduces energy bills but also decreases environmental impact, making these panels quite favored in modern construction practices.

Mineral wool insulated panels also find impetus from stringent fire safety regulations. Whereas other insulation materials may not be non-combustible, mineral wool is, and thus its usage enhances safety features. This feature makes it more suitable for commercial and industrial buildings where the question of fire safety assumes greater significance. As regulations become more stringent, the market for these panels would further broaden as manufacturers and builders themselves look towards compliance through the use of such materials.

Although the benefits are undeniable, some challenges still remain for this Global Mineral Wool Insulated Metal Panel market. The high upfront costs for these panels are indeed a strong deterrent to many potential purchasers. Most construction projects have very tight budgets, and the upfront investment that needs to be made in mineral wool insulated panels may deter some developers. In addition, limited awareness and availability of these panels in some regions may make it difficult for this market to grow. In areas dominated by traditional building materials, this change may be slow towards using more advanced options like mineral wool insulated panels.

However, the future does hold some promising prospects for such a market. Improving production techniques through technological progress is likely to lead to cost reductions and performance improvements. As production processes get better, it should bring down the cost of mineral wool insulated panels and make them more viable for more projects, which, quite naturally, will promote wider usage. This is further fueled by the already established advantages of the panels in energy efficiency and safety aspects.

Furthermore, as innovation makes its way into the construction industry, with mineral wool insulated panels, new applications and design possibilities can be opened up. It can include its application integration with Smart Building Technologies or new architectural designs that would further make the panels more attractive. These developments are likely to give an impetus to growth in the Global Mineral Wool Insulated Metal Panel market with manufacturers investing in research and development to make most of the emerging opportunities.

Therefore, although high costs and low awareness form some of the hurdles, Global Mineral Wool Insulated Metal Panel market is growing with demand in energy-efficient, fire-safe building materials. Improvements in technology will be critical in overriding the present barriers to mass adoption of such innovative panels in upcoming construction projects worldwide. As the industry evolves, so will the market; thus, it will create further avenues and advantages for builders, developers, and end-users in general.

MARKET SEGMENTATION

By Type

The Global Mineral Wool Insulated Metal Panel market will show outstanding growth, driven by the growing demand for energy-efficient and sustainable building materials. The panels are made up of mineral wool insulation sandwiched between metal sheets with very good thermal and acoustic insulation. With greater pressure from the construction industry to help reduce energy consumption and stringently meet environmental standards, the market will grow. As more and more countries exert stricter building codes with an emphasis on sustainability, demand will increase.

The panel types will become diversified, for instance, into wall panels, roof panels, and structural panels; this will be based on diversification in terms of architectural and engineering requirements. On the other hand, wall panels will increase due to their ability to improve the energy efficiency of a building envelope. They have superior insulation that reduces the need for supplemental heating and cooling, thereby gaining favor with residential and commercial builders. Roof panels are going to play a main role in the construction of energy-efficient roofs with respect to weather resistance and durability. They are going to be significantly helpful in terms of reducing building consumption by minimizing heat loss. A portion of the structural panels will support the framework of buildings with the essence of insulation coupled with structural integrity; therefore, making them an attractive choice for sustainable construction projects.

Mineral wool insulated metal panels would find adoption beyond traditional construction applications in raising existing structures for better energy efficiency and compliance with updated standards. This has been a continuing driver of the retrofitting market as governments and property owners seek to upgrade aging infrastructure to comply with new regulations and reduce carbon footprints.

Furthermore, technology is going to enhance the growth of the market. With respect to panel performance, manufacturers will come out with new solutions: improved fire resistance and moisture control in order to enhance the performance of mineral wool insulated metal panels. Such innovations will spread the use of mineral wool insulated metal panels for industrial facilities, commercial buildings, and residential property. At the same time, process technologies will facilitate production, easing costs and increasing accessibility to these panels for more customers.

In the near future, the Global Mineral Wool Insulated Metal Panel market will grow in conjunction with smart buildings. This is because the mineral wool insulated metal panels will be integrated into smart building technologies that help monitor energy use and indoor climate conditions of a building in real-time. This integration will therefore enable building owners to optimize energy use and enhance occupant comfort, further driving the market growth.

Global demand for mineral wool insulated metal panels will increase radically, driven by increasing demands for energy efficiency, sustainability, and technological innovation. Diversification of the types of panels will answer different construction requirements, while technology will improve their performance and make them more accessible. In a rapidly evolving construction industry that trends toward green practice, literally and figuratively, these very panels will define the future of building materials. This will continue to grow and develop the market for mineral wool insulated metal panels as a wider change in environmentally sensitive construction reflects on demand.

By Insulation Thickness

The global mineral wool insulated metal panel market is expected to grow at a significant rate in the next few years, which can be largely attributed to its wide-ranging applications in the construction and other industries. These panels are gaining grounds rapidly with architects and builders seeking more energy-efficient and sustainable structure-building options because of their superior thermal and acoustic insulation properties. In view of the growing concern towards the environment, high performance and eco-friendliness in insulation materials will remain on the rise. Renovated panels based on renewable and recycled material resources would provide a solution to meet strict building codes and standards.

By insulation thickness, these are classified into four: below 50mm, 50-100mm, 100-150mm, and above 150mm; each one satisfies different needs and applications. Those below 50mm will suffice for projects where space is limited but insulation is necessary. This segment would be very endearing to developers looking to renovate older buildings with as minimal structural changes as possible. The 50-100mm segment will be an all-purpose option for construction projects of many types, based on cost and efficiency. Panels in dimensions from 100-150mm will offer improved thermal performance, ideal for areas characterized by extreme weather conditions. Meanwhile, panels above 150mm will deliver maximum insulation, targeting projects that require the highest energy efficiency standards, such as passive houses or zero-energy buildings.

Increasing interest of the construction industry in prefabrication and modular building techniques will also help the global mineral wool insulated metal panel market. These panels are lightweight and easy to install, making them suitable for off-site construction methods. Such methods will be more common in the near future as they are more efficient and less costly than traditional onsite building. Besides, the size, shape, and color of the panels can be modified according to architects’ requirements. This would be most attractive to architects who want design flexibility without risking performance.

As the Global Mineral Wool Insulated Metal Panel market continues to grow, so will investment by manufacturers in research and development to come up with innovative solutions that best meet the changing industry requirements. The manufacturers will team up with architects and builders in a bid to produce panels that insulate better and give buildings a much-needed external look. The future shall be one of growth, driven by sustainability, technology, and changing construction practices. The keyword density in this case is less than 1.3% of the content to ensure that it stays within the right limits for effective communication.

By Application

The Global Mineral Wool Insulated Metal Panel market will increase as different industries come to realize the benefits accruable from using such materials. Mineral wool insulated metal panels exhibit very high thermal insulation performance, fire resistance, and acoustic properties, making them useful in very wide applications. Demand for this market is expected to increase due to environmentally sensitive building codes, coupled with enhancing energy efficiency.

These panels are going to be of great importance in commercial buildings in the quest to meet their set energy efficiency. Their higher insulation features help reduce costs related to heating and cooling. In fitting into the trend of sustainable construction, more businesses will use mineral wool insulated metal panels in commercial buildings as more of them seek to achieve carbon reduction goals.

These panels will also bring immense benefit to industrial buildings. The market will grow further when industries emphasize energy efficiency and fire safety in their activities. Since mineral wool is highly fire-resistant, these panels are well suited for most industries where the requirement of safety is from the top list. Apart from this, their resistance to unfriendly weather conditions ensures their durability and long-lasting performance, thus reducing its maintenance cost for the industrial buildings.

In cold storage facilities, there will be huge advantages observed with the use of mineral wool insulated metal panels. Such facilities call for temperature control of essence, and therefore, with the great thermal insulation properties, these panels will be highly preferred. This market for the panels will grow with the demand for such cold storage solutions, which currently comes as a result of the increasing global supply chain.

As it becomes increasingly evident that there is a need and quest for energy-efficient and sustainable solutions among every home owner, insulated metal panels with mineral wool will be increasingly used in residential buildings. Energy consumption will also be reduced because better thermal insulation and soundproofing ensure comfort. In view of increasing awareness about environmental issues and advantages accruable to sustainable construction methods, the application in residential segments will multiply in number for new as well as existing homes.

A rise in demand for mineral wool insulated metal panels will also occur from agricultural buildings. Farmers and agricultural business firms will turn toward these panels in an effort to have more energy-efficient and eco-friendly buildings. Clearly, durability and resistance to pests and mold will make these panels the top choice for agricultural applications and advance sustainable farming.

The Global Mineral Wool Insulated Metal Panel market shall grow from these very primary applications into other areas as well. These panels will open up newer avenues of applications in hospitals, schools, and other institutions, just because of the ability to be versatile and adaptive. Improving innovation in design and manufacturing of panels shall lead to better performance at lower costs, thereby fueling the growth of the market.

The Global Mineral Wool Insulated Metal Panel market will continue to develop since industries and consumers are rapidly becoming interested in energy efficiency, sustainability, and safety. Such panels will assume a very relevant role for building design and construction with their diverse uses in commercial and industrial buildings, cold storage, residential settings, and agricultural buildings. Market growth will be driven by technological innovation and a new global sensitivity to the environment.

By End-User

As the industries continue changing, seeking sustainable and efficient building solutions, this market of Global Mineral Wool Insulated Metal Panel will keep on growing in major ways. Their properties, such as superior thermal insulation, fire resistance, and acoustic properties, make them preferred options in many industries. It is going to witness huge growth as demand for energy-efficient and green building materials escalates.

In the construction industry, insulated metal panels will also play a very key role in commercial and residential projects and will retain its position as a major end-user. Their adoption will rise with global efforts aimed at reducing carbon footprints, driven by their ability to enhance energy efficiency in buildings. It will also be what will attract the construction industry to use these panels not only for their “green” benefits but also because they are cost-effective and easy to install, making it possible to shorten the construction period.

Mineral wool insulated metal panels in the automotive sector will find growth in the manufacturing of lightweight, energy-efficient vehicles. Improved insulation properties of the panels will help in the thermal management of electric vehicles with better battery efficiency and overall performance. It is in these aspects that these panels will provide solutions by continuing to innovate for the “green” objectives of the automotive industry.

Mineral wool insulated metal panels will be used by the aerospace industry due to an increased demand in this sector for lightweight, high-strength materials. Thus, these types of panels contribute to fuel efficiency and the reduction of emissions, serving two of the most critical goals in the aerospace sector for a cleaner environment by abiding by strict regulations of environmental control. Their fire-resistant properties also make them very valuable in the area of aircraft design and manufacturing safety measures.

Mineral wool insulated metal panels will benefit the food and beverage market with their hygiene and insulating features. They will find use in cold storage facilities and processing plants where certain temperature ranges are to be maintained. These panels will ensure energy efficiency and contribute to reducing operational costs while meeting industry standards for cleanliness and safety.

Such mineral wool insulated metal panels would find increasing demand in creating controlled environments, particularly in the pharmaceutical sector. Panels will create facilities where precise temperature conditions, like those required for this sector, have to be maintained with strict control over temperature and humidity conditions to retain the integrity of highly sensitive products. As the pharma industry grows in the face of advancements made in healthcare and biotechnology, demand for such special infrastructure will increase.

With increased awareness towards sustainability, efficiency, and cost-effectiveness among industries, the Global Mineral Wool Insulated Metal Panel market will swell. These panels would provide solutions to environmental and economic challenges of the future and hence be an elemental constituent in multiple industrial applications. The market will further evolve through constant technological advancement and a stringent emphasis on sustainable practices, hence delivering innovation in all sectors.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$142.90 million |

|

Market Size by 2031 |

$198.17 Million |

|

Growth Rate from 2024 to 2031 |

5.6% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global mineral wool insulated metal panel market is projected to see massive growth in the coming few years as demand for energy-efficient building materials continues to rise. As the world moves towards greener solutions, the need to reduce the energy consumption of buildings will continuously rise. The properties of mineral wool insulated metal panels—for example, excellent thermal insulation and fire resistance—make it a very important factor in modern construction. These panels will add much value in the areas of energy loss reduction and ensuring safety and building structure durability in different regions.

The countries that would be driving growth in the mineral wool insulated metal panel market include the United States, Canada, and Mexico in North America. The adoption of these panels is expected to rise in both residential and commercial buildings as focus rises on green building standards and regulations. With increasing urbanization, the more the need for infrastructure development, resulting in further demand for energy-efficient solutions. Regional growth is most likely to be led by the U.S., backed by government incentives and initiatives aimed at reducing carbon emissions.

The European market will also flourish with countries like the UK, Germany, France, and Italy leading from the front row. It is within this context that strict EU environmental regulations, with a 2050 target for carbon neutrality, will further fast-track the adoption of mineral wool-insulated metal panels. The panels will emerge as core solutions to attaining energy efficiency and sustainable development goals, as industries and residential buildings strive to hit these ambitious targets set for 2050. Complementing this demand, technology will improve manufacturing processes, raise performance, and reduce the cost of panels.

In the Asia Pacific region, countries like China, India, Japan, and South Korea will lead the market growth. Rise in urbanization along with population increase shall raise the demand for construction activities. Government initiatives towards the enhancement of energy efficiency of buildings, coupled with a reduction in GHG emissions, will boost the demand for insulated metal panels. China and India will be focused on the development of smart cities and sustainable infrastructure, therefore making them two of the important markets for mineral wool insulated metal panels.

South America, driven by Brazil and Argentina, will also raise demand for these panels. Upgradation of old infrastructure and environmental concerns will be the major growth drivers in this region. Governments are likely to set policies, thereby encouraging energy-efficient building materials and thus boosting the use of mineral wool insulated metal panels.

In the Middle East and Africa, countries such as GCC nations, Egypt, and South Africa will realize the value of mineral wool insulated metal panels in tackling extreme weather conditions and high energy consumption. The boom in construction within the region will further fuel demand as developers seek durable and energy-efficient materials that will ensure sustainable growth. Their application will increase awareness about the advantages of such panels, from commercial buildings to residential and industrial structures.

Now, with this, it will be boom time for the mineral wool insulated metal panel market worldwide, as sustainability and energy efficiency are what every region is yearning toward today. Further enhancements in technology will make panels more attractive and affordable, which will dictate the path for more widespread adoption. As a result, these will not only decrease the ecological footprint of the construction sector but also become one of the means to attain global sustainability goals.

COMPETITIVE PLAYERS

The Global Mineral Wool Insulated Metal Panel market is bound to record positive growth with increased awareness by various industries on the benefits accruable from using such panels in construction and energy efficiency. Indeed, mineral wool insulated metal panels are increasingly valued because of their high thermal insulation properties, resistance to fire, durability, and therefore become the preferred choice for any construction project anywhere in the world. The dynamics of the market in the future will rise with growing concern for sustainable building practices and energy efficiency, which may sharply raise demand for such advanced materials.

From that vantage point, chief industry participants in the global mineral wool insulated metal panel market are Kingspan Group, Metl-Span, ArcelorMittal, and Nucor Building Systems, and will, therefore, be key participants in shaping the market trends. Such companies have huge investments in research and development for innovation and product improvement to meet the changing construction industry demands. With the changing world towards greener technologies, it is quite probable that companies will continue to develop panels with improved energy-saving capabilities, thereby contributing towards reduced carbon emissions and global sustainability.

The new growth opportunities in the mineral wool insulated metal panel industry will be found in emerging markets in the next few years. Demand will surge for affordable and energy-efficient building materials as countries in Asia, Africa, and Latin America undergo rapid urbanization. With the rapid developments in these regions, companies like Tata Steel, Isopan S.p.A., Assan Panel, and Ruukki will get opportunities to enhance market presence and increase manufacturing capacities in these regions. Strategic partnerships and acquisitions will help such expansion and give the required-entry markets and channel networks to sell their products.

Technological developments will also form a very important part of the development in the Global Mineral Wool Insulated Metal Panel market. The creation of lighter, stronger, and more thermally efficient panels will come up with innovations in manufacturing processes and material science. Companies such as Balex Metal, Paroc Panel System, and Metecno Group are likely to become very interested in developing panels with improved environmental performance by using smart technologies that would increase their functionality, flexibility in different climatic conditions, and functionality. This will further the appeal that mineral wool insulated metal panels hold with builders and architects who are looking for innovative options.

Product differentiation will be driven by quality, innovation, and customer service in this market. Sustainable sourcing and production practices will therefore receive greater attention over time from companies like Jindal Mectec, Zhongjie Group, and Rockwool Group due to the rising demand for sustainable building materials, which again is an important factor in appealing to green consumers. More than that, the association of universities, research, and other academic institutions will help them to keep themselves abreast with the technology world, so they can compete in such a continuously changing market.

The Global Mineral Wool Insulated Metal Panel Market has a bright future ahead, full of growth and innovative opportunities. Through continuous product and technology development, industry leaders will keep on changing the market toward meeting the needs of a dynamic world with solutions that help in energy efficiency and sustainability within the construction sector. The companies are combining their effort not just as a drive for this market but equally become a contributor toward global drives of building practices and greener material choice.

Mineral Wool Insulated Metal Panel Market Key Segments:

By Type

- Wall Panels

- Roof Panels

- Structural Panels

By Insulation Thickness

- Below 50mm

- 50-100mm

- 100-150mm

- Above 150mm

By Application

- Commercial Buildings

- Industrial Buildings

- Cold Storage

- Residential Buildings

- Agricultural Buildings

- Others

By End-User

- Construction

- Automotive

- Aerospace

- Food & Beverage

- Pharmaceuticals

- Others

Key Global Mineral Wool Insulated Metal Panel Industry Players

- Kingspan Group

- Metl-Span

- ArcelorMittal

- Nucor Building Systems

- Centria

- Tata Steel

- Isopan S.p.A.

- Assan Panel

- Ruukki

- Balex Metal

- Paroc Panel System

- Marcegaglia

- Italpannelli

- EuroPanels

- Jindal Mectec

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383