MARKET OVERVIEW

The global NdFeB permanent magnets market is on track to increase its impact in many industrial scenarios, indicated on a comprehensive spectrum of use compared to currently viewed use with emerging applications. As industries prepare for more energy-efficient systems and mild technologies, the demand for materials such as neodymium-iron-boron (NDFEB) magnets will be likely to move from traditional roles to less estimated directions. While their appearance in motors, sensors and electronics is well documented, the way forward will see them embedded in areas where their high magnetic performances provide unique benefits that have not yet been fully detected.

One of the most promising areas lies in the miniature of medical technologies. While clinical instruments already use magnet-based components, NDFEB magnets will gradually be required in compact surgical devices and implanted systems. Without adding bulk, the strength and efficiency they bring make them an ideal match for a medical industry that is looking to innovate through size and innovation through accuracy. Magnetically controlled drug distribution systems and advanced neurostimulation transplant will potentially benefit from unique magnetic stability of NDFEB compositions.

Another dimension where the global NdFeB permanent magnets market is in aerospace engineering, especially in satellite propulsion and stabilization systems. These components demand durable and light magnetic materials capable of working under excessive temperature and vacuum conditions. The push running towards small and more cost -effective satellite constellations can lead to more use with NDFEB magnets due to their power density and performance stability.

In the consumer electronics sector, further travel suggests that a change has been suggested to enable completely new tasks from being part of existing equipment. Since wearable technologies become more advanced, NDFEB Magnets can create a magnetic infrastructure behind the gesture-controlled interface or magnetic power transfer system that charge many devices wirelessly in a local area. Their strength-to-size ratio opens the doors for innovation in form factor, user interaction and convenience. While in many cases it is still conceptual, the foundation is being laid for such a technique, and NDFEB Magnet can be at their core.

On a large-scale, the discovery of permanent infrastructure is likely to create unexpected locations for magnet-based systems. Architects and engineer are increasing interest in magnetism to reduce friction in construction materials, to detect magnetic lensing systems in transport corridors or increase accountability of smart urban structures. Although such applications can now seem to be in the form of a future, next decades can see the integration of magnetics in areas where mechanics were previously dominated.

The global NdFeB permanent magnets market, therefore, will not be limited to current industrial boundaries. This rapid shape and support will support technologies that are still in development or are still imagined. As industries pive towards optimization, performance and stability, this market will find itself in a company of innovations that less rely on historical demand and can enable maximum magnetic capabilities.

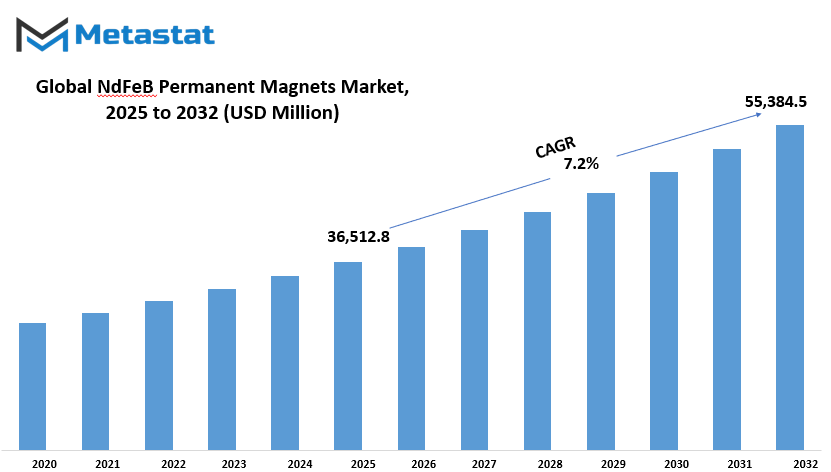

Global NdFeB permanent magnets market is estimated to reach $55,384.5 Million by 2032; growing at a CAGR of 7.2% from 2025 to 2032.

GROWTH FACTORS

The global NdFeB permanent magnets market will show major changes in the coming years in the market, which are inspired by increasing demand from rapidly growing areas. The biggest reason behind this growth will be the increasing requirement of powerful magnets in electric vehicles and renewable energy systems. These play an essential role in improving magnets performance and efficiency, especially in the motorcy and generator used in electric mobility and clean energy. As the world continues to move towards more durable practices, the industry will be bent over materials that can distribute strong magnetic properties in small and light forms. NDFEB magnets will become even more important to meet this requirement.

Another major factor supporting the market will be their widespread use in consumer electronics. As gadgets become small and smarter, the need for compact and efficient components will increase. NDFEB Magnet would be a favorite option for manufacturers who want to make products that are both powerful and space-saving. Smartphones, speakers, laptops and even wearable equipment rely on these magnets for performance in advance, and this trend will continue.

Despite these positive signs, the market is not without its challenges. The high cost of rare-earth materials used in creating NDFEB magnets can slow down adopting. These materials are expensive to extract and process, and their availability is limited. This deficiency can lead to unstable pricing, making it difficult for some industries to manage long -term supply. Additionally, environmental and geopolitical concerns around rare-earth mining will cause additional pressure on the market.

However, there will be some promising developments that may reduce these issues. One of the most important magnet recycling technology will progress. By recovering rare-earth material from the magnets used, manufacturers will be able to reduce dependence on mining. This approach will not only help the environment, but will also provide a more stable and cost -effective supply chain. As research continues and recycling methods improve, it can open new doors to companies that are looking to maintain stable production without contribution in resource shortage.

While in summary, while the global NdFeB permanent magnets market future will probably be shaped by innovation, increasing demand and smart strategies to deal with supply limits.

MARKET SEGMENTATION

By Type

The global NDFEB holds strong importance in the permanent magnet market material industry, roughly due to its unique magnetic properties and required use in many applications. As industries lead to more compact and efficient technologies, this market will find itself fast relevant. NDFEB Magnets, NEODYMIM, Iron and Boron are the strongest types of permanent magnets and are widely used in various fields, including electronics, automotive, wind energy and medical equipment. Their ability to generate a high magnetic field in small sizes suits them for devices that require accurate and reliability.

The global NdFeB permanent magnets market is divided by types in the Sinted NDFEB magnet and bonded NDFEB magnets. Out of these, sinters NDFEB Magnets hold a large share with a price of $ 15,152.8 million. These magnets are known for their high magnetic power and are usually used in applications that demand strong performance under pressure, such as electric motors and generators. On the other hand, bonded NDFEB magnets are produced using a separate process where the powder form is mixed with resin or plastic. While they are not as strong as sinful magnets, they offer design flexibility and mold in complex shapes, making them more suitable for small and more specific uses such as sensors or computer hard drives.

As the demand for electric vehicles is increasing, the use of NDFEB magnets in their motors will also increase. These help to improve magnets energy efficiency, which is an important feature in battery powered vehicles. Pawan turbines also benefit from these magnets as they help reduce mechanical damage and maintain consistent performance. Additionally, the electronics industry depends on them for speakers, smartphones and other portable devices where space is limited but performance is non-paralysis.

Despite being valuable, the production of NDFEB magnets also brings some concerns. The raw materials used are mined in most limited areas, and this can cause supply chain instability or ups and downs. In response, efforts will be made to develop recycling technologies or find substitute materials, although the efficiency of NDFEB Magnet makes them difficult to completely change. The purpose of innovations in manufacturing is to reduce physical waste and improve performance.

Overall, the global NdFeB permanent magnets market will continue to grow and modern technology will suit the needs. Its use in advanced machinery and electronic devices will make it an important material for future development.

By Application

The global NdFeB permanent magnets market is expected to grow in various applications, especially in motors and generators, sensors, acoustic equipment, magnetic resonance imaging (MRI), and other industrial and consumer sectors. As the technology continues to move, these magnets will play more important role in shaping the efficiency, design and stability of many modern products and systems.

NDFEB, small for Neodiyum-Ayron-Boron, magnets are known for their strong magnetic power. Due to this strength, they are widely used in motors and generators, where there are high performance and compact -sized cases. For example, electric vehicles, these magnets rely too much so that the size and weight of the vehicle can be efficiently given electricity to your motors. As more people and governments focus on switching on electric vehicles, the demand for such magnets will continue to increase. Similarly, wind energy, they help improve the efficiency of magnet turbines, reduce mechanical damage and make renewable energy systems more productive.

In the field of sensors, NDFEB Magnets will support better performance and miniatures. From anti-lock braking systems such as automotive applications to smartphones such as consumer electronics, these magnets enable accurate sensing and rapid response time. Since industries continue to work towards smart and automated solutions, the sensors using these magnets will become more common and necessary.

Acoustic equipment, such as speakers and headphones, also rely on these magnets to give clear and powerful sounds. Their strength allows for the manufacture of light and high quality sound systems. This has become rapidly important because consumers want better audio experiences in compact devices. In magnetic resonance imaging (MRI), NDFEB magnets are important for their ability to generate strong magnetic fields required for imaging. Although other magnet types are also used in the MRI system, NDFEB provides benefits in new, more compact designs that can be developed in the future.

In addition to these primary areas, there are many other uses for NDFEB magnets in robotics, aerospace and even home appliances. His ability to reduce energy consumption and improve performance makes him a popular option in various industries. The future of the global NDFEB permanent magnet market will depend on continuous innovation, efforts to recycle rare earth materials and push for more energy-skilled technologies in every field.

By End-User

The global NdFeB permanent magnets market will continue to grow in different fields, bringing its set of demands and expectations with each end-usage industry. These magnets, which are known for their strong magnetic properties and resistance to demanganization, will be important in developing technologies, which require compact and efficient energy solutions. In the automotive industry, high -performance electric motors in electric vehicles will push manufacturers to look for advanced magnet solutions such as NDFEB. As more consumers and governments move towards cleaner transport options, electric vehicles will become more normal, and it will naturally increase the demand for these magnets. Magnet's strength and efficiency will help vehicle manufacturers in design motors that are both powerful and light, which will be necessary to improve the vehicle range and performance.

In electronics, the model of devices will continue to shape the product growth. NDFEB magnets will be useful in everything from smartphones to advanced computing systems, due to their size and strength. Companies will aim to improve the user experience by offering small, faster and more competent devices. As this trend increases, these magnets will probably be a main component in ensuring that these compact electronics can still act efficiently. The same argument applies to the energy field, where wind turbines and other renewable technologies will rely on powerful magnets to convert energy more effectively. This will support changes in more sustainable energy sources without compromising efficiency.

Industrial machinery segment will also use NDFEB magnets to improve productivity and accuracy in equipment and equipment. At a time where efficiency and low energy consumption matters more than ever, businesses will seek clever and fast operating methods. These magnets will help by supporting machines that require reliable and strong magnetic fields. In medical devices, especially in imaging and clinical devices, the stability and strength of these magnets will ensure better results and accurate readings. The healthcare industry will depend on such improvements to offer better care with rapid diagnosis.

Finally, aerospace and defense sector will use these magnets to improve communication systems, navigation equipment and other advanced technologies. In these regions, weight, power and reliability are all important. NDFEB Magnet will offer solutions to meet these needs. In all other industries, their application will depend on the demands of the specific project, but their value will continue to grow in the form of technology and innovation boundaries.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$36,512.8 million |

|

Market Size by 2032 |

$55,384.5 Million |

|

Growth Rate from 2025 to 2032 |

7.2% |

|

Base Year |

2024 |

|

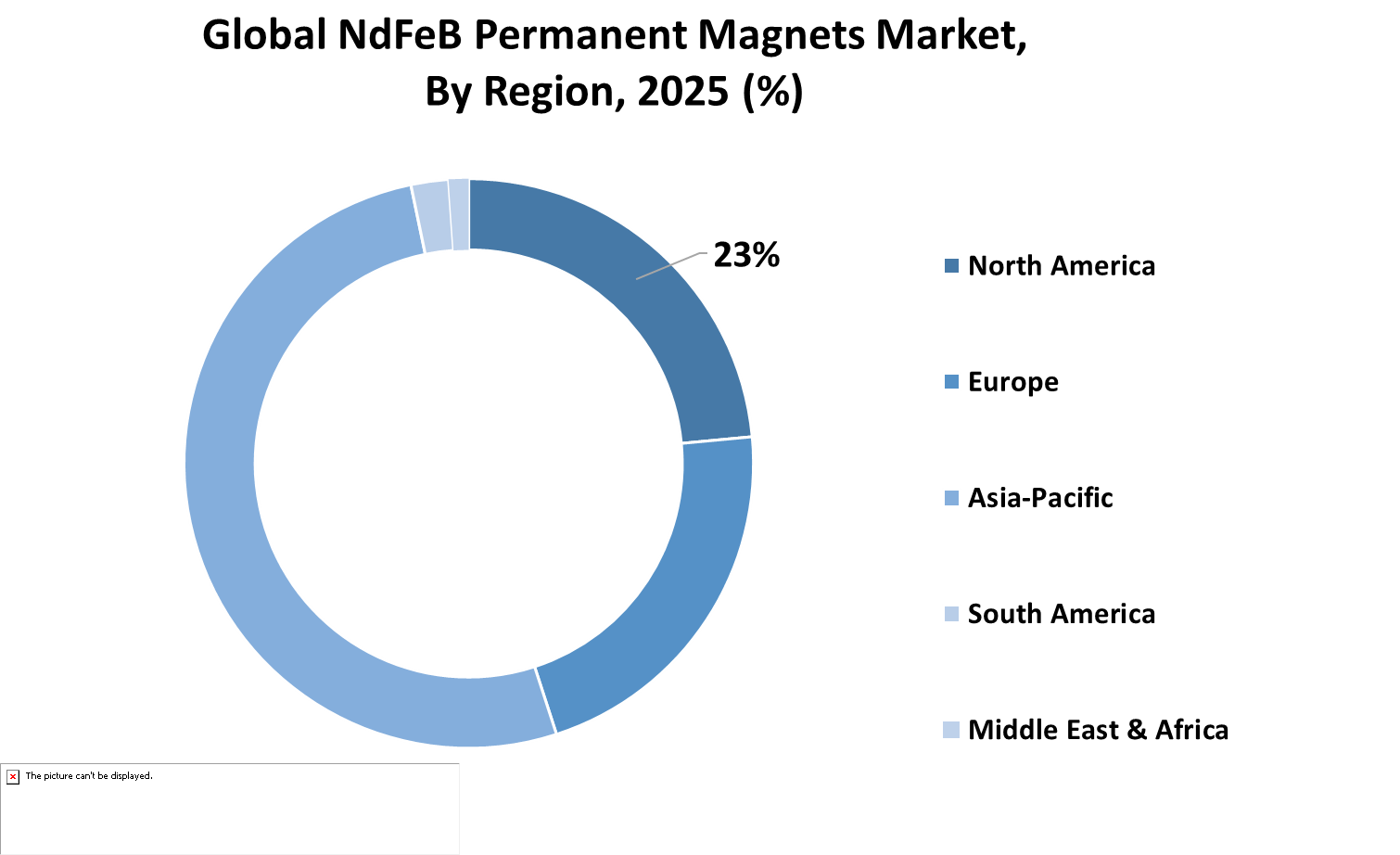

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global NdFeB permanent magnets market is geographically divided into several major regions: North America, Europe, Asia-Pacific, South America and Middle East and Africa. Each region has unique features that will continue to shape the development of the market. In North America, countries such as the US, Canada and Mexico are expected to show stable demand. U.S. due to its strong base in automotive, electronics and renewable energy sectors. Probably will lead, where NDFEB magnets are widely used. Canada and Mexico will also contribute to the market with their growing focus on green technologies and industrial applications.

Europe includes countries such as UK, Germany, France, Italy and other parts of the continent. Germany is estimated to be one of the major contributors in the region due to its advanced manufacturing and electric vehicle industries. France and the UK will also play an important role in the expansion of the global NdFeB permanent magnets market, for investments in clean energy and technological innovation. Italy and the rest of Europe are expected to add value to the market as the demand increases in areas such as consumer electronics and healthcare equipment.

Asia-Pacific is likely to see the most significant growth due to the presence of countries like India, China, Japan and South Korea. China will be not only a major consumer but also as the leading manufacturer of NDFEB Magnet. Its industrial scale, strong infrastructure and local availability of raw materials make it a central part of the global supply chain. India is expected to grow as domestic manufacturing growth and demand for electronics and automotive products are focused on. Japan and South Korea are known for their technology and innovation, market will continue to contribute to progress.

In South America, Brazil and Argentina are expected to support the market through their motor vehicle areas and increase energy-skilled solutions. Brazil, in particular, can see more demand as it invests in wind energy and electric mobility. The rest of South America will gradually participate as industries adopt more modern technologies.

The Middle East and Africa consists of GCC countries, Egypt, South Africa and other nations in the region. South Africa and GCC countries are expected to increase demand with industrial development and growing push towards renewable energy projects. Egypt and the remaining countries in the region can also witness market expansion as infrastructure and increase in technology investment.

COMPETITIVE PLAYERS

The global NdFeB permanent magnets market will be shaped by the functions and strategies of the major players who have long dominated the industry. These companies include well-installed names such as Hitachi Metals, Limited, Shin-Itu Chemical Company, Ltd., TDK Corporation, and Vacumskelz GMBH & Company Kilo. Their influence stems from years of research, development and innovation that enabled them to make magnets with high strength and performance capabilities. Other major participants, such as Ningbo Yusheng Co., Ltd, Beijing Zhong's San Huan High-Tech Co., Ltd., and Advanced Technology and Materials Company, Limited (AT & M), will also play an important role in shaping how the market moves forward, especially as the demand for skilled and sustainable technologies.

These magnets are used in various fields, such as consumer electronics, automotive, medical devices, and renewable energy systems. As the purpose of industries is to increase the efficiency of motors and electronic components, the relevance of NDFEB magnets will become even more noticeable. Zhejiang Innuovo Maggetics Co., Ltd., Ningbo Ketian Magnet Co., Ltd., and JPMF Guangdong Co., Ltd. As companies are expected to be actively involved in meeting these needs, ensuring that both supply and quality on competitive standards are maintained.

Arnold will continue to contribute to small firms, global landscapes including Magnetic Technologies Corporation, Bunting Magnetics Company, Moleicorp Inc., and Adams Magnetic Products, Inc. Their strength is often in customizing the solution for top applications or regional markets, and this adaptability will support the broader industry. In addition, companies such as Electron Energy Corporation, Deaddo Steel Company, Limited, Alliance LLC, UMAG, and NeoM Magnet Oi will continue to support innovation by focusing on special alloys, advanced processing methods and improving performance.

As the market moves forward, these companies will invest more in refining production techniques and improving the environmental footprint of magnet construction. The use of rare earth materials has increased environment and supply concerns, which are addressed through many of these firm recycling initiatives and alternative material research. In this context, cooperation between manufacturers, suppliers, and final-use industries will be important. Overall, the collective efforts of all these players will affect how skill and continuity the global NdFeB permanent magnets market develops in the coming years.

NdFeB Permanent Magnets Market Key Segments:

By Type

- Sintered NdFeB Magnets

- Bonded NdFeB Magnets

By Application

- Motors and Generators

- Sensors

- Acoustic Devices

- Magnetic Resonance Imaging (MRI)

- Others

By End-User

- Automotive

- Electronics

- Energy

- Industrial Machinery

- Medical Devices

- Aerospace & Defense

- Others

Key Global NdFeB Permanent Magnets Industry Players

- Hitachi Metals, Ltd.

- Shin-Etsu Chemical Co., Ltd.

- TDK Corporation

- Vacuumschmelze GmbH & Co. KG

- Ningbo Yunsheng Co., Ltd.

- Beijing Zhong Ke San Huan Hi-Tech Co., Ltd.

- Advanced Technology & Materials Co., Ltd. (AT&M)

- Zhejiang Innuovo Magnetics Co., Ltd.

- Ningbo Ketian Magnet Co., Ltd.

- JPMF Guangdong Co., Ltd.

- Arnold Magnetic Technologies Corporation

- Bunting Magnetics Co.

- Molycorp Inc.

- Adams Magnetic Products Co., Inc.

- Electron Energy Corporation

- Daido Steel Co., Ltd.

- Alliance LLC

- UMAG

- Neorem Magnets Oy

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252