MARKET OVERVIEW

Spark detectors are used for safety purposes in industry because they can detect sparks or hot particles that may start fires or explosions. They are found to be widely applied in the woodworking, mining, and material processing industries because they usually deal with combustible materials. Its purpose is to add more security in the workplace by limiting ignition source accidents.

This type of risk can happen when the materials accumulate in places, like sawmills or furniture factories, and especially if it is fine dust along with wood particles. These will readily catch fire due to the sparks or embers created by machinery. The similar scenario also applies to mining operations and material processing facilities, where it happens at the time of handling and transporting materials, especially by creating friction or at higher speed operations. In such cases, spark detectors are an early warning system, which helps workers deal with hazards before they worsen.

These devices work by using highly sensitive light or heat sensors. Upon detecting a spark or hot particle, the system will trigger an immediate response, such as activating a suppression system, halting equipment, or alerting personnel. This quick response can prevent a small incident from becoming a large-scale disaster. The effectiveness of spark detectors lies in their ability to respond in real time, which is crucial in fast-paced industrial settings.

Apart from safety, there is cost saving in using the spark detectors for business ventures. Fires and explosions could cause severe damage to equipment and halt operations and, of course, lead to loss in terms of money. In fact, by preventing such incidents, companies save on costly downtime and repair expenses. More so, the implementation of such devices would protect businesses from legal liabilities and ensure compliance with guidelines on workplace safety.

The demand for spark detectors has increased as industries focus more on safety measures and risk mitigation. Technological advancements have further improved their performance, making them more reliable and efficient. As industries continue to focus on the safety of their workers and assets, spark detectors will remain a vital tool in minimizing risks associated with fires and explosions. This makes them an important factor in industrial environments, ensuring safer workplaces and preserving valuable resources because of their ability to detect and react quickly to potential hazards.

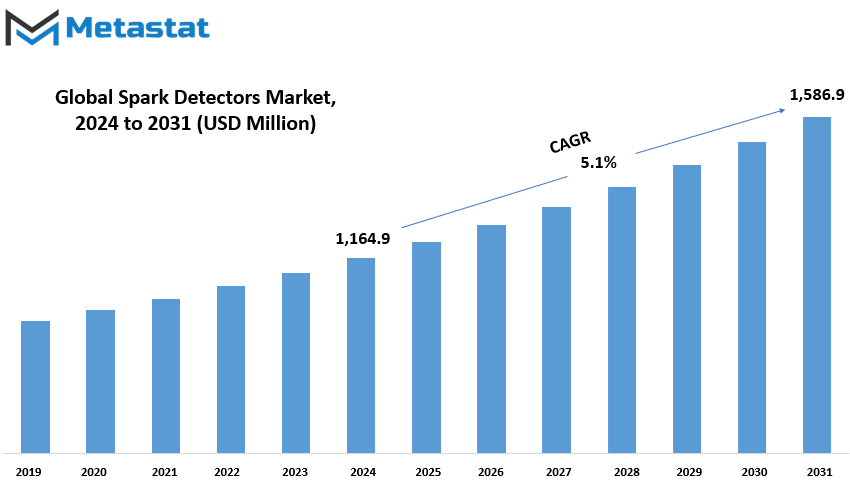

Global Spark Detectors market is estimated to reach $1,586.9 Million by 2031; growing at a CAGR of 5.1% from 2024 to 2031.

GROWTH FACTORS

The rising demands for industrial safety regulations and preventing fire hazards are key factors promoting the market. The companies around the world are getting more aware of the workplace safety and thus are demanding better protective systems to ensure safety and security for their employees and equipment, along with the surroundings. Increased deployment of industrial automation, which generally employs strict safety systems, propels the demand. Spark detection systems play a vital role in fire safety, especially in risk-prone environments involving flammable materials or high temperatures. All these factors collectively make the technology related to spark detection highly essential in the present industrial setting.

However, there are also challenges that will negatively affect the market growth of spark detection systems. Among them, the highest initial installation and ongoing maintenance cost of these detection systems is one such factor. These costs can be a significant burden to most businesses, especially smaller ones with fewer funds. In addition, awareness of these technologies is low in the smaller industries, which may not know much about them or the value they offer. As a result, most of them are usually underutilized, exposing small companies to the possibility of fire.

Despite these challenges, the outlook for the market is promising as technology continues to advance. Innovation is creating more effective and economical spark detection systems. As these technologies become affordable, they will likely be welcomed by industries of all sizes. This is also improving the effectiveness and reliability of detection systems, which will encourage wider application in industries that place a premium on safety.

These developments will have a huge impact on the growth of the market in the next few years. Increased affordability coupled with increased efficiency is likely to bridge the gap for smaller businesses and reinforce safety standards among the larger enterprises. The growing awareness of the significance of spark detection systems will expand this market further as more problems that exist are tackled while creating a safer industrial environment. Consequently, the future of spark detection systems appears promising, driven by the dual forces of technological progress and the need for heightened safety measures in industrial processes. These factors ensure that the market will continue to evolve and adapt to the changing needs of industries worldwide.

MARKET SEGMENTATION

By Type

Spark detection systems are very important in industries where fire hazards are always a concern. They are designed to detect sparks or hot particles that could ignite fires, thereby acting quickly to prevent major damage. The different technologies available for the classification of spark detectors include Optical Spark Detectors, Electrostatic Spark Detectors, Infrared Spark Detectors, and Ultrasonic Spark Detectors. Each of the types provides specific benefits that fit different environments and operation conditions.

Optical spark detectors are used in areas where flashes can be visually observed. They use light sensors to detect sparks in areas that might allow such detection with respect to lighting or reflective materials presence. They are effective in many industrial operations and promptly detect a potential ignition source.

Electrostatic Spark Detectors are best suited for environments that are prone to static electricity. These detectors detect changes in the electrical charge within a given area, making them very useful in facilities where materials such as plastic or textiles generate static buildup. Their ability to monitor such changes helps mitigate risks that might otherwise go unnoticed.

Infrared Spark Detectors work by detecting heat signatures produced by sparks. These are highly useful in industries involving high temperatures, such as metal processing or manufacturing plants. They are sensitive to thermal changes and ensure that the sparks are detected even when it is challenging for other detectors to do so. This method of detection can be particularly useful in preventing fires in areas where sparks are not visually evident.

Ultrasonic Spark Detectors will detect sparks using sound waves, which may be necessary in places where visual or heat-based detectors are insufficient. They take the specific sound frequencies corresponding to sparks and give an extra layer of safety in complex industrial settings. They ensure that all non-visible sparks are detected for a much more holistic approach to fire prevention.

Each kind of spark detector contributes to a safer work environment by reducing specific risks and environmental conditions. The type of detector used depends on the nature of the operation and the hazards involved. An appropriate spark detection system will prevent a possible outbreak of fire but will also save assets and lives, showing why these are important in various industries.

By Technology

The market for spark detectors has grown significantly in the last few years due to increased safety concerns in different industries. These devices are critical in preventing potential hazards caused by sparks, which may lead to fires or explosions in sensitive environments. Spark detectors are essential for maintaining workplace safety and minimizing risks associated with industrial processes by offering early detection and allowing prompt intervention.

The market can be divided into three primary types, namely fixed spark detectors, portable spark detectors, and wireless spark detectors, categorized by technology. Fixed spark detectors are permanently installed units designed to be placed in a given location. They are most useful in industrial facilities where there is a need for constant monitoring of high-risk zones. These detectors are reliable in detecting sparks and can be used with other safety devices to trigger immediate protection mechanisms. They operate consistently, making the surrounding safe when dangerous substances are processed on a daily basis.

Portable spark detectors are more versatile as they are mobile and can be transported to different locations for use. It's lightweight and conveniently designed, making it portable for professionals conducting assessments in different areas or locations. Portability does not compromise its effectiveness since they are equipped with modern detection of sparks with great accuracy. They represent portable detective instruments; the value is limitless in the industries that necessitate mobility without sacrificing safety standards.

These modern spark detectors work without much need for wiring, and therefore require minimal installation as well as minimal maintenance. They can be set to send live data to tracking systems or mobile devices which responds in little time, even in big or remote facilities. It is necessary for the people in charge of managing large or remote facilities as traditional wired systems may not prove feasible or too expensive for them to install. Through smooth connectivity, they contribute to efficient management and operationality of safety.

All in all, spark detectors play an indispensable role in protecting people, properties, and processes within numerous industries. These fixed, portable, or wireless devices meet varying needs and ensure overall coverage for spark detection. As safety remains a top priority for businesses around the world, these technologies are expected to gain further traction and drive research and development. Their role in preventing accidents and achieving safe practice cannot be underestimated, and so they are key constituents in industrial safety systems.

By Application

The applications range across industries requiring different solutions for their operations. Among them are dust collection systems, which play an important role because they maintain the quality of the air by capturing dust and other particulate matters. It is necessary where airborne particles pose health risks or damage equipment in the operation process. Its installation will contribute to the establishment of safer environments at work but will also respect regulatory standards.

The industrial process is another important application category. This encompasses various activities requiring precision and efficiency to provide a good outcome. In manufacturing, assembly, or material handling, smooth and reliable operation becomes paramount. Equipment designed for such processes often needs to be tough and flexible enough to cater to fluctuating demands while helping maintain long-term productivity with minimal downtime.

Flammable gas environments are inherently dangerous and require specialized solutions. In such environments, safety is the paramount concern, and equipment should be designed to prevent ignition and withstand challenging conditions. This application is particularly relevant in industries such as oil and gas, where the potential for accidents necessitates stringent safety measures.

High-usage applications also include food processing plants. In these facilities, hygiene and prevention of contamination are crucial factors. Specialized equipment used in processing is under high quality standards to avoid products from being harmful once consumed. From raw materials handling to packaging finished products, the process is to be carried out with precise perfection and compliance with industry norms.

There are specific applications that are designed to improve the productivity and sustainability of the agricultural industry. The equipment in this industry is usually used for irrigation, harvesting, and storage purposes, which demand efficiency and durability to support the demands of farming. Technology has further enhanced the capabilities of agricultural machinery, which has further led to better crop yields and resource management.

Pharmaceutical manufacturing is a very controlled industry, and the applications should be highly accurate and sterile. All stages of production, from making medicines to packaging, must meet very strict standards to ensure the safety and efficacy of the final product. Equipment used in this field is designed to handle sensitive materials with precision, emphasizing consistency and quality control.

With the many different applications that it serves, industries can get the better of their objectives- whether this means safety, efficiency, or mere compliance with regulations. As such, the innovations behind solutions are as varied as the challenges they face.

By End-User Industry

The global Spark Detectors market holds a very important position across various industries with the key role of maintaining safety while preventing fire in environments that are exposed to sparks or ignition sources. These are especially very important in locations where combustible dust and flammable materials are handled, putting workers at dangerous conditions. As such, prompt intervention would be possible for the risks related to property damage and personnel.

Of the various industries in which spark detectors are used, the mining industry relies extensively on them for safety in areas where flammable gases or dust particles are widespread. Manufacturing sectors include metal processing and paper production, among others. In the textile industry alone, for example, the number of spark detectors valued at 92.8 thousand units accounted for 8.12% of the total market share in 2019. The segment is expected to grow gradually at a compound annual growth rate of 5.40%, eventually reaching 133.9 thousand units by 2026. Growth of this nature further indicates that the industry keeps striving for safety improvements and risk management.

Other industries, such as cement production and power generation plants, also appreciate the use of spark detectors. These industries often work with materials that produce dust or heat during processing, making them particularly susceptible to ignition sources. Pharmaceutical plants, for instance, where precise control of the environment is of utmost importance, use spark detection systems to ensure uninterrupted operation and compliance with stringent safety standards.

The food and beverage industry uses spark detectors to protect their production lines, particularly where grinding or packaging materials may cause a fire under certain conditions. Chemical production facilities that use volatile substances depend on such systems to prevent explosions from occurring, thus keeping the production area safe and within legal requirements.

The gradual growth of the market for spark detectors indicates its growing importance in various industries. As safety requirements become more stringent and awareness of potential hazards increases, the demand for advanced spark detection systems will likely increase. These devices not only enhance operational safety but also contribute to productivity by reducing downtime caused by accidents or damage. They are an indispensable tool of modern industry because of their role in protecting both human lives and industrial assets, thus creating safe working environments and encouraging sustainable practices among all sectors.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,164.9 million |

|

Market Size by 2031 |

$1,586.9 Million |

|

Growth Rate from 2024 to 2031 |

5.1% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

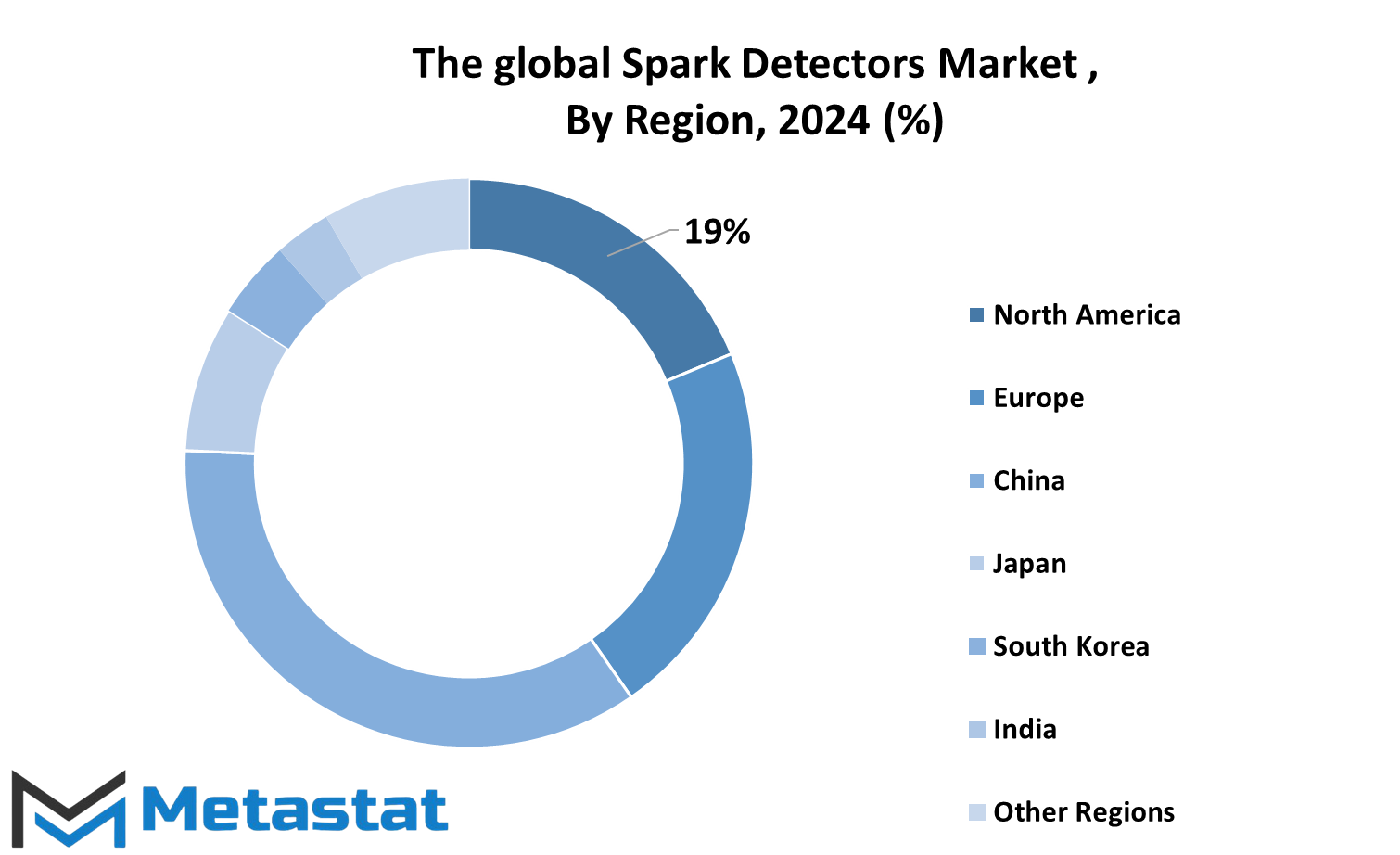

Based on the geographical regions, the worldwide market of Spark Detectors is segmented, allowing a clear understanding of the global distribution and scope. Among such regional categories, North America holds one important place, including the United States, Canada, and Mexico. Those nations greatly contribute to this market because of technological growth in their countries and booming industries. Europe, being another significant region, includes the UK, Germany, France, and Italy, with all other countries in the region are represented under the RoE category. The region enjoys strong industrial base and an emphasis on safety standard leading to demand of spark detectors. Asia-Pacific has been further sub-divided into India, China, Japan, South Korea, and Rest of Asia-Pacific. This region has grown immensely, primarily because of high-speed industrialization and the growth of manufacturing sectors within its territorial bounds in countries such as China and India. These countries hugely invest in industrial safety measures, thus forming a strong market for spark detectors. Japan and South Korea also greatly contribute to this segment with their well-established industrial ecosystems and their emphasis on innovation.

Brazil, Argentina and the Rest of South America comprises of the South America region. The largest growth in industrial safety applications was exhibited in Brazil and Argentina on the backdrop of growing manufacturing and mining sectors. Again, smaller compared to other markets is yet integral for the Middle East & Africa region. This again would be divided into three - the GCC Countries, Egypt, South Africa and the Rest of Middle East & Africa. The GCC countries, with their focus on oil and gas industries, create a steady demand for spark detectors, while South Africa and Egypt contribute due to their growing industrial bases and increased awareness of workplace safety. Geographical segmentation of the market for spark detectors depicts the high use of such sensors across all regions. However, drivers for regions are completely different-technology advancement, industrial growth, safety standards, and many more. Thus, an easy dive into these regional dynamics becomes important for interested stakeholders trying to benefit from such opportunities across this worldwide market.

COMPETITIVE PLAYERS

The industry of the Spark Detectors contributes to the safety of different kinds of industrial settings. These are meant to capture sparks that may light up fires; therefore, they come in handy where combustible materials are processed. Over the years, the industry has improved due to rising demand for fire prevention solutions and better safety measures. There are numerous companies specializing in the design and manufacturing of these detectors. Many companies have unique technologies and features to meet various industrial requirements.

Famous players in the industry include Fagus GreCon, a company reputed for its accuracy and reliability for spark detection systems. Then there is Argus Fire Control and Hansentek, famous for introducing new ideas about how best to control the risks presented by fires in industrial settings. Companies like Ampe Technology and Atexon Oy, which are part of IEP Technologies, provide highly efficient solutions meeting very high safety standards, with their products being utilized in different sectors. Another very significant name is Minimax, which focuses on its systems incorporating modern detection mechanisms for rapid response to fire hazards.

Flamex and Control Logic make major contributions to the growth of the industry through specialized detection solutions meeting the needs of modern industrial safety. Firefly really stands out because of their comprehensive approach in fire prevention, involving detection with suppression systems. GM SISTEMI and VDL Industrial Products bv present the latest cutting-edge technology, especially for specialized applications. The Lincoln Electric Company as well as BS&B Safety Systems also come into play when it comes to delivering robust yet dependable spark detection systems for vital applications. Companies such as L.L.C. further strengthen the offerings of the industry by providing customized solutions for specific needs of customers.

Together, these manufacturers and service providers cater to the rising demand for reliable spark detection systems. The products reduce the risk of fire and also help in operational efficiency by minimizing downtime due to potential fire incidents. The competition between these players drives innovation to ensure that highly effective and user-friendly systems are developed.

The Spark Detectors industry is continually changing due to changing safety standards and advancements in technology. Through the concerted efforts of these companies, industries across the world are equipped with better mechanisms to respond to fire risks and protect life, assets, and operations. Their innovations and commitment to safety give way to spark detectors as a critical component in modern industrial safety.

Spark Detectors Market Key Segments:

By Type

- Optical Spark Detectors

- Electrostatic Spark Detectors

- Infrared Spark Detectors

- Ultrasonic Spark Detectors

By Technology

- Fixed Spark Detectors

- Portable Spark Detectors

- Wireless Spark Detectors

By Application

- Dust Collection Systems

- Industrial Processes

- Flammable Gas Environments

- Food Processing Plants

- Agricultural Industry

- Pharmaceutical Manufacturing

By End-User Industry

- Mining Industry

- Manufacturing (Metal, Paper, Textiles)

- Cement Industry

- Energy and Power Plants

- Pharmaceutical Industry

- Food and Beverage Industry

- Chemical Industry

Key Global Spark Detectors Industry Players

- Fagus GreCon

- Argus Fire Control

- Hansentek

- Ampe Technology

- Atexon Oy (IEP Technologies)

- Minimax

- Flamex

- Control Logic

- Firefly

- GM SISTEMI

- VDL Industrial Products bv

- The Lincoln Electric Company

- BS&B Safety Systems, L.L.C

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252