MARKET OVERVIEW

The Global Plate Freezers market is fast becoming an essential part of the refrigeration and cold chain industry, which supports many sectors that require efficient freezing solutions. This market is defined by rapid freezing with minimal energy consumption and optimum product preservation. In such industries as seafood processing, meat packaging, and ready meal production, the most up-to-date systems in plate freezing are imperative investments for firms wanting improvement in operational efficiency and product quality.

At the heart of this market remains innovation, a quality that propels manufacturers to design systems that improve freezing speed while equally satisfying sustainability objectives. The focus on reducing carbon footprints while maintaining performance will dictate a shift within the market toward environmentally benign refrigerants and energy-efficient designs. Improvements in design will also be made through regulatory frameworks and international food safety standards, as manufacturers are compelled to integrate advanced features that help comply without affecting efficiency.

The Global market for plate freezers will see far-reaching changes in its applications, especially in sectors that reach outside the musty domain of traditional food preservation. With the demand on plate freezing technology faculties maintaining the precise temperatures required in vaccine storage bio-sample preservation and chemical stability, the pharmaceutical and biotech industries are expected to rely even more on plate freezing technology. The expansion of these sectors will, in all likelihood, increase the demand for specially designed plate freezers geared toward laboratory and medical applications and simultaneously provide opportunities for manufacturers to venture into other areas.

Customization is set to become a market defining force as companies prioritize modular designs catering to specific industry needs. Bulk freezing operations would require high capacity systems, while smaller operations would prefer compact models with intelligent automation. An overall push towards digitalization in industrial processes will also find its way into this sector, allowing for the integration of smart monitoring systems for remote control and predictive maintenance. These advancements will streamline processes, maximizing uptime and productivity for users across various industries.

Geographical expansion will remain a key aspect of market growth as developing economies are set to see the merits of efficient freezing solutions. The benefit derived from plate freezing technology by the food export sector in emerging markets will see increased adoption to enhance the shelf life of perishable goods so they can meet international trade requirements.

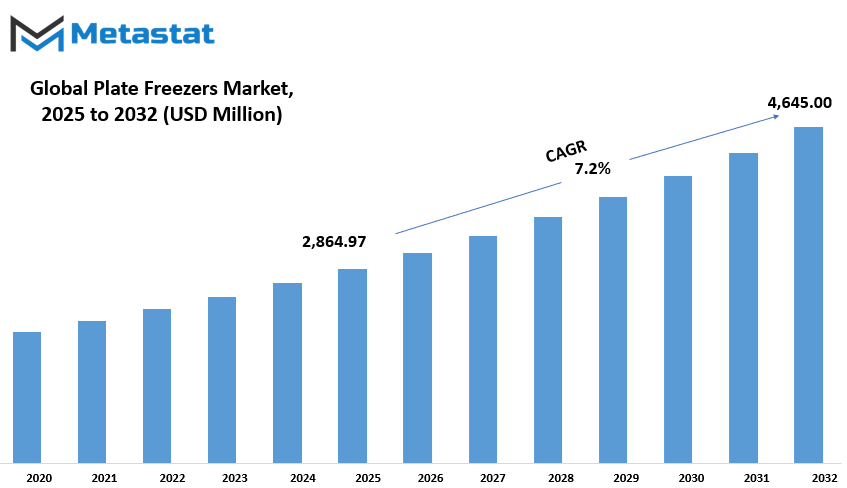

Global Plate Freezers market is estimated to reach $4,645.00 Million by 2032; growing at a CAGR of 7.2% from 2025 to 2032.

GROWTH FACTORS

The Global Plate Freezers market is growing due to the high demand for frozen seafood and ready-to-eat food products. Urban dwellers are much busier with their day-to-day work activities and their families; therefore, frozen food will always be the first choice for many consumers. Convenience really is what consumers are looking for-so frozen foods literally have it all: they last longer, and they allow higher quality and nutritional value for the consumer. It is precisely here that plate freezers help in saving food by freezing items quickly and efficiently, ensuring freshness and safety.

Energy-efficiency in freezing technology, however, has been a major trend defining this market. Food processing businessmen show concern in reducing their operational costs with their minimum effects on the environment by applying their cutting-edge freezing technologies considering the prospect of sustainability and energy use. Most areas of concern now in the manufacture of plate freezers are low energy consumption along with high efficiency in freezing. Improved refrigerants and automation in freezing systems show the industries the path to optimal performance concerning environmental regulations.

Challenges face the market despite this noted growth. One major constraint in this aspect is the high initial investment and operating costs. This financial disadvantage doesn't allow small or medium enterprises to adopt the use of these plate freezers since installation and maintenance of such freezing equipment is very expensive. Even with their exclusive benefits, plate freezers cannot be used to freeze all kinds of products, such as mismatch and larger food items. The limitation of such freezers confines operations to certain segments of the food industry, where some alternative freezing methods might work better.

Emerging technologies will, on the other hand, create new opportunities for market growth. Advancements in the automation and refrigerants drive innovative sustainable freezing applications. More investment in improving freezing efficiency while significantly reducing energy consumption and less environmental impact would boost the existing plate freezer technology to be more affordable and worthwhile for a wider variety among food processing industries.

Growth in the consumption of frozen food will further create a demand for Global Plate Freezers in the market. Manufacturers will invest in offering freezing solutions that are flexible, efficient, and eco-friendly to sway industry minds. Innovations continue to lead to an increasing number of benefits associated with sustainability and operational efficiency, and these make plate-freezing technology relevant and essential in contemporary food processing.

MARKET SEGMENTATION

By Type

The Global Plate Freezers market offers high demand in food and seafood processing industries, primarily providing efficient and reliable freezing solutions for the preservation of perishable goods. A plate freezer freezes products in between metal plates to ensure that the cooling is even across the product and thus retain the quality of the items being frozen. The increased demand for frozen food, seafood exports, and demand for efficient cold chaining are the major driving factors for the market. Food manufacturers and seafood processors utilize the freezing systems to enhance product shelf life and to conform to the regulations laid regarding food safety.

The types of market are being categorized according to the orientation of freezing plates. Among all, horizontal plate freezers dominate the market in terms of usage, with a valuation of $1,902.23 million; this popularization is attributable to its ability to freeze larger quantities of products and, therefore, bulk. The horizontal plate freezers are designed for bulk storage and are, therefore, usually common in an industrial space. These vertical plate freezers, in particular, are the kind most often found when space is of the essence. They are, for the most part, used in fishing vessels and smaller processing plants. With the capacity to freeze individual portions in quick time, they serve in applications where separation of the product becomes crucial.

Due to the evolution in refrigeration techniques, energy-efficient plate freezers are available low operational costs, and lesser eco-impact. Presently, the manufacturers are putting innovations on the table by incorporating automation and smart monitoring systems for improved performance and reliability. Demand for better energy-efficient and ecologically advantageous freezing has filtered deep into manufacturers' ability to innovate, with companies exploring possibilities in natural refrigerants and enhanced methods of insulating as an impetus for new ideas in the industry.

Emerging Markets have driven the Frozen food Industry development and thus provide some growth opportunity of these markets. Changing consumer attitude, busy schedules, and convenience in meal preparation are also increasingly creating demand for frozen foods. Similarly, the increasing demand from advanced freezing technologies, such as large-scale distribution networks, has generated the need for such applications due to supermarket chains and their online grocery platform extensions.

High initial investment cost and the need for maintenance after purchase also brought market challenges, but maintenance is very crucial for optimum performance. However, the long-term benefits of plate freezers concerning food quality and wastage reduction significantly outweigh their shortcomings. Research and development, for example, in effective and cost-efficient solutions that continue to evolve with developments in the food processing and seafood industries, are important topics for companies active in this field. The Global Plate Freezers market would, as a result of technology and demand, face growth in the coming years.

By Refrigerant Type

The Global Plate Freezers Market is projected to see an upsurge as industrialists seek reliable yet efficient freezing solutions. Applications of plate freezers widely span the food industry, especially seafood, red meat, poultry, etc., where proper freezing and preservation of quality are the main concern. The other applications of plate freezers are in pharmaceuticals and other industrial domains, where precision temperature control is required. Plate freezers are the core contributors toward minimizing energy consumption, providing uniform freezing, and reducing dehydration losses. Hence, they are an inseparable part of industrial refrigeration systems.

Engineering fluids chosen as refrigerants for plate freezers are among the prime determinants for the market. Refrigerants have further segregated the market into its types: Ammonia (NH₃), Carbon Dioxide (CO₂), and Hydrofluorocarbons (HFCs). Ammonia finds widespread application owing to its excellent cooling properties along with energy efficiency. It is an environment-friendly natural refrigerant in industrial applications.

Carbon Dioxide is gaining momentum as a refrigerant because of its non-toxic nature and comparatively low global warming potential when juxtaposed with synthetic refrigerants, particularly in regions with stringent environmental regulations. On the other hand, many countries are really racing to enact laws to restrict the use of HFCs, which have in the recent past been condemned for creating serious environmental problems, while conversely, advancing the case for other climate-friendly alternatives.

As the scope of regulatory parameters has now narrowed, the focus has come on sustainability, and the manufacturers have been investing in research for plate-freezers that can use these eco-friendly refrigerants without compromising performance. Globally, the demand for frozen foods is on the rise, adding to the growing demand for efficient freezing solutions. The focus is on innovations that enhance freezing speed along with the use of energy savings and automation to match industry demand. In addition, innovations in digital monitoring and control systems are increasing the efficiency and reliability of plate freezers.

Factors such as a rise in energy costs and the need to comply with food safety regulations also influence the market. Industries desire solutions that harbor outstanding performance and have a good prospect for market acceptance all along the value chain in terms of regulatory compliance. Moving ahead, as innovation applies, changing technology means plate freezers will continue to evolve with better efficiencies on sustainability and operational ease. With the industry's priorities in favor of cost and environment-friendly refrigeration, this scenario means promising growth of the Global Plate Freezers market.

By Application

The Global Plate Freezers market has immense importance in the food processing and preservation industries by serving different applications ensuring the long-term storage of perishable items. These freezers are extensively used in seafood freezing, meat processing, dairy products, and preservation of fruits and vegetables. The need for and demand for freezing solutions are increasing continuously as industries try to preserve the quality and texture and nutritional content of food products during storage and transport.

Seafood freezing is a major application where plate freezers render a helpful service in fresh preservation. Rapid freezing techniques are vast applications in the seafood industry to preserve the natural flavor and texture of fish, shrimps, and other marine products. Due to rapid temperature drop, plate freezers prevent the formation of ice crystals, and because of which seafood quality is not affected in any way. This keeps the product fresh over long periods and traveling long distances.

The other main application for plate freezers is in meat processing, an area where they are highly popular. The meat industry ensures that product integrity is maintained to ward off spoilage and bacterial growth. Besides, plate freezers provide a quick lap of freezing that locks moisture content while preserving the original texture of meat products. Plate freezers become even more important in large-scale meat processing facilities that need to maintain high volumes of products in an efficient manner while complying with food safety regulations.

Other products including butter, cheese, and other perishable dairy products benefit from plate freezing technology. These require very specialized freezing processes to maintain the integrity of the product from deterioration. The plate freezer helps attain the desired consistency and long shelf life of dairy products that render them well suited for both home and international marketing.

Plate freezing is also an important aspect in the cold storage and preservation of fruits and vegetables. Fresh products cannot be eaten or kept for long, and without proper freezing techniques, would spoil. Fast freezing with the plate freezer helps retain the original color, flavor, and nutritional value of fruits and vegetables. This is a great innovation for suppliers and distributors who need to store huge bulk without compromising the quality to the end consumers.

The increasing consumption of frozen food all over the world makes the importance of plate freezers to keep rising at every given time with respect to the food industry. Companies are investing in next-generation freezing technologies to achieve maximum efficiency and minimum energy consumption while still ensuring the highest food safety standards. The Global Plate Freezers market has been projected to undergo profuse advances because of the increasing focus of manufacturers towards innovation as a direct response to the evolving trends of food industry requirements.

By End-Users

The market for Global Plate Freezers is an essential part of industries that need effective freezing solutions to eliminate the chances of spoilage of perishable materials. A plate freezer freezes a product by rapidly pressing the item between cold metal plate surfaces for uniform cooling, thus preserving the quality of products stored. Plate freezers are increasingly becoming common in industries that pertain to freezing and storage in bulk as about the rising demand for frozen food and seafood worldwide. The difference between the time taken for freezing and the efficiency of the freezing capability makes such apparatus superior to machinery used for other bulk processing of products.

Plate freezing is one of the most important processing methods in the industry of food processing. Ready meal manufacturers, frozen vegetables, meat and dairy product manufacturers use plate freezers for their products to keep them viable for extended periods. Rapid freezing not only retains flavor and texture but also inhibits the growth of bacteria, which is very important for food safety maintenance. Freezers development trends have therefore maintained or enhanced the speed of freezing so as to maximize on consumer demand for the best quality frozen products.

Plate freezers also find their importance in the cold storage business. This sector serves as a hub for long-term preservation of perishable goods before being supplied to the retail markets. Processing these perishable raw materials into frozen foods or pharmaceuticals, from supermarket to distribution center, all rely heavily on cold storage for keeping products in prime condition. The quality of the stored items is further enhanced by the performance of plate-freezers in minimizing ice crystal formation and retention of nutritional properties. The increasing demand for efficient storage applications has also driven the technological advancements in freezings, aiming to make the plate freezers energy-efficient and able to carry larger quantities.

On the other side, the fishing industry is a major plate freezer user. Immediately freezing seafood is the only way to avoid spoilage and help with preserving its freshness. Fishing vessels with plate freezers can directly process and store fishes right after being caught, hence affording them optimal time to deliver quality seafood to markets around the globe. This mechanism also guarantees that in its original taste and texture, the seafood has been transported over long distances. Several fishing companies are investing in modern plate-freezing systems to comply with international quality standards and meet consumer expectations.

With the expansion of industries, the plate freezer demand will further take a rise. Enhanced freezing speed, energy efficiency, and automation technology are currently adopted by companies in light of productivity enhancement. Continuous innovations in freezing technology will thus develop systems that meet global high-product-quality demands.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,864.97 million |

|

Market Size by 2032 |

$4,645.00 Million |

|

Growth Rate from 2025 to 2032 |

7.2% |

|

Base Year |

2025 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The Global Plate Freezers market is geographical in nature, split into the most significant regions: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each region is a significant part of the industry ecosystem with respect to the different applicability of the segments, mainly food processing, seafood preservation, and pharmaceutical storage rooms.

The North America region includes the United States, Canada, and Mexico. This region is marked by a well-developed cold chain infrastructure and draws interest because of the plate freezer market. The major boosting factor is the increase in frozen food products and innovations in preserving foods. The market in Europe comprises the UK, Germany, France, Italy, and the rest of Europe. European performance continues to reinforce itself by food safety regulations putting healthy and high-quality food assurance into practice. Other factors that drive increased innovativeness in freezing solutions are the growing use of convenience food.

Asia-Pacific consists of major countries such as India, China, Japan, South Korea and many other countries in Asia-Pacific. Industrialization and urbanization have increased consumption of frozen products and thus raised needs for advanced freezing technology. The expansion of seafood exports in regions such as China and Japan also catalyzes demand for plate freezers. Steady growth is being experienced in this sector in South America, which also includes Brazil, Argentina, and other countries. This growth is attributed to the surge of investments in food processing industries. Demand for quality frozen products and improvements in cold storage are the major market drivers.

The environment of the Middle East & Africa is segmented into the GCC countries, Egypt, South Africa, and the rest of the region. The demand for plate freezers thrives with the rise in population growth, urbanization, and improved storage infrastructure. While the seafood and meat processing industries, which cannot do without the application of plate freezers, are majorly found in the GCC countries, it is the growing pharmaceutical sector that further addresses the issue of cold storage solutions, so enhancing the prospects of the market.

Each geographic segment presents its own unique opportunities and challengers, with varying levels of adoption and technological advancement. The Global Plate Freezers market, on the steady outlook, will register growth in all regions due to the increasing focus on food safety, preservation of quality, and efficient freezing solutions.

COMPETITIVE PLAYERS

The Global Plate Freezers market grows as more industries start relying on freezing solutions that are both efficient in long-term maintenance of product quality and extend shelf life. Plate freezers are at the forefront of rapid freezing applications in food processing, seafood conservation, and pharmaceutical application while retaining specific texture and nutritional value. As demand rises, technological improvements, energy efficiency, and automation are major areas some key players are currently focusing their attention on to modify their offerings further to meet the ever-changing needs of the consumers.

Some of the leading companies in the sector of plate freezers include DSI Dantech A/S, Jackstone Freezing Systems Ltd., and Optimar AS, establishing themselves as the frontrunners. Smart technologies together with improved refrigerants have become a priority for innovation among these manufacturers to reduce freezing time and energy consumption.

Significant developments have also been carried out by MHM Automation (Milmeq) and Beck Pack Systems A/S in the optimization of freezing systems to assure maximum reliability and cost-effectiveness for industries requiring freezing capacity at a large scale. As sustainability became an emerging concern, companies turned toward environmentally friendly refrigerants and energy-saving systems to ameliorate their environmental footprint while keeping as much productivity as possible.

In the seafood industry, the freshness of respective products is critical. Companies like Carsoe Seafood ApS and Shining Fish Technology Ltd. have developed advanced plate freezers capable of fast freezing without any loss in quality. Their equipment aids seafood processors in streamlining their operations and ensuring compliance with stringent food safety standards. Likewise, the likes of Teknotherm and Neptune Refrigeration Co. P. Ltd. make turnkey industrial freezing solutions specifically designed for the needs of different food processing sectors, providing equipment that ensures efficiency and minimizes losses.

Aside from food conservation, plate freezers also found fairly wide applications in the pharmaceutical sector, where maintaining temperature control is key to preserving the integrity of vaccines, biological samples, and medical supplies. Marefsol B.V. and Sartorius AG have developed advanced freezing technologies that meet these high-precision requirements and support medical research and healthcare facilities. Meanwhile, Barsso NV is leveraging the refurbishment of freezing machines, maintaining availability of advanced freezing technology for an increasing number of industries.

The Global Plate Freezers market promises a beneficial environment for further growth with the influx of technologies in this area. Companies invest heavily in R&D for designing more efficient, long-lasting, and eco-friendly freezing solutions. Barely anything else is available for industries to maintain product quality and shelf life while improving productivity and cutting energy costs. Having said that, with continuous innovations and the increasing sustainability consideration, the market expects steady growth innovations and increasing sustainability considerations bolstering the expected growth and further development of the Global Plate Freezers market.

Plate Freezers Market Key Segments:

By Type

- Horizontal Plate Freezers

- Vertical Plate Freezers

By Refrigerant Type

- Ammonia (NH₃)

- Carbon Dioxide (CO₂)

- Hydrofluorocarbons (HFCs)

By Application

- Seafood Freezing

- Meat Processing

- Dairy Products

- Fruits and Vegetables

By End-Users

- Food Processing Industry

- Cold Storage Facilities

- Fishing Industry

Key Global Plate Freezers Industry Players

- DSI Dantech A/S

- Jackstone Freezing Systems Ltd.

- Optimar AS

- MHM Automation (Milmeq)

- Beck Pack Systems A/S

- Carsoe Seafood ApS

- Shining Fish Technology Ltd.

- Teknotherm

- Neptune Refrigeration Co.P.Ltd

- Marefsol B.V.

- Sartorius AG

- Barsso NV

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252