Global Flexible Manufacturing System Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

What possibilities may want to rise up if flexible manufacturing structures end up the foundation for mass customization throughout industries, and the way might this shift redefine manufacturing efficiency on a international scale? Could the developing integration of automation, robotics, and AI in bendy structures disrupt traditional manufacturing fashions, or will the excessive cost of adoption gradual down their usual popularity?

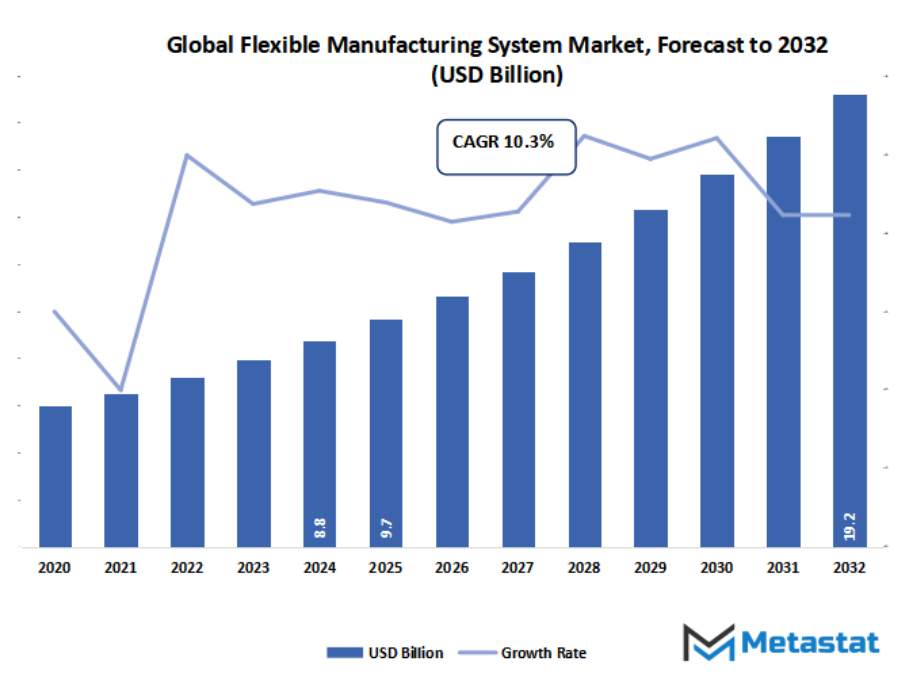

- Global flexible manufacturing system market valued at approximately USD 9.7 Billion in 2025, growing at a CAGR of around 10.3% through 2032, with potential to exceed USD 19.2 Billion.

- Hardware account for nearly 55.6% market revenues, driving innovation and expanding applications through intense research.

- Key trends driving growth: Increasing demand for mass customization and personalized products., Need for rapid adaptation to volatile market demands and shorter product lifecycles.

- Opportunities include Integration with Industrial IoT and AI for real-time optimization and predictive maintenance.

- Key insight: The market is set to grow exponentially in value over the next decade, highlighting significant growth opportunities.

The global flexible manufacturing system market and sector will transcend traditional horizons with technology continuing to reshape how the production lines are created and run. The market will not just look at efficiency but will progress to developing smart frameworks that adjust in an instant to diverse product requirements. Rather than being limited to conventional means, the future of this sector will demonstrate systems that think, react, and self-optimize with little human intervention. Factories of the future will not be about mass production in a fixed manner; they will trend towards customized manufacturing in bulk, where flexibility will be the key to success.

Outside of the present applications, the global flexible manufacturing system market will reach into sectors that have hitherto depended on rigid assembly lines. Aerospace, medical equipment, and renewable energy sectors will adopt these systems to cope with varied product lines without suspending production. The use of smart sensors, AI-based monitoring, and adaptive robotics will transform these systems beyond production tools—they will serve as intelligent collaborators in decision-making. This change will not only stop at technical innovation but will move towards operating sustainability, with minimized waste and maximized energy use becoming business commonplaces.

Market Segmentation Analysis

The global flexible manufacturing system market is mainly classified based on Component, Type, Application, End-User.

By Component is further segmented into:

- Hardware - The global flexible manufacturing system market will witness hardware play a pivotal role in determining efficiency. Next-generation factories will rely on sophisticated machines, robotics, and control units to guarantee faster production cycles. Investments in hardware will form the basis of precision-driven functions, enabling industries to embrace automation while reducing downtime and human error.

- Software - Software will be the brain of the global flexible manufacturing system market. Predictive analytics, integration of AI, and process simulation will enable smooth coordination between the machines and workers. Software upgrades in the future will provide scalable solutions that respond to different production requirements, increasing productivity and providing data-driven decisions.

- Services - Services in the global flexible manufacturing system market will be of greater significance as companies require installation, maintenance, and technical assistance. Demand in the future will increase for tailor-made services that improve flexibility, enabling companies to switch between production lines rapidly. System integration expertise will ensure smoother transition and long-term continuity of manufacturing processes.

By Type the market is divided into:

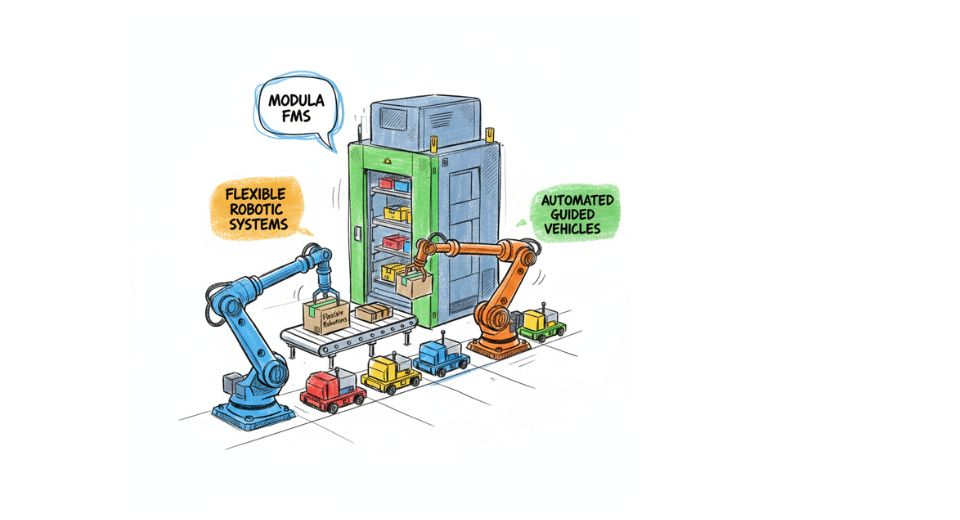

- Modula FMS - The global flexible manufacturing system market will see increased growth in modular configurations, giving industries cost-efficient and scalable options. Modular configurations will enable production units to grow incrementally without the major disruptions. This flexibility will make them perfectly suited for companies looking at long-term automation plans with manageable investments.

- Flexible Robotic Systems - Flexible robotic systems will rule the global flexible manufacturing system market in the future. Robotics will lead automation, velocity, and repetition across various sectors. Robots with artificial intelligence capabilities will adjust to intricate manufacturing functions, producing intelligent workflows. Their error-reducing capacity will revolutionize how companies handle mass manufacturing.

- Automated Guided Vehicles (AGVs) - AGVs shall re-make logistics in the global flexible manufacturing system market. Factories in the future shall characteristic AGVs to transport material correctly and correctly throughout production traces. With superior navigation and IoT connectivity, AGVs will lessen operation expenses and facilitate smoother approaches, making them a need in current production centers.

By Application the market is further divided into:

- Aerospace - The aerospace industry will depend significantly on the global flexible manufacturing system market to achieve precision. Flexible systems will provide precise production of components and help lower time-consuming delays. As the demand for lightweight and complex parts increases, aerospace companies will embrace top-notch automation, providing speed without sacrificing quality.

- Automotive - Automotive manufacturing will continue to benefit from the global flexible manufacturing system market through advanced automation. Flexible systems will allow automakers to switch between different vehicle models efficiently. In the future, demand for electric vehicles will push adoption of smart manufacturing processes, ensuring higher output and cost-effectiveness.

- Electronics - The electronics sector will see strong adoption of the global flexible manufacturing system market. As demand for smaller, smarter devices grows, flexible systems will provide the precision required. Automation will allow faster assembly of intricate components, ensuring both speed and quality. This will make electronics production more adaptable and competitive.

- Pharmaceuticals - Pharmaceutical manufacturing will look to the global flexible manufacturing system market to deliver accuracy and safety. Automated equipment will provide stable quality while adhering to stringent regulatory requirements. Future plants will draw upon flexible configurations to manufacture diverse drug forms with efficiency, delivering mounting global healthcare demands with speed and dependability.

By End-User the global flexible manufacturing system market is divided as:

- Manufacturing - Manufacturing sectors will embrace the global flexible manufacturing system market to optimize efficiency. Automated processes will allow for faster turnaround and reduced production costs. Future factories will integrate flexible systems to accommodate varying customer needs, maintaining sustainable operations while being competitive in international supply networks.

- Consumer Goods -Consumer products businesses will utilize the global flexible manufacturing system market in order to roll out products more quickly. Customer tastes are shifting so quickly that flexible systems will offer the means to easily change production lines. It will offer brands a competitive advantage to deliver on personalization and speed in mass production.

- Medical Device - Medical device companies will depend on the global flexible manufacturing system market for strict quality and safety standards. Future automation will enable accuracy in the manufacture of sensitive apparatus. As healthcare technology continues to evolve, flexible systems will facilitate rapid adaptation to new designs, allowing rapid innovation in the healthcare sector.

- Energy and Utilities - The energy and utilities industry will look to the global flexible manufacturing system market for secure, effective solutions. Flexible automation will enable the manufacturing of essential equipment for renewable energy and smart grids. Next-generation plants will implement adaptive systems in order to balance demand, sustainability objectives, and advanced energy technologies.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$9.7 Billion |

|

Market Size by 2032 |

$19.2 Billion |

|

Growth Rate from 2025 to 2032 |

10.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

Geographic Dynamics

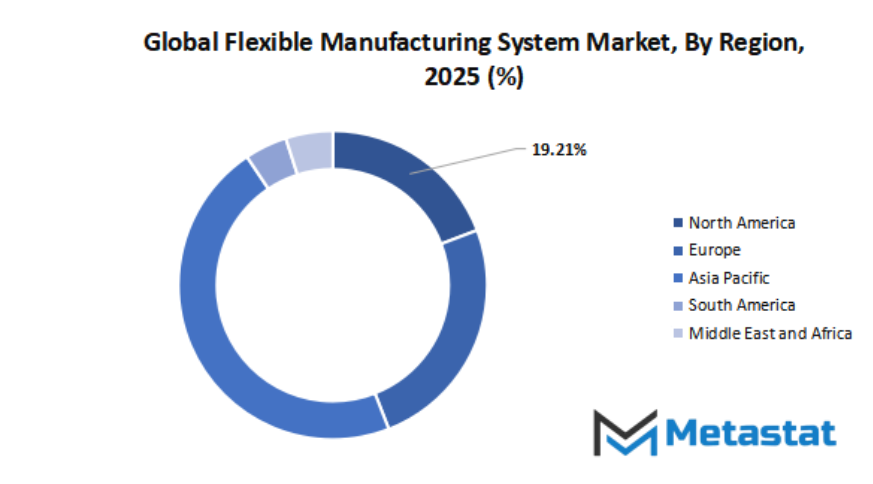

Based on geography, the global market is divided into North America, Europe, Asia-Pacific, South America, and Middle East & Africa. North America is further divided in the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and Rest of Europe. Asia-Pacific is segmented into India, China, Japan, South Korea, and Rest of Asia-Pacific. The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and Rest of Middle East & Africa.

Competitive Landscape & Strategic Insights

The global flexible manufacturing system market is fast becoming a significant aspect of contemporary industrial production, as companies in various regions seek effective means of enhancing productivity without escalating costs. The market is influenced by both well-established global firms and emerging regional players that are now starting to get noticed. As industries transition toward automation and more intelligent production processes, flexible manufacturing systems are viewed as worth investing in and will assist manufacturers in keeping up with dynamic demands without jeopardizing their momentum.

The market environment within this sector is characterized by a blend of international household names alongside smaller companies which are slowly developing their presence. Mazak, Hitachi Seiki, Toyoda, OKUMA, and Fanuc have already established corporation foundations with their leading-facet technologies and sturdy structures. These corporations had been recognized for driving innovation in manufacturing for quite a while now, and the fact that they're in the market indicates that flexible manufacturing isn't always simplest approximately being green but additionally about designing systems which can manage complexity at the same time as remaining flexible enough to deal with consumer desires.

Meanwhile, new nearby competition are starting to make their presence felt inside the marketplace. Companies like Edibon, Yawei, Beijing Jingdiao Group, Dongguan GKG, Nanjing Gongda CNC Technology, DOLANG Technology, and Jingyan Seiko Machinery are making their contributions by presenting systems which can be precise to local production desires. Their contribution is valuable since they introduce competition that compels global leaders to further innovate their products. These local firms typically offer affordable alternatives, hence a more viable option for smaller industries that cannot afford the capital-intensive systems provided by international giants.

The dynamics between global leaders and local challengers are influencing the direction of this market in fascinating ways. While established firms have global expertise and established solutions, new firms introduce innovative ideas and localized approaches. Collectively, they form a market that is both dynamic and capable of further growth. With industries across the world engaging in further investment in automation and flexibility, the global flexible manufacturing system market will keep growing, and it will open room for both established companies and new companies to contribute significantly to its development.

Market Risks & Opportunities

Restraints & Challenges:

Extremely high initial investment in specialized equipment and software. - The global flexible manufacturing system market will remain under restraint with the high initial investment in state-of-the-art equipment, robotics, and specialized software. This cost will remain a hindrance to adoption by small-scale producers, leaving large entities as the major drivers. Growth in the market in the future will rest upon cost-saving measures and government-sponsored financial incentives.

Significant complexity in system design, programming, and maintenance. - The other constraint for the global flexible manufacturing system market will be the technical sophistication involved in designing, programming, and maintaining such systems. Highly skilled expertise will be needed to deal with automation, robotics, and integrated platforms. Lack of such technical knowledge will hamper large-scale implementation unless training programs and standard tools are given high priority.

Opportunities:

Integration with Industrial IoT and AI for real-time optimization and predictive maintenance. - global flexible manufacturing system market will pick up pace with interfacing with Industrial IoT and Artificial Intelligence. These will permit for actual-time tracking, predictive renovation, and data-primarily based optimization. With system failures predicted ahead of time and operations adjusting right away, industries can have multiplied performance, much less downtime, and greater productivity, consequently making destiny structures sensible and sustainable.

Forecast & Future Outlook

- Short-Term (1–2 Years): Recovery from COVID-19 disruptions with renewed testing demand as healthcare providers emphasize metabolic risk monitoring.

- Mid-Term (3–5 Years): Greater automation and multiplex assay adoption improve throughput and cost efficiency, increasing clinical adoption.

- Long-Term (6–10 Years): Potential integration into routine metabolic screening programs globally, supported by replacement of conventional tests with advanced biomarker panels.

Market size is forecast to rise from USD 9.7 Billion in 2025 to over USD 19.2 Billion by 2032. Flexible Manufacturing System will maintain dominance but face growing competition from emerging formats.

In the years to come, the global flexible manufacturing system market will create an industry that coexists with digital twins and predictive analytics. The systems will become learning platforms, anticipating faults before they happen and reconfiguring themselves to sustain continuous flow. More than cost savings, the industry will emphasize resilience, where manufacturing systems resist disruptions and continue to deliver. With the globe's industries experiencing evolving product lifecycles and volatile requirements, flexible manufacturing will transcend a production philosophy to become a vision for industrial stability and innovation in the long term.

Report Coverage

This research report categorizes the Flexible Manufacturing System market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Flexible Manufacturing System market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Flexible Manufacturing System market.

Flexible Manufacturing System Market Key Segments:

By Component

- Hardware

- Software

- Services

By Type

- Modula FMS

- Flexible Robotic Systems

- Automated Guided Vehicles (AGVs)

By Application

- Aerospace

- Automotive

- Electronics

- Pharmaceuticals

By End-User

- Manufacturing

- Consumer Goods

- Medical Devices

- Energy and Utilities

Key Global Flexible Manufacturing System Industry Players

- Mazak

- Hitachi Seiki

- Toyoda

- OKUMA

- Fanuc

- Edibon

- Yawei

- Beijing Jingdiao Group

- Dongguan GKG

- Nanjing Gongda CNC Technology

- DOLANG Technology

- Jingyan Seiko Machinery

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252