Global Industrial Fasteners Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global industrial fasteners market has come a long way from the simple hand-made metal bolts and screws and has now grown into a sophisticated industry that caters to nearly all the manufacturing sectors around the world. Its origin can be traced back to the era of the Industrial Revolution when the use of dependable joining parts was a must for machines and buildings. The art of making fasteners started in small workshops and with the passage of time, it led to the large-scale production of fasteners as the industrialization trend moved from Europe to North America. The first half of the twentieth century saw the market getting standardization with regard to the establishment of uniform threading and material specifications being some of the market's first defining milestones.

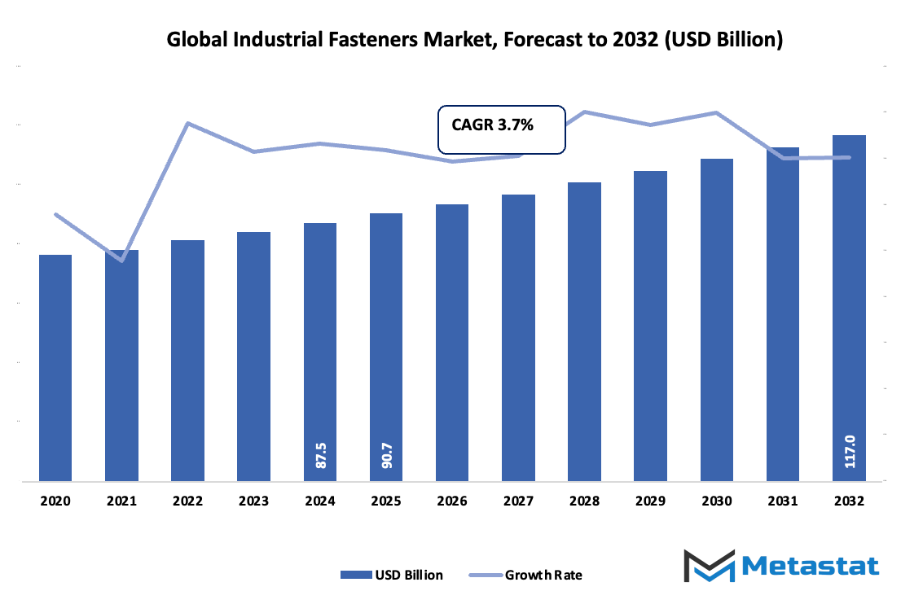

- The global industrial fasteners market was valued at approximately USD 90.7 billion in 2025 and is projected to grow at a compound annual growth rate (CAGR) of around 3.7% through 2032, with a possibility of going beyond USD 117 billion.

- Metal fasteners hold about 76.8% of the market share, actively participating in the innovation and application expansion through the vigorous research they undergo.

- The major trends that support growth are: Expansion of the automotive, construction, and manufacturing industries, Increased requirement for long-lasting and high-performance fastening solutions

- The benefits include: Creation of lightweight, corrosion-proof, and high-strength fasteners that are suitable for advanced industrial applications

- The major point: The market is projected to increase its value exponentially over the next ten years, hence emphasizing the existence of considerable growth opportunities.

During the middle of the 1900s, when the automotive and aerospace industries made a big leap, the need for precision-engineered fasteners increased enormously. Manufacturers moved from using the conventional iron and steel materials to using lightweight alloys, then to stainless steel, and finally to composite materials that are very expensive but also very efficient. With the setting up of automated assembly lines, the manual production techniques lost their edge in terms of skill and volume acceptance. A new generation of specialized fasteners for applications with such features as high temperature, vibration resistance, and corrosion control was launched around the same time.

In the following decades, the market began to reflect the shifts in the global economy. The manufacturing power of the Asia Pacific region has been rising and this has resulted in the transformation of supply chains that allow for mass production at lower prices but also require quality assurance efforts. The regulatory framework regarding the safety of materials and their impact on the environment has been getting stricter, leading to the emergence of green coatings and recyclable materials. In the meantime, the consumer sectors such as electronics and renewable energy were already asking for very small and powerful fasteners that could handle compact designs and complex assembly.

At present, the global industrial fasteners market is positioned exactly where old engineering meets the digital transformation of the future. Amongst the smart manufacturing practices will be the use of robotics, additive manufacturing, and real-time quality control that will totally change the way fasteners are produced and delivered. The fasteners industry has come a long way from simple mechanical connectors to precision-engineered parts and this has been a journey of adaptation and innovation that will continue to drive industrial progress for many more years. Furthermore, every new development has not only intensified the efficiency but has also opened up new areas of application for the industries that consume these essential products.

Market Segments

The global industrial fasteners market is mainly classified based on Material, Product, Application, Distribution Channel.

By Material is further segmented into:

- Metal Fasteners: This category of global industrial fasteners market consists of products made of steel, stainless steel, aluminum, and other alloys. The main characteristics of these fasteners are high strength, durability, and resistance to wear, thus they are perfect for heavy-duty applications. Their use is widespread in construction, automotive, and machinery sectors mainly due to their long-term trustworthiness.

- Plastic Fasteners: The global industrial fasteners market covers plastic-based products too which are referred to as lightweight, corrosion-resistant, and cost-effective. These products are particularly used in places where metal fasteners can result in electrical conductivity problems or rusting. Their main applications are in household items, electronics, and automotive interiors due to their flexibility and insulation capabilities.

By Product the market is divided into:

- Externally Threaded Fasteners: The global industrial fasteners market comprises the externally threaded varieties such as bolts and screws which have threads made on the outside. These are made to be fitted together with nuts or tapped holes, thus providing a tight connection. They are the choice for strong mechanically and easy for dismantling purposes during maintenance.

- Internally Threaded Fasteners: The market displays the internally threaded varieties like nuts which are meant to be paired with bolts or screws. These fasteners secure the joints and are in demand in the constructions that need full support and resistance against vibrations. They find a place in the automobile, heavy machinery, and infrastructure sectors as well.

- Non-threaded Fasteners: The market includes the non-threaded types such as pins, rivets, and clips among others. These fasteners bring about quickly and permanently joining solutions, especially in areas like construction and manufacturing. Their main advantages are simplicity, low price, and the ability to endure the stress while retaining structural integrity so they are oftentimes chosen.

- Aerospace Grade Fasteners: The global industrial fasteners market contains the aerospace-grade products that comply with the very stringent performance and safety requirement. These fasteners are produced from cutting-edge materials like titanium and high-strength alloys which guarantee the resistance to the harshest conditions of temperature and pressure. They play a role in the aircraft and military equipment industries in providing accuracy and safety.

By Application the market is further divided into:

- Automotive: The global industrial fasteners market are also the mainstay supplier of the automotive sector, as they furnish fasteners for various assemblies, such as the engine, the interior, etc. On top of that, fasteners ensure the same, i.e., safety, durability, and resistance to vibrations, amongst others. The rising demand for electric vehicles has additionally necessitated the production of fasteners that by their very nature are lighter and perform better.

- Aerospace: The market is instrumental in the context of the aerospace industry where fasteners in airplanes are used mainly for assembly and maintenance. These products are expected to have a very long service life since they are subjected to high stress, temperature, and pressure. The precision and adherence to safety norms are very crucial which makes the use of aerospace-grade fasteners necessary for reliability.

- Building & Construction: The market is one of the main suppliers of the building and construction industry, as it provides fasteners for every structural framework, roofing, and fixtures. These products offer stability, strength for carrying loads, and also resistance against bad weather. The demand is not going down, on the contrary, it is rising due to the increasing number of infrastructure and urban development projects.

- Industrial Machinery: The market is one of the main suppliers for those manufacturers who produce machines and other equipment that need to have their parts joined in a strong and secure way with the help of fasteners. These fasteners are intended to survive high operational stress and vibration. They are instrumental in maintaining the efficiency of the machinery, minimizing the downtime, and ensuring the long-term reliability of the production environments.

- Home Appliances: The market is a major player in the home appliance sector, as it supplies the essential parts that get the appliances together—washing machines, refrigerators, and others. The fasteners add to the safety, durability, and also at the same time they let the appliances work well. No wonder that the lightweight and the types that do not corrode are the ones that are picked for the electrical and electronic use of this segment.

- Lawns And Gardens: The market purposes is another market for lawn and garden equipment manufacturers. The use of fastening technology is evident in tools, outdoor furniture, and even in the machines, which provide durability and at the same time resistance to outdoor conditions. Corrosion-resistant materials like stainless steel and coated metals are preferred to withstand constant exposure to moisture and weather.

- Motors And Pumps: The market assists the motors and pumps sector by providing fastening solutions that create tight seals and support. These fasteners are the ones that discharge no leak and maintain mechanical strength even under high pressure. Their precision and resistance to corrosion make them suitable for both industrial and residential applications.

- Furniture: The market consists of a variety of fasteners employed in furniture manufacturing. Various types of screws, bolts, and connectors provide stability and simplicity in the installation process. The lightweight and decorative kinds in particular are becoming increasingly popular for the modular and ready-to-assemble furniture styles that are used in modern homes.

- Others: The global industrial fasteners market also covers applications in various sectors like electronics, marine, and energy. The different industries will require fasteners with specific properties such as conductivity, waterproofing, or heat-resistance. The multifaceted roles of fasteners in granting the sectors continued innovation and growth support thus, the fasteners will not be giving a slow pace in multiple industrial segments.

By Distribution Channel the global industrial fasteners market is divided as:

- Direct Sales: The global industrial fasteners market uses direct sales channels to serve large manufacturers and industrial clients. This method allows better customization, bulk purchasing, and consistent supply. Direct sales also help build long-term partnerships with customers by providing tailored solutions and technical support for various applications.

- Distributors: The market relies on distributors to reach small and medium-sized buyers across regions. Distributors provide easy access to a wide variety of fasteners, ensuring timely availability and cost efficiency. They also support local industries by offering technical assistance and inventory management services.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$90.7 Billion |

|

Market Size by 2032 |

$117 Billion |

|

Growth Rate from 2025 to 2032 |

3.7% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

By Region:

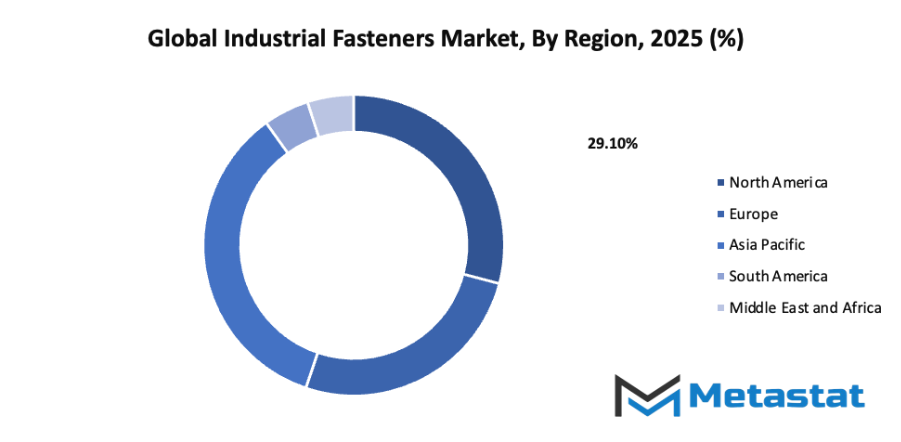

- Based on geography, the global industrial fasteners market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Growth in automotive, construction, and manufacturing sectors: The market benefits greatly from the steady rise in automotive production, infrastructure projects, and manufacturing operations. Each of these sectors requires a large volume of fastening products for assembly and maintenance purposes. With rapid industrialization and expanding production facilities, the need for efficient and durable fastening solutions continues to rise.

- Rising demand for durable and high-performance fastening solutions: The market is driven by the preference for long-lasting and high-quality fastening systems that can withstand extreme conditions. Industries are increasingly focusing on fasteners that ensure safety, efficiency, and reduced maintenance costs. These performance-based products help improve structural integrity, supporting their growing use in demanding industrial applications.

Challenges and Opportunities

- Volatility in raw material prices, particularly steel and alloys: The global industrial fasteners market is affected by frequent changes in the prices of essential raw materials like steel and alloys. Such fluctuations impact manufacturing costs and profit levels for producers. Maintaining price stability becomes difficult, forcing manufacturers to adopt cost-control measures and seek alternative materials to remain competitive.

- Intense competition from low-cost manufacturers: The market faces strong competition from producers offering cheaper alternatives, especially from regions with lower production expenses. These low-cost products attract price-sensitive customers, challenging established companies to balance quality and affordability. To stay ahead, firms are focusing on innovation, product reliability, and customer service.

Opportunities

- Development of lightweight, corrosion-resistant, and high-strength fasteners for advanced industrial applications: The global industrial fasteners market is advancing toward the production of fasteners that are lightweight, rust-resistant, and capable of withstanding high stress. These improved materials are suitable for aerospace, automotive, and construction industries that demand both strength and durability. This development is expected to open new growth avenues and enhance product performance standards.

Competitive Landscape & Strategic Insights

The global industrial fasteners market continues to play a crucial role in supporting multiple manufacturing and construction sectors. Fasteners serve as the foundation of product assembly and infrastructure development, ensuring safety, reliability, and durability across various applications. The demand for these essential components remains steady, driven by the growth of industries such as automotive, aerospace, construction, and machinery production. As technology advances, manufacturers are focusing on improving material strength, corrosion resistance, and precision engineering to meet the performance requirements of modern designs.

The market has witnessed continuous improvements in both production processes and product quality. Innovation in design and the use of advanced materials have led to better performance and longer lifespan of fasteners. Increased awareness of quality standards and stricter regulations have encouraged manufacturers to adopt sustainable methods and efficient supply chains. In addition, automation and digital tools are becoming more common in manufacturing plants, enhancing productivity and consistency in product output.

The industry is a mix of both international industry leaders and emerging regional competitors. Important competitors include Arconic Fastening Systems and Rings, Acument Global Technologies, In, ATF, Inc., Dokka Fasteners A S, LISI Group - Link Solutions for Industry, Nippon Industrial Fasteners Company (Nifco), Hilti Corporation, MW Industries, Inc., Birmingham Fasteners and Supply, Inc., SESCO Industries, Inc., Precision Castparts Corp., Rockford Fasteners, Inc., Slidematic, Manufacturing Associates, Inc., Eastwood Manufacturing, Brunner Manufacturing CO., Inc., Decker Industries Corporation, Penn Engineering & Manufacturing Corporation, EJOT, Illinois Tool Works, Inc., Stanley Black & Decker, Inc., and KOVA Fasteners Pvt. Ltd. in market. These competitors represent a wide range of expertise, offering products designed for specific applications and sectors. Their continuous focus on research, innovation, and global expansion helps maintain a competitive environment that encourages steady growth.

Growing infrastructure projects in developing countries and the expanding electric vehicle sector have also contributed to market growth. The focus on lightweight materials and energy-efficient solutions is pushing manufacturers to develop fasteners that support sustainability goals. Regional players are gaining importance as they cater to local demand with flexible production and cost-effective distribution. On the other hand, established global brands maintain strong relationships with major clients and rely on advanced research facilities to stay ahead in product development.

Price fluctuations in raw materials such as steel, aluminum, and titanium remain a major challenge. To manage costs and maintain profitability, many manufacturers are focusing on long-term contracts and strategic sourcing. Additionally, the shift toward environmentally friendly production methods is creating new opportunities for companies that invest in sustainable technologies and recycling processes. The global supply chain disruptions seen in recent years have further emphasized the need for diversification and reliable logistics networks to ensure timely delivery and stable operations.

Market size is forecast to rise from USD 90.7 billion in 2025 to over USD 117 billion by 2032. Industrial Fasteners will maintain dominance but face growing competition from emerging formats.

Overall, the market continues to grow steadily, supported by innovation, modernization, and expanding industrial activities. The focus on quality, efficiency, and sustainability will define the market’s future direction, ensuring that manufacturers remain competitive and capable of meeting the increasing demands of modern industries.

Report Coverage

This research report categorizes the global industrial fasteners market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global industrial fasteners market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global industrial fasteners market.

Industrial Fasteners Market Key Segments:

By Material

- Metal Fasteners

- Plastic Fasteners

By Product

- Externally Threaded Fasteners

- Internally Threaded Fasteners

- Non-threaded Fasteners

- Aerospace Grade Fasteners

By Application

- Automotive

- Aerospace

- Building & Construction

- Industrial Machinery

- Home Appliances

- Lawns And Gardens

- Motors And Pumps

- Furniture

- Others

By Distribution Channel

- Direct Sales

- Distributors

Key Global Industrial Fasteners Industry Players

- Arconic Fastening Systems and Rings

- Acument Global Technologies, In

- ATF, Inc.

- Dokka Fasteners A S

- LISI Group - Link Solutions for Industry

- Nippon Industrial Fasteners Company (Nifco)

- Hilti Corporation

- MW Industries, Inc.

- Birmingham Fasteners and Supply, Inc.

- SESCO Industries, Inc.

- Precision Castparts Corp.

- Rockford Fasteners, Inc.

- Slidematic

- Manufacturing Associates, Inc.

- Eastwood Manufacturing

- Brunner Manufacturing CO., Inc.

- Decker Industries Corporation

- Engineering & Manufacturing Corporation

- EJOT

- Illinois Tool Works, Inc.

- Stanley Black & Decker, Inc.

- KOVA Fasteners Pvt. Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383