MARKET OVERVIEW

In the industrial applications, the Global Abrasive Polishing Fluid market stands as a testament to the continuous quest for precision and excellence. This market, characterized by its diverse array of abrasive polishing fluids, plays a pivotal role in enhancing the efficiency and quality of various manufacturing processes across different industries.

Abrasive polishing fluids are not mere components but rather catalysts in the pursuit of impeccable surface finishes. These fluids, with their tailored formulations, cater to the specific needs of industries ranging from automotive to electronics, ensuring that the final product meets the highest standards of quality. The Global Abrasive Polishing Fluid market, fueled by innovation and technological advancements, addresses the demand for superior surface finishes in the ever-competitive global market.

One of the key drivers behind the market’s growth is its ability to adapt to the unique requirements of different materials. Whether it is metal, glass, ceramics, or composites, abrasive polishing fluids within this market are designed to optimize the polishing process for each material, contributing to the longevity and functionality of the end product. This adaptability not only showcases the versatility of these fluids but also highlights their instrumental role in the intricate world of material engineering.

Furthermore, the Global Abrasive Polishing Fluid market has witnessed a surge in demand due to the increasing emphasis on sustainability and environmental consciousness. Manufacturers are now leaning towards formulations that not only provide exceptional polishing results but also adhere to stringent environmental regulations. This shift reflects a broader trend in the industrial landscape, where responsible and eco-friendly practices are becoming integral components of manufacturing processes.

In addition to their role in traditional manufacturing, abrasive polishing fluids are finding new avenues in cutting-edge technologies. For instance, in the semiconductor industry, where precision is paramount, these fluids contribute significantly to the production of high-quality microelectronics. The ability of abrasive polishing fluids to refine surfaces at the microscopic level positions them as essential components in the rapidly advancing field of nanotechnology.

The Global Abrasive Polishing Fluid market, driven by innovation and the pursuit of excellence, is not merely a collection of products but a dynamic force shaping the future of manufacturing. As industries continue to evolve, this market is set to play a crucial role in ensuring that the surfaces we encounter daily, from automotive components to electronic devices, meet the highest standards of quality and functionality.

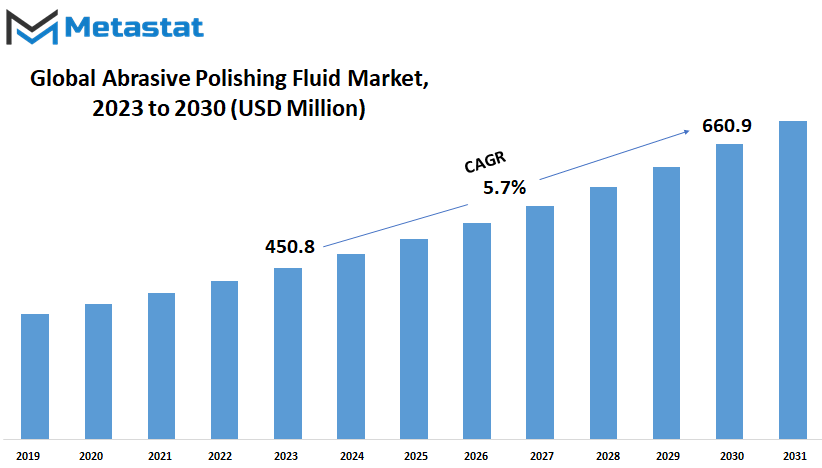

Global Abrasive Polishing Fluid market is estimated to reach $660.9 Million by 2030; growing at a CAGR of 5.7% from 2023 to 2030.

GROWTH FACTORS

The Global Abrasive Polishing Fluid market is propelled by significant growth factors that play a crucial role in shaping its trajectory. These driving factors contribute to the market’s expansion and overall development. However, it is essential to acknowledge that certain challenges may hinder the growth of the market. Despite the positive aspects, there are potential obstacles that need consideration to gain a comprehensive understanding of the market dynamics.

The growth factors of the Global Abrasive Polishing Fluid market are pivotal elements that fuel its progress. These factors act as catalysts, steering the market towards positive outcomes. They play a fundamental role in shaping the market landscape, allowing it to evolve and adapt to changing conditions. Identifying and understanding these growth factors is essential for stakeholders to navigate the market effectively and make informed decisions.

Conversely, it is imperative to recognize the existence of challenges that might impede the market’s growth. These hurdles, although posing obstacles, present opportunities for learning and improvement. Addressing these challenges head-on is crucial for the sustained development of the market. It requires a strategic approach to overcome these impediments and foster an environment conducive to growth.

Amidst the dynamic landscape, the market holds promising opportunities for the future. These opportunities emerge as potential avenues for growth and profitability. Exploring and capitalizing on these opportunities is key to unlocking the market’s full potential. The identification of lucrative prospects enables stakeholders to align their strategies with market trends, ensuring a competitive edge in the coming years.

The Global Abrasive Polishing Fluid market is driven by key growth factors that propel its advancement. While challenges exist, they serve as opportunities for improvement and innovation. Navigating through these dynamics requires a balanced understanding of both the positive and challenging aspects of the market. Embracing the opportunities that lie ahead will be instrumental in shaping the market’s future and fostering sustained growth.

MARKET SEGMENTATION

By Type

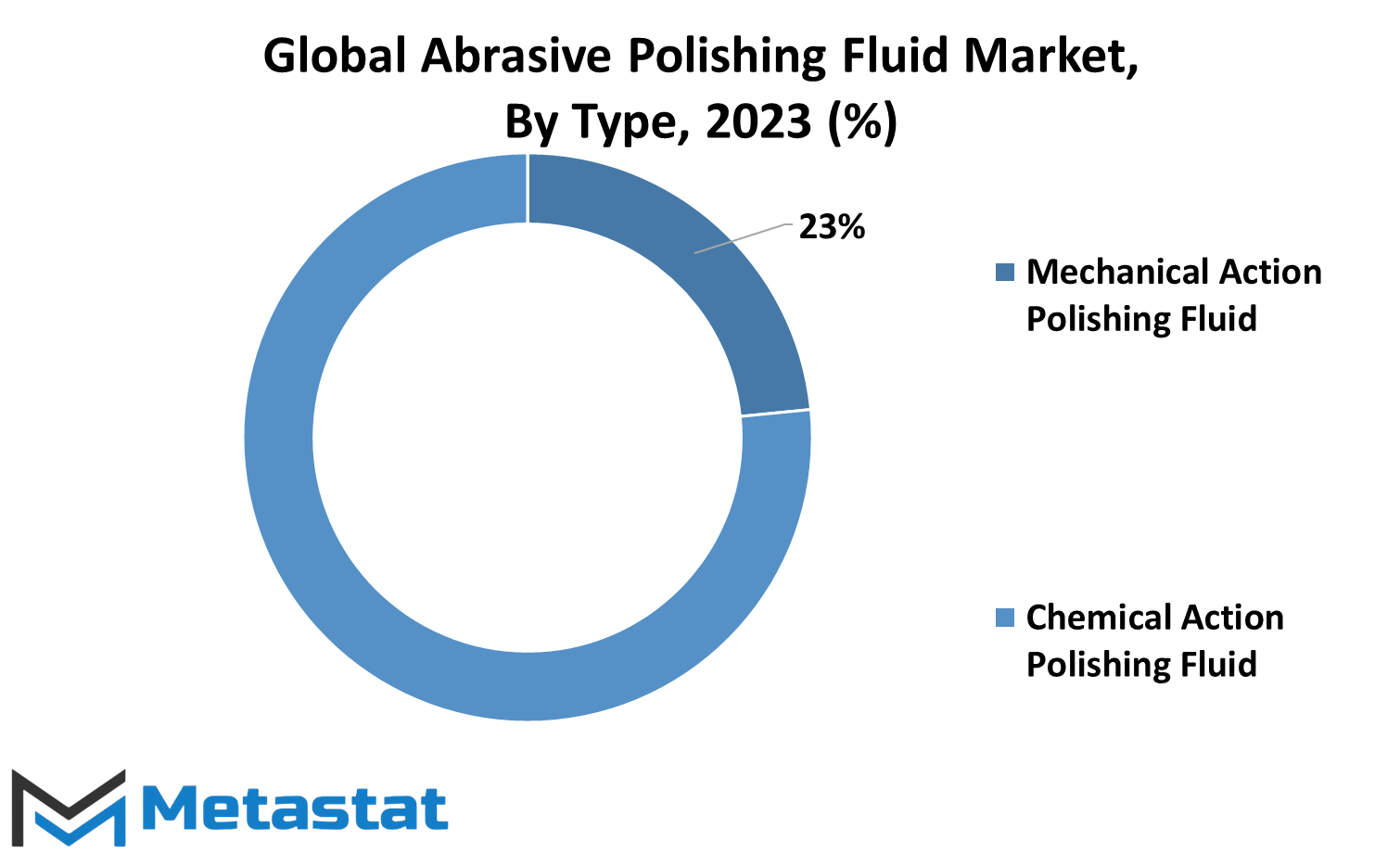

The Global Abrasive Polishing Fluid market is categorized by types, with Mechanical Action Polishing Fluid and Chemical Action Polishing Fluid being two distinct segments. These categories play a crucial role in the diverse applications of abrasive polishing fluids.

Mechanical Action Polishing Fluid involves the use of physical force to smooth and polish surfaces. It’s like the hands-on approach, where the abrasive particles, driven by mechanical means, interact with the material surface, resulting in a polished finish. This type finds utility in various industries where precision and meticulous detailing matter.

However, Chemical Action Polishing Fluid relies on chemical reactions to achieve the desired polishing effect. Here, specific chemicals interact with the material surface, causing it to undergo changes that lead to a polished outcome. This type is often preferred when dealing with materials that may be sensitive to mechanical forces or require a more controlled polishing process.

The choice between these two types of polishing fluids depends on the nature of the material being worked on and the desired outcome. Mechanical action is suitable for robust materials, where a more aggressive approach is needed. In contrast, chemical action is favored when dealing with delicate surfaces or materials that demand a gentler touch.

Both Mechanical Action Polishing Fluid and Chemical Action Polishing Fluid contribute significantly to the overall efficiency and effectiveness of the abrasive polishing process. Their roles are pivotal in ensuring that diverse materials can attain the desired level of smoothness and shine. The market’s segmentation into these categories reflects the practical considerations and preferences within industries that rely on abrasive polishing for various applications. This distinction provides users with tailored options, enabling them to choose the most suitable polishing fluid for their specific needs.

The segmentation of the Global Abrasive Polishing Fluid market into Mechanical Action Polishing Fluid and Chemical Action Polishing Fluid offers a practical approach to addressing the diverse requirements of materials and surfaces in various industries. Each type brings its unique advantages, ensuring that the polishing process is not a one-size-fits-all approach but rather a tailored solution for achieving the desired results.

By Application

The global market for Abrasive Polishing Fluid is categorized based on its applications, with notable segments including Silicon Wafers, Optical Substrate, Disk Drive Components, and Other applications.

Silicon Wafers constitute a significant application area for Abrasive Polishing Fluid. Silicon wafers are extensively used in the semiconductor industry for manufacturing integrated circuits and electronic devices. The polishing fluid plays a crucial role in achieving the desired surface finish and quality required for these silicon wafers, enhancing their performance and functionality.

Optical Substrate represents another key application segment. In industries related to optics and lenses, the use of Abrasive Polishing Fluid is integral. The fluid aids in the precision polishing of optical substrates, ensuring the clarity and quality of lenses and optical components. This application is vital in various sectors, including medical devices, cameras, and scientific instruments.

Disk Drive Components form a substantial part of the market. In the manufacturing of hard disk drives, precise polishing of components is essential to maintain optimal performance. Abrasive Polishing Fluid contributes to achieving the required smoothness and precision in the surfaces of disk drive components, thereby enhancing the overall efficiency of storage devices.

The category labeled as Other encompasses diverse applications where Abrasive Polishing Fluid finds utility. These applications may range across different industries and purposes, reflecting the versatility of the polishing fluid in addressing various surface finishing requirements. Its usage in unconventional sectors further highlights the adaptability and broad applicability of this fluid.

The segmentation of the Global Abrasive Polishing Fluid market by application reveals its diverse applications across Silicon Wafers, Optical Substrate, Disk Drive Components, and Other areas. Each of these segments plays a crucial role in different industries, underscoring the widespread utility and importance of Abrasive Polishing Fluid in enhancing the quality and functionality of diverse products and components.

REGIONAL ANALYSIS

The examination of the Global Abrasive Polishing Fluid market through a regional lens sheds light on the dynamics influencing its performance in various parts of the world. This analysis helps in understanding the market trends and factors that contribute to its growth or challenges in specific regions.

In North America, the market for Abrasive Polishing Fluid is influenced by factors such as technological advancements, consumer preferences, and economic conditions. The region's robust industrial infrastructure and high adoption of advanced polishing technologies play a pivotal role in shaping the market landscape. Additionally, consumer demand for high-quality finished products contributes to the steady growth of the abrasive polishing fluid market.

Moving on to Europe, a similar pattern emerges, albeit with regional nuances. The market in Europe is impacted by regulatory standards, environmental concerns, and the preferences of a discerning consumer base. The stringent regulations related to manufacturing processes and product quality necessitate the use of advanced abrasive polishing fluids, driving the market forward.

In the Asia-Pacific region, the market dynamics are shaped by a combination of factors such as rapid industrialization, increasing manufacturing activities, and a burgeoning automotive sector. The growing demand for consumer electronics and rising investments in infrastructure projects further contribute to the expansion of the abrasive polishing fluid market in this region.

Latin America presents a unique set of challenges and opportunities. Economic conditions, regulatory frameworks, and the level of industrialization vary across countries in this region. Understanding these variations is crucial for market players looking to establish a foothold and capitalize on the emerging opportunities in the abrasive polishing fluid market.

The Middle East and Africa exhibit a diverse landscape, influenced by factors such as economic stability, political situations, and the presence of key industries. The market in this region is driven by infrastructure development projects, particularly in the construction and oil and gas sectors.

The regional analysis of the Global Abrasive Polishing Fluid market unveils a mosaic of factors influencing its trajectory. By delving into the specifics of each region, market participants can tailor their strategies to align with the unique characteristics and demands of the respective markets. This regional perspective is indispensable for a comprehensive understanding of the global market landscape and for making informed business decisions.

COMPETITIVE PLAYERS

The global market for Abrasive Polishing Fluid is shaped by various key players, and among them, Cabot Microelectronics and Dow stand out. These companies play a significant role in the Abrasive Polishing Fluid industry, contributing to its growth and development.

Cabot Microelectronics is one of the prominent players in this field. The company has established itself as a key contributor to the Abrasive Polishing Fluid market, bringing forth products and innovations that have made a mark in the industry. Their presence is a testament to their commitment and expertise in providing quality solutions.

Dow is another noteworthy player in the Abrasive Polishing Fluid sector. The company's involvement in the market adds a layer of diversity and competition, fostering an environment that encourages advancements and improvements. Dow's contributions to the industry contribute to the overall dynamics of the Abrasive Polishing Fluid market.

These key players, Cabot Microelectronics and Dow, bring a wealth of experience and expertise to the Abrasive Polishing Fluid market. Their influence extends beyond mere participation, as they actively shape the direction of the industry. Through their products, innovations, and strategic initiatives, these companies contribute to the growth and sustainability of the Abrasive Polishing Fluid market.

The presence of key players like Cabot Microelectronics and Dow significantly impacts the Abrasive Polishing Fluid market. Their contributions go beyond individual success, influencing the industry as a whole. As these companies continue to navigate the challenges and opportunities within the market, their roles remain pivotal in shaping the trajectory of the Abrasive Polishing Fluid industry.

Abrasive Polishing Fluid Market Key Segments:

By Type

- Mechanical Action Polishing Fluid

- Chemical Action Polishing Fluid

By Application

- Silicon Wafers

- Optical Substrate

- Disk Drive Components

- Other

Key Global Abrasive Polishing Fluid Industry Players

- Cabot Microelectronics

- Dow

- Fujimi Incorporated

- Fujifilm

- Hitachi Chemical

- Saint-Gobain

- Asahi Glass

- Ace Nanochem

- UWiZ Technology

- WEC Group

- Anji Microelectronics

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383