MARKET OVERVIEW

The Global Wafer Handling Robots market is considered to represent a specialized segment of the semiconductor manufacturing industry, with the focus on automation systems that move and position silicon wafers around the manufacturing process. The main aspect that these robots are responsible for is achieving efficiency, precision, and contamination-free handling in their process of moving wafers, which are fundamental components in creating microchips and other semiconductor devices. With continuous developments in the semiconductor industry, the need for robust wafer handling solutions is expected to increase with high-paced technological innovations and far-reaching industrial adoption in this market. The market focuses on robots designed to handle wafers with careful precision because minute contamination or damage in handling can make a difference in production loss amount.

It is designed to function in a cleanroom environment, often operating under stringent requirements that are required by semiconductor fabrication plants. The technology in the Global Wafer Handling Robots market has continued to advance and support more complex applications into advanced packaging and extreme ultraviolet lithography. As device miniaturization accelerates and wafers grow to meet global production needs, wafer handling robots will play an even more indispensable role in optimizing manufacturing cycles and quality assurance. As the global supply chain for semiconductors continues to grow, the Global Wafer Handling Robots market will serve a geographic gamut of regions with different scales of production. The market includes single-arm configurations as well as more complex dual-arm configurations, able to handle wafers at any point in the manufacturing process.

Every system should seamlessly interface with other fabrication equipment, including chemical vapor deposition chambers, etching tools, and metrology systems. The robots must have those key attributes - precision, speed, and adaptability - so manufacturers can meet the requirements of high-volume production and cutting-edge technology nodes. Software algorithm improvements, artificial intelligence, and sensor technology will enable wafer handling robots to become even more effective and sensitive to faults. This will allow for even less downtime and fewer process-related errors, thus reducing costs and increasing output.".

In addition, automation solutions in this industry are going the way of increased connectivity and interoperability - just more recent manifestations of broader Industry 4.0 trends. Wafer-handling robots of the future could include machine learning for predictive maintenance requirements or dynamic adjustments to changing production parameters, further smoothing out the fabricating process. The Global Wafer Handling Robots market will be able to expand its space further into specialized manufacturing domains with semiconductor production diversifying in order to address the needs of the consumer electronics, automotive, and telecommunications industries. Emerging markets, mainly in Asia-Pacific, such as China, South Korea, and Taiwan, are expected to be key drivers of demand, considering their strong investment in semiconductor fabrication facilities.

At the same time, established markets in North America and Europe will continue to demand cutting-edge robotic solutions to sustain their competitive edge in semiconductor innovation. In summary, the Global Wafer Handling Robots market is a dynamic part of the semiconductor industry that takes care of the critical need for precision and efficiency in wafer management. As the demand for advanced technology and increased production heightens, this market will continue to grow, thus sustaining semiconductor manufacturing development across the globe. Its trajectory, however, will mirror the more generalized challenges and opportunities placed before such an industry that underpins modern technological advancements.

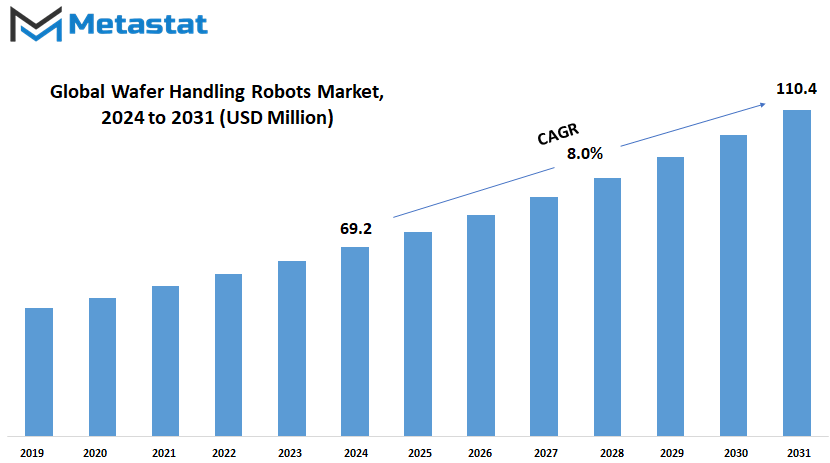

Global Wafer Handling Robots market is estimated to reach $110.4 Million by 2031; growing at a CAGR of 8.0% from 2024 to 2031.

GROWTH FACTORS

The global wafer handling robots market is poised to expand at a considerable growth rate, mainly because of increasing demand in a range of industries for semiconductors. Expansion in the consumer electronics and automotive sectors calls for higher needs to produce high-quality semiconductor components through sophisticated wafer handling solutions. In the manufacturing of semiconductors, the function of these robots is crucial as precision and consistency become necessary for the production of good-quality parts. Additionally, the push for greater automation in production processes is driving companies to adopt robotic systems to improve efficiency and minimize labor-related costs.

Automation has become a cornerstone of modern manufacturing, offering not only speed but also accuracy. In the semiconductor industry, where margins for error are exceedingly small, wafer handling robots are indispensable. By reducing the reliance on manual labor, companies can streamline their operations and achieve higher productivity. This is crucial in this respect because the need for smaller, yet mighty chips is on the increase. However, there are some challenges that might slow down the implementation of these technological trends.

One of the significant challenges is that setting up wafer handling robots is very costly. These equipment systems are not affordable for most small manufacturers, especially if they are financially restrained. Operations and maintenance also require some specific training in handling these robotic machines, which leads to increased costs and barriers for them. This could present a restraint in geographical expansion where resources are scarce or simply non-existent due to lack of expertise in that area.

Future: Artificial intelligence and machine learning can bring a great change to the Global Wafer Handling Robots market. In the near future, smarter robots that have AI capabilities can improve operational efficiency and adapt better to the emerging needs of semiconductor manufacturing. This flexibility would help companies compete well in fast-moving industries while addressing the problems of precision and scalability.

These technologies are likely to provide vast opportunities for growth in the next few years. By implementing AI technology in their features, wafer handling robots could eventually become much more efficient and easier to operate rather than requiring extensive training. It may well make this technology available to smaller manufacturers as well, enabling its broader application within the industry. While some challenges still abound, the future of the Global Wafer Handling Robots market seems bright, with innovation being the one major enabler for its journey forward and expansion.

MARKET SEGMENTATION

By Product Type

High growth in this market is expected, mainly because the global semiconductor manufacturing industry is heavily reliant on automation for better efficiency and accuracy. These robots are designed to handle wafers with minimal contamination and maximum accuracy. Moreover, modern technology is powered by microchips produced by these robots. The market, therefore, grows mainly due to technological advance and increased consumer electronics, electric vehicles, and renewable energy systems demand.

The market is classified based on product type as Cartesian Robots, SCARA Robots, Articulated Robots, and Delta Robots. Various types provide different capabilities and are suited to specific applications in wafer handling. Cartesian Robots, with a simple structure and linear movements, are preferred for use in tasks that require high repeatability with high precision and accuracy. SCARA Robots are compact in their structure and fast for handling tasks under confined spaces. Articulated Robots usually have more than one joint and are, therefore, more flexible and versatile; hence they are used more commonly for complex handling tasks. Delta Robots are, on the other hand, used in high-speed applications that require precision for rapid yet gentle task execution.

The future of the Global Wafer Handling Robots marke is innovation and integration with advanced technologies. Robotics developers are working on AI and machine learning to enable the robots to self-adjust real-time conditions, thereby effectively reducing errors and increasing productivity. Coupled with IoT technology integration, wafer handling robots will also be able to interact with other machines in manufacturing systems to develop seamless automatic workflows for production. It promises to revolutionize the semiconductor industry on grounds of reduced time and costs with unchanged quality.

As industries move toward smaller and more complex semiconductor designs, the market for wafer handling robots which fulfill strict requirements is likely to grow. The shift to 3D semiconductor packaging as well as the push for greener technologies are likely to exert their influence on the market. With global efforts to decrease carbon footprint, robots like these will play a crucial role in optimizing resource usage and minimizing waste during production.

Looking ahead, markets in Asia-Pacific with robust semiconductor manufacturing capacities will lead the way. But with increasing automation investment across North America and Europe, it is going to be an exciting period for growth in the global wafer handling robots market. As technology propels forward, the Global Wafer Handling Robots market will be at the center of every drive in the future of the semiconductor manufacturing.

By Application

The Global Wafer Handling Robots market will continue to expand significantly owing to the increasing needs of industries dealing with semiconductor manufacturing, solar cell production, laboratory automation, and material handling. These robots, which are detailed and accurate in handling jobs, have become an integral part of maintaining efficiency while reducing human error and increasing productivity in these industries. With the rapid development of technology and with the high demand for automating processes, this market holds much promise for the future.

Wafer handling robots are essentially the critical components of semiconductor manufacturing. Today, the demand for smaller and more efficient chips from the semiconductor industry is unparalleled. From the smartphones to the advanced AI systems, the semiconductor industry has now begun to challenge the core innovation through precision and reliability by these wafer handling robots. Able to work in cleanrooms, the robots speed up production cycles while maintaining the integrity of the wafers. This efficiency is critical because manufacturers aim at responding to the continually surging demand for high-performance devices.

The demand for renewable energy accelerates globally as the solar cell producing industry also sees an advantage in wafer handling robots. The production of solar cells requires very careful handling; anything mishandled could damage the product and compromise quality. Consistent output with reduced waste has resulted in lower production costs. As more countries create a “green” energy system to combat climate change, this technology will be adopted in the sector more dominantly.

Another significant area where wafer handling robots are becoming more and more important is laboratory automation. For research and development activities in almost every industry, accurate and repeated handling of materials is required, an area in which these robots outshine the rest. These robots do not only enhance the accuracy of experiments but also free the scientists from routine tasks for critical problem-solving. With the increasing focus on innovation and a drive for more efficient R&D processes, the role for these robots will expand further in the next few years.

The versatility of wafer handling robots in material handling is unmatched. The capability to move, stack, and organize materials with high accuracy is of great importance for warehouses and manufacturing plants. In trying to maintain seamless logistics and efficient supply chain management, these robots will increasingly form part of the solutions aimed at achieving this.

Global Wafer Handling Robots market has great potential due to the advance in technology and developing need for automation in each of its usages. Growth will continue, so will be the making for an efficient future with all these innovations.

By End-User

The Global Wafer Handling Robots market is slowly gaining attention with industries worldwide embracing more advanced technologies. These robots play a significant role in handling delicate wafers used in the manufacturing of semiconductors, solar panels, and other precision technologies. Their efficiency and ability to minimize contamination make them indispensable in industries where precision and cleanliness are critical. As technological advancements progress, the market for wafer handling robots is set to experience significant growth, driven by rising demand across various sectors.

At the vanguard of using wafer handling robots are electronics manufacturers, which rely on these robots to handle fragile wafers with unmatched accuracy, avoiding waste and raising production yields. Now that electronic devices are becoming increasingly diminutive and intricate, the necessity for the wafer handling automation increases, thus raising the progressively alarming reliance on these robots, further fueling the market as manufacturers strive to meet the world’s standards for developing ever- innovative electronic products.

Another major segment of the Global Wafer Handling Robots market is represented by solar energy companies. With the trend leaning more toward renewable energies globally, the use of solar panels is increasingly in demand. Processes used to manufacture solar wafers are highly precise, and handling robots do significantly play a role in ensuring efficient production. The ability of robots to produce repeatedly without error increases their output while lowering costs-solar energy becomes a more feasible and attractive proposition. This is likely to ensure an increase in the adoption of solar industry wafer handling robots over the next few years.

These robots are indispensable to research and development laboratories. For scientists working on high-level projects, precision handling of fragile substances is needed; wafer handling robots perfectly answer this end. The integration of these robots into laboratories thus augments the development of new technologies through the provision of accuracy and consistency in handling experiments and prototypes. This integration into laboratories indicates a promising future for technological innovation.

Other automation in warehousing and logistics advantages also come with wafer handling robots. Although this is a rather unusual application, it is indeed within the realm of these robots due to their careful treatment of fragile items. Thus, their application in precision movement environments will continue to build-up in importance as logistics continues to automate further.

In the Global Wafer Handling Robots market, technological advancements and growing demand in various industries will foster significant growth. This forward-looking approach ensures that these robots will be used throughout further improvement of efficiency and productivity.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$69.2 Million |

|

Market Size by 2031 |

$110.4 Million |

|

Growth Rate from 2024 to 2031 |

8.0% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

Global Wafer Handling Robots Market The market for global wafer handling robots holds great promise since technology is transforming industries worldwide. These robots are an essential part Of semiconductor manufacturing as they help maintain precision, efficiency, and productivity during the production process. Divergence and opportunities Regional analyses are presented on how different parts of the world mark out differences in variation and thus point to how this market is expected to evolve in the future.

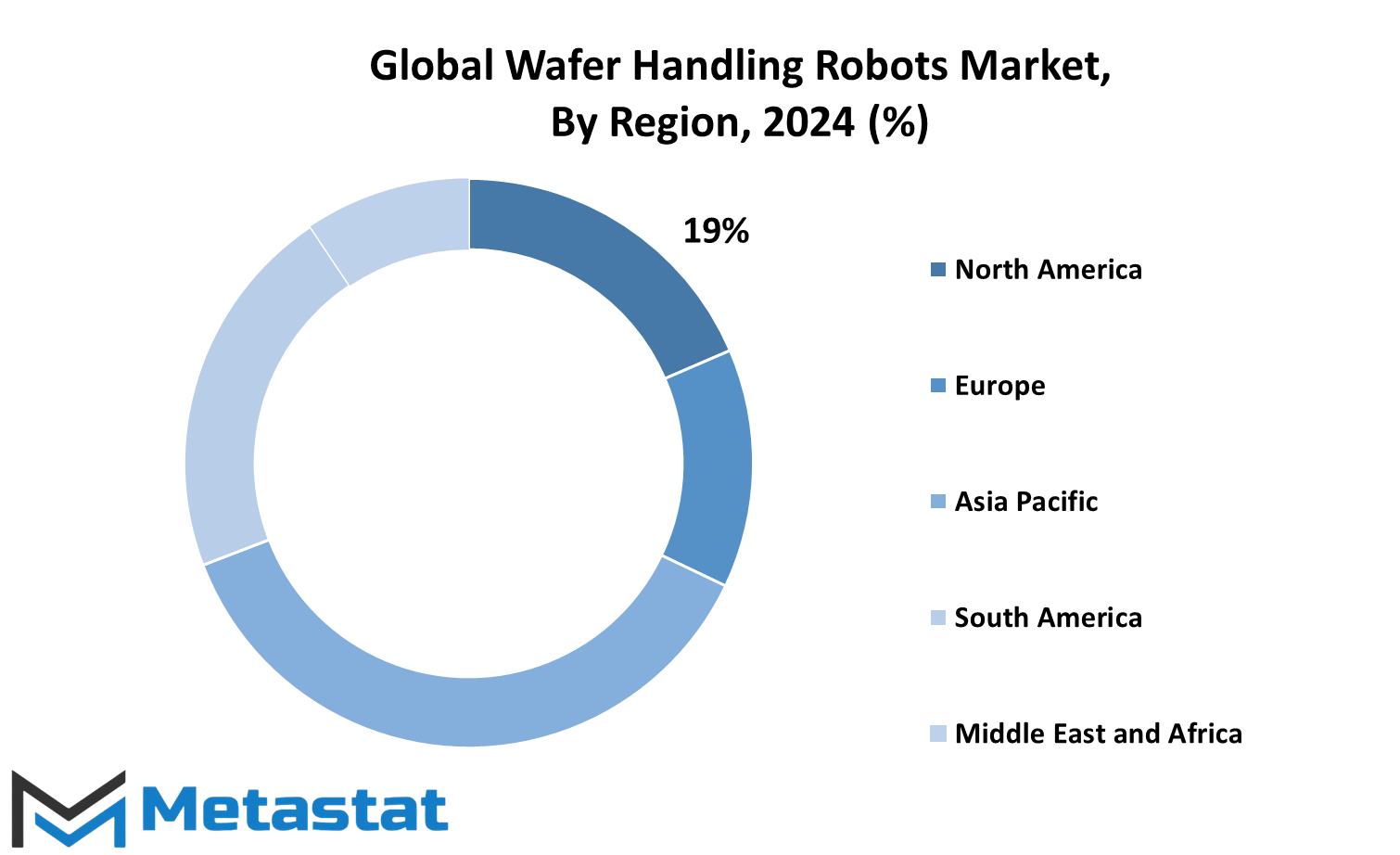

North America continues to be an important region for the Global Wafer Handling Robots market. The U.S., Canada, and Mexico are home to a strong semiconductor industry, influenced by the country’s advanced adoption of technology and investments in the research and development sectors. Regionally, the focus on innovation and increasing consumer electronics demand is expected to propel steady growth over the next few years.

Among the specific European countries, those with notable manufacturing sectors are the UK, Germany, France, and Italy. The region is expected to witness higher penetration of wafer handling robots in industries that increasingly focus on automation as well as sustainability. With respect to the continual increase in semiconductor production, this region would be able to maintain competitiveness while adhering to the most stringent environmental regulations.

Asia-Pacific will most likely witness the fastest growth in the Global Wafer Handling Robots market. Engine giants such as China, Japan, and South Korea lead the semiconductor production chain that is backed by significant government initiatives and investments in technological infrastructure. India is also slowly turning out to be a crucial player as it accelerates the demand for electronics while slowly shifting towards self-reliance in the manufacture of semiconductors. The region will play a key role in meeting global demand while it expands its domestic capabilities.

The South America region, though currently only dominated by the technology leaders Brazil and Argentina, is faced with the challenge of economic instability and therefore presents a challenge, but the industries within the region are modernizing towards efficiency and represent growing potential for wafer handling robots.

Growth opportunities can also be seen in the Middle East & Africa, in the GCC countries, Egypt, and South Africa. These governments are actively seeking to diversify their economies, invest in technology, and reduce reliance on oil. Such a shift is fertile ground for automation and advancements in semiconductors, and thus, wafer handling robots will play an important role in the process.

Across all regions, the Global Wafer Handling Robots market reflects the worldwide push for greater precision and efficiency in technology-driven industries. This growing demand underscores the need for continuous innovation and adaptation to regional market dynamics.

COMPETITIVE PLAYERS

The Global Wafer Handling Robots market is quickly becoming part and parcel of the semiconductor and electronics industries. Also, increases in automation and demand for higher process efficiency have boosted the growing global demand for semiconductor production. High precision coupled with lesser contaminations in wafer handling robotics ensure better product quality. It is becoming increasingly dependent on high-performance technologies, and therefore, the market for such robots is really an inescapable segment of focus.

ABB Ltd., KUKA AG, and Epson Robots are some of the key competitors that continue to fight to achieve higher levels of robot sophistication, thereby improving operational efficiency and being able to satisfy the stringent demands of semiconductor manufacturing. Similarly, companies such as Kawasaki Heavy Industries, Ltd. and Staubli Robotics invest heavily in research and development to continue expanding the boundaries of precision and speed. Their developments will set a new quality standard and, more broadly, look to have a penetration of wafer handling robots into almost every industry.

From here on, the demand for wafer handling robots will shoot through the roof over the coming years, as industries are keen to produce ever more complex semiconductor designs with minimal human intervention. Already, companies like Brooks Automation and Yaskawa Electric Corporation are getting on the bandwagon with robots that can handle bigger wafer sizes and accommodate complex production requirements that are increasingly being expected. These innovations are not only fastening the manufacturing line but also reducing operational costs, making them attractive options for manufacturers seeking to remain competitive.

Future Outlook Future outlook on the Global Wafer Handling Robots market would be even stiffer competition from the top players in the market, such as Yamaha Robotics, Nidec Sankyo and Genmark Automation, incorporating features of artificial intelligence and machine learning into their system designs. Such features could make predictive maintenance, real-time error correction, and even autonomous decision-making as normal industry performances. But, nowadays, with sustainability as an integrated focus globally, the same companies such as Hirata Corporation and Moog Inc can use energy efficiency designs in arriving at environmental goals.

The expansion in the semiconductor industry will be significant, relying on the growth of the Global Wafer Handling Robots market to fuel its development. Companies like Rorze Corporation and Hine Automation take leading positions in this critical area, providing a response to particular obstacles like miniaturization and precision to this trend in technological progress. A competitive environment is thereby required to keep ensuring that wafer handling robots stay at the forefront of the modern solution in manufacturing.

Wafer Handling Robots Market Key Segments:

By Product Type

- Cartesian Robots

- SCARA Robots

- Articulated Robots

- Delta Robots

By Application

- Semiconductor Manufacturing

- Solar Cell Production

- Laboratory Automation

- Material Handling

By End-User

- Electronics Manufacturers

- Solar Energy Companies

- Research and Development Laboratories

- Automated Warehousing and Logistics

Key Global Wafer Handling Robots Industry Players

- ABB Ltd.

- KUKA AG

- Adept Technology, Inc.

- Epson Robots

- Hirata Corporation

- Kawasaki Heavy Industries, Ltd.

- Staubli Robotics

- Yamaha Robotics

- Yaskawa Electric Corporation

- Brooks Automation

- Nidec Sanky

- Rorze Corporation

- Genmark Automation

- Hine Automation

- Mechatronic Solutions

- Moog Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252