Nov 26, 2024

The Global 3D Optical Profiler Market, as seen in the report elaborated by Metastat Insight, is a vast view of a field gaining impetus in all industries. This is actually a form of measurement technology advancement that will allow for highly accurate surface analysis and quality control across a range of industries. With growing reliance on accurate, non-destructive methods of assessment, 3D optical profiling has become indispensable for industries aiming to enhance their production standards and optimize processes.

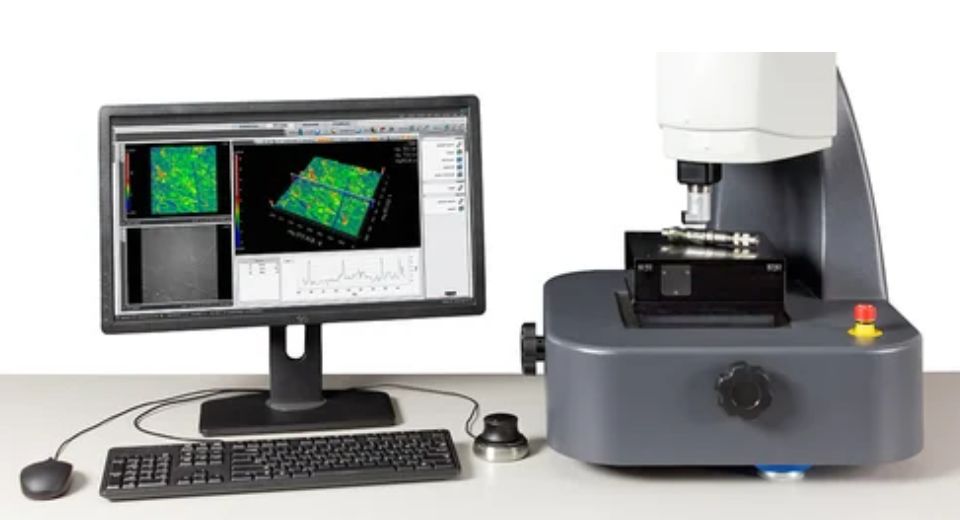

3D optical profilers utilize advanced optical measurement techniques to evaluate surface characteristics, such as texture, roughness, and topography, with high precision. Unlike traditional measurement tools, these instruments offer a contact-free way to capture critical details, ensuring the integrity of the surface remains unaltered. Measuring complex surfaces with accuracies in the sub-micron level has placed 3D optical profiling as an indispensable tool of many industries such as semiconductors, automotive, aerospace, and medical devices. In their pursuit of higher efficiencies and meeting more stringent compliance standards, the demand for strong and versatile optical profilers only continues to increase.

Industries adopted this technology not only because of its precision in measurement but also due to its efficiency in improving the workflow involved in operation. For example, in the production of semiconductors, the high degree of precision for producing quality and reliable parts for electronic devices is guaranteed through 3D optical profilers. Similarly, in the medical line, for guaranteeing safety and functionality of intricate implants and devices, these tools are very crucial. Their applications reach as far as the automotive and aerospace sectors, wherein components are highly required to meet exact specifications. Optical profilers contribute in several ways to reducing material waste and cutting costs so as to improve the sustainability of manufacturing processes as they present accurate surface data.

Indeed, one of the most compelling attributes of 3D optical profiling technology is its adaptability. These instruments are engineered to accommodate a wide variety of materials and surfaces, from reflective metals to delicate polymers. This adaptability has allowed them to play a transformative role in research and development, where innovation depends on an in-depth understanding of material behavior under various conditions. For example, researchers developing new compositions of materials use 3D optical profiling to confirm their results and verify that the samples produced match the expected outcomes.

A large increase in the footprint of businesses around the world, which now greatly depend on advanced measurement methods, has driven investment in 3D optical profiling technologies. Developers responded by introducing innovations that further improve accuracy, increase speed, and make their applications easier to use. In addition to the above factors, automation, user-friendly interfaces, and integration with analytical software have further entrenched their place as critical assets in modern laboratories and production lines. With these developments, 3D optical profilers not only fulfill current industrial requirements but also look forward to future demands, making them highly relevant in an increasingly competitive scenario.

Collaborative work by manufacturers and end-users drives market expansion. Such partnerships have led to bespoke solutions that meet the diversified needs of different industries. For example, in sectors involving both cleanliness and surface quality, like pharmaceuticals or food processing, a custom-designed profilers provide new advantages, allowing businesses to achieve the highest levels of quality. At such a highly customized level, close collaboration plays a significant role in energizing technological development within the market.

The use of 3D optical profiling technologies varies geographically, mainly influenced by industrial density, technological infrastructure, and economic priorities. Traditionally, the developed regions with established manufacturing hubs have been at the forefront of adopting these tools. However, emerging economies are rapidly catching up by investing in advanced manufacturing technologies to compete with global markets. This geographical diversification adds momentum to the expansion of the market, as established players and new entrants are benefiting from growth prospects in different parts of the world.

The future of the Global 3D Optical Profiler Market is rather promising. With all that advancing industries can do with materials and with manufacturing techniques, the requirement for more precise, reliable measurement technologies is only going to rise. Continuous innovation in 3D optical profiling is expected to enable applications in areas that were once considered to be beyond reach, like nanotechnology and advanced robotics.

Metastat Insight in-depth research into the field brings into view how crucial 3D optical profilers are to enhancing production and research capabilities globally. The reports shine a light on market complexities that are pivotal to current-day technological development. In changing industry conditions, the Global 3D Optical Profiler Market will continue to be the base for innovation and excellence in various applications.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479