MARKET OVERVIEW

The Europe wood chipper market will expand past its conventional limits as the next few years create new avenues for use and technology. No longer will wood chippers be considered solely machinery for gardening or forestry use, but rather the industry will reposition itself as a part of a larger system that integrates environmental management, urban planning, and energy conversion. This change will enable the market to move beyond its past boundaries and will make it a story not just of chopping wood but of influencing the way societies manage waste, resources, and sustainability.

The future of the Europe wood chipper market will no longer depend on mechanical yield but on how well wood chippers are included in grander loops of circular economies. Municipalities in Europe will come to recognize them as essential components in the handling of biomass, supplying renewable energy facilities, and powering urban greenery initiatives. The devices will no longer be relegated to countryside locations; they will be brought into urban systems where city planners, environmental engineers, and utility industries will depend on their operation to meet expanding ecological needs.

This broadening function will also broaden the definition of the Europe wood chipper market. Rather than merely being qualified by horsepower or durability, future wood chippers will be judged by how they can interface with digital platforms, give data-based insights, and evolve to fit the increased emphasis on automation. As Europe will keep on building smart cities, the machines will have an unexpected role in converting garden rubbish and construction wood scraps into worthwhile energy inputs. This step will put the market beyond its traditional framework and into spaces where energy transition policy, climate policy, and industrial design intersect.

Outside of forestry, the Europe wood chipper market will be closely linked to public health and safety policy. Municipal governments will find themselves looking at effective wood management as a way to avoid drainage obstructions, stop fires, and keep urban spaces more clean. Through this, the industry's role will not only be technical but highly interrelated with the manner in which society mitigates the dangers that come with living on the planet.

Cultural factors will also determine this growth. European cultures with their rich histories of working in wood and with landscapes will apply a new perspective to how the industry develops. The machines will be not only for utilitarian purposes but also for purposes such as conserving heritage forests, keeping public parks intact, and complementing community values of sustainability. This cultural aspect will integrate the industry further into everyday life, more than just an industrial intervention.

Briefly put, the future trajectory of the Europe wood chipper market will amplify some distance past the slender idea of reducing or shredding equipment. It will evolve as part of an overarching imaginative and prescient wherein technology, sustainability, subculture, and concrete increase come together. With the continent moving forward with regulations centered on aid performance and ecological stability, the industry could be poised at the edge of latest possibilities, opening up a area that extends a long way beyond its preceding limits.

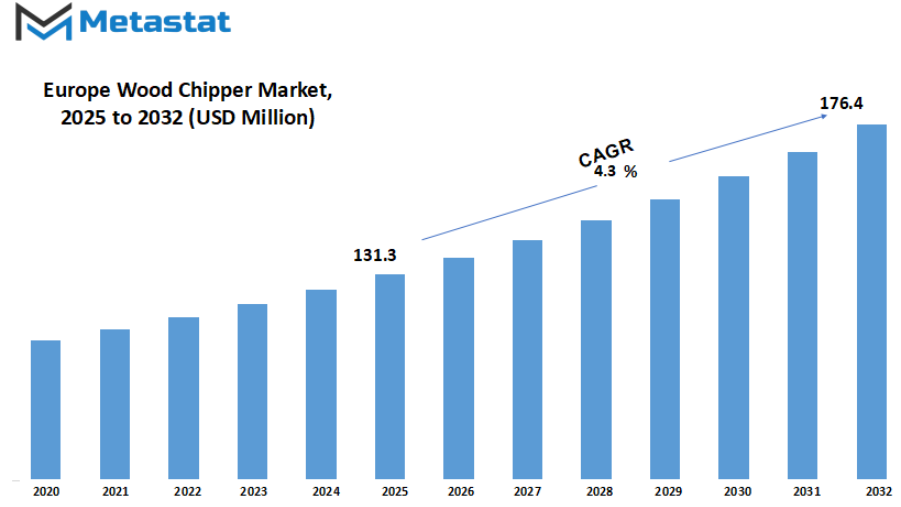

Europe wood chipper market is estimated to reach $176.4 Million by 2032; growing at a CAGR of 4.3% from 2025 to 2032.

GROWTH FACTORS

The Europe wood chipper market is seeing consistent focus as an increasing number of industries and communities resort to effective methods of wood waste and natural debris processing. This includes one of the largest drivers being the increasing demand for biomass power and eco-friendly fuel supplies. With Europe's emphasis on renewable strength and reducing carbon footprints, timber chippers have become increasingly more important as devices for turning organic waste into usable biomass gas. This pass toward cleaner resources of power will hold to power the use of wooden chippers in business and municipal tasks alike, positioning them as a need in Europe's renewable energy arsenal.

Another full-size driving force originates from expanding landscaping and forestry protection work at some stage in the area. Municipalities, parks, and other inexperienced spaces want to be maintained regularly, and forestry activities ought to have efficient device to cope with heavy amounts of branches and logs. Wood chippers enable effective disposal and recycling of the cloth, producing mulch or energy-manufacturing feedstock. As Europe increasingly specializes in ecological harmony and clever utilization of herbal regions, the need for green wood processing machinery will follow match.

While these prospects exist, there are several challenges in the market. The substantial initial outlay and upkeep expenses of wood chippers mean they are less affordable for small companies and independent operators. They need special servicing and parts, which can further increase costs. Furthermore, aggressive environmental and noise pollution regulations in Europe cap mass use of some wood chipper models. Companies have to keep modifying designs and technologies to comply with such requirements, raising the expense and curbing dissemination among price-conscious consumers.

However, the sector also has bright prospects on the horizon. The increasing use of electric and hybrid wood chippers is creating new possibilities, particularly in countries with stringent emission regulations. These alternatives not only decrease pollution but also minimize noise levels, hence can be used in urban settings. Further, with the increasing recycling and waste control programs in Europe, timber chippers are rising as crucial system for converting waste into consumable products. Municipal governments and personal entities will increasingly more keep in mind the use of wood chippers as a way of supporting reap sustainability objectives, enhancing round economic system practices, and minimizing landfill reliance.

The Europe wood chipper market is encouraged by using a mixture of demand for inexperienced solutions, demanding situations that involve value and regulation, and opportunities through technological improvements. As a good deal as there are constraints, the destiny of the market will in all likelihood be willing towards cleanser, less noisy, and greater green machines, as it aligns with the long-term energy and environmental goals of Europe.

MARKET SEGMENTATION

By Type

The Europe wood chipper market is regularly becoming popular given that industries and groups placed greater emphasis on sustainable wooded area use, landscaping, and powerful waste management. Wood chippers are important machines to reduce massive branches, logs, and different wooden material into pieces that are without problems possible, normally applied for recycling into mulch, biomass power, or compost. As environmental guidelines grow to be greater stringent during Europe, there is an increasing want for system that now not best conserves time and hard work but also aids in environmentally pleasant solutions for wooden waste control.

Among this market, various kinds of wood chippers are exhibiting varying growth trends depending on their uses. The drum chipper market has been present with a significant value of $65.1 million, owing chiefly to its high volume processing capacity of wood. These machines find special favor in forestry applications where ruggedness and heavy-duty operations are the primary considerations. Disc chippers, however, are at $46.2 million and find common use for their precision and capacity for uniform chip size. These make them appropriate for businesses that demand consistency, like the paper and pulp industry. Screw chippers, while a smaller market than the other two, are gaining ground among users who require a dependable solution for lighter workloads and smaller operations.

Technological traits and the tasks of producers to introduce more green and less complicated-to-use system force increase inside the market. Firms are working to broaden improvements that eat less gas, are quieter, and have improved safety features, which are all pertinent in Europe where customers care about productivity in addition to environmental conservation. Furthermore, the growing usage of timber chips inside the manufacture of renewable electricity has made wood chippers an increasing number of pertinent, with groups and regional governments putting budget into such gadget.

As urbanization persists and sustainable landscaping gains reputation, demand for wood chippers will stay excessive in the course of Europe. From major forestry operations to nearby landscapers, the usage of those machines will increase, boosted by recycling and renewable strength regulations. With discernible variations in usage between drum, disc, and screw chippers, the enterprise is in all likelihood to extend step by step, providing prospects for set up groups as well as new entrants who target innovation and performance.

By Fuel Type

The Europe wood chipper market is progressively increasing in popularity as industries, municipalities, and home clients are trying to find to utilize wooden waste correctly. Wood chippers are worthwhile machines that flip logs, branches, and diverse types of timber waste into small, usable fragments. The chips are often reused for landscaping, as biomass gasoline, or different beneficial purposes, making the equipment extraordinarily precious. Demand in Europe is buoyed by using expanded recognition for sustainable waste control, in addition to the requirement for low-fee alternatives in farming, forestry, and creation operations.

On the basis of gasoline kind, the marketplace is segmented into diesel engine, petrol engine, and electrically driven models, each of that is applied for a distinct application. Diesel engine timber chippers are commonly desired for heavy-duty or big-scale operations. Their robust performance qualifies them for forestry work, municipal waste management, and business packages, wherein strength and reliability are vital. Petrol engine chippers, however, tend to be the choice for medium-sized jobs. They balance performance with convenience and are attractive to landscapers and small contractors who desire mobility and convenience.

The electric powered wood chipper has skilled growing usage in latest years in large part because of environmental troubles and tighter emissions controls on the continent of Europe. Electric fashions are cleanser and quieter, that is a advantage in city or residential settings where there are noise regulations. While they may not offer as a lot energy as diesel counterparts, performance and their environmentally pleasant nature will cause them to a desirable option for homes, small farms, and companies inquisitive about decreasing their carbon footprint. As energy infrastructure keeps to enhance in most areas, using electric-powered machines is probable to increase even more.

The timber chipper marketplace in Europe will preserve developing as corporations alter to new sustainability norms and evolving strength developments. Every fuel category can have its area of interest, with diesel engines for heavy-responsibility packages, petrol engines for all-round mid-variety use, and electric-powered models as the green choice. This equilibrium will permit groups and people in Europe to choose the best gadget based on their precise needs, retaining the market dynamic and active in the future as well.

By End Users

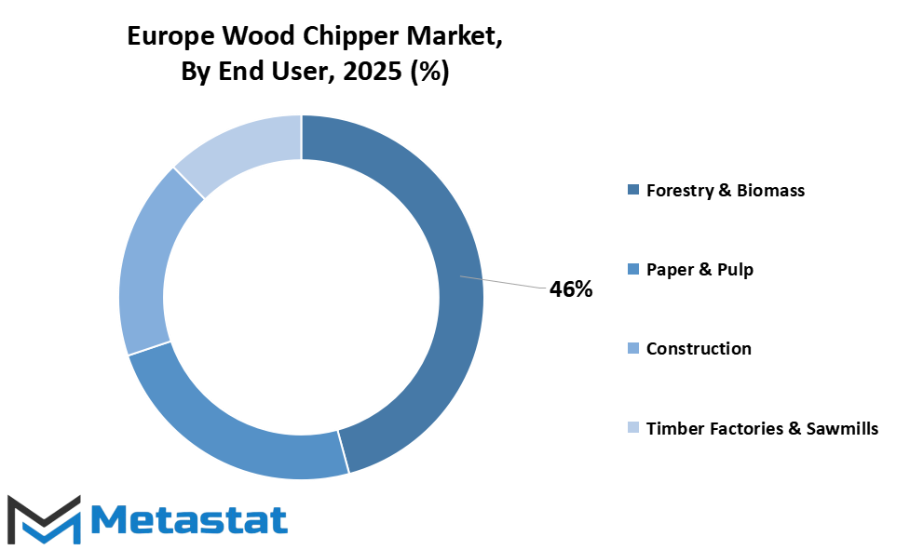

The Europe wood chipper market is becoming increasingly significant as industries look for effective means to deal with wood processing and waste reduction. Wood chippers are no longer viewed as machines of a singular function but as essential machines to multiple industries. They assist in breaking down large wood into smaller, usable chips, which can be reused or reused in different industries. This has made them a worthwhile investment in an area where efficiency and sustainability are gaining importance.

One of the principal consumers of wood chippers is the forestry and biomass industry. With increased demand for renewable energy, biomass has been a favored substitute, and wood chips are a good source of fuel. Forestry activities also depend on wood chippers to manage remaining branches, logs, and other residues, thus making the entire process more eco-friendly. By ensuring waste wood is converted into something of utility, the application of wood chippers in this sector will also grow.

The paper and pulp industry also utilizes wood chippers significantly. In this industry, regular quality and quantity of wood chips are required to yield high-quality pulp. Because paper production has a long tradition in Europe, this segment will continue to utilize sophisticated chipping technologies to fulfill demand while ensuring cost-effectiveness. Aside from paper, wood chippers also benefit construction works in Europe because wood waste generated in construction sites can be minimized and properly handled. This not only reduces disposal expenses but also supports the area's drive towards cleaner and greener approaches.

Timber mills and sawmills complete the end-user groups, which extensively depend on wood chippers for recycling offcuts and residues. These mills produce huge quantities of scrap wood, which are reusable as chips for particleboard, fuel, or other industrial applications. Through the application of wood chippers, sawmills and timber mills minimize waste and generate new sources of revenue, which is ever more critical in a competitive market. With these diverse uses, the European Wood Chipper market will continue to be indispensable, propelled by the combined need across forestry, paper, construction, and timber sectors.

By Chipper Size

The Europe wood chipper market is displaying consistent action as companies in the construction, landscaping, and forestry sectors remain constant in their need for effective machinery to process wood waste. A wood chipper serves a significant function in cutting up branches, logs, and wood material into smaller chips that can be recycled for use as fuel, mulch, or biomass energy. As more focus is being put on sustainable practices, the applications of wood chippers are more prevalent now in many sectors in Europe, and interest has consequently grown in the various kinds of machines on the market.

By the size of chipper, the European market is segmented into two broad categories, the 6–12 inches category of undercarriage and the ones above 12 inches. Machines falling in the 6–12 inches category are generally selected by landscaping firms, municipalities, and small-scale operators who require handy and portable equipment to conduct minor operations. These machines are convenient for handling regular wood clearing and are extremely popular due to their performance-mobility balance. Conversely, wood chippers larger than 12 inches are predominantly employed in bigger forestry operations and by industries that need heavy-duty machines. Their powerful cutting ability and capability for thicker logs make them extremely useful for demanding work.

Demand for both types is determined by the nature of work being undertaken in various European nations. Urban sites with high frequencies of landscaping requirements will still prefer the smaller chipper sizes, whereas areas covered in forest activity will prefer larger equipment. The demand split also indicates the variability of Europe's market, whereby there is no single size that prevails but rather caters to different user segments. The manufacturers and suppliers are keeping this in perspective while they seek to launch models that not only adhere to efficiency criteria but also aim at the region's increasing emphasis on environmental sustainability.

In the future, the Europe wood chipper market will keep growing as the private and public sectors invest in machinery that minimizes wastage and maximizes productivity. The gap between 6–12 inches undercarriage and the ones greater than 12 inches will stay significant because it leaves customers free to pick based on their scale of operations. With construction, forestry, and landscaping projected to remain significant in the continent, demand for wood chippers that are robust and effective will guarantee steady growth for the two categories in the coming years.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$131.3 million |

|

Market Size by 2032 |

$176.4 Million |

|

Growth Rate from 2025 to 2032 |

4.3% |

|

Base Year |

2024 |

COMPETITIVE PLAYERS

The Europe wood chipper market is progressively making waves as industries and municipalities alike keep looking for effective solutions in the management of wood waste and biomass. The need for equipment that can break down branches, trunks, and other wood products into usable chips is growing due to a mix of environmental objectives and functional requirements. Wood chippers are no longer considered niche machinery but as necessary tools in forestry activities, landscaping, and even energy generation. To this end, manufacturers in Europe are firming up their presence and coming up with designs that appeal to large-scale forestry services as well as small commercial uses.

A broad array of established names is crucial in this market. Well-known brands like Timberwolf, Redwood Europe (Först), Jensen Service GmbH, and GreenMech Ltd have gained confidence through longevity and innovation. German manufacturers like Schliesing Machinery GmbH, Müllers & Backhaus GmbH & Co. KG (JBM), and Heizomat - Gerätebau + Energiesysteme GmbH are recognized for precision engineering, while firms like Linddana A/S and Laski, s.r.o. concentrate on producing flexible machines that can withstand varying work conditions. Each one of them has its own experience, either in the form of portable chippers to be used in urban applications or heavy-duty equipment for forestry applications.

The inclusion of international players enhances competition and increases customer choice even further. Vermeer Corporation, Morbark, LLC, Bandit Industries, Inc., and Pezzolato S.p.A. help define industry standards by providing powerful and dependable equipment capable of dealing with stringent workloads. Eschlböck Maschinenfabrik GmbH, Mus-Max, and ALBACH Maschinenbau AG emphasize the European heritage of precision craftsmanship in machine manufacturing. In contrast, Ufkes Greentec and BENTELE Biomasse Technologie GmbH concentrate on solutions that not only minimize waste but also contribute to renewable energy activities by converting wood into biomass fuel.

Sustainability has emerged as a major force behind the direction of the future for the Europe wood chipper market. Municipal corporations and private companies are increasingly utilizing wood chippers as part of waste management policies, decreasing landfill use and extracting value from materials otherwise destined for the landfill. This is consistent with the expanding push toward renewable energy, where wood chips provide feedstock for biomass power plants. As regulations drive industries to cleaner and more efficient operations, wood chipper companies will continue to innovate both design and function.

In the future, the market will be competitive, with seasoned players like JENZ GmbH, Saelen, Bugnot, and Deutz-Fahr Forestry driving technology advancements and service excellence. The increasing blend of local and international industry players will increase the number of options for the consumer from small machines for routine landscaping to heavy-duty chippers for commercial biomass production. As there is increasing focus on efficiency, safety, and environmentalism, the Europe wood chipper market will grow steadily with innovation and the complete industry presence of prominent players backing the trend.

Europe wood chipper market Key Segments:

By Type

- Drum Chipper

- Disc Chipper

- Screw Chipper

By Fuel Type

- Diesel Engine

- Petrol Engine

- Electric Driven

By End Users

- Forestry & Biomass

- Paper & Pulp

- Construction

- Timber Factories & Sawmills

By Chipper Size

- 6- 12 inches Type of Undercarriage

- > 12 inches Type of Undercarriage

Key Europe Wood Chipper Industry Players

- Timberwolf

- Redwood Europe (Först)

- Jensen Service GmbH

- Müllers & Backhaus GmbH & Co. KG (JBM)

- GreenMech Ltd

- Schliesing Machinery GmbH

- Saelen

- Bugnot

- Linddana A/S

- Laski, s.r.o.

- Vermeer Corporation

- Forestry

- Ufkes Greentec

- Morbark, LLC

- Bandit Industries, Inc.

- Pezzolato S.p.A.

- Eschlböck Maschinenfabrik GmbH

- BENTELE Biomasse Technologie GmbH

- JENZ GmbH

- Mus-Max

- Heizomat - Gerätebau + Energiesysteme GmbH

- ALBACH Maschinenbau AG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252