MARKET OVERVIEW

The Global Advanced Robotics for Industrial Automation market leads the manufacturing and industrial technology industry with the growing adoption of intelligent systems in production environments. Robotics that limit human intervention, while performing complex tasks autonomously, form the core of this market. Such robots perform these tasks with a high degree of accuracy and consistency. These machines are made to work in different industrial fields like electronics, automobile, aerospace, and heavy machinery productions. The futuristic technologies in advanced robotics are still being innovated to improve the precision demands and manufacture complex production workflows.

Global Advanced Robotics will develop systems capable of responding flexibly to varying requirements in the emerging factories of the world. As industries move into a more automated ecosystem, robotics will not only be limited to simple assembly and/or workpiece handling but will also conduct their own decision making based on real-time data and environmental predictions. These types of machines will learn from the operational rules developed when they are being used, have different patterns in energy applications, and adapt to various production conditions without complete, recurrent reprogramming. They will place such advanced robotics squarely at the center of next-generation industrial automation strategies.

The Global Advanced Robotics for Industrial Automation market is intended to respond to that requirement-the search for flexibility by industrial facilities engaged in high-mix, low-volume production. Develop robotic arms with more dexterity, machine vision, and sensory feedback systems, then it is possible to continue without sacrificing quality in the presence of custom or variable production demands. This will include mechanical performance as well as software enablement so that robotic units can interface across digital platforms and enterprise systems. Robotics systems will act as intelligent agents within these infrastructures as factories move toward interconnection.

The market will also be shaped by the demand for machines that can keep running even under uncertain environmental conditions. These robotic systems are to operate adroitly and resiliently, be it in an environment with variable temperature, confined space, or risk from exposure to hazardous agents. In relation to safety issues, the Global Advanced Robotics for Industrial Automation market will embark on systems where human intervention is minimized through the automated function to meet the standards of workplace safety and reliability of output.

Manufacturers who want to tap into scalable automation will find value in deploying robotics platforms that can be tailored to one's workflow. The Global Advanced Robotics for Industrial Automation market will be introducing systems that will fulfill these requirements with a modular design, so that upgrade, or adaptation to other production lines will be easy. This will be relevant for the companies functioning in various regions with different operational standards and output requirements.

In the future, the Global Advanced Robotics for Industrial Automation market will set the precedent for how factories, warehouses, and production units will organize their processes. This will create an environment where physical processes are increasingly governed by cognitive systems residing within those machines, thus reaffirming the strategic importance of robotics in industrial automation. As digital-mechanical integration deepens, the accent will swing toward maximizing performance with intelligent autonomous tools, thereby recreating the standard for industrialism.

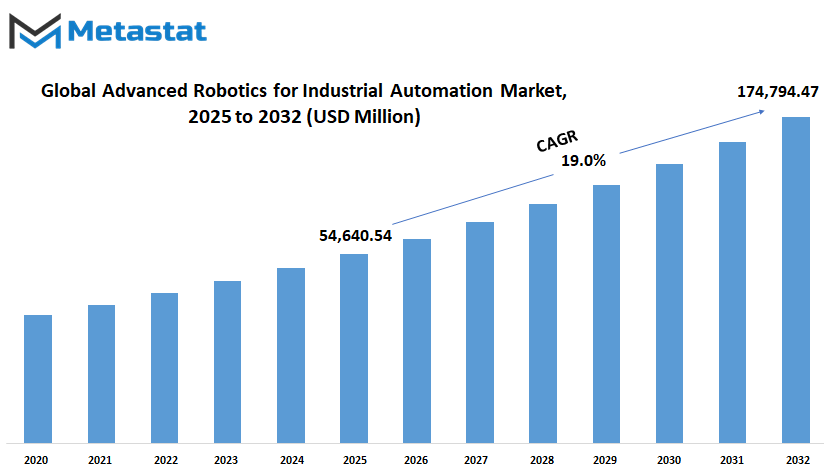

Global Advanced Robotics for Industrial Automation market is estimated to reach $174,794.47 Million by 2032; growing at a CAGR of 19.0% from 2025 to 2032.

GROWTH FACTORS

As industries are under continuous pressure for better performance, accuracy, and faster production cycles, the Global Advanced Robotics for Industrial Automation market continues to grow. More than a mere option, advanced robotics automation is becoming a necessity with the rapid advancement of technology. Companies search across factories and production lines for ways to reduce errors, achieve higher output, and meet tight deadlines without compromising quality. Increased precision robotics that work tirelessly and adapt to changes in demand are therefore needed now more than ever.

One of the considered taxations of this market growth will come from the burden experienced by many industries in regard to sourcing and retaining skilled employees. Labor shortages are now common in manufacturing. Also with increasing wages, organizations are turning to reputable alternatives. Advanced robots provide automation for those concerned about production needs that don't get affected by human resource issues. The introduction of user-friendly and programmable machines will now see these alternatives embraced by smaller companies.

However, not everything about the shift will be easy. Especially for cash-strapped companies, setting up robotic systems is costing them dearly. Some will think twice about investing unless there is strong evidence of a quick return. Also, combining these robots with outdated machines that are still in use presents another huge obstacle. Making everything mesh well will often require extra planning and a definite level of skill. Then there remain issues with benefits for workers concerning any increase in automation. While robots are a strong support for numerous process improvements, fears of job loss start to emerge among the workforce when companies begin to adopt machines in place of human workers. Further, these robots have a simultaneous need for trained human personnel for their operation and maintenance, thus making the development of the right skills among the employees a major area of concern.

But the future holds even greater promise. AI is helping produce robots with the ability to think for themselves. Robots are now able to see objects, judge small deviations in parts, and work safely alongside humans, thanks to machine vision. These advancements set the stage for a more advanced applications across diverse sectors. The collaborative robots that work directly alongside humans also facilitate the operational transition to more automated systems. As all these technologies are maturing, new capabilities for meeting challenges and generating value will be opened up in the Advanced Robotics for Global Industrial Automation space.

MARKET SEGMENTATION

By Robot Type

The Global Advanced Robotics for Industrial Automation market is advancing more closely in the direction of a future where systems would be more precise, collaborative, and smarter in terms of working practices. With this modernization in production lines, robots have developed from being machines that repeat these simple tasks to now becoming smarter, safer, and more adaptable. Hence, this transformation now sets the stage for very robust growth across a number of robots-a widening range of types specifically designed for the various needs surrounding the manufacturing and industrial processes. There are millions of companies investing in improving newer technologies, should it be in adding costs to their capital to gain efficiency, precision, and lower costs in the long term; as demand for fast output with fewer errors becomes critical in international trading.

Among numerous varieties of robots, articulated robots are pioneers and expected to witness USD 25,626.41 million growth by 2025. Its flexibility and ability to perform complex work raise its usefulness in several sectors, such as assembly and welding. They are often found in industries requiring detail-oriented, repetitive actions done quickly and precisely. As factories aim for ever-increasing consistency and safety, articulated robots' demand can be anticipated to continue solid.

SCARA robots, known for their speed and stability of movement in the horizontal direction, are projected to make USD 9,196.00 million in 2025. They are primarily adopted in applications such as pick-and-place and packaging where both speed and accuracy are really involved. For manufacturing small items, such as electronics, needing gentle handling along the production line, SCARA robots will take over to ensure that a large volume is achieved without compromising quality.

With simple design and easy programming, Cartesian robots will reach about USD 8,982.90 million. They are especially well suited for 3D printing, CNC machining, and handling tasks that cannot be done without simple motion. Besides being highly cost-effective and reliable, they represent a good choice for companies that want automation but do not want to complicate things any further.

Collaborative robots or "cobots" were anticipated to cross a barrier of USD 6,783.62 million. They are very different from robot assistants in that cobots are explicitly designed for working alongside people. Increased productivity is made possible through the "additive" efficiency rather than replaced. More industries will increasingly turn to cobots as pairs of safety devices are engineered and designed specially to tackle repetitive or physically taxing jobs.

However, they are more specific than the other types but very much including important emerging nowadays, and the projection of the same goes beyond USD 4,051.60 million by 2025 in the market. They may be used in highly specialized fields where traditional robots do not present a fit. All these categories, when weighed as a unit, give the true picture of what the Global Advanced Robotics for Industrial Automation market has ahead in terms of creating a more advanced, connected, and efficient future.

By Application

In short, the Global Advanced Robotics for Industrial Automation market is on its way to a bright and promising future where efficiency, precision, and consistency matter all the more. On the way to productivity improvement, most industry forms keep looking at the costs while developing advanced robotics, which would be one of the important technologies along the journey toward plant and production unit goals. An examination of their applications across different kinds of work will show just what an impact these systems will have on the future of work in industry.

The major difference that advanced robotics will make in life is going to be assembly. As products grow more sophisticated and the customer base becomes more demanding, it will demand increased robotics speed to get things done faster and more accurately. This will reduce errors and speed up putting together things for a more reliable process. The much more demanding customer will never be satisfied with assembly being done on anything-from small electronic items to gigantic machinery-using hands alone.

Material Handling is also an essential segment of the Global Advanced Robotics for Industrial Automation market. However, coming days will see companies increasingly depending on robots for the transport, lifting, and placement of parts in the production line, all in a safe and smooth manner. These robots will also have less workplace injuries and a higher overall speed production. Factories will be able to inject their warehouse operations with robots that don't tire and can maneuver goods around heavy or fragile items.

Changes will happen even in welding tasks. Robots meant for welding purposes will be very accurate and can weld without creating a lot of waste. This quality will be useful for the automotive industries, construction where welding quality has to be supreme. At the same time painting jobs will also be made easy and clean with robots that would work applying an even coat without waste and fewer harmful fumes to be inhaled by workers.

Inspection and quality control will gather steam in the coming years. As goods are made faster, there is more emphasis on making sure all products meet the set standards. Early identification by robotic systems with sensors and cameras will bring down the problems that require rework and hence save money. On the packaging front, robotic systems will pitch in to hasten up this last part of production; - putting products in place, sealing, labeling, and getting them ready for delivery.

However, the rest of the applications are going to continue to grow, especially with the advent of new industries and methods of production. To sum up, the Global Advanced Robotics for Industrial Automation market is all set to become a major part of the future readiness kit for industries.

By End-User Industry

The Global Advanced Robotics for Industrial Automation market is poised for rapid growth as industries globally seek to implement robotic systems to ensure productivity, safety, and accuracy across wider application areas. As automation technology expands, the demand for even more advanced robotic solutions will increase. The absorption of these technologies across various industries will spur their market growth as well as the shaping of their future.

The automotive industry will remain one of the pillars of advanced robotics. Robotic systems for manufacturing have revolutionized the automobile assembly line, increased efficiency and minimizing human error. As the demand for electric vehicles and smart manufacturing solutions rises, robots equipped with artificial intelligence and machine learning capabilities will become even more indispensable. These systems will aid in improving assembly accuracy, shortening production lead time, and enabling flexible manufacturing that will allow automotive companies to meet rising consumer demand for high-quality, customized vehicles.

In the electronics and electrical industry, the role of robots will continue to expand. With an increasing need for precision in manufacturing small and complex components, the role of robotics is poised to provide infinite solutions. Advanced robotics will enhance assembly and testing processes that involve electronic products, including smartphones, computers, and components. With smart homes and more connected electronics, there will be increasing demand for robots in precision assembly, component inspection, and ensuring high-quality stands.

The advancement of robotics will also heat up their use in the metal and machinery industry. In metalworking operations, robots are used for welding, cutting, and assemblies, and artificial intelligence and automation will be enhancing their capabilities. With the increased demand from industry for mass customization and quick turnaround times, robotic systems will be adapted to perform a far greater scope of tasks, which in turn will improve productivity and quality.

The food and beverages industry would get more and more safety and consistency from the use of robotics. The robots will keep automating food manufacturing processes from sorting to packaging to even cooking. These systems will enable manufacturing companies to comply with regulations while boosting speed and minimizing human error.

The pharmaceutical industry will be another area that will see massive growth on the back of advanced robotics. Robots will be used in the accurate handling of fragile drugs and materials, thus enhancing safety and reducing the risk of contamination. This method will also streamline the work in packaging to keep in pace with the demanding production schedule with stringent quality requirements. The aerospace and defense industry will still depend on robots for activities demanding extreme precision and safety.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$54,640.54 million |

|

Market Size by 2032 |

$174,794.47 Million |

|

Growth Rate from 2025 to 2032 |

19.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

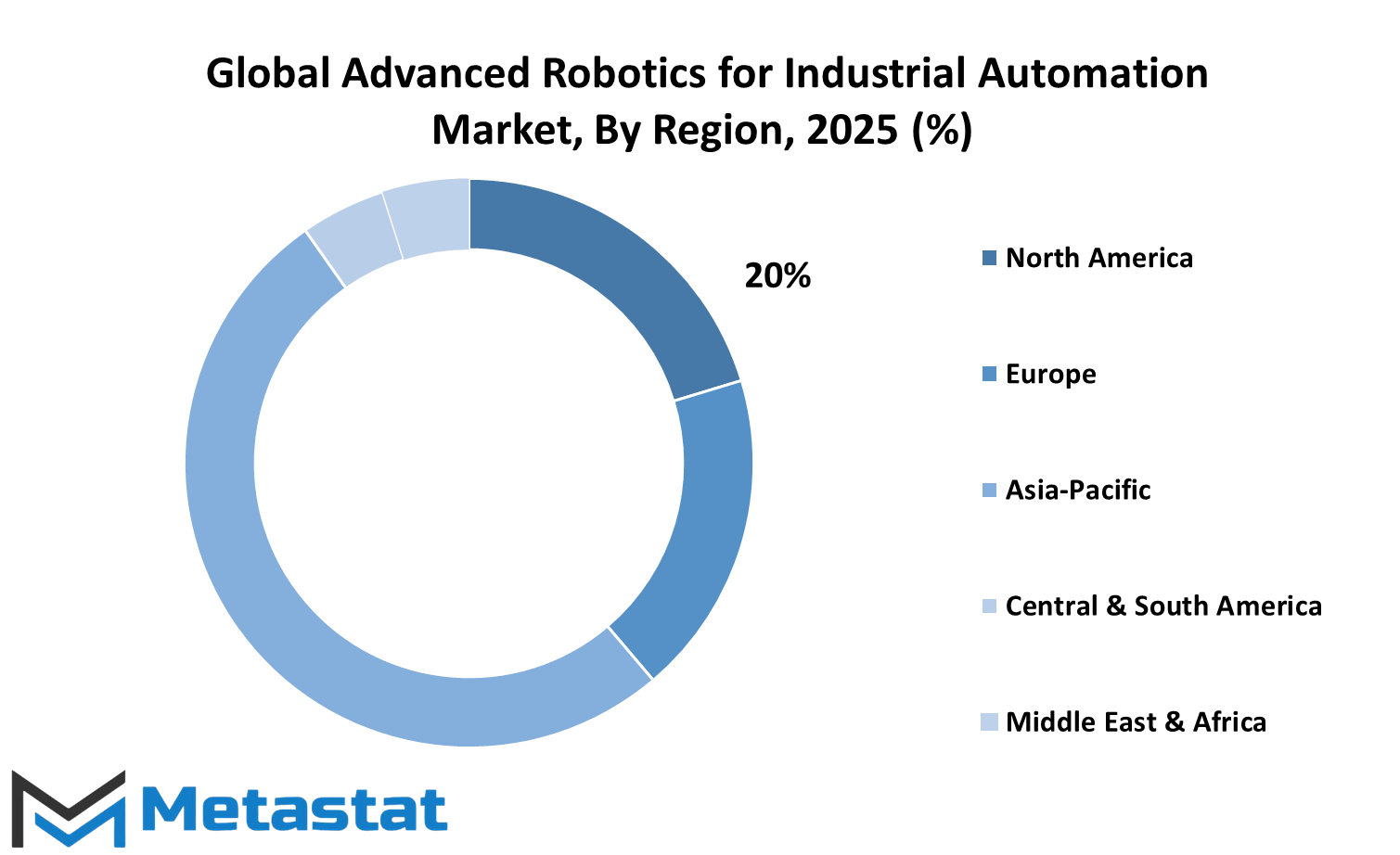

The Global Advanced Robotics for Industrial Automation markets are undergoing a paradigm shift and heading toward the most significant growth phase due to technology advancement and increasing demand for effective and automated production systems. Industries are deploying robots for manufacturing processes. Through different geographic regions, each can have a different contribution to the total market along with putting a unique perspective on the evolution of this market. Knowledge of regional dynamics helps in forecasting the trajectories that the future of this market would unfold.

North America, especially the adoption of advanced robotics within the United States, Canada, and Mexico, is anticipated to grow steadily in terms of advanced robotics adoption in the future. As for automation to answer the demands from an ever-increasing requirement for high precision and efficiency, industries in these countries will be utilizing robots. The U.S. will remain the world's lead in the development and deployment of robotics for industrial automation, aimed primarily at retrofitting for enhancing factory production lines, labor cost reduction, and safety. Canada is also moving toward bringing robotics into multiple sectors such as automotive and manufacturing. Mexico is expected to increase its robot buying once it becomes more integrated into North America and world supply chains.

Similarly, Germany, the UK, France, and Italy are anticipated to hold their best positions in the market within the region of Europe. This is seen as such nations have been the forerunners in industrial automation for a long time, and they will continue to spur growth while adopting the latest robotics technologies. Automotive and engineering industries will keep Germany on top as a country with a reputation in the automotive and engineering industries. The U.K. and France, focusing on high-tech manufacturing and innovation, are also increasingly likely to experience higher demand for robots in their industrial sectors. Italy will go ahead, with its great tradition in manufacturing, and continue integrating robotics into its operations to ensure efficiency and quality.

Consequently, the Asia-Pacific region would be in the eye of the future regarding the Global Advanced Robotics for Industrial Automation market. Interactive countries among China, Japan, South Korea, and India will drive the industry's development. China will continue to promote its manufacturing base for domestic production of quality products at reduced labor costs through automation. Japan and South Korea will follow suit with their strong technology know-how as they are at the forefront of developing and implementing advanced robotics systems. On the other hand, India, with an emerging industrial base, will also see an uptick in the adoption of robotics in modernizing its manufacturing systems.

Countries of South America with Brazil and Argentina equally anticipate incremental increases in the use of robotics over the years. When the region's industrial base becomes more developed, so will automation. Not spared from this phenomenon will be countries in the Middle East and Africa, such as the GCC countries.

COMPETITIVE PLAYERS

It will no doubt be evolutionarily enhanced for Global Advanced Robotics for Industrial Automation, with the leading companies providing a basis for future growth and creativity. The market is directed by industry veterans in the likes of ABB Ltd., KUKA AG, Fanuc Corporation, and Mitsubishi Electric Corporation, which will now continue to set limits on robotics in manufacturing or associated industrial processes. As we move on with technology, these companies are studying ways to improve the efficiency, accuracy, and flexibility of robotic systems able to translate into prevailing complexities of demand posed by industries across the globe.

These companies are likely to deliver still more advanced and intelligent robotic solutions in the coming years. For example, ABB Ltd. would probably be enhancing its industrial automation with robots integrating AI and machine learning for adaptive, self-learning capabilities. KUKA and Fanuc, with their vast experiences in automation and robotics, shall spearhead the development of robots that enhance autonomy and speed in carrying out a larger palate of tasks from assembly to packaging. By improving productivity, such developments will also reduce reliance on human intervention in hazardous or monotonous tasks.

The introduction of different solutions by smaller, specialized companies such as Right-hand Robotics and Omron Corporation will stimulate the shift towards customization and versatility in robotics worldwide. For example, Right-hand Robotics focuses on automation for e-commerce, where robots pick and sort items inside warehouses. Their technology is aimed at improving robot dexterity and understanding of objects and will continue to evolve to make robotic systems more efficient and adaptable across a plethora of industries. Omron Corporation has similar plans for developing robots capable of collaborating with humans in a safe and productive environment, which will be key for the next phase of industrial collaborative automation.

On the other hand, Yaskawa Electric and Teradyne Inc. will keep pushing the advancements of robotics with industrial manufacturing applications. As demand grows for robots performing functions such as welding, painting, and quality control, these companies will continue to develop robots that perform with higher precision and reliability in such environments. The integration of robotics into industries such as automotive manufacturing, electronics, and food production.

The history, as well as R&D activities by these enterprises, are going to form the future of the Global Advanced Robotics for Industrial Automation market, seeking the creation of robots that would be more efficient and productive but also safe and easy to work with in the diverse industrial environment.

Advanced Robotics for Industrial Automation Market Key Segments:

By Robot Type

- Articulated Robots

- SCARA Robots

- Cartesian Robots

- Collaborative Robots (Cobots)

- Other

By Application

- Assembly

- Material Handling

- Welding

- Painting

- Inspection and Quality Control

- Packaging

- Other

By End-User Industry

- Automotive

- Electronics and Electrical

- Metal and Machinery

- Food and Beverage

- Pharmaceuticals

- Aerospace and Defense

- Other

Key Global Advanced Robotics for Industrial Automation Industry Players

- ABB Ltd.

- KUKA AG

- Fanuc Corporation

- Comau

- Mitsubishi Electric Corporation

- RUTRONIK Electronics

- RightHand Robotics

- Yaskawa Electric

- Omron Corporation

- Teradyne Inc.

- Nachi-Fujikoshi Corp.

- Denso Wave Inc.

- Epson Robots

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383