MARKET OVERVIEW

The Global Laser Welding Machine market is an important segment in the manufacturing industry that provides advanced welding advantages of precision, efficiency, and durability. This market deals mainly with high-powered laser technologies for easy joining of metals and non-metals with minimal thermal distortion. As industries are moving toward automation and high-performance fabrication processes, laser welding machines continue to be a cardinal element of modern production systems.

Laser welding machines use a concentrated laser beam to fuse materials with unmatched accuracy. Unlike traditional welding processes, where heat severely impairs the integrity of the materials being worked with, laser welding, therefore, presents an advantage in that the laser provides a controlled high-energy source that strongly welds and really fine controls most of the parameters. The Global Laser Welding Machine market services different industries, including automotive, aerospace, electronics, and medical device manufacturing, where stringent quality requirements demand much more from welding technologies. The laser welding machine is likely to find wide acceptance in applications requiring minimum post-processing and maximal strength in weld joints, which translates to manufacturers looking for combinations of speed and precision.

The segment will cover different kinds of tools in laser welding: fiber, CO2, and solid-state laser systems for different materials and industrial needs. These laser welding machines will continue to stay in use, while fiber laser welding is bound to emerge as the most appealing option with its efficiency and flexibility among industries that stress on high-speed and precision welding. Robotization will also fall under the ambit of the Global Laser Welding Machine systems, and such an integration is very likely in modern welding systems of the future. The ambition behind automated laser welding is to enhance productivity while minimizing manual labor. This would offer manufacturers a chance to execute much more consistent and repeatable processes via the means of automation.

The market for laser welding machines will be stimulated by new technological innovations and improvements in manufacturing standards. With the increasing demand for lightweight and high-strength materials in automotive and aerospace, laser welding has provided the means to join dissimilar metals and delicate components with the preservation of the structural integrity. The Global Laser Welding Machine market will respect sustainability, as laser welding creates little waste while reducing the use of filler material and other consumables. This energy-efficient system permits the companies to minimize operational costs and rightly boast about their production.

These will affect the adoption of laser welding technologies in various industries, based on their lovely regulatory standards and safety parameters. As safety regulations concerning high-powered lasers tighten, machinery manufacturers will start concentrating on developing systems that increase protective schemes-by means of automated shielding, enclosed workspaces, and advanced fume extraction systems. Accordingly, the global laser welding machine market will move to provide solutions to all these requirements while taking care of compliance with industry standards for operator safety and efficiency.

The way toward high-precision make has been turning from industrial production toward increasingly automated production. The Global Laser Welding Machine market thus retains its space in defining modern fabrication methods. During that time, as it continues to enhance the capabilities of laser technology, it will also diversify into many materials and industries. Thus, laser welding will always be the tool to meet the ultimate forge quality, efficiency, and low cost in industrial applications.

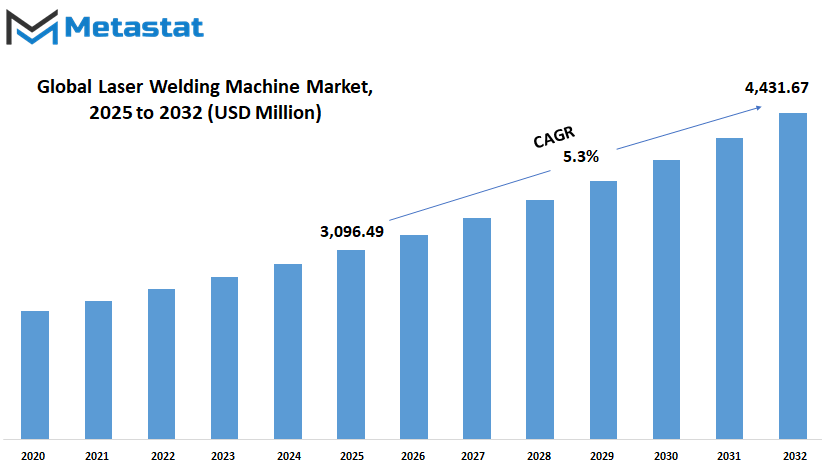

Global Laser Welding Machine market is estimated to reach $4,431.67 Million by 2032; growing at a CAGR of 5.3% from 2025 to 2032.

GROWTH FACTORS

The Global Laser Welding Machine market will experience tremendous growth as industries begin to embrace more efficient and precise welding technologies. The very essence of the client driving the new dispensation towards adopting advanced improvements in welding solutions is found in particular sectors that include automotive, aerospace, electronics, and construction where demand for high quality welding solutions will increase. As manufacturing companies move towards automation along the manufacturing lines, laser welding will play a big part in making production more efficient and keeping errors low. Whether strong and precise welds made this technology, the result is that it is considered an increasingly dominant industry choice across that require durability and accuracy.

Of the major factors energizing demand in the market, automation in manufacturing raises the profile. This is such that as part of their efforts to improve productivity and cut costs, companies have turned to laser welding machines, which offer a solution to reduce human error and speed things up. The increased use of lightweight materials in sectors such as automotive and aerospace is another driving trend. Among these materials, progress in welding process needs has outgrown the capabilities of traditional welding techniques; hence such investment is inevitable for laser welding.

Medical applications for laser welding technology will also open business for this market. Increasing manufacturing of medical devices and equipment will require precise welding for reliable components within them. In addition, new versions in the fiber laser technology will also add more efficient machines with reduced energy consumption but performing high efficiencies. Industries need to replace conventional welding with laser-based solutions with their ability to weld complex designs under much less heat impact.

However, there are some impediments to the growth of the market. The high initial cost of laser welding machines and the requirement for a skilled operator can be barriers to small and medium-sized businesses from adopting this technology. The initial investment becomes a drawback for most companies who otherwise would have seen a return in their investment over time with a reduction in labor costs. There might be other concerns with protecting maintenance and the complexity of operating these machines restraining adoption to companies widely practicing conventional welding methods.

While Great challenge does face the market, future scope is bright. The new frontiers will be opened as laser welding systems bring artificial intelligence and machine learning into their performance, allowing the machines to adjust parameters in real-time for improved efficiency of production. The whole concept of sustainability will push certain innovations leading to harnessing welding applications using energy-efficient systems. Laser welding will definitely advance semblance on greener and more eco-friendly manufacturing processes.

With technological advancements and increased applications across all industries, the Global Laser Welding Machine market is bound to grow steadily. The research and development companies will remain on top, offering solutions aimed at changing the demands modern approaches to manufacturing are bringing about.

MARKET SEGMENTATION

By Technology

The best thing that can happen to the Global Laser Welding Machine market is continuous growth because industries demand extremely accurate and efficient welding solutions-as seen in booming sectors such as automotive, aerospace, electronics, and manufacturing, where laser welding machines are betters than traditional welds. These machines have greater accuracy, processing speed, and material compatibility. With increasing advancements in technology, industries will continue to demand automated and intelligent welding systems into which industries will later have to transform their metal joining methods.

A major portion of growth in this segment is induced by the ever-rising trend of fiber laser welding machines, which is promising to capture significant market shares. According to estimates, this segment will dominate the market holding a worth of USD 1,580.31 million in 2025 because of the high efficiency and less maintenance required for operations. Additionally, versatility in applications with a wider deployment of deep penetration welding with less heat-affected zones has made it appropriate in delicate and high precision applications. Therefore, increasing application in such sectors as electronics and manufacture of medical devices will further catalyze their increased acceptance.

Also, CO2 laser welding will become a critical contributor to the market as it will be worth USD 494.35 million in 2025. High power and deep penetration have been the indispensable characteristics imparted by CO2 laser welding machines in most applications. They are still handy, especially for welds of non-metals and thick metals. So industries where the welding processes are quite versatile could depend on the CO2 laser welding machines to fulfill production requirements.

Solid state laser welding equipment will share significant sales, expected to be around USD 818.07 million in 2025 with a continuous supply of such machines in the future. These machines are well known for their energy efficiency and precision, making them suitable for applications that need delicate welds with less distortion. Further, the trend of better productivity and reduced operational costs will prove favorable for solid state laser welding machine adoption by industries thriving on precision and repeatability.

Other laser welding technologies, with a collective worth of around $203.76 million by 2025, would contribute to the market development. Development and innovations in hybrid laser welding, blue laser welding, and ultra-short pulse laser welding will open avenues for various industries looking for specialized solutions. These technologies would facilitate welding operations to be more automated and digitally integrated at various companies.

The streak of innovation can see industries speeding even faster to the next interesting phase in the Global Laser Welding Machine market. There will be a complete discourse made by embedding artificial intelligence, real-time monitoring, and adaptive control systems into that process-down to even less than a minute with intelligence and efficiency.

By Application

A surge will be witnessed in medical applications, where laser welding will be very relevant in the manufacture of very sophisticated devices and surgical instruments. The rationale behind assembling medical implants and electronic components used in healthcare in a specific assembly will necessitate developing advanced welding systems. Manufacturers will require the design of machines that will hold delicate materials without damage so that medical devices can meet very stringent safety and performance standards.

In the electronics industry, laser welding will heighten as companies seek better options for producing smaller, more complex components. As consumer electronics continue to evolve, manufacturers will require welding solutions that offer greater control and precision. Welding without the generation of excess heat will be extremely important for assembling circuit boards and delicate electronic parts. With the push toward miniaturization, companies will need to invest in high-tech welding solutions that maintain quality but speed up production.

Jewelry manufacturing would also gain from laser welding since the works that can be done through conventional welding will not be matched by the efficiency of laser welding. This will enable the jeweler to repair and come up with extremely complicated designs without compromising the integrity of the material being worked upon. With more demands for personalized and high-quality jewelry, more professionals will be adopting laser welding machines to improve efficiency and craftsmanship in their work.

The automotive sector will remain one of the most dominant users of laser welding technology. With the uptake of electric vehicles by more drivers, laser welding will be commonplace during assembly of battery components and those lightweight materials that construct vehicle structures. There will be demand from manufacturers for durable and very high-precision welds, stimulating the development of machines that can handle more materials feasibly. With the focus on enjoying sustainable modes of transportation, automakers will be searching for welding solutions to improve production efficiencies while ensuring the long-term performance of vehicles.

Tool and mold-making industries will keep adopting laser welding for the repair and fabrication of specialized kinds of equipment. It will be significant for electric welding to be precise and strong enough to retain the longevity of their molds during production. Other industries, such as aerospace and energy, will explore laser welding for their specific needs so that critical components can be reliably connected.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3,096.49 Million |

|

Market Size by 2032 |

$4,431.67 Million |

|

Growth Rate from 2025 to 2032 |

5.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The demand for laser welding machines will increase as industries search for efficient and precise welding solutions. With automation and advancements in manufacturing, laser welding technology fronts will improve production speed and quality. Such welding is also growing in popularity because it makes strong, accurate welds with minimal heat-introduced stress. Further growth in the requirement of reliable and high-performance welding systems is expected due to the ever-increasing demand by the automotive, aerospace, electronics, and medical equipment manufacturing industries. Nowadays, companies are looking for machines that support energy-efficient performance, better control systems, and the capacity to work with a range of materials.

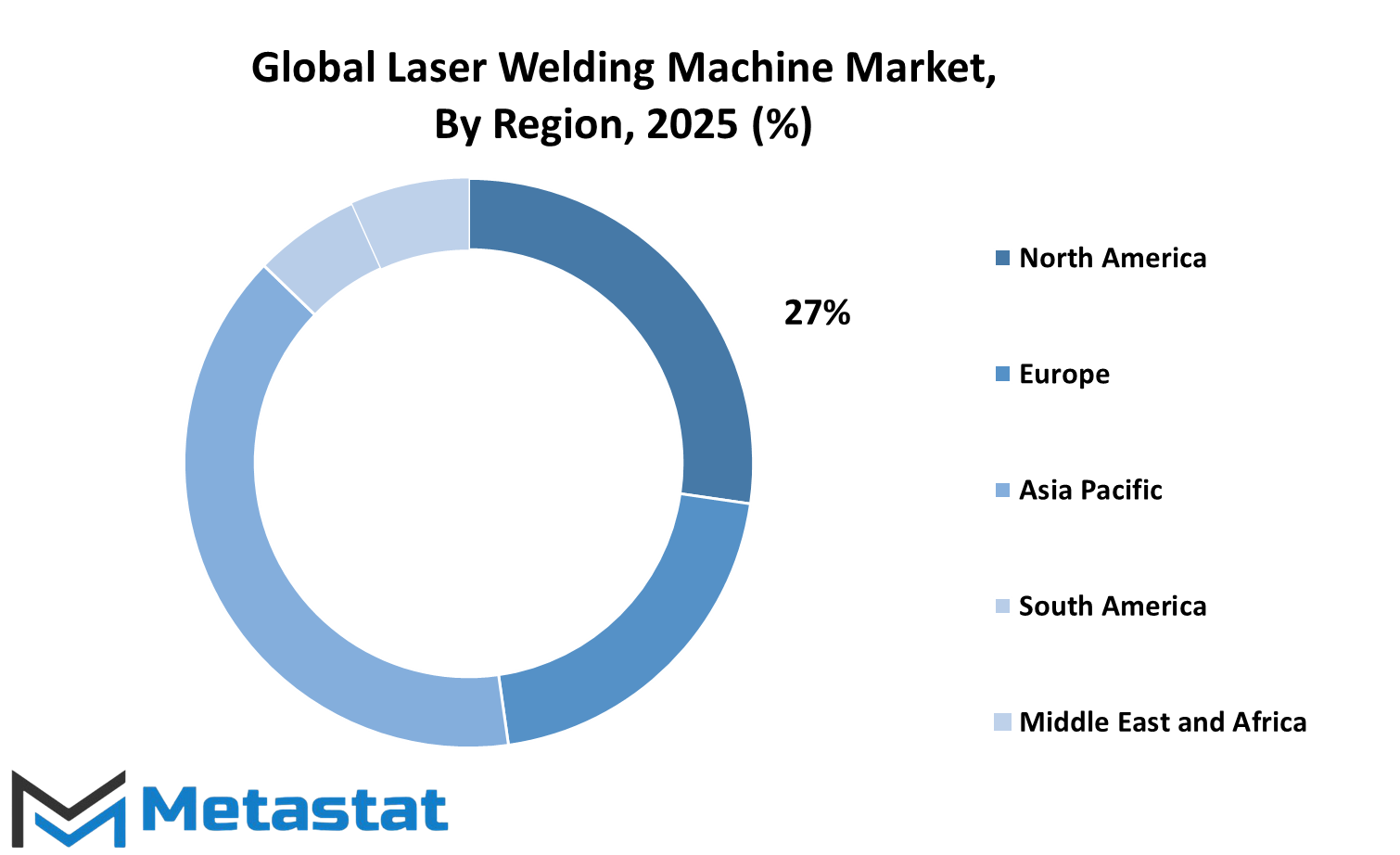

The overall growth of the Global Laser Welding Machines market will be a contribution to other regions. North America is found to be a strong market with the U.S., Canada, and Mexico collectively increasing demand. The presence of immobile industries, the investment for automation, and the push for advanced manufacturing would collaborate together to cause growth of this market. Manufacturers in this region aim to implement laser welding within their production lines for cost-cutting measures and efficiency improvements.

Europe shall also play its part with popular regions being the UK, Germany, France, and Italy. This region has a strong industrial base wherein automotive, and aerospace are sectors that hinge on precision welding. R&D will see greater adoption of advanced laser welding systems to ensure that industries will remain competitive. With the push for lightweight materials and high strength components, there will be an upward demand for advanced welding technologies.

Rapid industrialization will grow sales demand for laser welding solutions within joined regions of China, India, Japan, and South Korea in the Asia Pacific regions. Many companies operating in the region are trying to move toward automated production lines, with laser welding serving to maintain product quality and efficiency. Government initiatives aimed at enhancing advanced manufacturing and technological promotion will also play a very big role in sustaining market growth.

South America will contribute to the growth of this market as well, led by Brazil and Argentina, for developments in manufacturing and infrastructure. The adoption of laser welding technology in these regions will be driven by the pressing needs for modernization of production techniques and improved product quality.

Demand for laser welding machines will grow by increment with infrastructure projects due to modern industries increasingly investing in industrial advancement. There, the Middle East & Africa will emerge as a rising player in this market.

COMPETITIVE PLAYERS

The Global Laser Welding Machine market is forecast to boom in the years to come as it continually develops in industries wanting precision, efficiency, and productivity attached to automated manufacturing. Advances in welding technology have been shaping its trends, resulting in the growth of laser-based welding applications as popular solutions that provide fast and solid welds combined with less thermal damage in weld joints. In automotive, aerospace, electronics, and healthcare sectors, productivity enhancement with the aid of automated and AI-driven systems has become the focus of the manufacturers to meet increasing demands while facilitating accuracy and savings in operating costs.

The biggest phenomenon's regarding development in the industry will be the integration of artificial intelligence and real-time monitoring. In addition, the self-detecting dysfunction of machines will be possible for them to make automatic adjustments to ensure the weld quality itself is always consistent. Furthermore, as industries are moving towards sustainability, laser welding machines would be designed in their operation for less energy consumption as well as reduced material waste. Companies will invest in R&D for more compact and efficient machines with a wider range of applications.

Innovation will be propelled with competition between major players. Such reputed companies are Wuhan HGLaser Engineering Co., Ltd, Coherent Inc., and IPG Photonics Corporation, who would dominate the market with their advanced technologies. Other manufacturers include Razortek CNC Co., Ltd, Han's Laser Technology Industry Group Co., Ltd, and KEYENCE CORPORATION, working towards extending their ranges according to the newest industry demands. These all companies will focus on improving laser sources, cooling systems, and software integration to optimize the welding process.

Demand for laser welding machines with robotic integration will increase as industries are becoming automated. Companies such as Penta Laser (Zhejiang) Co., Ltd, Emerson Electric Co, and Amada Miyachi Co. Ltd, are investing in solutions utilizing robotics combined with advanced laser systems. That will help gain higher flexibility, reduce human intervention, and improve precision in producing large amounts. Manufacturers such as LPKF Laser & Electronics AG, Nanjing Prima CNC Machinery Co., Ltd., and Laser Technologies are studying innovation in fiber lasers and hybrid technology for welding, which increase the flexibility of their systems for differing materials and thicknesses.

Performance is future-oriented, but affordability will also be a concern. The likes of Precitec GmbH & Co. KG and Suresh Indu Lasers Private Limited are expected to work towards enabling small and medium-sized enterprises to afford these high-quality laser welding machines. Global transformation in Laser Welding Machines will occur, assuring accuracy and reliability for the industries as they witness major improvements in automation, AI-driven analytics, and energy efficiency.

Laser Welding Machine Market Key Segments:

By Technology

- Fiber Laser Welding Machine

- Co2 Laser Welding Machine

- Solid-State Laser Welding Machine

- Others

By Application

- Medical

- Electronics

- Jewelry industry

- Automotive

- Tool and Mold-making

- Others

Key Global Laser Welding Machine Industry Players

- Wuhan HGLaser Engineering Co., Ltd

- Coherent Inc.

- IPG Photonics Corporation

- Razortek CNC Co.,Ltd

- Han’s Laser Technology Industry Group Co., Ltd

- KEYENCE CORPORATION

- Penta Laser (Zhejiang) Co., Ltd

- Emerson Electric Co

- Amada Miyachi Co., Ltd.

- LPKF Laser & Electronics AG

- Nanjing Prima CNC Machinery Co., Ltd.

- Laser Technologies

- Precitec GmbH & Co. KG

- Suresh Indu Lasers Private Limited

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252