Apr 30, 2025

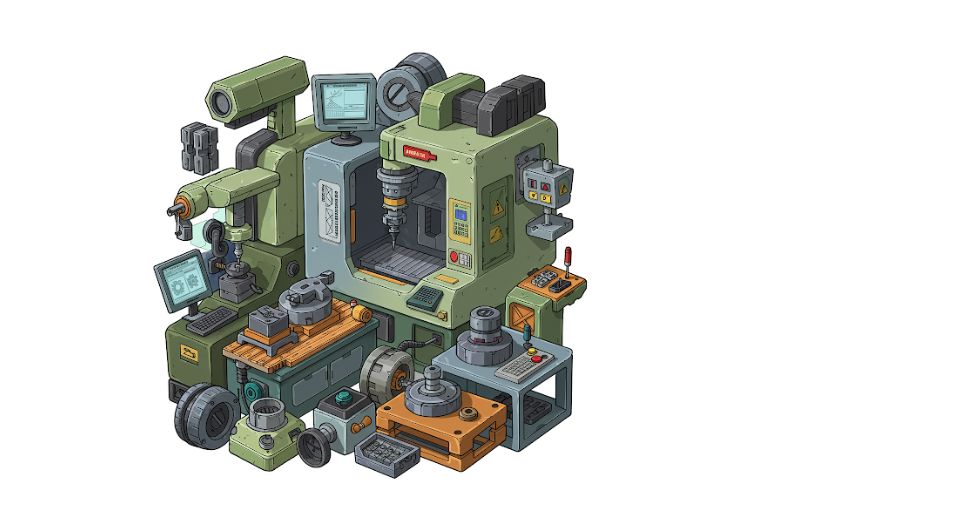

The latest findings of Metastat Insight, the global precision manufacturing market is too complex and competitive, ever-changing with the latest technologies, production patterns, and alignment of industrial strategies. What it becomes is not only a numerical report but indeed an industrial refinement narrative into high-performanced requirements, speaking for machinery-driven sectors in today's time. From space parts to medical grade equipment, the production specificity and measure demand precision that will allow very little error margin. Precision in this context is not a nice-to-have; it is indeed a must-embedded in the very logic of modern industrial growth.

Global Precision Manufacturing market is estimated to reach $5,652.0 million in 2025 with a CAGR of 8.1% from 2025 to 2032.

The highest level of manufacturing represents the distance that engineering has traveled in terms of integrating CAD with the disciplines of materials science and robotics. Gone are the days when tolerances could receive some kind of negotiated rounding. Today's production chains operate under conditions in which a deviation in the neighborhood of a millimeter can jeopardize structural integrity or functionality. Contextually, therefore, the Global Precision Manufacturing market goes beyond shallow growth into a phase characterized by advanced competitiveness where every entrant must now beat competition not only with speed or scale but on too high a demand for perfection.

This is very different from the world as it brings to each application not only which it has but continuously without sacrificing conformity. Very true, especially in the high-stakes fields like automotive safety systems or making surgical instruments, where the tiniest error can lead to dire consequences. It is not just the capacity that matters in this industry, but also being one of the most willing to spend in research, training, and adaptive process engineering. Trial and error is the secret of success in this industry-the correct command of all the unseen variables: thermal expansion, vibration control, wear of tools.

Such a closer look into the various regions traces two different patterns of evolution between them in approaches and emphases. Some countries have focused their energy on cleanroom fabrication and nano-scale detailing, while others have committed themselves to the establishment of modular systems easily integrated into existing industrial chains. Each region is a reflection of its own priorities, hence regulatory conditions and historical strengths in engineering, forming the tapestry of strategies that all feed into the larger landscape of precision manufacturing. This regional diversity, however, brings with it a wealth of knowledge exchange but also certain frictions, primarily concerning standardization and export regulations.

Raw material selection can also be counted as another aspect which goes unnoticed during the over-reaching discussions. That might be critical in the consistency of a high-precision output. The right alloy or composite material can enhance production standards drastically by reducing wastage and improving lifecycle performance. Many companies functioning in the Global Precision Manufacturing Market have quietly forged alliances with metallurgical research institutes in pearly string with such practice. Thus, these collaborations further boost the materials using which performance is achieved that can withstand greater mechanical stresses, retain their shape under extreme conditions, and perform better with automation systems.

Meanwhile, the reorientation without losing quality in production into sustainability is becoming conspicuous. Even though precision has always been associated with tolerance control above all, the concept is changing to include energy consumption, waste heat management, and intelligent resource planning. The technical accuracy matched with ecological concern will bring out innovations at the design and operation levels. It can be seen as a new industrial thinking era, where clean production lines do not dilute the quality of output but reinforce the brand positioning in the conscious market.

Behind the scenes, though, the labor force gets to be evolving, too. Rather than replacing, augmenting the capabilities of traditional machine operators, digital training programs and augmented workflow systems serve to supplement. The line seems increasingly to blur between manual skill and digital precision leading to a hybrid model where skilled, experienced technicians are now working alongside AI-supported diagnostics. The evolution of workforce dynamics thus becomes as critical to market momentum as the machinery itself, emphasizing that precision is a collaborative achievement.

This is the well-defined picture about the current disposition of Global Precision Manufacturing market drawn through geographic focus by the study presented by Metastat Insight. The analytical strip paints an audio picture of an industry that is not simply dependent on high-end equipment or investments but instead on the intelligence of its processes, the foresight of its strategy, and the discipline of its execution. An apparent requirement for increased tolerance and cleanliness in output production demonstrates that those working in this environment produce more than products: they redefine production standards.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479