MARKET OVERVIEW

The global industrial power tools market will keep to extend its have an impact on far beyond conventional programs and production landscapes. As a essential factor of the economic tools enterprise, this market will shape how operations unfold in excessive-call for sectors together with automotive, aerospace, shipbuilding, and infrastructure tasks. While its ancient cognizance has targeted on improving mechanical efficiency and lowering manual hard work, the approaching years will take the marketplace into directions that redefine its relevance and functionality on a broader scale.

The market will circulate closer to integrations that align with superior technology with out being restricted to smart factories by myself. It will embed itself in broader ecosystems, contributing to remote maintenance competencies, area operations in intense environments, and hybrid strength packages. Industrial sectors working in offshore drilling structures or excessive-altitude creation web sites will rely on tailored strength equipment that deliver not best overall performance however adaptability to non-widespread environments. This will function the global industrial power tools market as a middle enabler of excessive-chance discipline sports.

Another shift so one can push the boundaries of this market will come from emerging markets in which infrastructure demands might be inconsistent and frequently rugged. Here, durability will now not be a premium characteristic but a need. Power equipment in these areas will need to function independently of based electricity deliver chains, introducing innovations that prioritize portability and sustainable electricity utilization. In response, manufacturers will put money into structures that allow for dual-energy functions, prolonged battery overall performance, and compact ergonomic designs meant for severe, prolonged use below minimal aid situations.

Beyond operational usage, the identity of the economic strength device itself will go through transformation. It will now not be perceived really as a piece of hardware. It might be considered a records-producing node that could relay comments on wear, torque tiers, and usage periods. This transition could be enabled via embedded diagnostics, real-time sensors, and compatibility with principal facts systems. The global industrial power tools marketplace will therefore enter an intersection between mechanical engineering and statistics intelligence, shifting closer to predictive performance models and proactive protection alerts that enhance safety margins and reduce operational downtime.

At the global alternate stage, policy frameworks and labor rules will play an indirect but definitive role in shaping destiny demand. As exertions legal guidelines shift in reaction to fitness and protection issues, industries will demand power tools that minimize consumer fatigue and offer greater manipulate precision. This call for will no longer stem from innovation on my own however from compliance pressures, requiring worldwide providers to revisit center design philosophies. Accordingly, the global industrial power tools marketplace will embed compliance as a design principle, producing equipment that reply to both technical requirements and human-centric usability.

The coming decade may even witness this market's alignment with educational establishments and vocational education facilities. These tools will now not be extraordinary to expert websites however will appear in getting to know environments wherein destiny workforces are educated. As a result, their evolution will replicate not simply industry demand but also instructional dreams and curriculum systems.

The global industrial power tools marketplace, therefore, will amplify a long way beyond production floors. It will take on new obligations, input unusual settings, and assist missions some distance eliminated from its current footprint—redefining what business electricity tools are anticipated to acquire.

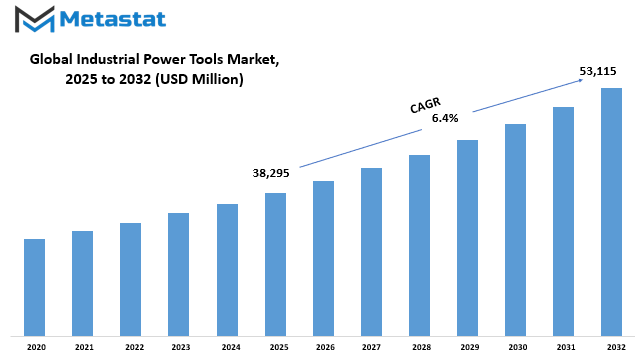

Global industrial power tools market is estimated to reach $53,115 Million by 2032; growing at a CAGR of 6.4% from 2025 to 2032.

GROWTH FACTORS

The global industrial power tools market is strongly inspired by means of the tempo of industrial boom and the continuing improvement of infrastructure projects round the arena. As extra international locations cognizance on expanding their production sectors and building new facilities, the need for powerful and green tools becomes greater vital. Industrial electricity equipment are used widely in construction, car, aerospace, and other sectors where velocity, precision, and sturdiness are essential. One of the primary motives this marketplace will hold growing is the expanded awareness on improving productiveness and decreasing guide effort in work environments. Manufacturing plants and manufacturing gadgets are continuously seeking out approaches to paintings quicker with out compromising on excellent, and these tools help attain that purpose.

At the identical time, the marketplace faces a few challenges that would gradual down its boom. The high preliminary value of commercial power equipment is a challenge, mainly for small and medium-sized corporations that frequently have tight budgets. For those corporations, the rate of putting in with expert-grade device might be too steep, which makes them hesitant to make investments. Besides the purchase fee, normal upkeep and repair additionally add to the prices. Tools used in hard industrial settings are uncovered to put on and tear and retaining them going for walks smoothly takes each time and money. These factors can discourage smaller players from adopting business strength equipment on a massive scale.

Despite those hurdles, the destiny of the industrial power gear marketplace seems promising. There is a growing interest in growing gear that use much less strength whilst delivering excessive overall performance. As greater corporations aim to lessen their environmental effect and cut operational charges, energy-efficient solutions becomes extra appealing. Companies that invest in innovation and bring out gear with longer lifespans, faster charging instances, and safer handling can be better placed to steer the market. This shift now not only enables producers meet stricter rules but also supports global sustainability efforts.

In the years beforehand, the demand for smarter, more reliable equipment will growth. Those who respond with nicely-designed, fee-effective, and energy-saving products will probably gain a competitive edge. The marketplace will advantage from this developing interest in sustainability, and the development of superior energy tools will open up new possibilities across industries.

MARKET SEGMENTATION

By Type

The global industrial power tools market is split through kind into categories which include drills, saws, wrenches, grinders, sanders, and others. Each of these tools performs a key position in different business obligations, and their use will keep growing across sectors like production, manufacturing, automotive, and aerospace. Drills are one of the most extensively used power tools in business settings. They are critical for making holes in diverse surfaces and substances, and their performance and simplicity of use lead them to a top desire for experts. As more industries automate and intention for higher productiveness, the call for reliable and sturdy drills will probable increase.

Saws are any other vital type, extensively used for slicing thru wood, metal, plastic, and other substances. From handheld round saws to greater advanced sorts, those tools assist lessen manual exertions and save time. Industrial customers depend upon saws for both precision and pace, which might be essential in big-scale production and production paintings. Their developing use in manufacturing facility settings and creation web sites indicates how critical they are for daily operations. Wrenches, used for tightening or loosening bolts and nuts, additionally have an vital location on this marketplace. In business settings in which meeting and renovation paintings is consistent, energy wrenches are preferred over manual ones due to their pace and accuracy. As industries grow and gadget turns into more complicated, the need for such tools will retain to upward thrust.

Grinders, that are used for shaping, polishing, or cutting tough surfaces, are important in metalworking, construction, and fabrication. Their ability to deal with hard materials makes them a favored tool in workshops and factories. Sanders are used to smooth surfaces and prepare them for completing. These gear are especially useful in woodworking, furniture production, and automotive refinishing. Their developing call for is related to the expanded attention on end fine and surface education in lots of industries.

The "others" class includes tools like warmness weapons, Nailers, and polishers, that are used in greater specialized tasks. Though those gear won't be as extensively used as drills or saws, they nevertheless serve critical roles in particular industries and will see steady demand as business initiatives diversify. As industries adopt quicker, more secure, and more particular equipment, the call for for these kinds of power device sorts will probably keep growing steadily within the coming years.

By Mode Of Operation

The global industrial power tools market is segmented based at the mode of operation, with electric powered, pneumatic, and other tools being the primary categories. Each type performs an essential position depending on the character of the paintings, the industry’s wishes, and the working environment. Electric tools are the maximum normally used due to their ease of use and availability. These equipment are powered either by means of batteries or via direct connection to a electricity supply. Battery-powered tools have turn out to be greater famous in recent years because of their flexibility and potential for use in places in which get admission to to electricity may be limited. Their portability and simplicity of preservation have made them a favored desire in creation, woodworking, and production.

Pneumatic tools, which run on compressed air, also are broadly used, specifically in commercial settings in which high energy output is wanted over lengthy running hours. These equipment are valued for their sturdiness and the reality that they tend to be lighter compared to their electric counterparts. Pneumatic gear are best for obligations that require non-stop use without overheating, together with in automobile and heavy machinery industries. However, they require a constant supply of compressed air, which means that they are better acceptable for desk bound work environments where air compressors are to be had.

The third category consists of other kinds of power tools, which can also function using hydraulic systems or different mechanical strength assets. While no longer as commonplace as electric or pneumatic gear, they nevertheless serve a purpose in specialized fields where particular pressure or motion is needed. For instance, hydraulic gear are often used in upkeep work on huge system, in situations wherein strong force and unique control are necessary.

Overall, the choice of operation mode depends at the worksite situations, type of challenge, and stage of mobility required. As industries continue to grow and undertake more efficient gear, demand for all three classes will maintain to rise. Innovations in battery technology and improvements in tool layout will also force using electric equipment even similarly. Pneumatic equipment will stay robust in industries where performance and reliability are pinnacle priorities. Other tools, although less tremendous, will nonetheless find use wherein precise operating situations require alternative answers. The marketplace will hold adapting based on person wishes and technological progress, making each mode of operation essential in its own manner.

By Application

The global industrial power tools market keeps to develop across unique application regions, each pushed through its very own demand and industry developments. Among those, the concrete and creation phase leads with a full-size fee of $28,145 million. This sturdy figure displays the ongoing increase of creation tasks around the arena. Power tools play an vital function in production with the aid of making responsibilities quicker, less complicated, and greater unique. Tools used for drilling, reducing, grinding, and fastening are heavily relied upon at process web sites. As cities grow and infrastructure projects boom, this phase will keep expanding, growing more want for long lasting and green tools.

Woodworking is some other major software location that helps the global marketplace. Carpenters, fixtures makers, and domestic improvement experts all use energy gear like saws, sanders, and drills to shape and finish wood merchandise. With greater focus on indoors layout, custom fixtures, and do-it-yourself home projects, woodworking tools will stay in excessive call for. This phase is also seeing boom in small workshops and individual customers, mainly as tools turn out to be extra low-cost and less difficult to handle.

The metalworking section includes gear used for shaping, slicing, and becoming a member of steel substances. Industries including automotive, equipment production, and shipbuilding rely on these tools to create elements and additives. As generation in production improves, so does the need for gear that offer both electricity and precision. This will lead to similarly development on this a part of the marketplace, wherein overall performance and lengthy tool life are important.

Welding is a greater specialised application that still uses commercial energy gear. Welders want dependable tools to cut and be part of metallic components appropriately and safely. From creation sites to restore shops, welding equipment assist build and hold many varieties of structures and products. With more emphasis on safety and performance, demand for welding equipment will hold growing, specially in industries that want robust, everlasting connections among steel parts.

There are also different application areas that make up a smaller a part of the market. These include tasks in agriculture, packaging, upkeep, and household upkeep. Even even though those areas may not have the same excessive value as construction or production, they still contribute to the market's general power. The wide variety of makes use of across special industries shows that energy gear are not constrained to at least one discipline. As industries develop and develop, the want for higher and faster equipment can even upward push.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$38,295 million |

|

Market Size by 2032 |

$53,115 Million |

|

Growth Rate from 2025 to 2032 |

6.4% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

.

REGIONAL ANALYSIS

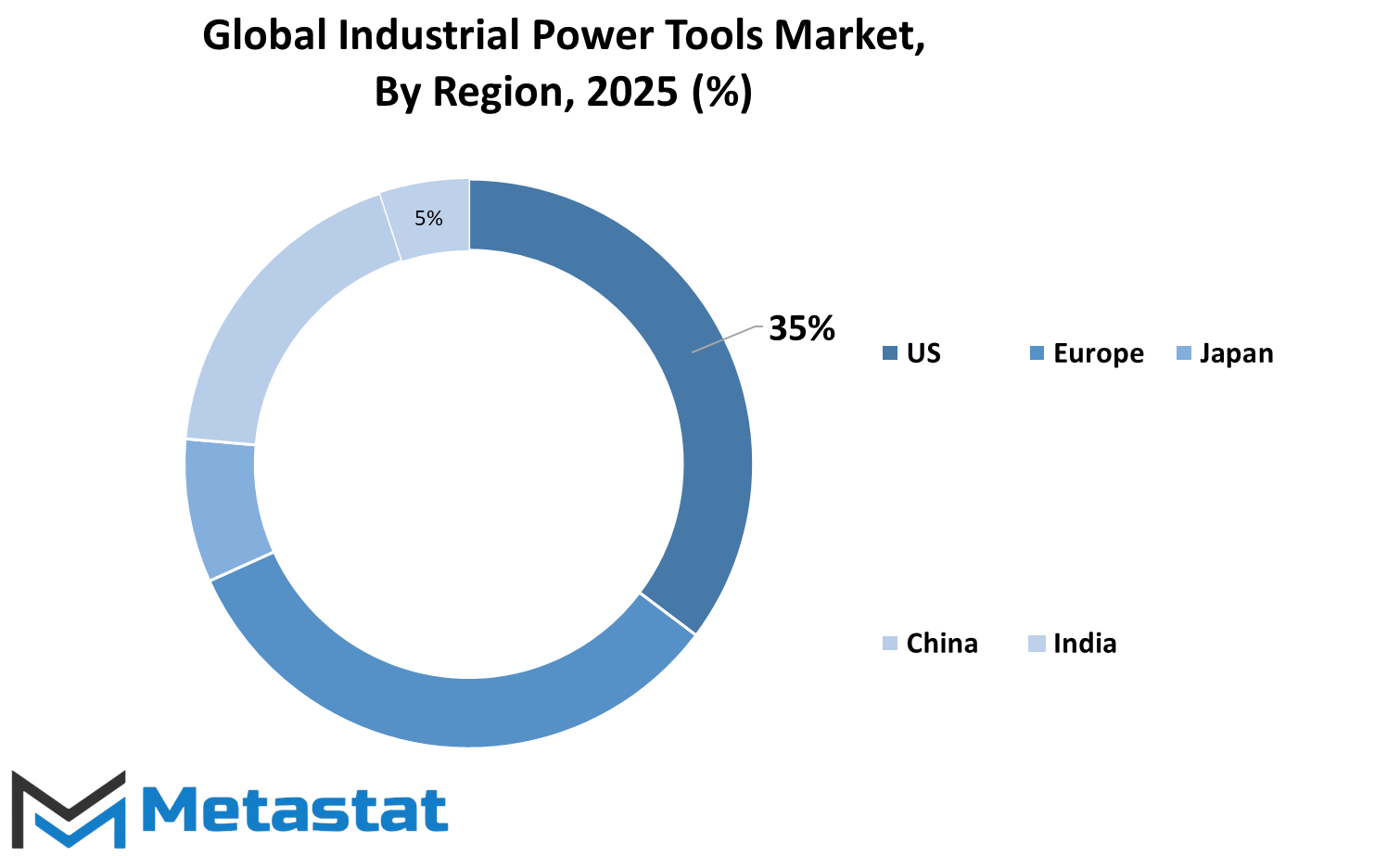

The global industrial power tools market is unfold throughout numerous areas, every playing a key function in shaping its general growth. North America is one of the essential areas and is broken down into the USA, Canada, and Mexico. The United States will probable lead this region because of its sturdy manufacturing base and consistent demand for superior gear in creation, car, and industrial applications. Canada and Mexico additionally guide the marketplace with developing investments in building and repair work, at the side of their industrial sectors that require dependable and green power equipment.

In Europe, international locations just like the UK, Germany, France, and Italy are main members. These countries have properly-evolved manufacturing industries and strict first-rate requirements, as a way to hold to reinforce the want for business electricity equipment. Germany, known for its engineering strength, will possibly remain a key player in tool usage, specifically in automotive manufacturing and manufacturing unit protection. France and the United Kingdom also show regular call for, supported by using infrastructure improvements and the continued shift in the direction of automation. Across the region, there is a robust push for long lasting and easy-to-use equipment on the way to help enhance productiveness, and that is expected to pressure the marketplace ahead.

The Asia-Pacific region is predicted to expose the quickest growth, with nations like India, China, Japan, and South Korea main the way. Rapid development in infrastructure, housing, and enterprise will help robust call for strength gear. China and India, with their large labor forces and industrial increase, might be predominant drivers of this demand. These equipment are critical for both big-scale initiatives and everyday protection, making them a key a part of industrial development. Japan and South Korea, with their attention on superior generation and precision engineering, will maintain to push for excessive-performance equipment that fit their modern structures. The relaxation of Asia-Pacific is also probable to make contributions as smaller countries enhance their business talents.

In South America, Brazil and Argentina are the principle nations in focus. Brazil is seeing constant increase in production and manufacturing, which will help amplify the use of business power equipment. Argentina and different international locations inside the area also are expected to growth their call for, in particular with new infrastructure initiatives and protection desires across numerous sectors.

The Middle East & Africa includes the GCC countries, Egypt, South Africa, and others. These regions are seeing a rise in production and industrial pastime. Large development plans within the Gulf international locations will retain to aid tool call for, while countries like Egypt and South Africa also show promise as their industries develop. Overall, the marketplace will increase with various increase charges relying on the tempo of industrial improvement in each vicinity.

COMPETITIVE PLAYERS

The global industrial power tools market is shaped with the aid of numerous famous organizations that hold to guide with innovation, reliability, and robust customer support. These companies play a key function in riding product pleasant and putting enterprise requirements internationally. Stanley Black & Decker, Inc. Is one of the most diagnosed names in the area. Known for its durable and efficient gear, the organization has constructed a robust recognition over the years and could probable continue to be a prime player within the market. Robert Bosch GmbH is every other essential contributor, supplying a huge range of gear known for precision and overall performance. Its dedication to generation and user-pleasant designs will help it hold its place inside the international marketplace.

Techtronic Industries Co. Ltd. Is likewise a sizeable pressure, specially with brands below its umbrella that concentrate on each commercial and family strength gear. Its growth is supported via steady product innovation and a robust worldwide presence. Makita is any other relied on call that maintains to construct excessive-performance tools that meet the desires of professionals. With its attention on lightweight and battery-powered gear, Makita will in all likelihood continue to be a desired desire in lots of industries. Hilti Corporation stands out for its attention on construction and infrastructure tools, and its emphasis on customer support will help it hold a robust position.

Atlas Copco AB is widely respected for its industrial equipment, especially tools used in heavy-duty applications. Its advanced technology and global outreach support its growth. Ingersoll Rand and Snap-on Incorporated also have strong reputations, especially in the automotive and manufacturing sectors, where durable and high-precision tools are in high demand. Apex Tool Group and Koki Holding Co., Ltd. continue to expand their reach through innovation and smart product development. Honeywell International Inc. and 3M, though more diversified, also support the power tools segment with technology and accessories that boost tool efficiency and user safety.

Emerson Electric Co., Festool GmbH, KYOCERA Corporation, and Husqvarna Group round out the list of key players. Each of these companies brings unique strengths to the table, whether it is in advanced engineering, tool design, or sustainable product development. As demand continues to rise in both industrial and commercial sectors, these companies will play a vital role in shaping the future of the global industrial power tools market by improving productivity and meeting growing customer expectations.

Industrial Power Tools Market Key Segments:

By Type

- Drills

- Saws

- Wrenches

- Grinders

- Sanders

- Others

By Mode Of Operation

- Electric

- Pneumatic

- Others

By Application

- Concrete and Construction

- Woodworking

- Metalworking

- Welding

- Others

Key Global Industrial Power Tools Industry Players

- Stanley Black & Decker, Inc.

- Robert Bosch GmbH

- Techtronic Industries Co. Ltd.

- makita

- Hilti Corporation

- Atlas Copco AB

- Ingersoll Rand

- Snap-on Incorporated

- Apex Tool Group

- Koki Holding Co., Ltd.

- Honeywell International Inc.

- 3M

- Emerson Electric Co.

- Festool GmbH

- KYOCERA Corporation

- Husqvarna Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252