MARKET OVERVIEW

The glass fiber reinforced polymer (GFRP) market is entering a phase where innovation, application-specific material engineering, and regulatory foresight will shape your direction more than the cluster demand or traditional use pattern. This industry, defined by standard applications once construction and motor vehicle components, will gradually expand to new areas operated by the emerging environmental mandate, design philosophy and emerging performance benchmark. What is further for this market is not only the expansion of current practices, but a change affected by the strategic alignment of material science and stability preferences.

Researchers and stakeholders of the industry will begin to focus on bio-based resins and recycling overall structures. This change will arise not only from ecological concerns but also by operational requirements. Industries such as aerospace, marine engineering and civil infrastructure will seek GFRP solutions that provide long -term durability without compromising environmental safety. The thermal resistance, fatigue demonstration, and life -cycle forecasting improves improvement through research, the market will push into areas that once hesitated due to technical boundaries.

In the coming years, we will probably be a witness to a more harmonious cooperation between educational research institutes and industrial manufacturers. This partnership will aim to standardize novels and score them for high-protest applications. Advanced simulation tools and digital prototypes will also become major features, allowing designers to model stress behavior, moisture absorption, and UV fall patterns before committing physical production.

Geological, global glass fiber reinforced polymers (GFRP) will face diverse regulatory landscape in the market. As various fields introduce local performance and recycling standards, producers will need to adapt to construction methods and raw materials to maintain global competition. This will promote the development of modular production units and decentralized supply chains, increasing accountability for regional compliance framework. Over time, this structural flexibility will reduce dependence on a unique production hub and encourage localized innovation.

In addition, the role of additive manufacturing in overall construction will expand. This will allow GFRP-based components to produce with more dimensional precision and low waste. Unique geometry required industries, such as wearable technology and special sports items, their strength-to-wise ratio and design will detect GFRP materials for flexibility. This diversification of uses will not necessarily increase the market in quantity, but will redefine its complexity and access.

In educational regions, the story around the glass fiber reinforced polymer (GFRP) market will shift as universities begin to offer special courses focused on overall mechanics and durable designs. This infusion of knowledge will gradually shut down the gap between academic principle and industrial application, resulting in more adaptive and skill-taiyar task forces.

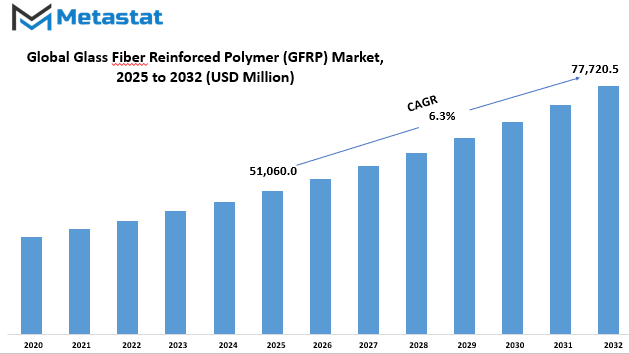

Glass fiber reinforced polymer (GFRP) market is estimated to reach $77,720.5 Million by 2032; growing at a CAGR of 6.3% from 2025 to 2032.

GROWTH FACTORS

The global glass fiber reinforced polymer (GFRP) market is looking at significant changes because industry has changes towards materials that offer both strength and low weight. One of the main reasons behind this increasing interest is increasing demand from motor vehicle and aerospace areas. These industries require materials that are not only durable, but also mild to improve fuel efficiency and performance. GFRP fits this need well as it combines strength with low weight, making it a favorite option for various components. Along with this, the development of infrastructure running around the world is further promoting the use of GFRP in construction and civil engineering. The resistance of material for rust and its long life makes it suitable for bridges, buildings and other mass projects.

However, there are also some challenges in the market that are growing rapidly. The first major issue is the high cost of production and processing. Unlike traditional materials, GFRP requires special equipment and efficient labor, which increases the overall cost. This makes it less accessible to some companies and industries, especially in areas where budgets are tight. Another concern is environmental impact. Since GFRP is not biodegradable, its waste can create and build problems for a long time. Settlement and recycling are not straight, and it raises questions about its stability in the long run.

Despite these challenges, there are still promising opportunities for the GFRP market. One of the most exciting regions is renewable energy. GFRP is now being used more frequently in the production of wind turbine blades, thanks to its light weight and durability. As the world cleaner moves towards energy sources, this trend is expected to continue and grow. In addition, progress in recycling technologies GFRP is offering a way to handle waste more responsibly. New techniques are being developed to reuse the materials that were once seen to be difficult for the process, which reduced the manufacturers more options and environmental concerns.

Overall, the global glass fiber reinforced polymer market stands at a point where the opportunity and challenge run with both hands. The demand for strong, light materials is unlikely to fade, especially with increasing attention to efficiency and stability. If issues around cost and recycling can be addressed, GFRP can play even more in the future of manufacturing and infrastructure.

MARKET SEGMENTATION

By Resin Type

The glass fiber reinforced polymer (GFRP) marketplace is progressively increasing, particularly due to its huge use in industries such as production, motor vehicles, aerospace and electrical. GFRP is understood to be robust yet to be lighter, which makes it a treasured cloth for a series of structural and non-structural packages. One of the main components of GFRP is the resin utilized in its manufacturing. The resin kind within the GFRP market is similarly divided into UPR resin, vinyl ester resin, epoxy resin, PA resin, PP resin, phetic resin and different resins. Each of these resins performs a completely unique role within the performance and durability of the final product.

The UPR resin, additionally referred to as unsaturated polyester resin, is the maximum commonly used resin type in the marketplace. It is favored due to the fact it is cost powerful, clean to address, and works nicely for wellknown-objective programs. On the opposite hand, vinyl ester gives better resistance to resin, water and chemical compounds, which makes it ideal for industries where these residences are essential. Epoxy resin is extensively used for its high-quality mechanical power and robust relationship ability. It is usually chosen for high-protest applications, especially where prolonged durability is important.

PA resin, or polyamide resin, adds cruelty and heat resistance to the product. It is often used in engineering applications where strength and endurance are required. The PP resin, which refers to polypropylene resin, is chosen for its mild and moisture resistant nature. It works well in environment that require protection from water exposure. The phenolic resin is standing out to its fire resistant and heat resistant properties. This makes it highly suitable for applications where safety and heat management are priorities. Other resins category include different types of resins that may not usually be used, but still serve specific objectives based on the requirements of the application.

Increasing demand for mild and corrosion resistant materials in various regions is carrying forward the growth and use of various resin types in GFRP products. As industries search for materials that may offer power, flexibility and price performance, the resin segment performs an important function in shaping the destiny of the GFRP marketplace. Each resin brings its very own advantages, lets in producers to tailor merchandise that meet unique performance requirements in a extensive range of industries.

By Product Type

The glass fiber reinforced polymer (GFRP) market is predicted to grow step by step because of increasing demand across more than one industries. By product type, the marketplace is split into E/ECR-Glass Fiber Composites, S-Glass Fiber Composites, C-Glass Fiber Composites, and Others (NE, R, T). Each of those types has distinctive properties that lead them to be appropriate for precise applications. For example, E/ECR-Glass Fiber Composites are broadly used due to the fact they offer good strength and resistance to corrosion, making them a realistic choice for creation and electrical industries. S-Glass Fiber Composites are recognized for his or her excessive power and are often utilized in aerospace and protection sectors. C-Glass Fiber Composites are specifically selected for his or her amazing chemical resistance and are suitable for packages that involve harsh environments. The different categories like NE, R, and T are less not unusual but serve specialized purposes relying on undertaking needs.

The upward push in production activities, specifically in growing countries, is one of the foremost reasons for the increase of the GFRP market. Infrastructure development, consisting of bridges, buildings, and water structures, calls for strong and lightweight substances. GFRP fits properly in these areas because it isn't simplest durable but also enables lessen overall weight with out compromising electricity. Additionally, the growing desire for non-corrosive materials in industries including marine, oil and gasoline, and transportation is pushing agencies to apply more GFRP-primarily based products.

Environmental concerns and push for stability are also affecting market growth. GFRP products last long and require less maintenance than traditional materials, making them more attractive to industries that reduce long -term cost and environmental impact. The motor vehicle industry, in particular, focus on reducing vehicle weight to improve fuel efficiency. Using GFRP in car construction helps to meet these goals, making it a favorable option.

Another factor that supports the market is on research and development. Manufacturers are constantly working on enhancing the electricity, flexibility and value-effectiveness of GFRP merchandise. Since these materials come to be extra superior, their use is likely to make bigger in new regions, similarly selling the market potential.

Overall, the call for for GFRP products is expected to growth as industries are looking for materials that offer a mixture of performance, sturdiness and fee savings. With many types of GFRPs being to be had, agencies have extra options to select based on their unique necessities.

By Manufacturing

The glass fiber reinforced polymer (GFRP) market is steadily increasing due to its increasing use in market construction, car, aerospace and other industries. GFRP is known to be mild-wisdom, strong and resistant to corrosion, which makes it a popular desire in areas in which durability and low weight are important. One of the essential elements driving this market is the growing demand for electricity-green and long-lasting materials, mainly in industries trying to cut down on protection costs and improve product lifestyles.

By production, the marketplace is similarly divided into Hand Lay-Up, Spray-Up, Resin Infusion, Filament Winding, Pultrusion, Injection Molding, Compression Molding, Prepreg Lay-Up, and Others. Each technique has its own use relying on the application and manufacturing quantity. For example, Hand Lay-Up is one of the most effective and most fee-effective strategies, mostly used for making huge elements where precision isn't a top precedence. Spray-Up, alternatively, allows faster production however might not be as strong as a few other methods. Resin Infusion is understood for producing parts with better energy and finish because it involves vacuum pressure to drag resin into the fiber layers.

Filament Winding is widely used to make cylindrical shapes like pipes and tanks, presenting right power and steady nice. Pultrusion is a continuous system best for producing profiles with steady go-sections such as rods and beams. Injection Molding and Compression Molding are usually selected for high-quantity production of small and particular parts due to their velocity and accuracy. Prepreg Lay-Up entails pre-impregnated fibers and is often utilized in industries that need high-performance components with strict standards, like aerospace. The “Others” class includes strategies which might be nevertheless evolving or utilized in particular cases.

The manufacturing techniques selected often rely upon the size, form, performance wishes, and price limits of the very last product. Companies have a look at those factors carefully before figuring out which procedure fits their needs first-rate. As extra industries flow closer to lightweight and sturdy substances, the call for for GFRP and its distinct manufacturing strategies will possibly upward push. In the approaching years, boom in creation and transportation sectors, together with innovation in production strategies, will maintain pushing the GFRP marketplace forward. This makes it a key region to watch for each manufacturers and industries that want higher, more dependable substances for his or her merchandise.

By End Use

The glass fiber reinforced polymer (GFRP) market is growing regularly because of its growing use all through unique industries. GFRP is known for its strength, mild weight, and resistance to corrosion, which makes it beneficial in lots of programs. By quit use, the global GFRP market is cut up into Transportation, Marine, Wind Energy, Aerospace, Pipes & Tanks, Construction, Electrical and Electronics, Consumer Goods, and Other End Uses. Each sector benefits from GFRP's ability to improve average overall performance, reduce protection fees, and offer lengthy-time period sturdiness.

In the transportation area, GFRP is used to make vehicle additives lighter, which allows improve gas performance and reduces emissions. It additionally provides energy and safety without including greater weight. In marine programs, GFRP is a desired material due to the fact it can deal with moisture and saltwater with out rusting. Boats, panels, and underwater systems made with GFRP closing longer and require less upkeep. The wind power quarter, worth $6,608.7 million, closely relies on GFRP for manufacturing turbine blades. These blades must be sturdy but light-weight to feature efficiently, and GFRP offers the proper balance. It additionally reduces the wear and tear caused by constant motion and exposure to climate.

In the aerospace industry, GFRP is used to reduce the load of plane with out compromising strength or protection. This allows enhance gasoline economy and allows plane to carry more weight. Pipes and tanks made from GFRP are sturdy and corrosion-resistant, making them useful for storing chemical compounds, water, and different beverages. In production, GFRP is used to boost homes, bridges, and other systems. It helps to increase their lifetime when cutting maintenance. In electrical and electronic devices, GFRP helps protect the devices from heat and effects while keeping the devices light and durable.

Consumers also benefit from GFRP properties. Its uses this material to increase strength and comfort without adding bulk to the sports equipment, furniture and home appliances. Other end uses include industrial equipment and specialized equipment, where GFRP helps improve performance by reducing overall weight.

Since industries look for materials that offer both power and flexibility, GFRP is being used more widely. The range of its applications and the benefit provides that it is an important material for modern development and innovation in many areas.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$51,060.0 million |

|

Market Size by 2032 |

$77,720.5 Million |

|

Growth Rate from 2025 to 2032 |

6.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

.

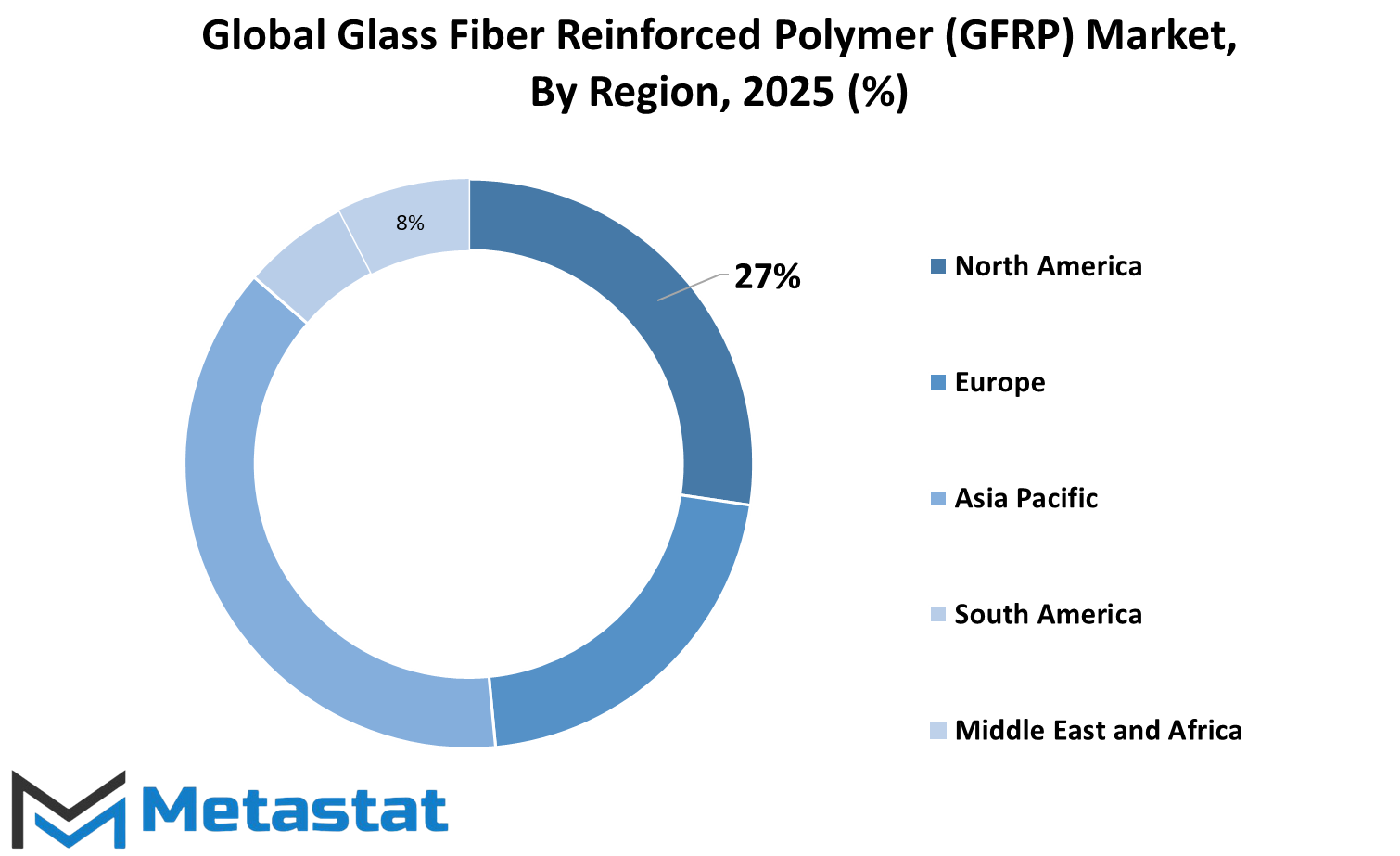

REGIONAL ANALYSIS

Based on geography, the glass fiber reinforced polymer (GFRP) market is divided into five major regions: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each of these regions shows different growth patterns and potential depending on industrial development, infrastructure needs, and the presence of key manufacturers. In North America, the market is further split into the U.S., Canada, and Mexico. Among these, the U.S. continues to lead due to strong demand from construction, automotive, and aerospace industries. Canada and Mexico are also showing steady growth, supported by increasing investments in infrastructure and manufacturing.

In Europe, the market includes the UK, Germany, France, Italy, and the Rest of Europe. Germany and the UK are at the forefront because of their established industrial base and growing use of lightweight materials in transportation and building sectors. France and Italy also play important roles, with rising awareness about the advantages of GFRP in reducing maintenance and improving durability. The Rest of Europe, although more varied, is gradually adopting GFRP materials as regulations push for more sustainable and long-lasting building components.

The Asia-Pacific region, which includes India, China, Japan, South Korea, and the Rest of Asia-Pacific, is expected to show the fastest growth. China is a major contributor, driven by rapid urban development, government-backed infrastructure projects, and the growing automotive market. India follows closely, with expanding construction activities and efforts to modernize its transport and power sectors. Japan and South Korea, with their advanced manufacturing technologies, are also increasing their use of GFRP in multiple industries.

South America includes Brazil, Argentina, and the Rest of South America. Brazil leads in this region, benefiting from large-scale construction projects and investments in renewable energy. Argentina is slowly expanding its market share as awareness of GFRP's benefits spreads. The remaining countries in the region are progressing at a modest pace, often influenced by local economic conditions and availability of raw materials.

The Middle East & Africa region is categorized into GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa. GCC Countries are growing rapidly, thanks to major infrastructure development and the drive toward modernization. Egypt and South Africa also show promising growth, supported by urban expansion and energy-related projects. The rest of the region is gradually catching up, depending on national development plans and international investments.

COMPETITIVE PLAYERS

The glass fiber reinforced polymer (GFRP) market continues to grow steadily as industries such as automotive, aerospace, construction, and energy increasingly use lightweight and durable materials. GFRP stands out because of its excellent strength-to-weight ratio, resistance to corrosion, and low maintenance requirements. These features make it a strong alternative to traditional materials like steel or aluminum, especially where reducing weight and improving performance are important. As governments push for eco-friendly solutions and fuel efficiency, especially in transportation, GFRP finds wider use due to its ability to reduce vehicle weight and emissions.

Manufacturers are also focusing on improving production processes to lower costs and boost efficiency. This helps make GFRP more affordable for a variety of applications. In construction, for example, it is used in bridges, buildings, and highways because it does not rust and can last longer than steel in harsh weather. The growth of smart cities and infrastructure upgrades also contributes to higher demand for GFRP products. In the wind energy sector, GFRP is commonly used in turbine blades due to its lightweight structure and high flexibility, which helps improve energy production.

Key players operating in the Glass Fiber Reinforced Polymer (GFRP) industry include Advanced Composites Inc, AGY Holdings Corp, Asahi Fiber Glass Co., Ltd, BASF SE, BGF Industries Inc, Celanese Corporation, China Beihai Fiberglass Co., Ltd, China Jushi Co Ltd, Chongqing Polycomp International Corp (CPIC), Jiangsu Amer New Material Co., Ltd., Johns Manville Corporation, Nippon Electric Glass Co., Ltd., Nitto Boseki Co., Ltd, Owens Corning, PFG Fiberglass Corporation, Reliance Industries Ltd, SAERTEX GmbH & Co KG, Saint-Gobain S.A, and Taishan Fiberglass, Inc. These companies play an important role in shaping the market through innovation, expanding production, and strengthening distribution networks.

As competition grows, many companies are investing in research and development to bring better and more affordable GFRP products to the market. The trend also shows increased collaborations and partnerships to meet changing industry demands. Overall, the future of the GFRP market looks promising, supported by strong demand from various sectors and continued innovation by leading companies. This steady growth is expected to create new opportunities, both for existing players and for new businesses entering the market.

Glass Fiber Reinforced Polymer (GFRP) Market Key Segments:

By Resin Type

- UPR Resin

- Vinyl Ester Resin

- Epoxy Resin

- PA Resin

- PP Resin

- Phenolic Resin

- Other Resins

By Product Type

- E/ECR-Glass Fiber Composites

- S-Glass Fiber Composites

- C-Glass Fiber Composites

- Others (NE,R,T)

By Manufacturing

- Hand Lay-Up

- Spray-Up

- Resin Infusion

- Filament Winding

- Pultrusion

- Injection Molding

- Compression Molding

- Prepreg Lay-Up

- Others

By End Use

- Transportation

- Marine

- Wind Energy

- Aerospace

- Pipes & Tanks

- Construction

- Electrical and Electronics

- Consumer Goods

- Other End Uses

Key Global Glass Fiber Reinforced Polymer (GFRP) Industry Players

- Advanced Composites Inc

- AGY Holdings Corp

- Asahi Fiber Glass Co., Ltd

- BASF SE

- BGF Industries Inc

- Celanese Corporation

- China Beihai Fiberglass Co., Ltd

- China Jushi Co Ltd

- Chongqing Polycomp International Corp (CPIC)

- Jiangsu Amer New Material Co., Ltd.

- Johns Manville Corporation

- Nippon Electric Glass Co., Ltd.

- Nitto Boseki Co., Ltd

- Owens Corning

- PFG Fiberglass Corporation

- Reliance Industries Ltd

- SAERTEX GmbH & Co KG

- Saint-Gobain S.A

- Taishan Fiberglass, Inc

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252