Sep 22, 2025

Metastat Insight latest study of the methyl methacrylate (MMA) market in perspective how this material becomes part of everyday life less frequently known. From impact-resistant surfaces in household buildings to glassy panels in automobiles, its use goes far beyond the plant. Increased focus on quality, durability, and responsiveness has shifted industries toward looking for materials that can get the job done while responding to today's design and functional requirements. This is why emphasis on this market and its wider significance across various industries increases.

Modern industries are faced with the balancing act of performance against sustainability and affordability. Traditional materials are not up to the task, being problematic in terms of design, toughness, and versatility. Lightweight but high-strength solutions are being called for across a wide range of applications from construction to automotive, electronics, and medicine. In this world, methyl methacrylate holds its position as a workhorse. Its transparency, weatherability, and toughness are qualities that make it an indispensable part in problem-solving industrial applications and making growth possible in consumer-oriented applications.

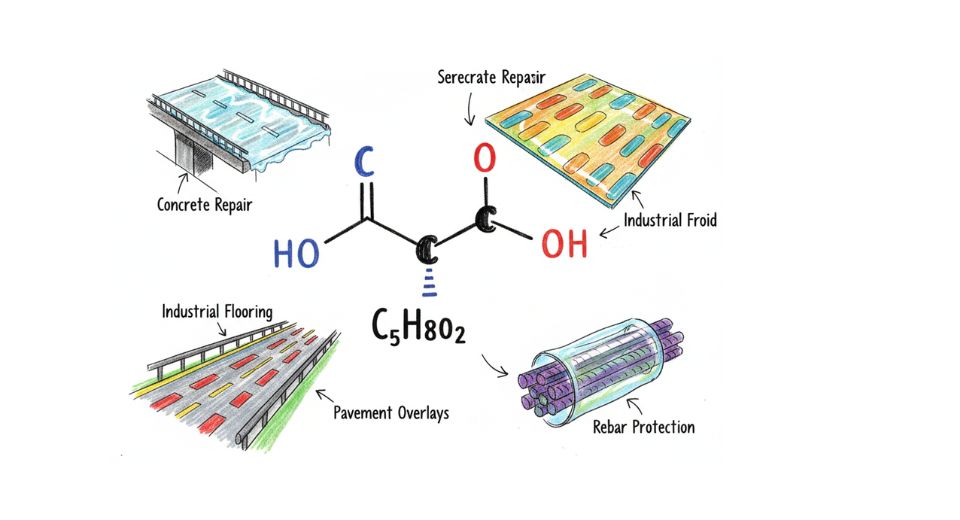

Valuable Methyl methacrylate is fundamentally a building block with transparency, resistance, and moldability to offer. Such attributes make it a preferred choice for use in applications where form and function are important.

It's worth lies in its ability to find application in numerous methods of processing, making it perform just as well in various divergent industries. It is, for example, suitable to produce resilient coatings, performance plastics, and impact-resistant sheeting. It will not become opaque with time like others but instead can withstand outdoor exposure, reducing replacement needs. Consumers of this product are treated to long lifespan, minimal maintenance, and uniform performance features assigned higher priority in the agenda of production plans.

The market itself has traced a path driven by both need and technology. It begins as renowned for application in special purposes but has incrementally evolved into mass production. Development of manufacturing processes has also brought its use within reach of mass projects.

Development of polymer science has improved its strength, processing efficiency, and Eco compatibility. Such consistent development over years has enabled industries to make use of methyl methacrylate with more confidence in new products, making it shift from niche uses to widespread use across industry.

Adoption has been considerably strong in developed economies that have state-of-the-art production facilities leading the demand. Those economies with strong automotive, construction, and electronics industries have embraced this material more widely with the assistance of established supply chains and hubs of innovation. Developing economies are increasingly interested, however, on account of increasing infrastructure projects and industrialization. These markets are fertile terrain for large-scale adoption, presenting opportunities for manufacturers to leverage demand driven by urbanization, increased consumer aspirations, and modernization initiatives.

Despite the benefits, the market also presents some challenges. Environmental controls and production costs present limitations for manufacturers. Challenges from competitive materials also exist, especially in price-sensitive markets. Challenges also arise with ongoing developments in manufacturing technology, offering cost advantages and increasing efficiency. Studies on bio-based or more environmentally friendly feedstocks also presented new opportunities for expansion.

In addition, complementarities with emerging digital manufacturing technologies and industries such as renewable energy open room for more applications. Through the removal of barriers, the market is poised to meet existing industrial demand as well as future demands for sustainability.

The current significance of this market finds its roots in its alignment with broader global agendas. Firms are being prompted to develop materials that offer strength, flexibility, and an environmental commitment. Methyl methacrylate fits the bill and hence is a material of preference in industries attempting to innovate while using resources to the fullest. Growing sensitivity to sustainability, growing consumer demands for durability, and the necessity for lightweight materials with responsiveness indicate its application. The methyl methacrylate (MMA) market as it is characterized by Metastat Insight reveals its increasing influence on manufacturing policy and consumption-oriented products. Standing at the intersection of industrial performance and sustainability, it is sure to be a key player in the realignment of world industries in the years to come.

Drop us an email at:

Call us on:

+1 5186502376

+91 73850 57479