Nov 06, 2025

The new report on the global honeycomb core materials market by Metastat Insight offers an in-depth examination of a market that has consistently attracted industries looking for lightweight yet robust structural solutions. This report is more than a report of market statistics; it is a testament to the change under way within sectors where material efficiency and design innovation are preeminent. Global demand for honeycomb core materials remains robust, approximately USD 3.9 Billion in 2025, growing at a CAGR of around 7.9% through 2032, with potential to exceed USD 6.6 Billion.

For access to complete insights and findings, go to: https://www.metastatinsight.com/report/honeycomb-core-materials-market

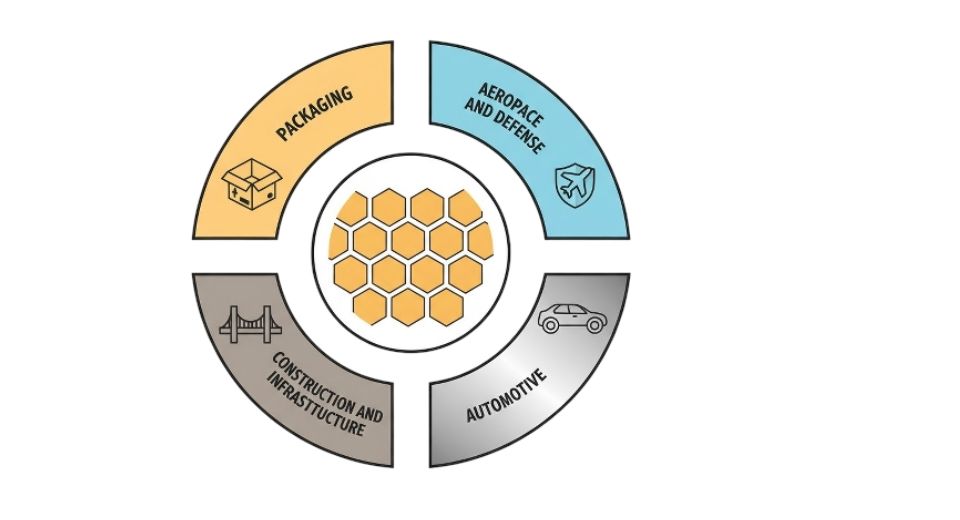

Honeycomb core materials are now standard in industries where stability, strength, and lesser weight matter. The hexagonal geometry of these structures provides outstanding mechanical performance with minimal material use. Honeycomb cores are used extensively in aerospace, automotive, marine, construction, and packaging industries, providing a rigidity-to-lightness balance that solid materials cannot offer. Beyond the functionality, their versatility influences how companies perceive efficiency and sustainability in contemporary production systems.

Honeycomb cores in aerospace and aviation are widely utilized in interior parts of aircraft, floor panels, and control surfaces because of their excellent resistance-to-weight ratio. Their application comes second in the automobile industry, where they are incorporated into body panels, roofs, and energy absorption areas to improve fuel consumption and passenger safety. Equally, the construction sector applies honeycomb panels to building facades, partition walls, and furniture systems due to their strength and simplicity of installation. Marine engineering and packaging have also effectively utilized these materials, highlighting the versatility of these products across high-performance and typical use.

What distinguishes the honeycomb core material, however, is not only its strength but also its alignment with sustainability objectives. The lower material usage in manufacturing reduces environmental footprint, while aluminum, thermoplastic, and paper-based cores' recyclability promotes circular economy practices.With industries persevering with to spotlight greener manufacturing, the utilisation of such low-value materials factors toward an overarching fashion in the direction of accountable innovation.

Technological advances have endured to decorate manufacturing accuracy, with manufacturers now capable of customise mobile sizes, densities, and materials based totally on character engineering requirements. Improvements in composite era have led to new variations that feature under heavy strain situations, starting from excessive temperatures to corrosive environments. This combo of flexibleness and resilience makes honeycomb structures extra appealing to industries where overall performance and durability are non-negotiable.

The global honeycomb core materials market manufacturing maintains to develop geographically as established producers and new players add their contributions to innovation and opposition. The enterprise's fantastic ahead momentum captures an increasing appreciation for the way clever layout and materials technology can restandardize industry. As industries hold to look for solutions that combine performance, sustainability, and fee-effectiveness, honeycomb cores will possibly remain at the leading edge of that endeavor.

In uniting layout intelligence, engineering uses, and inexperienced cognizance, Metastat Insight's report on the global honeycomb core materials market outlines a colourful quarter described each by way of technological sophistication and purposeful vital. The research emphasizes how innovation in materials keeps to push across numerous industries, underscoring the urgency of systems that are not merely robust and light however additionally compatible with an increasingly inexperienced business destiny.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479