MARKET OVERVIEW

The Global Belt Conveyor Idlers market is an essential part of the material handling industry, which encompasses the manufacturing and installation of idlers that are crucial parts of a conveyor system. Idlers are cylindrical rollers that have been placed along the length of the belt for the purpose of supporting and guiding its movement, ensuring that materials are transported across different industries efficiently. As conveyor systems have numerous applications in mining, manufacturing, agriculture, and logistics, idlers have emerged as the most indispensable item in order to provide minimum downtime and ensure a running operation.

This is more of a niche market; however, it clearly delineates a focus area by the manufacturers on innovations leading to development of durable and effective idlers that can meet diversified environments. Idlers are important not just for the support of weights being transported but also the reduction of wear and tear on conveyor belts. An idler is designed so that it allows smooth flow of the belt while increasing energy efficiency, which determines the total cost of working. The market also accounts for some specific challenges involving abrasive materials, extreme weather, and heavy loads, making material handling an integral part worldwide.

The Global Belt Conveyor Idlers market is widespread across various industries, including mining, construction, food processing, and power generation. Each of these industries depends on conveyor systems to transport materials efficiently, and idlers are an essential component in ensuring the long life and performance of such systems. This market does not solely represent standard idler designs but also represents the more technological varieties, like self-aligning idlers, impact idlers, and return idlers, each suited specifically for the various demands put forward by each application. Integration of technology and material science will be continually going to influence further the development in making lighter, more resilient, and environment-friendly idlers.

Customization and specialty are two major aspects in this market. Manufacturers are turning to idlers that they make for specific client requirements; these can range from the variation in size to selection of material and even features that minimize noise. Other technological developments in monitoring systems have enhanced the functionality of idlers, allowing real-time condition monitoring to prevent impending failure. This focus on specific solutions mirrors the market’s commitment to addressing the unique needs of end-users along with the global sustainability trend.

The Global Belt Conveyor Idlers market will continue to expand its presence, driven by advancements in automation, increased industrialization, and the ongoing demand for efficient material handling solutions. Emerging economies are expected to play a prominent role in this growth, as infrastructure development and industrial projects in these regions create substantial opportunities for conveyor system installations. In turn, this will spur demand for reliable and high-performance idlers capable of supporting large-scale operations.

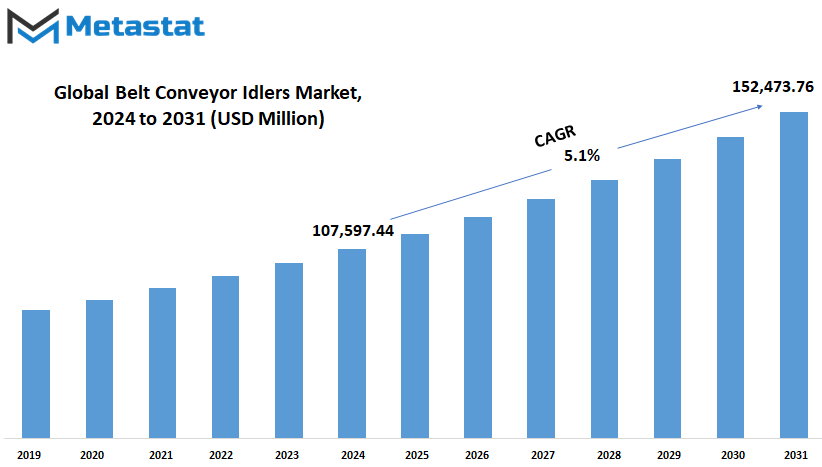

Global Belt Conveyor Idlers market is estimated to reach $152,473.76 Million by 2031; growing at a CAGR of 5.1% from 2024 to 2031.

GROWTH FACTORS

The Global Belt Conveyor Idlers market is in a growth curve because of many key drivers over the next few years, creating opportunities for innovation. Owing to the growth within the various industries, it would be in need of more effective and automated material handling equipment. Some of these have already embraced advanced technologies related to manufacturing and mining by adopting innovative belt conveyor idler technologies to enhance the operational performances of these industries. These parts play a very important role in ensuring that materials are transported smoothly and without interruption, hence they are not dispensable in high-capacity industrial settings.

Investments in the development of infrastructure further prove to be an expansion of this market. Governments and private parties are investing in the construction of roads, railways, and transport networks, which are highly dependent on the effective conveyor systems. These systems not only improve the overall efficiency of large-scale projects but also reduce manual labor, which leads to a rise in the adoption of advanced idlers. Therefore, the market is expected to grow significantly as industries increasingly turn to automated and energy-efficient solutions.

Nevertheless, some factors may hamper the growth of the market. The first challenge is high replacement and maintenance costs for conveyor idlers. The cost of maintaining these components can be very high, especially after long periods of usage. Most industrial settings expose conveyor idlers to extreme conditions that accelerate wear and tear, leading to operational delays and increased costs for companies. These factors may act as a potential barrier for the companies, especially those operating under limited budgets.

Although challenges exist, the future has much to offer for the Global Belt Conveyor Idlers market. Manufacturers are focusing on designing energy-efficient and durable idlers for longer operational lives. Such developments not only serve to reduce wear and tear concerns but also contribute to lowering energy consumption, which works in line with global intentions to promote sustainability in industrial processes. Such innovations will attract investments from businesses looking to optimize operational efficiency while saving costs in the long term.

With an emphasis on efficiency and sustainability, the Global Belt Conveyor Idlers market is poised to grow steadily. This is due to the adoption of advanced technologies and the increased emphasis on durable and energy-saving solutions that will define the future of the market. These advancements are sure to form a vital part of the growth of industries and infrastructures across the globe, even with challenges still being prevalent.

MARKET SEGMENTATION/REPORT SCOPE

By Type

The Global Belt Conveyor Idlers market is an integral part of modern industrial processes, providing the backbench for material handling across the sectors. The market size is expected to reach some significant figures by 2024. Steel idlers have the projected valuation of 55,444.19 USD million, and dominate this area because of its strength to carry heavy loads, used in mining, construction and other industries. Plastic idlers, at a value of 22,996.02 USD million, present a lightweight yet efficient alternative with high corrosion resistance and suited to scenarios where weight is to be reduced. Meanwhile, rubber idlers, with an estimated value of 17,181.72 USD million, are favored for their shock absorption properties, contributing to quieter operations and reduced wear on conveyor belts. Ceramic idlers, expected to reach 11,975.51 USD million, cater to specialized needs such as high-temperature or abrasive conditions, showcasing their growing importance in niche applications.

In the near future, the Global Belt Conveyor Idlers market is set for drastic changes, where productivity and sustainability become core preferences. New technologies would also shape the manufacturing and utilization of idlers into superior versions that enhance their life spans and efficiency. For example, idler mounted with smart sensors could easily become a standard, because then one could monitor at any given time the state of wear and tear in order to reduce downtime as well as maintenance costs. Increasing concern for environmental protection will eventually stimulate the production of recyclable or biodegradable idlers that align with global efforts on industrial operation environmental protection.

The future also holds a promise of customization to be the new focus. As industries diversify and expand, the demand for idlers will grow for specific requirements. Manufacturers will likely innovate to meet these unique demands, whether it involves specialized coatings, designs, or materials that cater to challenging environments or high-performance needs.

As the automation of industrial processes continues to advance across the globe, the Global Belt Conveyor Idlers market will be an important contributor to the smooth flow of materials. The evolution of this industry will ensure that it remains relevant and expansive, as it is spurred on by technological advancements and the ever-growing need for efficiency in a competitive global landscape.

By Material

The Global Belt Conveyor Idlers market will see significant growth as more industries seek efficient solutions to material handling systems. In conveyor systems, belt conveyor idlers are important in ensuring smooth transportation of materials while reducing operational challenges. As the demand for advanced and durable idlers is increasing across various industries, their importance in enhancing productivity and reducing downtime cannot be overstated.

Among the key segments driving this market forward is classification by material, with the two major types being low noise rollers and self-aligning rollers. Low noise rollers are gaining popularity since they are able to make the working environment quieter than usual, which is greatly beneficial in industries where a reduction in noise is emphasized. This feature not only supports worker safety and comfort but also complies with stricter environmental regulations, making these rollers a preferred choice for businesses looking to adopt sustainable practices. On the other hand, self-aligning rollers are increasingly recognized for their ability to correct belt misalignment during operation, thereby reducing wear and tear and extending the lifespan of conveyor belts. Their practical use ensures operational efficiency and cost-effectiveness, making them irreplaceable in modern industrial installations.

As technology is expected to continue shaping the industry, the future of the Global Belt Conveyor Idlers market looks promising. Innovations in materials and manufacturing processes will be expected to result in lighter, more durable, and energy-efficient rollers. Industries are going to adopt these developments to meet evolving demands for higher productivity and lower maintenance costs. The increasing automation will pave the way for idlers with upgraded features, with real-time monitoring and capabilities for predictive maintenance, for further development in the domain.

The global push towards sustainable practices will also influence market trends. Manufacturers will likely prioritize eco-friendly materials and designs to align with environmental goals and reduce the overall carbon footprint of industrial operations. Additionally, expanding industries in developing regions will contribute to increased demand for conveyor idlers, as these areas invest heavily in infrastructure and industrial growth.

In summary, the Global Belt Conveyor Idlers market would witness significant growth due to innovation and the need to have efficient material handling solution. Low noise rollers would play a vital role shaping this dynamic market while on the other hand self- aligning rollers will bring out the industry's responsive nature to future challenges and opportunities at large.

By Distribution Channel

The Global Belt Conveyor Idlers market is likely to experience considerable growth due to its use in various industries and ability to simplify material handling. As the world's industries continue to become more modernized, the demand for effective and long-lasting conveyor systems is likely to increase. One of the essential parts of the conveyor system is the belt conveyor idler, which supports the conveyor belt and reduces friction in the conveyor system. This market is influenced by advancements in manufacturing technologies, the adoption of automation, and the growing need for sustainable solutions. Among the factors shaping this market is the increasing diversity in distribution channels.

Availability of products through online and offline platforms offers buyers flexibility and convenience. Online distribution channels in particular are gaining traction as digitalization transforms purchasing patterns. E-commerce platforms are being used by businesses to reach a wider market, thus allowing customers to view the specifications of products, compare features, and order with ease. This method reduces procurement time and also saves on costs, which makes it appealing to both manufacturers and end-users. However, offline distribution is essential for most industries that need customized solutions and hands-on interaction. Many companies favor offline channels for their ability to provide personalized service, technical expertise, and immediate access to products. From the futuristic perspective, the Global Belt Conveyor Idlers market will witness innovation driven by the integration of smart technologies.

Predictive maintenance tools and sensors to monitor idler performance in real-time will reduce downtime and extend equipment lifespan. Eco-friendly manufacturing practices must also be reflected in the design composition of idlers, because it will have to compete with the global sustainability approach. Companies that invest resources in research and development will strive to use lightweight yet effective materials that will help reduce consumption of energy and cut running costs. The increasing mining industries, agriculture, construction industry, and manufacturing will increasingly require reliable conveyor systems in their operations.

By End-Users

The Global Belt Conveyor Idlers market is experiencing high development with changes in various industries. The belt conveyor idlers, which are part of a conveyor system, allow efficient material handling, and it is therefore necessary in most industries. The growing need for streamlined operations, low labor dependency, and improved productivity is what influences the market. The adoption of automation in various industries implies that belt conveyor idlers are essential for keeping such systems operational.

A crucial factor about the market is that it has been divided according to end-users. Such sectors as food, coal, cement, electric power, metallurgy, and pharmaceuticals are of particular importance. For the food industry, advanced idler conveyor systems are critical in moving bulk ingredients and final products. The strength and accuracy of such systems significantly influence the quality and conformance to tight regulatory conditions. Similarly, the coal and cement industries are still growing for conveyor systems with a higher load-carrying capacity. These sectors have the demand for robust conveyors that are long-lasting and low maintenance; thus, advanced belt conveyor idlers are preferred.

The manufacturing and mining industries also depend on these systems to optimize material transport. Mining operations, in particular, require high-performance idlers that can withstand harsh environments and heavy usage. With the expansion of global energy needs, the electric power industry is another significant contributor to the market. Conveyor systems equipped with efficient idlers streamline processes in power plants, ensuring reliability and reduced operational downtime.

In addition, these systems benefit the transportation industry in conveying goods across different facilities. Conveyor idlers are used for controlled material movement in highly sensitive environments in the pharmaceutical and chemical industries, with a need for precise handling and safety. These are just some of the widespread applications that show the depth and significance of belt conveyor idlers in modern times.

The market is poised to grow steadily as automation becomes more prevalent in industry. Technological advancements, such as real-time monitoring and predictive maintenance integration with smart features, will characterize the future of belt conveyor idlers. Efficiency and cost-effectiveness combined with safety will be on par with the changing requirements of industrial operations. As industries continue to focus on efficiency and sustainability, the Global Belt Conveyor Idlers market will remain at the forefront and offer solutions adaptable to future needs and challenges. Expanding application across multiple sectors ensures its importance in driving industrial progress around the globe.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$107,597.44 million |

|

Market Size by 2031 |

$152,473.76 Million |

|

Growth Rate from 2024 to 2031 |

5.1% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

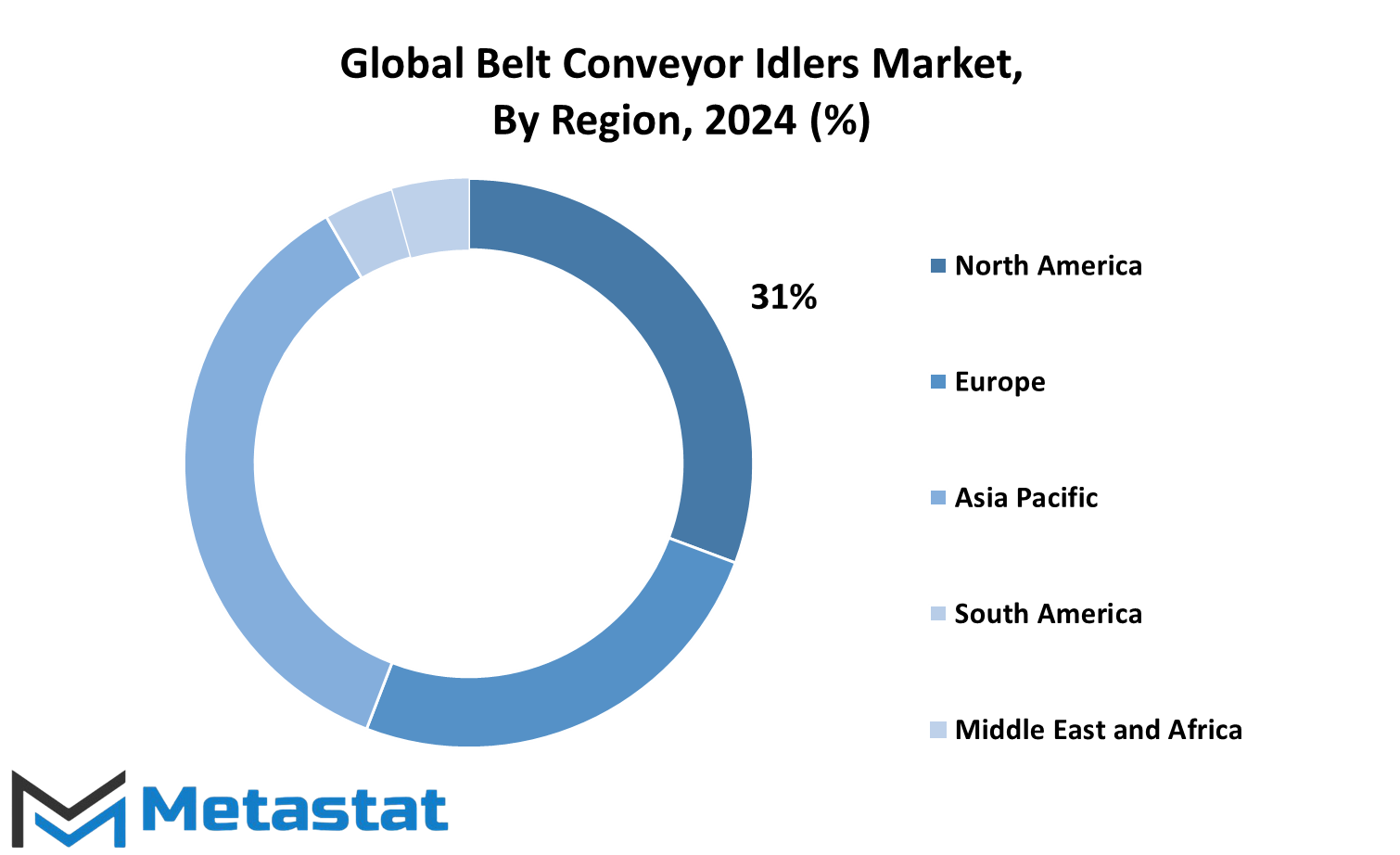

The global Belt Conveyor Idlers market is experiencing rapid growth in every region, which has a different set of factors affecting its growth and adoption. The market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. This diversity presents different opportunities and challenges, which influence the market's direction. The regional dynamics give insight into the demand, technological advancements, and investments in belt conveyor idler systems.

North America, including the United States, Canada, and Mexico, has emerged as an important region in this market. This is because of significant industries such as mining, manufacturing, and construction which drive the need for effective conveyor systems. The United States itself has experienced an increase in automation and the use of advanced conveyor technologies, an indicator of a focus on operational efficiency and sustainability. Canada and Mexico are adding to the growth of the region with rising industrial activities and infrastructural developments.

The UK, Germany, France, and Italy are major market leaders in Europe. They are supported by robust manufacturing sectors and a growing emphasis on eco-friendly industrial practices. Advanced engineering expertise in Germany has played a significant role in the development and adoption of innovative belt conveyor idler solutions. France and Italy are continually developing their industrial bases. Hence, there is consistent demand for such systems in this region. The remaining European countries also have positive growth prospects as industries develop and modernize their processes.

Asia-Pacific, comprising India, China, Japan, South Korea, and the remainder of the region, holds immense potential for expansion in the global Belt Conveyor Idlers market. China and India, with their booming economies and increasing industrialization, dominate the demand for conveyor systems. Japan and South Korea, with their technological advancements, contribute to the development of high-performance idlers that cater to a wide range of applications. The region's overall growth is driven by large-scale infrastructure projects and the expanding manufacturing sector.

South America, led by Brazil and Argentina, is rising, as the region will increasingly focus on industrial expansion and resource extraction. The usage of conveyor systems in mines and agricultural sectors is favorable to the growth of this market. Similarly, the Middle East & Africa region, especially the GCC countries, Egypt, and South Africa, are witnessing an increase due to increased investments in construction and mining projects. In turn, these activities bring in the requirement for reliable and durable conveyor idlers.

Looking ahead, the global Belt Conveyor Idlers market will expand further as industries all over the world adopt advanced technologies to enhance efficiency, sustainability, and operational capabilities. Every region's unique industrial landscape ensures a dynamic and competitive future for the market.

COMPETITIVE PLAYERS

The Global Belt Conveyor Idlers market will experience extreme development because all industries on earth continue to evolve towards embracing the technology. All idlers that are needed for belt conveyors carry a critical role in an industry that focuses on conveyor belt material handling, covering mining, construction, and manufacturing and logistics. With increased importance on automation and efficiency in industrial operations, the demand for high-performance conveyor idlers is likely to increase, thereby impacting manufacturers' design and production capabilities in this market.

There are several key players operating in the Global Belt Conveyor Idlers market, contributing to the development of innovative solutions tailored to meet diverse industrial needs. Companies like Rulmeca Holding S.p.A, Precision Pulley & Idler (PPI), and ASGCO invest continually in the R&D aspect to improve their products regarding durability, reliability, and efficiency. All these companies are essential investments, mainly because the current demand is to increase idlers, which are built to function in adverse climatic conditions, heavy load carrying capacities, and extended operating periods. Continental Conveyor and Syntron Material Handling have been using advanced materials and engineering methods to deliver products that meet specific industrial challenges and global standards.

The sustainability factor is also something that is shaping the Global Belt Conveyor Idlers market. With more industries looking to reduce their environmental footprint, companies such as Douglas Manufacturing Co., Inc. and Superior Industries are finding ways to work with eco-friendly materials and to minimize energy consumption in the manufacturing process. This shift not only goes hand in hand with the sustainability goals of the world but also increases the competitiveness of companies in the market. Furthermore, smaller but innovative firms like Gram Conveyor, Rite Idler, and Luff Industries Ltd. are making significant strides by offering customizable solutions, targeting niche markets, and providing exceptional customer service.

With the growth of globalization and industrial development, regions across Asia-Pacific, North America, and Europe are facing a growing demand for advanced conveyor idlers. Companies such as JRC Co., Ltd., Global Conveyor Supply Co., Ltd. (GCS), and Ritika Engineering Pvt. Ltd. are capitalizing on this trend by strengthening their distribution networks and collaborating with local businesses to expand their reach.

Looking ahead, the technological advancements, sustainability efforts, and strategic collaborations will define the Global Belt Conveyor Idlers market. Companies that are innovative and responsive will do well in such a dynamic and competitive space, serving the diverse, growing needs of industries all over the world.

Belt Conveyor Idlers Market Key Segments:

By Type

- Steel Idlers

- Plastic Idlers

- Rubber Idlers

- Ceramic Idlers

By Material

- Low Noise Rollers

- Self-Aligning Rollers

By Distribution Channel

- Online

- Offline

By End-Users

- Food Industry

- Coal Industry

- Cement Industry

- Electric Power Industry

- Metallurgy Industry

- Chemical Industry

- Pharmaceutical Industry

- Manufacturing Industry

- Mining Industry

- Transportation Industry

Key Global Belt Conveyor Idlers Industry Players

- Rulmeca Holding S.p.A

- Precision Pulley & Idler (PPI)

- ASGCO

- Continental Conveyor

- Syntron Material Handling

- Douglas Manufacturing Co., Inc.

- Superior Industries

- Luff Industries Ltd.

- Gram Conveyor

- Rite Idler

- JRC Co., Ltd.

- Global Conveyor Supply Co., Ltd. (GCS)

- Ritika Engineering Pvt. Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252