Sep 27, 2024

The recent report from Metastat Insight explores the theme of the Global Radiation-resistant Fibers market and should help you peer into a rather specialized world of materials designed for extreme conditions. These fibers are essential in areas of high radiation levels and find critical applications across a wide spectrum of industries, demonstrating both precision in and care taken in their production. With technological demands rising and safety standards becoming ever stricter, the fiber that can resist radiation has come under attention like never before.

Global Radiation-resistant Fibers market is estimated to reach $21.6 million in 2025 with a CAGR of 8.5% from 2025 to 2032.

Radiation-resistant fibers serve a distinct purpose of protecting the equipment and humans in nuclear power generation and certain segments of the aerospace, defense, and medical fields. They are designed to retain their integrity and function even when impinged upon by harsh radiative forces that would have otherwise compromised standard materials. Their very creation is a result of many years of research and stringent testing to ensure that these fibers can adequately meet the unique challenges posed by these unforgiving environments.

In the nuclear industry, these fibers are either integrated into or form the basis of components that must still perform after extended radiation exposure. In a similar manner, in aerospace, materials are helped by the fibers to maintain structural rigidity and safety requirements in the presence of cosmic radiation during long missions. Defense applications, especially in contexts of radiological warfare or operations close to contaminated areas, also call for fibers of such high performance that constituents of protective gear and equipment may be responsible for functioning under such conditions without fail. In medicine, fibers contribute equally in terms of maintaining durability and reliability for instruments utilizing radiation-therapeutic and imaging devices.

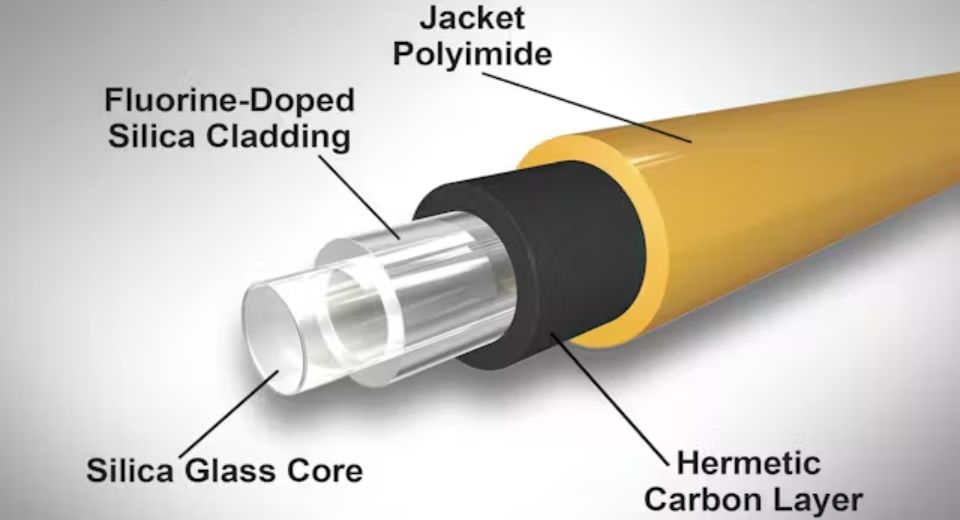

Manufacturers making radiation-resistant fibers have dedicated themselves to the improvement of a fiber's material properties. A lot of fibers are made from complex combinations of materials through newer kinds of production methods, which caught up with the desired performance standards. Resistance to temperature, tensile strength, and chemical stability, in contrast, should be primarily centered on maintaining the fiber's performance in the presence of radiation. Also, this warrants not only scientific prowess but also great rigor in quality management and assurance in all aspects of production.

With shifting demand patterns, the supply chains for these materials have adjusted, with developing regions in search of advanced materials for their growing infrastructure and technological projects. Producers are left to ramp up their capacities after ensuring that every batch meets the specified criteria. This cooperation between fiber producers and industries using the end products has expedited the use of advanced fibers for safer and more durable solutions in radiation environments.

Safety and eco-sustainability regulatory frameworks are indeed making their play in determining the market dynamics. Adherence to internationally accepted standards will not be compromised, and they demand consistency in the quality of products offered by companies while they are innovating different formulations with less environmental burden. This will maintain a delicate balance between performance and being eco-friendly, which is believed will govern any future developments within the industry.

An hallmark of the market is the sustained interest from research institutions, which continue to investigate ways to push the boundaries of what these fibers can achieve. With funding and partnerships often linking private enterprises to academic bodies, the pipeline for next-generation materials is kept alive. A constant flow of research feeds into the commercial market, therefore steadily improving the options available for those critical industries worldwide.

The possibilities for the advancement of radiation-resistant fibers are highly correlated with advancements in radiation exposure management sectors. Flexible and portfolio fibers will be warranted as mankind enters deeper into space, makes wider use of nuclear energy, and enhances the healthcare-related technologies. In that stead, geopolitical occurrences and climate-related emergencies will only underline preparedness and resilience- domains in which these specialized fibers are greatly required.

In consideration of Metastat Insight's study, it is evident that the global radiation-resistant fiber market behaves differently from the rest of the materials industry. The report highlights a field characterized by precision technical know-how and an uncompromising attitude toward safety. Though niche, this market has industries where resistance to extreme conditions is not just an asset but a fundamental necessity.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479