MARKET OVERVIEW

In the future, new technologies will significantly reshape the MRO services landscape. Predictive maintenance based on AI and ML will be at the center of all operations. This will allow companies to predict failures of equipment even before they happen, hence preventing downtime and cost-involved repairs. Equipped sensors and data analytics will inform real-time information of what the equipment is doing, giving allowances toward the identification of performance issues and prompt interventions. The Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market is moving towards more automation-based data-driven maintenance which enables the operators to pool their efforts for continuous production.

The future MRO services market will be critical to the integration of sustainability and environmental considerations into operations. MRO service providers are expected to respond by taking environmentally friendly practices seriously as regulatory pressure intensifies and the need for greener practice grows. These service providers will introduce eco-friendly solutions such as materials and maintenance emission reduction. In a highly regulated sector, this trend towards sustainability will increasingly influence market strategies to gain competitive advantage.

Most importantly, the digitalization trend in the oil and gas sector will mean an increase in prospects for MRO services. The use of digital twins, virtual simulations, and augmented reality will improve maintenance strategies. Using these technologies, technicians can perform remote inspections and repairs that would reduce the need for their visits on-site while still significantly reducing operational risks. The remote monitoring systems will be integrated into centralized control rooms, which will efficiently monitor and control more than one location and piece of equipment.

Other factors influencing the Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market are changes in the dynamics of the workforce. There is a constant demand for skilled labor in the industry, and companies will invest more in training programs for technicians. This will be fueled by a focus on attracting the new talent generation with the benefit of state-of-the-art technology and innovation offered by MRO services. Meanwhile, the partnerships between MRO providers and equipment manufacturers will deepen in order to provide more integrated service packages, with the latest technologies and best practices being applied all along the board.

Global geopolitical developments and energy transitions will notably impact the market. With energy companies shifting toward alternative sources of energy, such as wind and solar, MRO services will diversify to cover renewable energy sectors. Offshore and deepwater oil and gas operations will expand and increase the demand for specialized MRO services designed for these challenging environments. Companies operating in these regions should focus on safety, reliability, and efficiency, and have MRO services as part of their business. Finally, in the future, there will be an end to the complexities and opportunities characterized by the rapidly changing energy landscape.

All this will define how MRO services are delivered and consumed owing to emerging technologies, sustainability initiatives, and changes in the workforce. In turn, such change in the industry would see the ever-growing importance of quality MRO services as those machinery that feeds the global economy keep running reliably, safely, and efficiently.

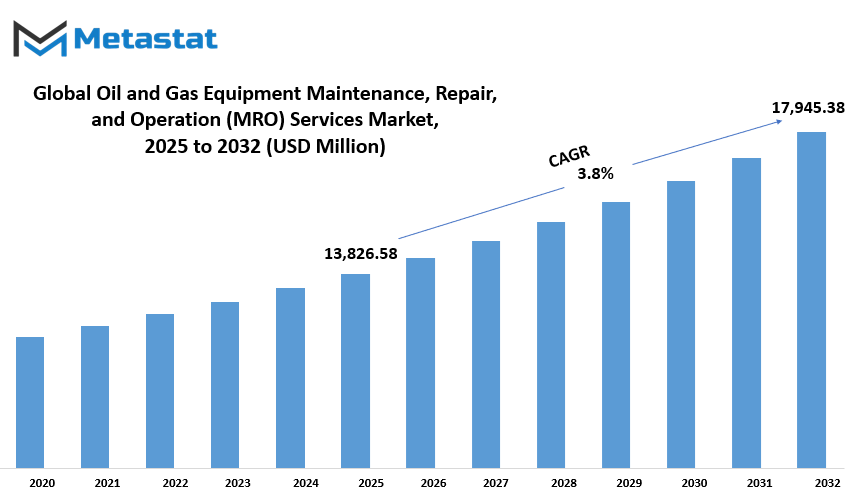

Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market is estimated to reach $17,945.38 Million by 2032; growing at a CAGR of 3.8% from 2025 to 2032.

GROWTH FACTORS

The Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market will keep molding the energy sector's dynamics by providing crucial support to operations concerning oil and gas production, exploration, and transportation. As the oil and gas sector becomes more sophisticated, companies will increasingly leverage MRO services to keep their equipment safe, operational, and efficient. These services will extend beyond simple repair and will become a critical component in the process of extending the life and reliability of equipment in some of the most demanding environments.

The global market of oil and gas equipment MRO services is expected to grow through the rising need for energy production and the constant searching for new discoveries of oil and gas. A world that gets more dependent on these resources, powering industries and transportation and serving homes, further increases the need to assure that oil and gas facilities would run smoothly. The growing interest in enhancing the operational efficiency and safety standards is also given importance in the industry. Operating at a high risk level, along with productivity, requires assessment in order to adhere to strict regulatory compliance, which develops the MRO services market.

Some challenges are there in this market that will slow down the expansion of its growth. The highly cost-intensive aspects of advanced maintenance technologies and the skilled labor that is required to implement these technologies are more severe issues. These technologies improve efficiency and reduce downtime, but they are also very expensive. Moreover, the complexity of maintaining modern oil and gas equipment requires a high-skilled workforce, further compounding operational costs.

Another concern is the volatility of crude oil prices, which can influence investments in maintenance activities. When oil prices fluctuate, companies may delay or scale back on investments, including MRO services, as they try to navigate the uncertainty in the market.

Even with the challenges ahead, there are opportunities that may give way for growth in the industry in the coming years. Predictive maintenance techniques and the use of IoT in the monitoring of equipment will transform the market. Predictive maintenance will enable companies to anticipate equipment failure, hence saving them from losing valuable time and further prolonging the lifespan of equipment.

Real-time monitoring with IoT solutions keeps track of performance and conditions and ensures the best management of the equipment, so there is faster reaction to the issues that have occurred. These advancements could not only reduce costs but also improve safety, ultimately benefiting the MRO services market.

In summary, though the global oil and gas MRO services market faces such challenges as high operational costs and fluctuating oil prices, the need for energy, coupled with safety and operational efficiency, continues to fuel growth. Technologies such as predictive maintenance and IoT monitoring promise a promising future and could drive market expansion in the coming years.

MARKET SEGMENTATION

By Type

The global market for Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) services is vast and encompasses several different types. Among those, the biggest is the Gas Turbine MRO segment with a value of $4,026.03 million. Since the elements of maintaining, repairing, and operation of equipment in the oil and gas industry are involved, all its activities must be considered. These are fundamental components of ensuring operational efficiency and safety.

The gas turbines are one of the very most essential machines applied in the industry. They are utilised considerably in power generation, mechanical drives, and many more operations. Because of their applications, maintaining these turbines is very essential in the daily functioning of the industry. These services in gas turbines for maintenance, repair, and operation services are essential in order to optimize performance and extend the life span. This is the largest part of the overall MRO market, and further growth on its part is reflective of the need for reliable energy production in the oil and gas sector.

Besides gas turbines, the report also incorporates Oil and Gas Equipment MRO. This segment deals with the critical machinery and equipment used to extract, transport, and process oil and defines and encompasses the maintenance and repair activities associated with it. Most of the equipment, including pumps, compressors, valves, and drilling rigs, require scheduled maintenance so these parts will operate and function correctly and safely.

Usually, oil and gas operations occur in harsh locations and remote locations, and any equipment failure on their part necessitates proper and excellent maintenance for the prevention of costly downtime as well as a possible safety issue. It's simply because of the increased energy requirement, for which oil and gas equipment MRO services is required, to get the best service and, thus, continued growth.

Lastly, the Plant and Facility MRO segment includes the maintenance of oil and gas facilities such as refineries, processing plants, and storage facilities. These types of facilities need to be constantly kept up to running order and repaired to avoid interruptions in operations. The demand for MRO services is rising due to the increasing global energy demands and stricter safety and environmental regulations.

Together, the three segments are Gas Turbine MRO, Oil and Gas Equipment MRO, and Plant and Facility MRO. These form the heart of the global Oil and Gas Equipment MRO market, as the demand for oil and gas continues to be met for the world's energy needs. Therefore, these services will become all the more significant as equipment and facilities continue to be kept functional and efficient.

By Application

The Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market is growing significantly with the rising demand for efficient and reliable services in the industry. The market that deals with maintenance, repair, and operational support for critical equipment is categorized into several significant applications. Onshore facilities, offshore facilities, refineries, petrochemical plants, LNG facilities, and power generation plants are very critical applications in terms of supporting global energy infrastructure.

A larger market share accounts for onshore facilities. Such facilities are set on land and have oil and gas extraction and processing activities. Demand for MRO services in the onshore facility arises from keeping the equipment fit for operation without a potential possibility of downtime affecting the productivity output. Maintenance and repairs ensure a prolonged equipment life span, minimize operation risk, and optimize the total efficiency of operations at onshore locations.

Specialized MRO services are required for offshore facilities because the environments in which they operate can be particularly challenging. Most offshore facilities are located in water bodies, quite far from the shore, so maintenance and repairs are more difficult. Skilled technicians and reputed service providers have to be available to ensure that the operations go on without interruption under such challenging conditions. MRO services for the offshore facility should ensure the safety and integrity of equipment and personnel, reduce the risks of accidents, and reduce operational costs.

Other huge industries that have a vital role to play by MRO services are refineries and petrochemical plants. These facilities upgrade crude oil and natural gas to various finished products including fuels and chemicals. Refineries and petrochemical plants are operations so complex and vast that equipment failures can only be avoided with routine maintenance and timely repairs, otherwise stoppages in operations. This means that the MRO services help keep the production running by ensuring that equipment is in good condition and, therefore, safety measures and environmental regulations are upheld.

LNG facilities that process and deliver liquefied natural gas also heavily depend on MRO services. Such facilities require highly specialized maintenance support, since the complex machinery used in LNG production, storage, and transport demands specific, advanced-level knowledge for the management of their equipment. Preventive maintenance and timely repairs would avoid costly delays and ensure safety of operations in cases where any malfunction may mean severe loss.

The final important area is the power generation plants, which fuel demand for MRO services. Power generation plants rely on large-scale equipment and machinery for electricity generation. Preventive maintenance is critical in preventing breakdowns and ensuring power generation without disruption. The productivity of power generation plants is correlated with the degree of equipment maintenance, and, therefore, MRO services play a critical role in optimizing operations while minimizing downtime.

By End User

The global Oil and Gas Equipment Maintenance, Repair, and Operation market is one of the main sub-segments in the energy sector. It performs the critical functions required for equipment safety and effective production, transportation, refining, and energy generation through oil and gas. The market is broken down into diverse end-user segments such as producers of oil and gas, midstream operators, operators of refineries, petrochemical companies, and companies engaged in energy and power generation, together with owners and operators of industrial equipment.

Oil and gas producers with significant presence employ MRO services for maintenance purposes of the drilling and exploration and extraction apparatus. The services thus offered are required to minimize down time, for safety, and for maximum output extraction. Other than that, midstream operators, which manage oil and gas in pipelines, including storage facilities and terminals, would need ongoing maintenance and repair services as well. If the flow of oil or gas is disrupted in any way, it results in very heavy financial losses and operational delays. Thus, reliable MRO services are more than crucial for maintaining this infrastructure for transporting.

The producers of MRO services benefit from the activities of refinery operators, which ensure that the involved equipment works as expected. In a refinery, processes basically transform crude oil into various other products, such as gasoline, diesel, and other petrochemical products. The involved refining processes are complex and therefore require maintenance and repair procedures for safety purposes and efficiency. Petrochemical companies, which manufacture chemicals from oil and gas, also need MRO services to maintain their machinery and facilities in proper working order. Efficiency is crucial in such industries because equipment failure can result in production delays and financial losses.

Energy and power generation companies are another important end-user group in the MRO market. These companies often maintain large, complicated systems that power electricity from many different energy sources, including oil and gas. Periodic maintenance should be performed so that unexpected shutdowns do not occur, which might impact the provision of power, leading to possible financial losses.

Industrial equipment owners and operators-including manufacturing, among other heavy industries-need MRO services to maintain equipment used in operations. Prevent downtime, elongate the equipment lifetime, and have fewer possibilities for expensive repair - these services assist in accomplishing all these requirements.

By Oil and Gas Equipment MRO

On an overall scale, the oil and gas MRO market worldwide has different types of sectors requiring MRO to get their operation back on track. Be it any production, transport, refinement, or electricity generation, the oil and gas sectors require MRO services in various forms.

The Global Oil and Gas Equipment MRO Market plays an essential role in keeping the smooth working of the industry. It further sub-categorized on the basis of different kinds of equipment being required to maintain and repair, the primary types of equipment that have been classified include pumps, compressors, valves, heat exchangers, boilers, and many more. Each of these parts is vital for the overall operation of oil and gas operations, and regular maintenance is necessary to avoid costly downtime or breakdowns.

Pumps are among the essential apparatus in the oil and gas sector since they transport liquid and gases. Malfunction of pumps will greatly cause operational delay; therefore, maintenance and repair services are quite crucial in maintaining their functionality. Their efficiency and reliability require frequent checks, lubrication, and changing parts.

Another vital equipment in the industry is compressors that increase the pressure of gases for transportation or processing. Such machinery should be frequently serviced so as not to allow problems that might bring costly operational breakdowns. Traditionally, compressor maintenance entails checking on leaks, perfecting the configuration of pressure, and replacing any worn parts.

Valves are used to regulate the flow of liquids and gases in various systems in the oil and gas industry. Since they control the passage of substances under high pressure, maintaining their proper functioning is crucial for safety and efficiency. Valve repair and maintenance often involve sealing, cleaning, and replacing damaged components to prevent leaks and malfunctions.

Heat exchangers, where the heat from one fluid is transferred to another, also require routine servicing. Gradually, they start collecting dirt and scale which leads to increased cost of operations while reducing efficiency. Heat exchanger maintenance entails cleaning, inspection of corrosion and parts replacement in case they wear out to allow the efficient transfer of heat.

Boilers are other critical equipment involved in oil and gas operations and are used in the generation of steam for process use. There is a high possibility of the boiler failing and hence needs regular monitoring. Leakage, burner, and faulty part replacement are just some of the regular maintenance routines to ensure proper operation of the boiler.

Apart from these categories, other equipment in the oil and gas sector also require regular maintenance and repair to avoid disruptions in production. With a growing focus on operational efficiency, the global Oil and Gas Equipment MRO Services market continues to expand, providing essential services to keep the industry running smoothly.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$13,826.58 million |

|

Market Size by 2032 |

$17,945.38 Million |

|

Growth Rate from 2024 to 2031 |

3.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

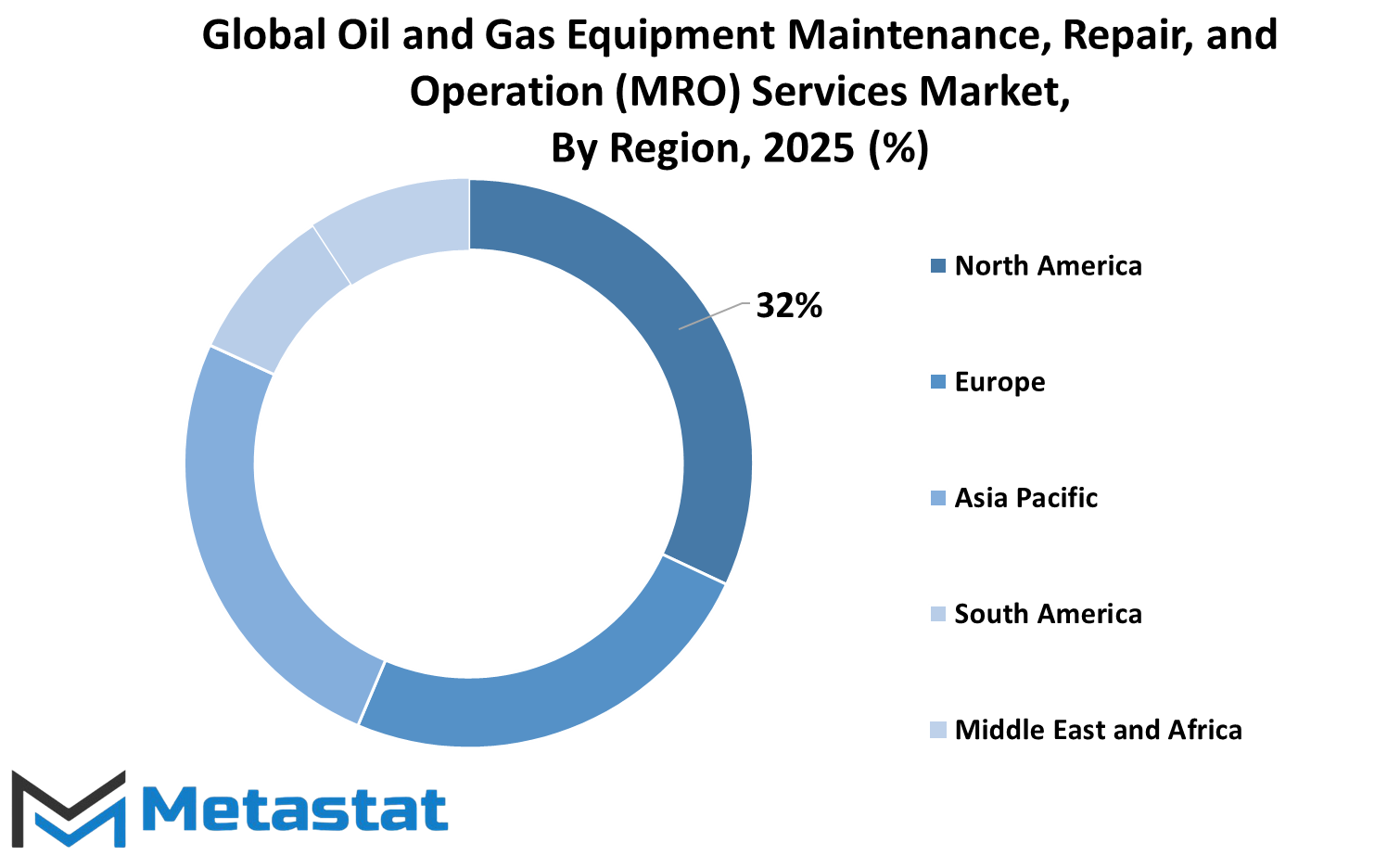

Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services market can be segmented based on geography into several regions, each subject to distinct operating factors and market forces. These include North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

It is divided into three major countries in North America: the United States, Canada, and Mexico. Every country has its own requirements with different regulations, therefore the total demand for MRO services in this region has been raised. The U.S. is one of the major consumers of oil and gas equipment. Canada and Mexico also make a significant contribution to this market due to the presence of lots of reserves and increasing infrastructure.

The MRO services market also has Europe as another major region, and this region further divides into countries like the United Kingdom, Germany, France, and Italy. The "Rest of Europe" category is used for countries not mentioned but are relevant to the general market landscape. The oil and gas industry in Europe also faces all its challenges, such as regulation change, which directly impacts the demand for oil and gas equipment for maintenance and repair services. Therefore, this market is significantly impacted by these influences.

In the Asia-Pacific region, the market is segmented into countries like India, China, Japan, South Korea, and the wider Asia-Pacific region. This is because the region industrializes rapidly, and energy usage increases. One good example is that China is the world's second-largest oil consumer and producer and thus has big investments in equipment for oil and gas. Moreover, India and Japan, as their energy market expands, give way to increasing MRO service.

South America, comprising Brazil, Argentina, and the Rest of South America countries, is another area of interest. Countries like Brazil are rich in oil are creating a need for MRO services. Exploration and drilling activities are constant, which generates the need for maintenance and repair.

The Middle East & Africa region further divides the scope into the four regions GCC Countries, Egypt, South Africa, and remaining Middle East & Africa. Saudi and UAE are key markets in this list of Oil and Gas market which drives its main demand for MRO services. Oil reserves, thus, as an enormous amount here is coupled with ever-growing activity into exploration -maintenance, repair and operational support -will not find a negligible spot in such high numbers.

The unique features of each geographical region thus affect the demand for global MRO services, driven by factors like production capacity, technological advancement, and government regulatory framework.

COMPETITIVE PLAYERS

Oil and gas equipment maintenance, repair, and operation is one of the major markets related to the effective, uninterrupted working of oil and gas operations in the whole world. MRO-related services keep on arising in the oil and gas industry as it requires maintenance, repair, and operation of equipment used in exploration, production, and transporting processes. It helps to reduce downtime, maximizes efficiency, and increases the life cycle of machinery and equipment.

The most prominent players in the global MRO services market of oil and gas equipment are mature companies, including General Electric (GE), Schlumberger, and RWG (Repair & Overhauls) Limited that provide services across a range, starting from maintaining and repairing critical equipment such as pumps, compressors, and turbines. Such experience is indeed necessary to ensure the operation goes as smoothly and safely as possible without a chance of any sort of operational disruption.

Other notable contributors to this market are Neptunus Power, Henkel Adhesives Technologies India Private Limited, Linde PLC, ABB Ltd., and Oceaneering International, Inc. Neptunus Power holds a reputation for the most advanced repair and maintenance of power generation equipment. Henkel Adhesives Technologies India Private Limited is specialized in high-quality adhesives and sealants, particularly for the oil and gas industries. Linde PLC, ABB Ltd., and Oceaneering International Inc. emphasize equipment maintenance, repair, and operational solutions among the demanding industry standards.

Baker Hughes Company and Aker Solutions also play important roles in the MRO services market. Baker Hughes offers several services relating to oilfield equipment and infrastructure maintenance while Aker Solutions provides full-scale maintenance services looking to optimize the performance of oil and gas assets. Contributions from these companies are vital in ensuring the optimal operational efficiency of oil and gas assets and safe and reliable production.

The global MRO services market for oil and gas equipment is a very competitive arena that involves an extensive variety of players. As stated above, these companies have an important role in providing the industry with maintenance, repair, and operational solutions for its smooth-running nature. This, therefore, increases the demand for reliable MRO services with energy demand still going high. In fact, these companies are a significant component in ensuring the continuous prosperity and stability of the oil and gas sector.

Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services Market Key Segments:

By Type

- Gas Turbine MRO

- Oil and Gas Equipment MRO

- Plant and Facility MRO

By Application

- Onshore Facilities

- Offshore Facilities

- Refineries

- Petrochemical Plants

- LNG Facilities

- Power Generation Plants

By End User

- Oil and Gas Producers

- Midstream Operators

- Refinery Operators

- Petrochemical Companies

- Energy and Power Generation Companies

- Industrial Equipment Owners and Operators

By Oil and Gas Equipment MRO

- Pumps

- Compressors

- Valves

- Heat Exchangers

- Boilers

- Other

Key Global Oil and Gas Equipment Maintenance, Repair, and Operation (MRO) Services Industry Players

- General Electric (GE)

- Schlumberger

- RWG (Repair & Overhauls) Limited

- Neptunus Power

- Henkel Adhesives Technologies India Private Limited.

- Linde PLC

- ABB Ltd.

- Oceaneering International, Inc.

- Baker Hughes Company

- Aker Solutions

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252