MARKET OVERVIEW

The global industrial concrete flooring market will witness a segment of transformation that extends past conventional use and application. Anchored within the broader construction and infrastructure enterprise, this section will shift from being perceived simply as a structural necessity to a key useful element shaping operational efficiencies across production gadgets, logistics facilities, and processing plants. Unlike the static notion often connected to concrete flooring, future eventualities will discover how material improvements and process upgrades will adjust its motive and presence in commercial environments.

As industries look to lessen downtime and beautify sustainability, the demands positioned on floors solutions will accentuate. The global industrial concrete flooring market will now not be defined by using surface power or load-bearing potential alone. Instead, new expectancies will arise starting from power performance thru thermal interplay to integration with smart technologies embedded under surfaces. With the upward push of Industry 4.Zero, the floors will function a base for sensor placement, self sustaining equipment pathways, and temperature regulation mechanisms, gambling a subtle however critical position in maintaining managed workspaces.

Moreover, the lifecycle of business floors might be reevaluated. Rather than focusing solely on initial installation, upcoming strategies will emphasize recyclability, adaptability, and ease of upkeep. This will possibly result in the evolution of concrete mixtures, wherein the blend will consist of next-technology components for durability and decreased carbon footprint. The cognizance will now not just be on substances but also on the way in their software automation in pouring, laser-guided leveling, and AI-assisted curing techniques.

Geographically, the global industrial concrete flooring market will withstand various challenges and opportunities. In areas where industrial automation will move rapidly, floor demands will require high precision, flexibility and adaptation. In contrast, in emerging areas, the focus will be rapidly deployed and strength. This deviation will open new routes for sewn products and localized manufacturing strategies, taking the market closer to decentralized production and installation models.

Cross-sector cooperation will re-define what the industrial floor can give. Partnership between flooring solution providers and software developers emerges, which enable integrated systems to future maintenance and operational tracking. Will not happen after the floor; This will become an active component in the industrial scheme. Decision makers will need to treat it as activist security, machine performance and long -term convenience management costs that affect a variable.

As the global industrial concrete flooring market prepares for the future beyond its traditional boundaries, the role of data, innovation and adapted execution will be central. The upcoming year will not be about replacing the old floor with new people-it will be about what a destination can do in a digitized, skilled and conscious world, telling it again. From above the ground, this market will move from passive support to active contribution, the way the industrial environment is designed, manufactured and operated.

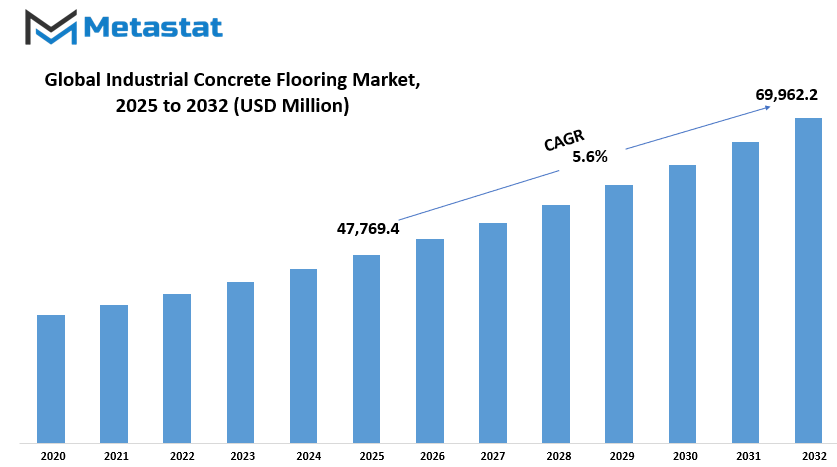

Global industrial concrete flooring market is estimated to reach $69,962.2 Million by 2032; growing at a CAGR of 5.6% from 2025 to 2032.

GROWTH FACTORS

The global industrial concrete flooring market will keep to enlarge as business operations around the arena vicinity more importance on power, safety, and price-efficiency. In warehouses and production areas, floors needs to endure heavy machinery, high site visitors, and consistent put on, making concrete a dependable option. This demand for hard and long-lasting flooring will play a central role in pushing the market ahead. At the same time, industries in developing areas are increasing rapidly. As countries invest extra in infrastructure and installation new industrial vegetation, the want for concrete flooring will growth. These tendencies advise that the market will see sturdy demand within the coming years, in particular in regions in which industrialization is just gaining pace.

However, no matter its developing appeal, the marketplace will face some demanding situations. One foremost problem is the excessive value of preliminary installation. Before the concrete can be poured and completed, the surface ought to be organized cautiously, and that method can take time and require luxurious device. For many small or price range-conscious groups, those expenses can emerge as a barrier. Another task relates to environmental worries. Cement, that is a key component in concrete, is understood to release a huge quantity of carbon dioxide for the duration of production. With increasing awareness of weather change and strain to reduce emissions, agencies may additionally hesitate to increase their use of concrete flooring until greater sustainable options are introduced.

On the alternative hand, this concern for the surroundings will even open new doors. There is developing hobby in eco-friendly construction solutions, and that consists of flooring. As groups explore approaches to lessen their environmental effect, there may be a shift toward concrete made with recycled substances or low-emission procedures. This fashion will create clean possibilities for producers who are geared up to innovate. In addition, the use of new substances, finishes, and coating technology will improve the performance and lifespan of concrete flooring. These advancements will allow the market to meet each performance and environmental dreams more successfully. Over time, such innovations will no longer simplest remedy existing troubles but also result in wider recognition of commercial concrete flooring, even in regions where it became previously taken into consideration too high priced or dangerous to the environment.

MARKET SEGMENTATION

By Type

The global industrial concrete flooring market will hold to witness big development as industries prioritize sturdiness and long-term performance in floors structures. Concrete flooring is desired throughout warehouses, factories, distribution centers, and production plants because of its strength, fee-effectiveness, and simplicity of preservation. Over time, call for will upward thrust for greater advanced finishes that provide each aesthetic fee and more suitable resistance to heavy wear and tear. Among the various types, epoxy coatings preserve a dominant position, worth $18,510.2 million, and will continue to be a favored alternative for areas that require chemical resistance, brief software, and seamless finishes. These coatings will serve a extensive range of industries, mainly where hygiene and clean environments are essential, like meals processing and prescribed drugs.

Polyurethane coatings will also end up increasingly more famous because of their flexibility and resistance to abrasion, making them suitable for areas with high foot visitors or publicity to temperature fluctuations. Their ability to deal with thermal cycling and stay long lasting underneath harsh conditions could be liked throughout cold storage gadgets and industrial kitchens. Meanwhile, polished concrete will gain interest for its glossy look and low upkeep wishes. It will in shape industrial showrooms, stores, and tech offices seeking out a contemporary but practical ground surface.

Stained concrete will entice agencies looking for a decorative end without compromising sturdiness. It lets in for a lot of shades and tones whilst nonetheless delivering the sturdiness wished in commercial settings. Although no longer as not unusual as epoxy or polyurethane coatings, stained surfaces will locate their area in hospitality-focused industrial areas and innovative work environments. Other types within the marketplace, including sealers and hybrid coatings, will cater to specialized wishes like slip resistance, anti-static residences, or eco-friendliness.

As industries develop extra aware of their specific floors desires, providers will respond with tailor-made solutions that combine capability with design. The cognizance could be on surfaces that ultimate longer, require much less maintenance, and carry out well below heavy machinery, spills, and constant use. With ongoing innovation and customization, the concrete flooring zone will not simply meet utility demands but additionally contribute to the broader dreams of safety, productiveness, and value financial savings throughout diverse industries. Over the approaching years, companies will retain to invest in reliable flooring answers, and this steady shift will shape the future of the global industrial concrete flooring market.

By Technology Type

The global industrial concrete flooring market is steadily transferring as technology introduces greater reliable and green flooring methods. Two key era types main this shift are traditional concrete flooring and jointless concrete floors. Both play a giant position, every supplying unique advantages based on the particular necessities of business areas. As industries purpose to enhance operational protection, sturdiness, and maintenance performance, the choice between these flooring options turns into extra than just a construction decision it will become a strategic funding.

Traditional concrete flooring has lengthy been used throughout warehouses, factories, and production devices. It has been favored for its especially easy installation manner and tremendous availability. This form of flooring makes use of widespread concrete and includes seen joints that help manipulate cracking because the slab expands or contracts. While it gives electricity and affordability, traditional concrete regularly requires extra protection over the years. The joints, though vital, can lead to put on and tear in excessive-site visitors regions, causing the need for common maintenance or replacements.

On the other hand, jointless concrete floors is gaining popularity for its smooth and seamless end. It removes the need for joints through the use of specialized materials and design techniques that allow the concrete to withstand cracking with out the aid of growth joints. This results in a cleaner appearance and a more durable surface which can handle heavy equipment, huge-scale storage systems, and in depth foot and car movement. Industries that prioritize hygiene, such as food processing and prescribed drugs, will gain from this kind because it reduces the danger of bacteria or dust gathering within the gaps.

The global industrial concrete flooring market will see demand for each these kinds depending on the character of operations and the long-term planning of business facility managers. While traditional concrete flooring will nevertheless be desired in tasks wherein finances and time are limited, jointless concrete floors will appeal to businesses aiming for efficiency, sustainability, and long-term value. Manufacturers and contractors will maintain to offer custom designed solutions based on client wishes, supporting each floors kinds preserve a steady region within the market.

With industries increasing globally and infrastructure requirements growing, the desire for advanced flooring technology will shape the future of commercial production. Whether it's far the acquainted reliability of traditional concrete or the forward-searching promise of jointless systems, the marketplace will keep growing with generation at its facet.

By Floor Type

The global industrial concrete flooring market will witness first rate transitions as needs shift across one-of-a-kind ground kinds. The market, segmented by means of ground kinds which includes Seamless, Overlay, On Piles, Suspended, and Others, will continue to form the way commercial infrastructure is designed and maintained. Each sort of flooring serves a exceptional motive, and as industries prioritize each feature and sturdiness, the desire for specific types becomes greater obtrusive.

Seamless floors are expected to benefit attention because of their smooth look and resistance to dust and chemical spills. These flooring will become commonplace in environments that require excessive stages of hygiene, like food processing and pharmaceutical units. They are poured in vicinity, which gets rid of joints and decreases the chance of wear and tear at the rims. This sort of ground also helps faster cleaning and preservation, so one can be important in industries that fee operational performance.

Overlay floors, however, will function a value-powerful solution for restoring worn-out surfaces. Instead of casting off the complete base layer, overlays are carried out directly to existing concrete, saving both time and resources. As industries attempt to reduce down protection prices without compromising on safety or aesthetics, overlays will present a sensible option. Their ease of utility and potential to decorate durability will pressure their adoption across sectors that can't manage to pay for prolonged downtimes.

The On Piles category will remain important for business setups constructed on unstable soil or in flood-susceptible zones. By elevating the floors above floor stage, this approach adds a layer of safety and allows manipulate moisture and soil motion. Industries running in areas with bad soil situations or extreme weather will maintain to apply this method to defend both the constructing and the machinery inside.

Suspended flooring, designed with out contact with the ground, will be selected for unique architectural desires, mainly in multi-story factories or warehouses. Its power and versatility make it appropriate for sporting heavy machinery whilst minimizing pressure at the decrease systems. It lets in higher space usage and permits modern layouts that traditional ground floors can not assist.

Other floor types will include specialized designs made for area of interest industries or those with unusual environmental conditions. These alternatives will hold to fill unique marketplace gaps, imparting answers wherein preferred floors fails to satisfy expectations.

By Application

The global industrial concrete flooring market will keep to increase as call for increases throughout numerous key utility regions. Among the maximum outstanding sectors are production centers, warehouse facilities, and other industrial or business units that require sturdy, long-lasting flooring answers. Each of those sectors has its personal particular desires, but they all share a requirement for floors that can resist heavy loads, resist put on and tear, and continue to be stable in demanding situations.

Manufacturing facilities will possibly remain one of the fundamental users of business concrete floors. These facilities function with heavy equipment, common foot and vehicle visitors, and chemical spills that would damage much less long lasting floors options. Concrete, known for its electricity and resilience, will remain a desired material in those environments. The flooring not handiest helps the load of system however additionally guarantees worker protection by using presenting anti-slip surfaces and smooth cleaning functions. As automation and superior equipment grow to be greater commonplace in those facilities, the demand for flooring that could cope with vibration and stay even over the years will develop.

Warehouse centers additionally contribute extensively to the demand for commercial concrete floors. These spaces are frequently large and require floors which can handle each static and dynamic hundreds. With the rise of e-trade, warehouses are now operating at better capacities than earlier than, which puts even greater stress at the floors structures. Pallet jacks, forklifts, and automated retrieval structures all call for floors that is not simplest strong however additionally easy to allow for green motion.

The "other" category will include settings such as data centers, utility fields and large -scale retail or commercial space. These fields cannot withstand daily physical pressures similar to manufacturing plants or warehouses, but they still require reliable floor solutions. For example, data centers require floors that support heavy server racks helping temperature regulation and fire resistance. Retail and commercial settings prefer concrete floors for their modern look, ease of cleaning and ability to handle high leg traffic.

Like -construction standards improve and have expectations for durability growth, industrial concrete floors will get its role in new and more diverse applications. Its long lifetime, cost-effectiveness, and adaptability will make it an essential part of the industrial infrastructure worldwide.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$47,769.4 million |

|

Market Size by 2032 |

$69,962.2 Million |

|

Growth Rate from 2025 to 2032 |

5.6% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

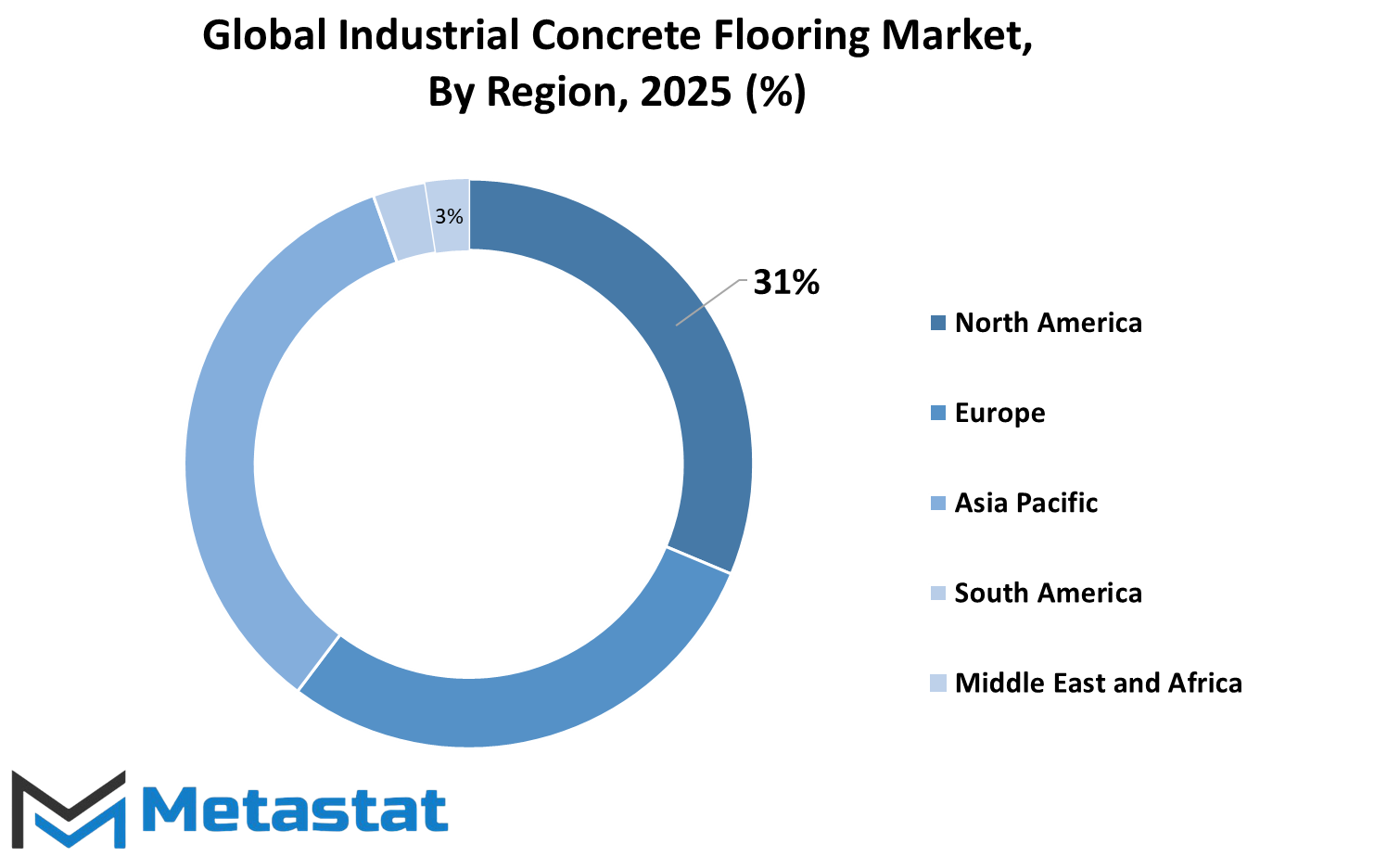

REGIONAL ANALYSIS

The global industrial concrete flooring market will continue to be fashioned significantly via geographical distinctions, with every location providing its very own set of needs and advancements. North America will stand as one of the predominant contributors, driven through consistent business expansion and preservation developments. Within this place, the US will take the lead with its good sized business infrastructure, observed via Canada and Mexico, each of in order to preserve a sluggish tempo in adopting long lasting flooring solutions for warehousing and logistics centers.

In Europe, the marketplace will locate sturdy footing throughout nations just like the UK, Germany, France, and Italy. These countries will push the call for ahead thru industrial modernization and the want for excessive-performance flooring in sectors which include automobile, production, and meals processing. The rest of Europe will also guide this growth, although at a barely numerous tempo because of differing levels of business investment across the vicinity.

Asia-Pacific could be one of the fastest-developing areas in this market. Nations which include India, China, Japan, and South Korea will power huge demand due to rising industrialization, city improvement, and authorities-subsidized infrastructure tasks. India and China, specifically, will focus closely on increasing logistics parks and warehousing hubs, a good way to obviously require robust concrete floors answers. The rest of the Asia-Pacific region will even make a contribution regularly, motivated via both domestic and overseas investments in production and export sectors.

South America will have the capacity for gradual development, mainly fuel from economic activities in Brazil and Argentina. While the adoption rate cannot match the Asia-Pacific or Europe, these countries will still introduce a frequent requirement of reliable floors in processing plants and large-scale storage facilities. Other parts of South America will show separate degrees of market movement based on local industrial development.

The Middle East and Africa region will show promise promises especially in regions such as GCC countries, Egypt and South Africa. These places will benefit from infrastructure improvement and increasing attention to commercial construction. The remaining nations in the Middle East and Africa will experience mixed trends, in some areas the government's initiative or energy, logistics and foreign investment will progress rapidly.

Overall, the global industrial concrete flooring market will reflect a wide but associated pattern of development of the market. Based on each region, its current industrial landscape and future capacity, will continue to shape the demand and application of concrete floors in different fields.

COMPETITIVE PLAYERS

The global industrial concrete flooring market will continue to shape and support infrastructure in various fields. Industrial concrete floors, known for their strength and durability, will be required in areas such as manufacturing plants, warehouses, logistics hubs and commercial buildings. These floors are designed to handle high level pressure, heavy equipment and constant legs and vehicle traffic. As industries demand long-lasting, low-ravaged surfaces that can withstand wearing and tears, the need for quality concrete floor solutions will continuously increase. With the construction of new industrial facilities and renewal of existing people, concrete will play a major role in performing floor performance and safety requirements.

Many companies are already contributing to the development and supply of high-demonstration floor solutions, and they will be important in shaping the future of this industry. Sika AG, Tikkurila Oyes, Semex SAB De C.V., PPG will focus on improving the quality and innovation of the product and innovation of products. Their purpose will be to offer floors which not only lasts for a long time, but also require minimal maintenance. Duramen Engineer Products Inc., Euclid Chemical Company and other people like Frick Company are also working towards creating solutions that are both functional and visually. These companies will invest in research to bring out better coatings, seallers and application methods that save time and cost during installation.

Firms together with Twintec Group Limited, Flowcrete UK Ltd, and Sherwin-Williams Company are already exploring environmentally pleasant substances and methods, in order to probably turn out to be a standard industry practice. Companies consisting of Stanford Industrial Concrete Floorings Ltd, Ardex Group, and Tarmac Holdings Limited are presenting tailor-made floors structures that in shape the particular needs of every task, taking into consideration extra bendy and sustainable construction approaches. Mapei SpA, RCR Industrial Flooring, EP Floors Corp, and Armorpoxy Inc. Are strengthening their worldwide presence through strategic partnerships, expansions, and improvements in product lines. These ongoing efforts will make certain the marketplace remains responsive to shifting needs in industries like meals processing, prescribed drugs, electronics, and retail, wherein specialised flooring functions will be required.

As the global want for efficient and strong business areas increases, so will the demand for reliable concrete flooring. The paintings of these key gamers will make sure that the market maintains to develop in terms of overall performance, sustainability, and layout.

Industrial Concrete Flooring Market Key Segments:

By Type

- Epoxy Coatings

- Polyurethane Coatings

- Polished Concrete

- Stained Concrete

- Others

By Technology Type

- Traditional concrete Flooring

- Jointless Concrete Flooring

By Floor Type

- Seamless

- Overlay

- On Piles

- Suspended

- Others

By Application

- Manufacturing Facility

- Warehouse Centers

- Others

Key Global Industrial Concrete Flooring Industry Players

- Sika AG

- Tikkurila Oyj

- CEMEX S.A.B. de C.V.

- PPG Industries, Inc.

- Fosroc International Limited

- Duraamen Engineered Products Inc.

- Euclid Chemical Company

- The Fricks Company

- Twintec Group Limited

- Flowcrete UK Ltd

- Sherwin-Williams Company

- Stanford Industrial Concrete Floorings Ltd

- Ardex Group

- Tarmac Holdings Limited

- Mapei SpA

- RCR Industrial Flooring

- EP Floors Corp

- Armorpoxy Inc

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383