MARKET OVERVIEW

The Global Rail Grinding Vehicle market is critical in the maintenance of railway infrastructure worldwide to ensure efficiency and safety. This industry is likely to become increasingly important as countries continue to invest in modernizing their rail systems to meet the increasing demands for transportation. Rail grinding vehicles, essential in the maintenance of tracks, offer a cost-effective solution to extend the lifespan of railway lines. These vehicles are intended to strip off the irregularities smooth the surfaces of the rails as well as to restore their profiles for achieving smooth rides and wearing the rolling stock less. This, however, entails the entire range of the market of the Global Rail Grinding Vehicle and it goes beyond basic maintenance of railway tracks only. It will be enhanced further when railways expand along with this increase in needs of special equipment for these operations. Rail grinding vehicles are expected to incorporate more advanced technologies, such as automation and real-time data monitoring, to enhance performance and reduce downtime. These developments will ensure that the vehicles can handle the increasingly complex demands of modern rail systems, where precision and efficiency are critical.

New players will be emerging in the Global Rail Grinding Vehicle market in the coming years. Established manufacturers will also be innovating to suit both developed and emerging economies. As the rail industry increases its focus on sustainability and cost-effectiveness, the role of rail grinding vehicles will become even more prominent. These vehicles help reduce maintenance costs by preventing rail damage, improve operational efficiency, and minimize the risk of accidents caused by track imperfections. With the upgrading and expansion of rail systems around the world, the need for regular track maintenance using rail grinding vehicles will only continue to grow.

Moreover, there would be an increased demand for more environment-friendly solutions that would force the makers of rail grinding vehicles to offer greener, energy conserving machines. Low-emission engines and new innovation to reduce their foot-print in the environment are something to look forward to, and this is part and parcel of the worldwide bid to reduce greenhouse gases, making the market go from efficient performance to equipment usage in tandem with sustainability in practices.

Regional developments will also have a significant impact on the Global Rail Grinding Vehicle market. As the rail network is expanding in developing regions such as Asia-Pacific and the Middle East, these regions will require more rail grinding vehicles to meet the growing demand for rail infrastructure. In mature markets like Europe and North America, the focus would be on upgrading and optimizing already existing rail networks, wherein rail grinding vehicles would prove to be indispensable in the maintenance of the quality of the tracks.

The Global Rail Grinding Vehicle market is poised to see exponential growth in the years to come. In that context, the usage of rail grinding vehicles continues unabated through the phases of the upgrading and refurbishing process; therefore, maintenance of its kind has already been well-established with great demand through the time elapsed. Being a safety concern factor in preventing rail fragmentation on smoothness and performance would also take an impressive portion within sustainable environmental practices by such transportation networks. These services have continued gaining market into expansion.

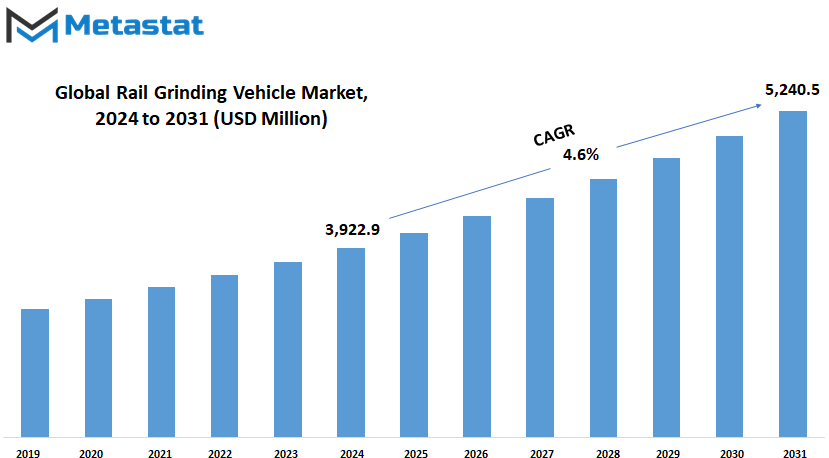

Global Rail Grinding Vehicle market is estimated to reach $5,240.5 Million by 2031; growing at a CAGR of 4.6% from 2024 to 2031.

GROWTH FACTORS

The Global Rail Grinding Vehicle market is expected to witness a tremendous growth in the coming years, with a combination of factors that will change the way railways are maintained and improved worldwide. As the demand for more efficient railway maintenance solutions increases, passenger safety and operational costs will be at the forefront. Rail grinding machines are an essential component for the maintenance of track quality as they prevent issues which could lead to accidents or delay. This increasing demand for effective track maintenance solutions continues to drive market growth.

Rail infrastructure investment is also considered one of the key factors driving growth in this market. Huge funds are being allocated by governments and private sectors for improving and expanding rail networks, especially in high-speed rail systems. With countries looking to upgrade their transportation infrastructure, regular and accurate track maintenance will become even more important. Expansion of high-speed rail systems, for example, will demand advanced rail grinding vehicles so that tracks can withstand increased pressure and speed without sacrificing safety. These developments are likely to push the demand for such specialized vehicles to new heights.

While the market shows great promise, there are challenges that may slow down its growth. One of the significant hurdles is the high initial procurement and operational costs of rail grinding vehicles. These vehicles are expensive to purchase, and their maintenance costs can add up, making them a large financial commitment for railway operators. Besides this, the complexity of maintenance of these vehicles and the need for very skilled operators also make their adoption more difficult, especially in areas with fewer resources or technical capabilities.

The future of the Global Rail Grinding Vehicle market is promising with increasing adoption of automated and AI-powered vehicles. Such advanced machines will be able to bring great efficiency and precision to the track maintenance work, which can be faster and more accurate. It will allow the integration of artificial intelligence to monitor and predict in real time, decreasing the likelihood of track failures and further slashing operational costs. As technology becomes highly advanced, these automation solutions will continue to give businesses such lucrative opportunities for growth in the market that will promise an excellent future for the industry.

With its ups and downs, the growth of the Global Rail Grinding Vehicle market is surely affected by such challenges, however growth factors including an increased need for effective maintenance solutions, wider rail networks, and high technology developments will certainly prevail in determining its future. With a more widespread introduction to automation, the market should be heading toward cheaper yet more effective ways of keeping tracks on track for more secure and reliable rail services across the globe.

MARKET SEGMENTATION

By Type

The Global Rail Grinding Vehicle market is to grow significantly over the coming years as the need for effective and precise maintenance of the rail continues to rise. This market finds growth stimulus in technological development and in the need for extending and improving the service life as well as increasing the safety factor of rail systems across the globe. Future changes in this industry are most likely to be based on advancements in rail grinding technology. They will make trains safer, smoother, and cost-effective to operate. Another segment within the global market is the variety of rail grinding machines that serve different needs. This variety is crucial to maintaining the optimal condition of rail tracks, thereby lowering the cost of maintenance and the least possible disruptions in rail traffic.

It breaks into several primary categories on the basis of the kind of rail grinding vehicle, each for a purpose in maintaining the rail track. For example, there are rail grinding machines; these have the capability of restoring the rail's profile by removing surface irregularities and wear. In this respect, the machines help train movement along rails and thereby prevent the destruction of rails. Rail Profile Grinding Machines are as important as the others as they are specifically used to recover the rail profile. These machines help in keeping the rail in its intended form, thereby improving its performance and extending its service life.

Another important segment within the market is Rail Head Grinding Machines. These are designed to grind the head of the rail, that is, the most important area that comes in contact with train wheels. Such machines exist to avoid all rail defects that might eventually affect both the safety and comfort level of train traveling. These machines combine straightening as well as grinding for solving the curvatures problems of rail and weariness of surfaces. These machines are particularly useful in restoring tracks that have bent or deformed over time. Lastly, Rail Flange Grinding Machines ensure the maintenance of the flanges of the rail, which is important in preventing wheel derailments and smooth transition of trains along tracks.

Looking ahead, the Global Rail Grinding Vehicle market will be seen with even more specialized machines that can address specific needs of various regions. Demand will increase as cities and countries keep investing in expanding their rail networks. Automation and AI-based machines will be more predominant and help operators achieve higher precision and efficiency in rail maintenance. The future promises even better improvements in speed, cost-effectiveness, and environmental impact, offering a brighter perspective for the industry and its users.

By Rail Type

The Global Rail Grinding Vehicle market will be seen to grow very high in the coming years as the countries and organizations continue investing in the maintenance and development of their rail infrastructure. It is a market that stands to benefit from the increasing concern for improving rail safety, efficiency, and sustainability. Rail grinding vehicles are crucial for keeping the tracks in their best conditions, minimizing wear and tear, and thus maximizing the overall life of the railway system. The demand for efficient transportation systems around the world is growing, and the role that these vehicles play in the maintenance of railroads will become increasingly vital.

The market is segmented by the various types of rail systems, each of which has different needs for specific types of rail grinding vehicles. One of the largest segments is light rail, which, in general, refers to shorter-distance rail systems used typically for urban transport. Such systems are becoming very common in cities all over the world with increasing rates of urbanization. Light rail systems require grinding vehicles specially designed to handle tracks that involve frequent stops and starts. These systems focus on noise and vibration abatement, as well as the smooth and safe transit of passengers.

The Global Rail Grinding Vehicle market also has this significant segment. Such trains generally are used for long haul purposes, such as freight services, and intercity passenger train service. Heavy rail networks require many more heavy-duty grinding cars to respond to the significant increase in wear and tear on the tracks, thanks to increased loads and elevated speeds. The demand for these is going to increase with the added pressure from the need to revamp freight capacity and efficiency and reduce dependence on transport means that tend to contribute immensely to emissions.

High-speed rail has started gaining popularity in most countries, which will enhance the growth of the market. Such networks require specialized grinding vehicles with high pressure and speed characteristics associated with such a network. This segment will stress track precision and safety to prevent trains running at higher speeds from going wrong or delaying operations. With more countries building high-speed rail networks, the requirement for rail grinding vehicles to maintain these networks will increase.

The market segment would be urban rail systems, including trams and metros. It is a necessity for commuting in large cities, which will continue to grow in the future with increasing populations of cities. Grinding vehicles for such systems will have to accommodate stops very frequently and track wearing in populous areas. To that end, these vehicles can play a crucial role in keeping the tracks smooth, which will lead to the improved efficiency of mass transit.

In the future too, advances in the technologies of the rail system and its operation will result in an overall increase in the Global Rail Grinding Vehicle market. The number of vehicles for different types of rails to be used within a wide range of application environments will be on the increase. With sustainability becoming the key focus in transport, rail grinding vehicles will play an important role in ensuring that rail infrastructure remains in top condition, ultimately supporting the growth of rail systems worldwide.

By Application

The Global Rail Grinding Vehicle market is expected to have a highly positive growth outlook in the coming years as demand surges for maintenance and further improvement of railway infrastructure. There will be a growing demand for good rail maintenance as the global network of rails increases and wears out. An integral part of this maintenance would be rail grinding, utilizing high-tech vehicles to restore a rail's profile and allow it to perform better. These grinding vehicles prevent any problems that may occur on the rail, such as wear and tear, the misalignment of tracks, and other forms of decay because of constant use. These vehicles are becoming more efficient and environmentally friendly with the constant improvement of technology, and that will probably be a significant reason for their increasing popularity in the market.

In the future, the Global Rail Grinding Vehicle market will be divided into several applications, which will be a contribution to the general growth of the sector. The main application is track maintenance, which involves regular upkeep of existing rail tracks to ensure safety and functionality. Rail grinding vehicles are essential in this area, as they help maintain smooth and even rail surfaces, preventing damage that could result in accidents or delays. These vehicles will continue to play a vital role in preserving the quality of railways worldwide, particularly in countries with large and busy rail networks.

Another significant application within the Global Rail Grinding Vehicle market is track rehabilitation. This involves restoring older tracks that have suffered from wear and tear, allowing them to function effectively for many more years. Grinding vehicles are indispensable in this process as they help reshape and repair the rail profile, removing imperfections that could lead to issues down the line. The demand for track rehabilitation will increase as the demand for high-speed trains increases and older tracks require more attention.

New track construction will also be driving the demand for rail grinding vehicles. As cities and countries continue to invest in the expansion of their rail networks, new tracks must be built and smoothed to meet the required safety and performance standards. Rail grinding vehicles will play an essential role in ensuring that newly constructed tracks are properly shaped and aligned, offering a smooth and reliable ride from the very beginning.

Last but not least, monitoring and inspection of track is increasingly becoming important for railways in maintenance and operations. Monitoring tools are frequently used together with rail grinding vehicles to identify areas that require grinding. This kind of approach helps prevent big problems from arising and keeps rail systems safe and efficient.

As the Global Rail Grinding Vehicle market grows, so will the demand for these vehicles across all applications because of the need for enhanced track performance, safety, and longevity. The future of this market is bright as technologies evolve, and the world continues to invest in better and more sustainable rail infrastructure.

By End-Use Industry

The Global Rail Grinding Vehicle market is highly growing with importance because it plays a significant role in rail network maintenance and enhancement. As the railway remains one of the major modes of transport within most countries worldwide, smooth train operation is of utmost importance for safety, reliability, and performance. One crucial instrument involved in this process are the rail grinding vehicles, which actually tend to maintain the tracks under ideal conditions by removing their irregularities, improving quality through enhanced surface quality on rails, and extending track lifetime. The market of this type of vehicle continues expanding as the demand from new users for high performance through modernized rail system growth accelerates.

The Global Rail Grinding Vehicle market would most probably grow parallel to rail transport that is getting more importance. It is seen that one of the critical factors that propel this growth is the growing necessity for enhancing the maintenance capability of the rail infrastructure. Some of the end-user industries that would determine the future of this market include railway operators, companies dealing with the maintenance of rail infrastructure, government and transport authorities, rail contractors, engineering firms, and urban transport systems. Each one of them will require new solutions for their particular purposes.

Railway operators-public and private will be among the key market drivers. The need for the advanced rail grinding vehicle will continue to drive investment into these efforts as operators strive to make their services efficient and safe. These are public or private operators who realize the value of high-quality tracks to ensure passenger safety and the reduced chances of accidents. Companies dealing with rail infrastructure maintenance will be key demanders of the rail grinding vehicle. These companies are tasked with holding the rail tracks in proper working condition. The larger that the rail networks get to be, so the jobs will be, therefore they will require better and dedicated grinding vehicles for doing their job.

Government and other transport authorities would be substantial contributors too. This expenditure will be there by spending money on rail grinding vehicle to enable the public rails infrastructure without disruptions or snagging in smooth running trains. Similarly, rail contractors and engineering houses will also be a big contributor in the market. Most of them are working on a large infrastructure project and are looking for quality rail maintenance tools, such as grinding vehicles to keep the projects on the right track.

With the increasing urban transport systems, especially in the growing cities, the need for rail grinding vehicles is going to be very high. The demand for efficient, sustainable transport solutions is growing, and these vehicles will be of utmost importance to ensure that the tracks remain in good condition for a long time.

The Global Rail Grinding Vehicle market will continue to grow, as the rail transport system evolves. Innovations from different industries, investments made, and thus demand contributed to more efficient and effective solutions in rail grinding for the future.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$3,922.9 million |

|

Market Size by 2031 |

$5,240.5 Million |

|

Growth Rate from 2024 to 2031 |

4.6% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

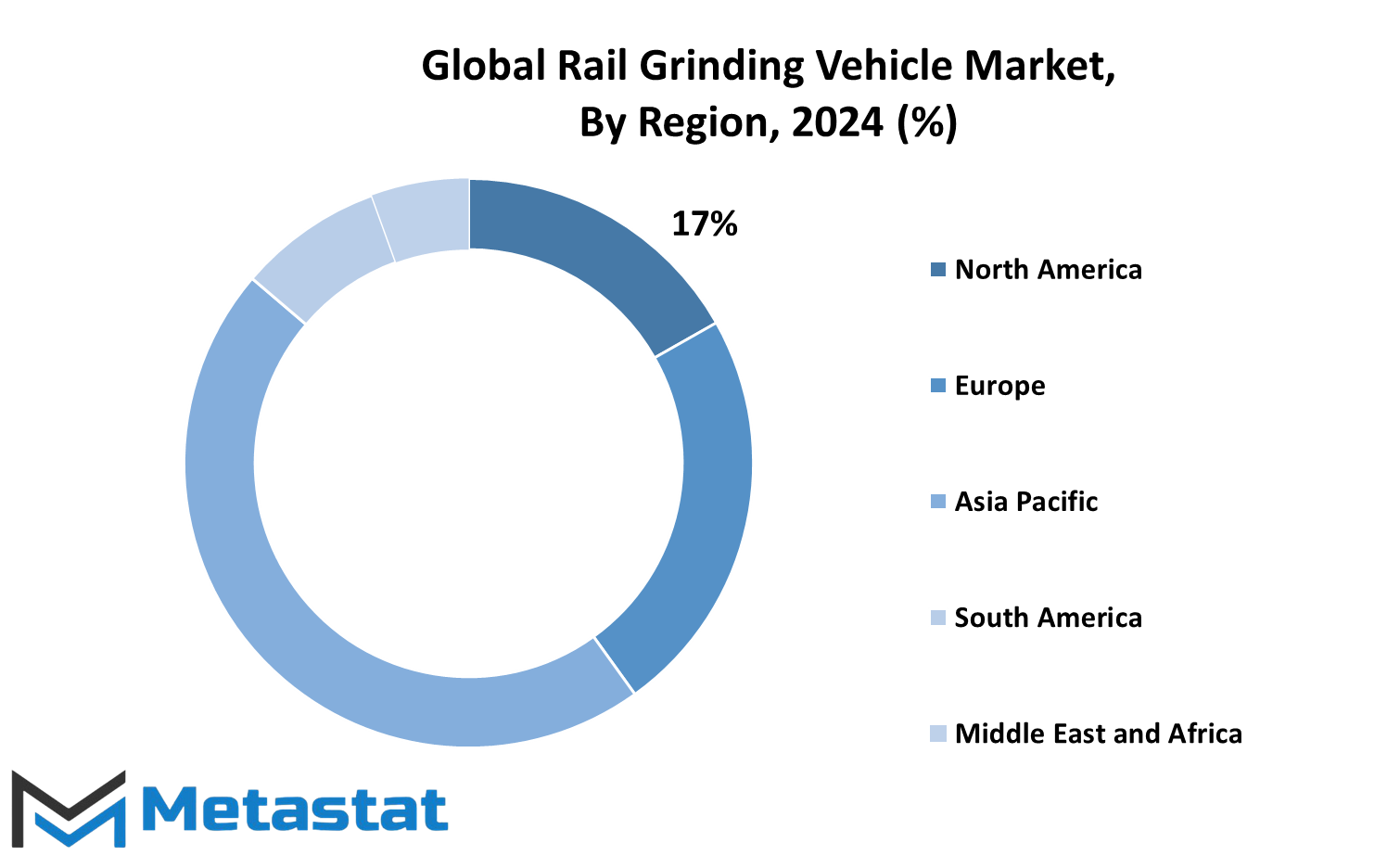

Due to developments in technology and growing requirements for efficient maintenance of rail lines, the global rail grinding vehicles market is going to see high development in the years ahead. Geographically, the market stretches across regions which are as varied as they are unique, ranging from North America, Europe, Asia-Pacific, South America, to the Middle East & Africa, each offering its share to the total growth of this industry.

North America, which includes the U.S., Canada, and Mexico, has been steadily developing rail infrastructure with increased investments in modernization projects. The demand for rail grinding vehicles in this region is mainly because of the need to maintain quality existing rail systems, ensuring smooth operations, and lowering the cost of maintenance. Increased urbanization and the increased length of rail networks will see an increase in the need for these particular vehicles. It thus offers a new chance for the manufacturers as well as the service providers.

The European countries, such as UK, Germany, France, and Italy, have been classical powerhouses in the world of rail transport and infrastructure maintenance. The European rail grinding vehicles market will grow steadily as the network expands and modernizes further. The European countries have started adopting sustainable modes of transportation. This will increase the need for efficient and environmentally friendly rail maintenance technologies, such as grinding vehicles. Governments in Europe are investing heavily in rail infrastructure, so the region will define the future of the market.

Asia-Pacific, which includes major players such as India, China, Japan, and South Korea, will be one of the regions with the highest growth in rail grinding vehicles. Countries such as China and India, which are rapidly expanding rail networks along with modernizing existing systems, will provide a strong demand for rail maintenance technologies. The high-speed rail expansion in Asia also will demand more of this type of rail vehicle as quality tracks become an increasing need to ensure safety and efficiency in rail operations.

The South American market, including that of Brazil and Argentina, is expected to grow gradually. In this region, rail transport has not been as developed as in other regions, but investment in improving the infrastructure and expanding the rail network is continuous. It will be a continuous demand for rail grinding vehicles. Governments are promoting improvements of public modes of transport and enhancing rail services. The market will, therefore, grow steadily in the coming years.

The Middle East & Africa market for rail grinding vehicles is expected to rise quite significantly. In the Middle East, it is heavily investing in its expansion of rail networks and countries like the UAE and Saudi Arabia are taking the lead. In Africa, this is creating a boom for the rail industry with more people demanding better transport infrastructures. In 2019, the Middle East & Africa market was at 173.9 million US dollars and is expected to increase further up to 240.1 million US dollars by 2026 with a CAGR of 5.0% during the period from 2020 to 2026.

The global rail grinding vehicle market will grow in each region due to rail network modernization, more awareness of efficient rail maintenance practices, and sustainable transportation development. Growth and innovation in the future trends of the market are dependent on the current needs and infrastructure developments of the regions.

COMPETITIVE PLAYERS

The Global Rail Grinding Vehicle is one of the leading markets in transportation and infrastructure. Rail grinding vehicles value will, therefore, be evident in proportion to the increasing number of rail systems that are quality and good. These are designed with the aim of helping improve on the performance of railways through more smooth tracks and long rails. Greater growth in the market will be witnessed in the forthcoming years with a growing requirement for better efficiency, safety, and sustainability in railway systems throughout the world.

The key players in this Global Rail Grinding Vehicle market are the most important to frame its future. Companies that are leading include Loram Maintenance of Way, Inc., Vossloh AG, and Plasser & Theurer. They have developed advanced technologies in rail grinding. Their innovative solutions and know-how have uplifted the rail maintenance efficiency, letting passengers travel smooth and freight without any danger. Other significant contributors in the market are GE Transportation, CRRC Corporation Limited, and Harsco Corporation, bringing on new technologies and approaches in the rail grinding. These companies strongly invest in research and developments of machines that do not only address the present but sense the future demands for the market.

The increasing number of Global Rail Grinding Vehicle in the market will give way to further competition between the mentioned firms. Some of the giants in the rail industry, Kawasaki Heavy Industries, Hitachi Rail Ltd., and Siemens AG, will tend to increase their attention towards rail grinding vehicles with new models which give higher performance, efficiency, and environment friendliness. Their automation and digital advancements are likely to give them machines that are intelligent in all ways, with lesser errors on human sides and optimised maintenance schedules. Atlas Copco Construction Tools AB, RPM Group, and Speno International SA are less-known companies within the larger railway industry, but they play a more important role in the development of rail grinding vehicles.

Their products and services look into the niches on the market and serve distinctive solutions for the rail maintenance business, therefore supporting the major corporation's activities. What really cannot be forgotten are how these players push and facilitate innovation into what might happen in the future for the performance of rail grinding vehicles. The future of the Global Rail Grinding Vehicle market will be determined by the competitive players, each bringing out their strengths and innovations. It is an era where expansion and modernization of the railway networks will increase demands for more efficient, cost-effective, and sustainable rail maintenance solutions. These companies are going to be instrumental in meeting the demand and make railways one of the critical means of transport for people and commodities alike.

Rail Grinding Vehicle Market Key Segments:

By Type

- Rail Grinding Machines

- Rail Profile Grinding Machines

- Rail Head Grinding Machines

- Rail Straightening and Grinding Machines

- Rail Flange Grinding Machines

By Rail Type

- Light Rail

- Heavy Rail

- High-Speed Rail

- Urban Rail (Trams/Metros)

By Application

- Track Maintenance

- Track Rehabilitation

- New Track Construction

- Track Monitoring & Inspection

By End-Use Industry

- Railway Operators (Public and Private)

- Rail Infrastructure Maintenance Companies

- Government and Transport Authorities

- Rail Contractors and Engineering Firms

- Urban Transport Systems

Key Global Rail Grinding Vehicle Industry Players

- Loram Maintenance of Way, Inc.

- Vossloh AG

- Plasser & Theurer

- GE Transportation

- CRRC Corporation Limited

- Harsco Corporation

- Kawasaki Heavy Industries

- Hitachi Rail Ltd.

- Siemens AG

- Atlas Copco Construction Tools AB

- RPM Group

- Speno International SA

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383