Global Aluminum Brazing Sheets Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global aluminum brazing sheets market within the metal manufacturing sector will follow an interesting path from its infancy in experimental form to today's advanced applications. In the beginning, aluminum was utilized mostly in simple structural uses, and the idea of producing specialized sheets for the purpose of brazing alone started to gain traction during the mid-20th century, when industries like automotive and HVAC required lighter, corrosion-free materials. Early experimentation focused on alloy pairings that would be structurally sound under high-temperature processing. As early as the 1960s, all this experimentation began paying off in the way of commercially accessible aluminum sheet maximized for efficient heat transfer and joining, a breakthrough in the technology.

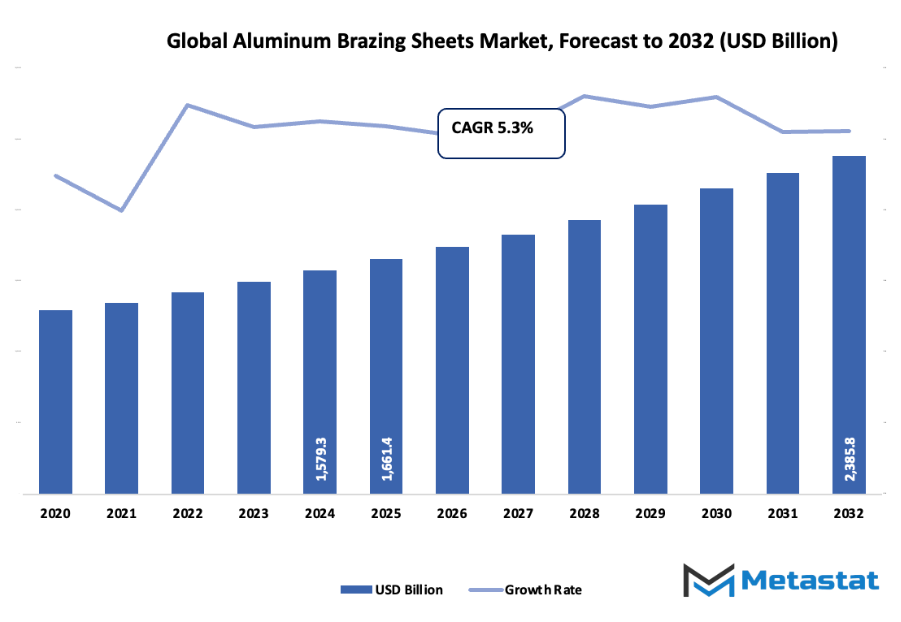

- Global aluminum brazing sheets marketof approximately USD 1661.4 Billion in 2025, at a Compound Annual Growth Rate of roughly 5.3% between 2032, with future prospects greater than USD 2385.8 Billion.

- Clad Aluminum Brazing Sheets account for approximately 66.5% market share, fostering research and more applications through intense research.

- Major trends fueling growth: Rising usage of lightweight materials in automotive and aerospace applications, Increased usage of energy-efficient HVAC and refrigeration units

- Opportunities are: Increased adoption of electric vehicles propelling demand for next-generation heat exchanger materials

- Key insight: Over the next ten years, the market will increase exponentially in value, indicating strong growth opportunities.

The 1980s and 1990s will be decades of revolutionary change as consumer needs and industry requirements started to shift. Air conditioner systems and self-heating exchangers called for sheets that were more thermally conductive, more formable, and more resistant to brazing flux corrosion. Over the years, technological advancements in rolling and cladding operations will allow producers to make multilayered sheets capable of meeting these increasingly stringent requirements. Regulatory shifts with regards to environmental standards will also drive manufacturers to create lower-emissions alloys during manufacturing, driving the industry to greener processes. In the early 21st century, the global aluminum brazing sheets market will change to accommodate higher usage of electric vehicles and energy-efficient refrigeration systems, calling for sheets capable of accommodating new performance requirements. Computer modeling and emerging test equipment will enable producers to precision-tune alloy compositions and sheet characteristics to precise industry requirements.

Stronger, lighter, and more thermally efficient product specifications by consumers will continue to pressure investigation into advanced coatings and composite films, and stricter environmental legislation will pressure the manufacturing process toward greater sustainability. The industry will embrace materials science innovations in the future that provide better, faster, and more reliable brazing without sacrificing performance. Markets such as the automotive, aerospace, and refrigeration market will rely on aluminum sheets, which combine mechanical strength with optimum heat management, resulting in universal application across applications. The global aluminum brazing sheets market will continue to evolve as manufacturers strive to reconcile the technological possibilities, the constraints imposed by regulation, and shifting end-user requirements in order to maintain its position as a pillar industry of modern metal fabrication.

Market Segments

The global aluminum brazing sheets market is mainly classified based on Type, Application, , .

By Type is further segmented into:

- Clad Aluminum Brazing Sheets: Clad aluminum brazing sheets are so designed that one side of them has a thin layer of filler material, which improves bonding in brazing. Clad sheets are widely used where leak-free, high-strength joints must be obtained with better thermal and mechanical performance than is available from non-clad systems.

- Non-Clad Aluminum Brazing Sheets: Non-clad aluminum brazing sheets do not involve a pre-applied filler layer and are therefore suitable for application in situations where expert brazing material is used. The sheets provide flexibility in manufacturing processes and are mostly chosen in applications where cost-sensitive projects include the use of conventional brazing methods.

By Application the market is divided into:

- Automotive: In the automotive sector, aluminum brazing sheets are used in the manufacture of components such as radiators, heat exchangers, and condensers. Their low weight lightens the vehicle weight and improves fuel efficiency, and corrosion resistance gives longevity over a long span in every type of weather.

- HVAC: Aluminum brazing sheets have an essential application in the HVAC industry for producing heat exchangers, evaporators, and condensers. They ensure efficient heat transfer, possess structural stability at elevated temperatures, and ensure stable performance in refrigeration and air conditioning systems.

- Electrical: Aluminum brazing sheets are used in electrical use in parts which require superior thermal and electric conductivity. They provide consistent performance under the weight of electricity, reduced energy loss, and aid in the production of light and tough electrical products.

- Others: Multiple industries utilize aluminum brazing sheets in everyday manufacturing and machinery where lightweight and anti-corrosion products are utilized. These sheets are versatile and strong, allowing different fabrication processes while being efficient and reliable in most industrial applications.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1661.4 Billion |

|

Market Size by 2032 |

$2385.8 Billion |

|

Growth Rate from 2025 to 2032 |

5.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

By Region:

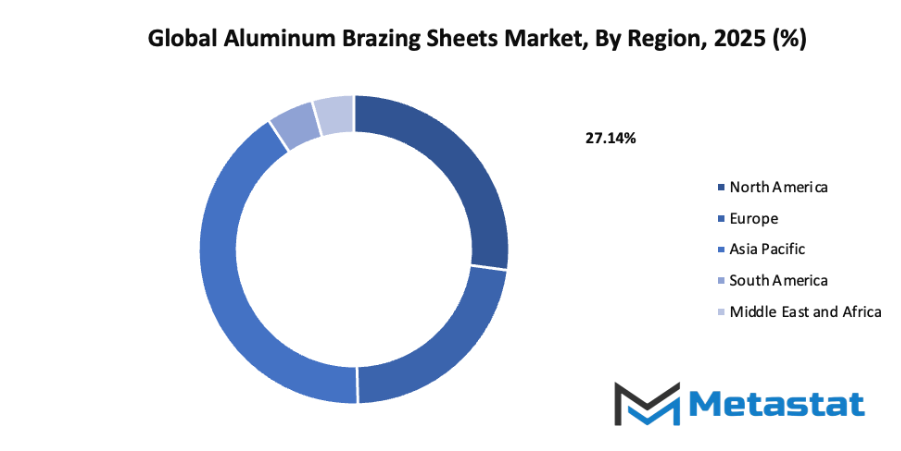

- Based on geography, the global aluminum brazing sheets market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Increasing demand for lightweight materials in automotive and aerospace industries: The use of lightweight materials will continue to grow as manufacturers aim to reduce overall vehicle weight and improve fuel efficiency. This demand is fueled by the need for better performance and lower emissions, which encourages the adoption of materials that maintain strength while reducing mass.

- Growing adoption of energy-efficient HVAC and refrigeration systems: Energy-efficient HVAC and refrigeration systems will drive demand for materials that improve heat transfer and durability. These systems require components that can handle higher efficiency standards while maintaining reliability, creating a consistent need for materials that can meet these performance expectations.

Challenges and Opportunities

- Fluctuating prices of aluminum raw materials: Variations in aluminum prices will impact production costs and supply chain stability. Manufacturers must plan for these fluctuations to avoid disruptions and maintain profitability while meeting the increasing demand for high-performance materials.

- Complex manufacturing processes requiring precise temperature control: Manufacturing advanced materials will require strict control over temperature and production conditions. Any deviation can affect the final product’s quality, making precise process management a critical factor for successful production.

Opportunities

- Rising use of electric vehicles driving demand for advanced heat exchanger materials: The growth of electric vehicles will increase the need for high-performance heat exchanger materials. Efficient thermal management in electric powertrains will push manufacturers to adopt materials that improve cooling efficiency and overall vehicle performance.

Competitive Landscape & Strategic Insights

The global aluminum brazing sheets market will continue to grow as both international industry leaders and emerging regional competitors shape its development. The industry is a mix of well-established global players and newer companies seeking to gain a foothold in key markets. Important competitors include UACJ Corporation, Nippon, Navard Aluminium, Lucas-Milhaupt, ALCOA Corporation, SRA Solder, Superior Flux & Mfg, brazetec USA, Solvay, VBC Group, S-Bond, Pietro Galliani Brazing, Kobe Steel Ltd., Novelis Inc., Norsk Hydro ASA, Constellium SE, Granges AB, and Toyo Aluminium K.K. These companies will continue to drive innovation, improve production efficiency, and expand product offerings to meet rising demand in various industries.

In the coming years, the industry will increasingly focus on sustainable practices and advanced manufacturing techniques. New materials and alloys will be developed to enhance performance while reducing environmental impact. Regional competitors will bring fresh perspectives and cost-effective solutions, creating opportunities for collaboration and healthy competition with global leaders.

The market will likely see further consolidation as companies aim to strengthen their positions and expand geographic reach. Investments in research and development will shape the future of Aluminum Brazing Sheets, enabling better performance, lighter materials, and increased durability for industrial applications. Companies that anticipate market trends and adapt quickly will have an advantage in meeting evolving customer needs and regulatory requirements.

Market size is forecast to rise from USD 1661.4 Billion in 2025 to over USD 2385.8 Billion by 2032. Aluminum Brazing Sheets will maintain dominance but face growing competition from emerging formats.

Overall, the global aluminum brazing sheets market will evolve as a dynamic ecosystem where established leaders and emerging players drive innovation and set new standards for quality and sustainability. The focus on advanced materials and manufacturing efficiency will ensure the industry continues to grow while meeting the demands of a rapidly changing industrial landscape.

Report Coverage

This research report categorizes the global aluminum brazing sheets market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global aluminum brazing sheets market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global aluminum brazing sheets market.

Aluminum Brazing Sheets Market Key Segments:

By Type

- Clad Aluminum Brazing Sheets

- Non-Clad Aluminum Brazing Sheets

By Application

- Automotive

- HVAC

- Electrical

- Others

Key Global Aluminum Brazing Sheets Industry Players

- UACJ Corporation

- Nippon

- Navard Aluminium

- Lucas-Milhaupt

- ALCOA Corporation

- SRA Solder

- Superior Flux & Mfg

- brazetec USA

- Solvay

- VBC Group

- S-Bond

- Pietro Galliani Brazing

- Kobe Steel Ltd.

- Novelis Inc.

- Norsk Hydro ASA

- Constellium SE

- Granges AB

- Toyo Aluminium K.K.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252