MARKET OVERVIEW

The global chemical anchors market, which falls in the construction and infrastructure sector, will increasingly become a focal point that facilitates high-performance bonding solutions in structural and non-structural applications. The market will entail the manufacturing, distribution, and integration of chemical-based anchoring systems that secure materials to concrete, masonry, and other substrates. As opposed to mechanical fastening techniques, chemical anchors will provide better load distribution and vibration resistance, making them appropriate for high-load applications, seismic areas, and situations requiring precision installation. The global chemical anchors market will be influenced by a blend of industrial needs, regulatory environments, and specialized building requirements.

Producers of materials in this arena will create custom resin compositions that adapt to fluctuating conditions like temperature changes, humidity, and substrate quality. These chemically reacting anchors, such as injectable adhesives and capsule forms, will be designed for use in retrofitting applications and new building work. As infrastructure assets continue to age in leading economies and the demand for structural reinforcement intensifies, the use of chemical anchoring systems will increasingly apply across commercial, industrial, and institutional markets. What characterizes the market is the technical specificity of the product and the need for precise on-site implementation. Chemical anchors will frequently have to satisfy stringent performance standards, such as resistance to dynamic loads and corrosion.

With increasingly sophisticated project specifications requiring greater levels of durability, the use of tailored anchoring solutions will become more intense. All parties to the global chemical anchors market suppliers and contractors, engineers and regulatory agencies will be concerned with securing compatibility between anchoring material and base substrate, a consideration that will become essential for preventing structural failure. The scope of the market will far exceed mere residential or commercial structures. Bridges, tunnels, dams, and even wind and solar installations will feature chemical anchoring systems because of their capacity to provide long-term performance under extreme stress. Furthermore, industries like marine construction, transportation networks, and power plant facilities will increasingly need anchoring solutions that provide safety and efficiency without sacrificing structural integrity.

The global chemical anchors market will also exhibit regional differences, where building codes, seismic categories, and project types will determine the formulation and application method needed. In addition, market growth will not only be based on physical products but also on training programs, certification, and compliance systems that will dictate the use of chemical anchors. Project managers are going to have to be highly knowledgeable in unique product behaviors to include curing time, load-carrying capability, and resistance in the environment. These dynamics will place the market as having heavy technical interaction and strict monitoring. Software modeling and computing-based project planning will further converge with chemical anchor use, allowing for predictive simulations of long-term behavior prior to starting physical implementation.

In short, the global chemical anchors market will become a critical industry within the overall construction ecosystem, and its use will span a vast range of industries and geographies. Its evolution will be in response to certain technical, structural, and regulatory requirements, which will keep changing with evolving engineering practices and infrastructure priorities.

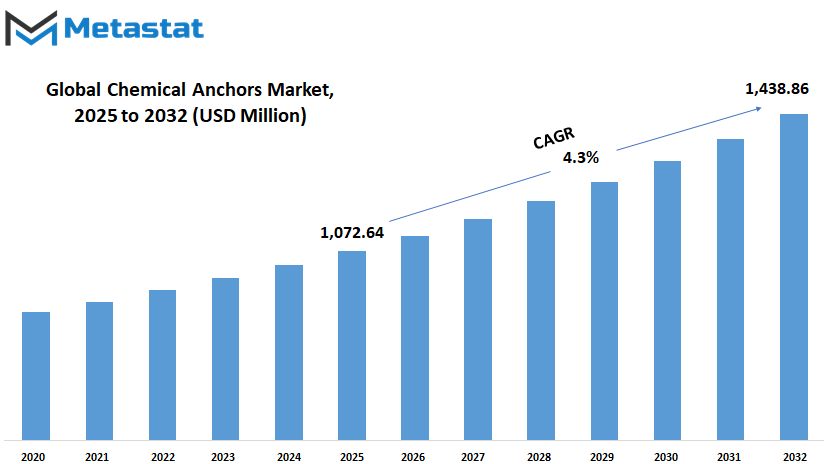

Global chemical anchors market is estimated to reach $1,438.86 Million by 2032; growing at a CAGR of 4.3% from 2025 to 2032.

GROWTH FACTORS

The global chemical anchors market is slowly attracting greater interest with the ongoing development and transformation of the construction industry globally. Chemical anchors are increasingly being selected because of their high holding strength and versatility across various construction requirements. They are particularly convenient in cases where conventional anchors are inadequate, having greater support and reliability in concrete structures. As an increasing number of nations invest in new infrastructure, chemical anchoring technologies are gaining popularity as an everyday solution on building sites. New buildings, bridges, and public buildings are driving demand upward as all these constructions demand fastening solutions that are secure. One of the primary reasons chemical anchors are getting so popular is that they outperform mechanical systems.

These anchors support higher loads and are appropriate for a greater range of materials and environments. This makes them the choice in projects that need high precision and safety levels. They also come in handy when dealing with older structures where conventional anchors might not be useful. As cities grow and there is a greater demand for residential and commercial use space, so too does there need to be a more stable anchoring system. Not all is easy along the route for this market, though. The price of chemical anchors is still higher than its conventional counterparts, making some consumers sit on the fence.

For minor projects or tight-budgeted areas, this will prove to be a big deciding factor. A worry is also the health and safety hazards that accompany working with the chemical substances utilized in such anchors. The mixing and application of the resin expose workers to toxic fumes and chemicals, particularly in confined areas. This could result in illnesses and delays in work without the right safety precautions. Despite these problems, the future is bright. One developing sector of interest is in the retrofitting of existing buildings and reinforcement of buildings where earthquakes are common. Chemical anchors are perfect for this purpose since they can be set in restricted or confined areas, and they create a secure grip without harming the original building.

Such applications present new avenues for expansion in the global chemical anchors market. As construction standards increase and safety's presence increases, more projects will look towards chemical anchors as a reliable choice. Through careful innovation and improved safety measures, this market is expected to expand consistently over the next few years.

MARKET SEGMENTATION

By Product Type

As engineers and builders seek more dependable and time-saving solutions, the application of chemical anchors will continue to grow. Classified by product type, this market is also divided further into injectable adhesive and capsule adhesive.

Both of these are utilized for precise functions in construction operations. Injectable adhesives are used extensively as they enable accurate application in deep holes and odd surfaces to suit a great variety of structural repairs. Capsule adhesives provide reliability of quality and quicker installation in controlled settings. With further advances in technology, it is possible that both types will be driven to further formulation and performance improvements, which will allow them to be applied to more advanced and challenging construction scenarios.

The market value of the injectable adhesive and capsule adhesive segment stands at an estimated USD 813.60 million and USD 259.04 million, respectively, by 2025. This is a testament to the increased demand for safer and more durable bonding products for use in residential and industrial projects. Nations that are currently funding massive infrastructure development projects, including bridges, tunnels, and business buildings, are likely to spearhead this market. In the long term, the global chemical anchors market will be driven by some significant factors. Growing interest in building safety and cost of long-term maintenance will make chemical anchors a favored choice compared to conventional fastening techniques.

In addition, as building practices keep trending towards green and sustainable materials, manufacturers could also create anchors with reduced emissions and enhanced energy efficiency both in production and consumption. This way will not only aid growth in the market but also correspond to the world environmental targets. Technology will also be important. Developments in application tools and material science will probably lead to faster installation, more durable bonds, and more extended service life. These advances will enable contractors to save time and lower labor expenses while maintaining superior safety levels. The global chemical anchors market is thus poised to continue as a central component of construction trends well into the future.

By Resin Type

Chemical anchors are selected according to the specific requirements, particularly when one is working with diverse situations like temperature fluctuations, strength of the load, or susceptibility to moisture. In terms of resin types, the market is segmented into a number of broad categories Polyester, Unsaturated Polyester, Epoxy Acrylate, Pure Epoxy, and Hybrid Systems. Each has a unique characteristic, and one industry favors one type over another based on their specifications.

Polyester resins are typically employed for light to medium-duty applications. They tend to be easier to use and cure more quickly, so they are helpful for less demanding applications or where speed is crucial. Unsaturated Polyester is also popular, although it is slightly more sophisticated and might be better at resisting in some situations. Epoxy Acrylate has improved adhesion and tends to be used where strength and weather resistance are key considerations.

Pure Epoxy is the most dependable when dealing with heavy-duty or tough environments. It has a longer curing time but provides better performance in the long run. This kind of resin will become increasingly vital in projects where safety can never be traded off. Hybrid Systems bring the best features from over one type of resin, providing versatility and tailor-made performance. They are gaining popularity as construction requirements get more specific.

As technologies advance and environmental issues become more widespread, manufacturers will have to concentrate on developing more efficient and environmentally friendly versions. Future products will also be able to contain smart technology that reacts to stress or temperature changes. The global chemical anchors market will keep growing as building trends move toward more resilient and environmentally friendly infrastructure. Engineers and project developers will turn increasingly to these materials for new build as well as repair.

While the market still follows current preferences, it is clear that innovation will push companies to explore advanced formulas and applications. This shift will shape how the global chemical anchors market develops, with resin type playing a central role in how it adapts to future construction challenges.

By Application

The global chemical anchors market is anticipated to witness gradual but consistent growth through rising demands in contemporary construction methods. With the urban environment still expanding, the call for stronger and more secure fastening solutions becomes increasingly apparent. Chemical anchors provide a stable solution for fastening heavy loads and are preferred due to their strength, particularly in situations where accuracy and long-term stability are crucial. Their application in reinforcing key infrastructure is increasingly important, and the market will continue to be interested in a range of applications. One key area of application is in structural connection.

As structures rise and increase in complexity, materials applied must keep pace with evolving architectural requirements. Chemical anchors offer a solution that can accommodate these demands, particularly when conventional alternatives prove inadequate. This is especially helpful in environments where steel or concrete elements need to be connected firmly. Rebar connections are also receiving increased popularity. In construction, rebar plays a crucial role in the reinforcement of concrete, and chemical anchors assist in making these connections stronger, particularly when there is the need for altering or expanding existing structures. The installation of heavy machinery is another way that this market will remain active.

Whether it's machinery in a factory or large units in power plants, there needs to be anchoring to maintain safety and performance. Chemical anchors provide that. They are also used in façade installation, to hold panels and other exterior components firmly in place. In metropolises where building designs are evolving and aesthetic appeal matters, this is particularly useful. Handrails and safety barriers are also reliant on chemical anchors for a solid grip. These elements tend to be placed in public spaces, where safety is paramount. Anchors that can withstand stress or frequent use will continue to be selected by construction companies. Seismic retrofitting is another area that will gain from this. In earthquake-prone regions, chemical anchors provide a reliable means of securing older structures without rebuilding them in their entirety.

In the years to come, new material and application innovations will dictate the way the global chemical anchors market will develop. As construction becomes increasingly complicated, there will be an even greater demand for secure anchoring. Engineers and builders will continue to seek out products that are not only secure enough for safety, but also hold up well over the long term. This will make chemical anchors useful in many forms of construction.

By End Use Industry

The global chemical anchors market can anticipate steady growth for the next few years with increasing demand from various industries. With advancing construction methods and stricter safety requirements, the demand for robust, dependable fastening systems is on the rise. Chemical anchors provide solutions for the fixation of heavy loads on concrete and other substrate materials, and they are increasingly being selected due to their capability to function under harsh conditions. The market is attracting growing interest from both public and private sectors, particularly with the increasing growth of global infrastructure projects. The demand for tough and effective anchoring systems will become increasingly strong in the future.

Chemical anchors assist with structural support that is heavy in roads and bridges. They play a critical role in achieving enduring performance. As governments increase their spending on repairing and renovating transportation infrastructure, this industry will be responsible for much of the market's growth. Tunnels and dams are frequently operating in harsh conditions, so anchors must be resistant to pressure, dampness, and long-term stress. This is where chemical anchors have the advantage, providing performance that mechanical techniques can't. In railroads, precision and safety are imperative. Tracks and fixtures have to stay in place regardless of continuous movement and shocks. Chemical anchors offer the kind of grip that regular anchors can't always provide.

Likewise, in manufacturing, the emphasis on automation and heavy equipment requires that equipment be locked firmly in place to avoid accidents and enhance efficiency. The global chemical anchors market will gain from the growth of this sector. Marine and offshore operations also have a significant contribution to make towards future demand. Anchors deployed in such environments have to endure harsh weather and corrosive conditions. Chemical anchors, designed to withstand these, will become the preferred option. The oil and gas sector, which tends to operate in far-flung and harsh locations, depends on stable and long-term support solutions. Chemical anchors are increasingly being utilized to cater to these demands.

Mining and other heavy industries will also drive market development. The relentless drive for deeper and more complex projects of excavation will generate demand for heavier anchoring solutions. As businesses continue to look for improved safety, reliability, and performance, the global chemical anchors market will continue to grow. This development will be influenced by the manner in which each industry utilizes anchors to achieve its unique requirements.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,072.64 million |

|

Market Size by 2032 |

$1,438.86 Million |

|

Growth Rate from 2025 to 2032 |

4.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

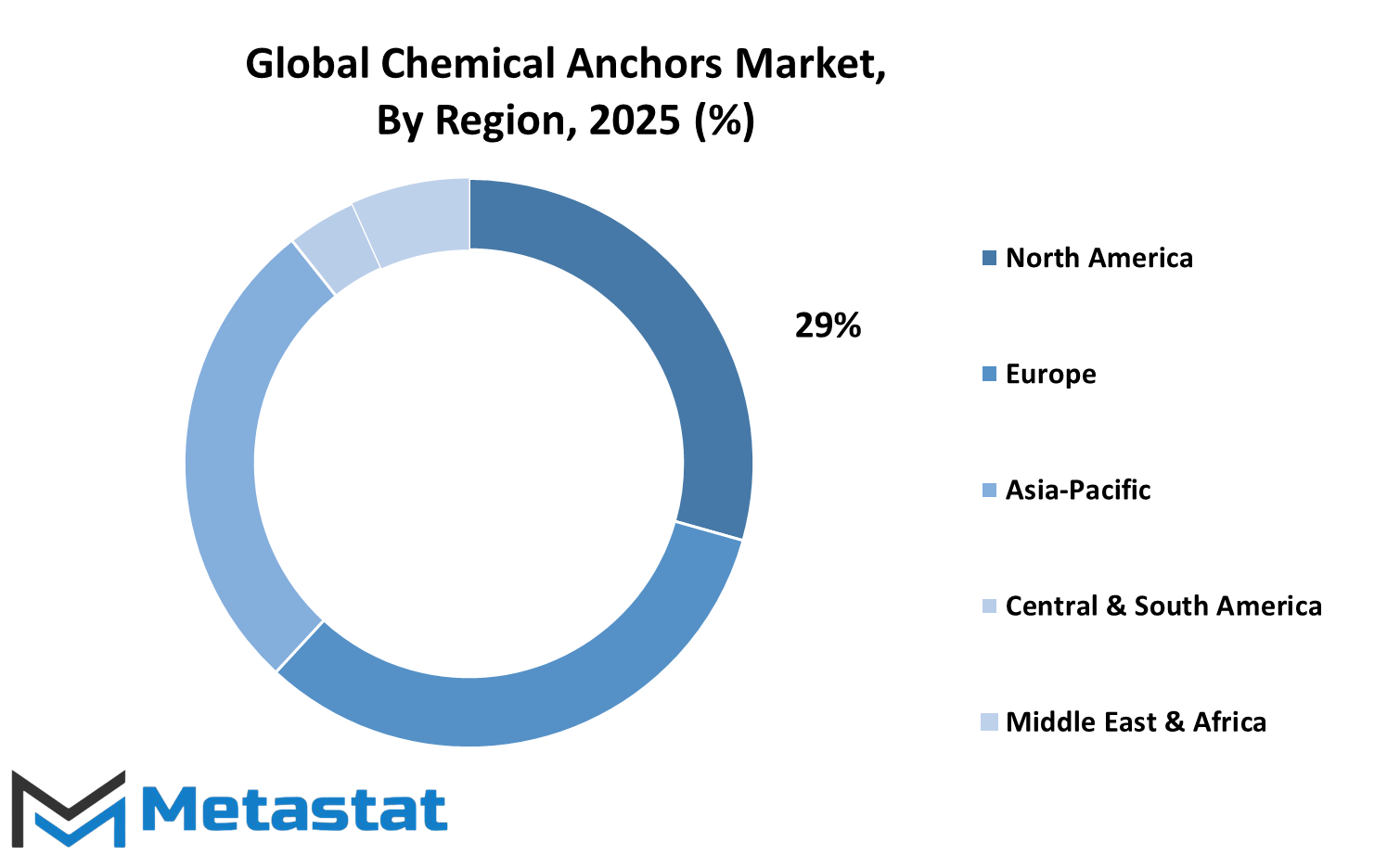

The global chemical anchors market is slowly charting its course through constant evolutions in technology, construction practices, and local needs. With increasing demands for stronger and more resistant construction materials, chemical anchors have emerged as a reliable answer. Chemical anchors are sometimes selected since they provide excellent strength and dependability in holding heavy loads or strengthening key structures. Though their applications have been witnessed in small-scale as well as large-scale projects, their significance is only increasing as more infrastructure is built all over the globe. Geographically, the global chemical anchors market is wide-ranging across multiple prominent regions, with each contributing in different ways to growth.

In North America, i.e., in the U.S., Canada, and Mexico, there is continued interest in replacing aging infrastructure, which will tend to drive demand for chemical anchoring solutions. The U.S. particularly has a significant role to play in this market because of its continued investments in the transportation and commercial buildings sectors. Its transition to Europe, including the UK, Germany, France, Italy, and others, will see increasing building codes and environmental programs continue to drive the need for more sophisticated methods of anchoring. Safety and long-term performance are also given high priority, and chemical anchors can provide this. In the Asia-Pacific region, which encompasses India, China, Japan, South Korea, and the areas surrounding them, the market is very promising. Fast build-up in urban areas and constant industrial expansion will see chemical anchors capture even more market share.

China and India, especially, are going through radical changes in residential and industrial construction patterns, and this will see the market move ahead. In South America, there is increased demand for cost-effective and productive building methods in nations such as Brazil and Argentina, which can potentially trigger demand for chemical anchoring systems. Even though the growth here is slower than in other parts of the world, there are chances for future growth. Lastly, in the Middle East & Africa comprising GCC nations, Egypt, South Africa, and surrounding areas the market is bolstered by massive investments in commercial real estate and massive public infrastructure. Demand for stability under severe weather conditions also makes chemical anchors an appropriate solution in these regions. In the future, the global chemical anchors market will continue to grow as various regions embrace new building technologies and enhance standards of safety and performance. Every region adds to a larger picture where strong, dependable, and convenient anchoring solutions are needed more than ever.

COMPETITIVE PLAYERS

The global chemical anchors market will most probably continue expanding as companies from construction, infrastructure, and manufacturing industries seek solutions with increased strength and reliability in fastening. The anchors find applications to fasten materials to concrete and comparable surfaces, providing a strong and durable grip even under high stress. As there are increased demands on projects for longer lifespan and improved safety requirements, chemical anchors are being seen as their equal in durability and performance in harsh environments. They are preferably used as a substitute for mechanical fasteners when the aim is to prevent cracks in the base material or when the work involved is with uneven surfaces. With requirements in construction work spreading in developing and developed regions, demand for these products is not likely to decline. Increased emphasis on sustainability and innovation will also dictate the future of this market.

With increasing mainstreaming of green building, manufacturers are formulating chemical anchors with lower emissions and friendlier application processes. Industry leaders such as Hilti Group, Fischer Group, and Sika AG are investing in research to make their products more sustainable without sacrificing strength. Equally, companies like Fixdex Industrial and Henkel AG & Company, KGaA (Ceresit) will need to extend their portfolio to accommodate various requirements for performance. These firms are investing in new materials that bond faster, last longer, and operate under a broad variety of conditions. Increasingly rapid setting times and enhanced strength enable projects to progress more rapidly and securely. As cities expand, the need for skyscrapers, tunnels, and transportation systems will offer new applications for chemical anchors. Manufacturers are already making changes.

Simpson Strong-Tie U.K., Ripple India, and DeWalt are improving anchor compositions to function in extreme weather conditions, underwater, or seismic areas. As governments globally are investing more in upgrading infrastructure, particularly transportation and energy, the market for solid and dependable anchors will remain strong. Every new project provides a chance to do it better, and the competition between companies is driving the market towards improved products. Looking forward, digital technologies will also have a part to play. From enhanced design software to accurate application methods, technology will assist users in applying these anchors more accurately and efficiently. With continuing innovations from firms such as MKT Metall-Kunststoff-Technik GmbH & Co.KG and Klimas Sp. z oo, the global chemical anchors market is on a trajectory of continued growth and development, influenced by the changing requirements of industries globally.

Chemical Anchors Market Key Segments:

By Product Type

- Injectable Adhesive

- Capsule Adhesive

By Resin Type

- Polyester

- Unsaturated Polyester

- Epoxy Acrylate

- Pure Epoxy

- Hybrid Systems

By Application

- Structural Connections

- Rebar Connections

- Heavy Equipment Mounting

- Façade Installations

- Handrails and Safety Barriers

- Seismic Retrofitting

- Others

By End Use Industry

- Highways and Bridges

- Dams and Tunnels

- Railways

- Manufacturing

- Marine and offshore

- Oil & gas

- Mining

- Others

Key Global Chemical Anchors Industry Players

- Hilti Group

- MKT Metall-Kunststoff-Technik GmbH & Co.KG

- Fixdex Industrial (Shenzhen headquarter) Co., Ltd.

- Fischer Group

- Chemfix Products Ltd.

- Koelner Rawlplug IP

- Ripple India

- EJOT SE & Co. KG

- ITW Construction Products (Singapore) Pte. Ltd.

- Sika AG

- Simpson Strong-Tie U.K.

- Henkel AG & Company, KGaA (Ceresit)

- DeWalt

- Klimas Sp. z oo

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252