MARKET OVERVIEW

The global hydraulic cylinders market inside the commercial equipment and automation zone is shifting closer to an generation of complexity, customization, and evolving dynamics that extend beyond its traditional makes use of. Though maximum of what's stated approximately this section relates to not unusual narratives of boom and recurring metrics, the true story is the diffused changes that are revolutionizing how hydraulic cylinders could be visible, designed, and applied within the destiny years.

The future to return will probably not be all about merely designing better-appearing or low-cost cylinders, but more approximately designing solutions engineered particularly for given functional requirements, situations, and restrictions. Individualization will not be a fee-addition; it is going to be a mandate as marine, aerospace, protection, and alternative energies begin requiring greater custom and area-saving hydraulic systems. This need will compel producers and machine integrators to re-look at modern design ideologies, moving in the route of flexibility, multi-capability, and more integration with virtual systems.

One of the below-explored but robust adjustments that are probable to appear within the global hydraulic cylinders market is the mixing of sensors and shrewd monitoring technology. As the arena gears up for the entire-pressure effect of automation and smart structures, conventional hydraulic factors might be re-engineered as sensible devices that can take a look at their fitness, forecast screw ups, and optimize strength intake. This revolution will rewrite the very function of these elements—not only as actuators, but as intelligent members of overall system intelligence.

Environmental issues will also become an increasingly important factor in guiding the course of this market. The need to minimize leakage, reduce the waste of energy, and decrease the carbon footprint related to fluid power systems will test designers to move toward new materials and fluid options. This is not going to happen in a vacuum; it will involve supply chains getting more responsible, open, and innovative in sourcing, production, and distribution habits.

The different important trade comes in the form of the way the global hydraulic cylinders market may be organized geographically. With changing geopolitical climate and nations focusing extra on localized manufacture, the global version of distribution may want to skew in the direction of nearby autonomy. Such a shift would now not simplest influence manufacturing facilities but also result in nearby gamers surfacing with specialised technological techniques to suit neighborhood commercial requirements. It is in those localized subtleties that innovation can bloom inside the unlikeliest of locations, diverging from traditional worldwide requirements.

The workforce shift will also quietly impact the future of this enterprise. As set up generations retire and sparkling, era-succesful engineers and technicians be part of the staff, the discussion of hydraulic structures will broaden past mechanical know-how to encompass software integration, data evaluation, and machine-level optimization. These changes in brainpower and mindset will necessarily affect the manner hydraulic cylinders are designed, promoted, and used.

Finally, the global hydraulic cylinders market is not only heading into a brand new era of innovation however is likewise quite modestly losing its mechanical-only photo and getting into a website where local adaptability, environmental awareness, intelligence, and customization will set up its well worth. This trade, although much less conspicuous, can have a long-time period touching on the general commercial and automation landscape.

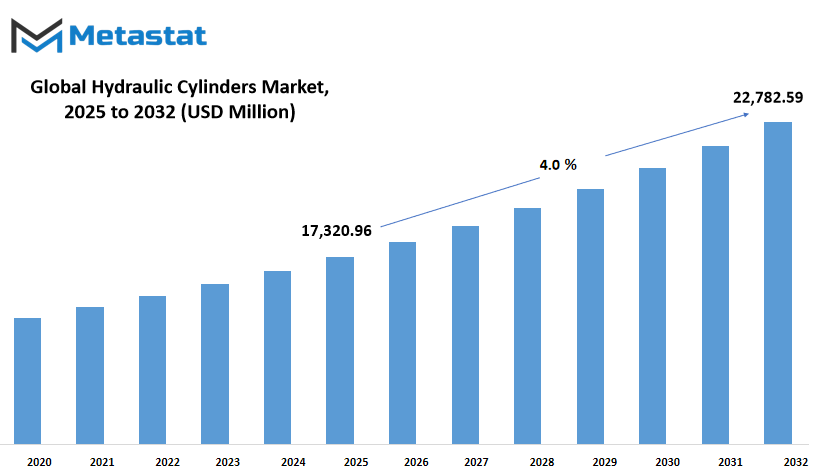

Global hydraulic cylinders market is estimated to reach $22,782.59 Million by 2032; growing at a CAGR of 4.0% from 2025 to 2032.

GROWTH FACTORS

The global hydraulic cylinders market is gradually gaining momentum, in large part because of the increasing demand for heavy machinery in production and agriculture. These sectors depend on hydraulic power to function gadget that ought to deal with excessive bodily obligations, from lifting and pushing to digging and plowing. As infrastructure tasks grow and cutting-edge farming expands, the need for durable and green hydraulic systems will best emerge as greater critical.

Another vital component riding the global hydraulic cylinders market is the shift towards automation throughout industrial and cloth dealing with environments. Factories, warehouses, and transport systems are gradually adopting automatic machines to reinforce productiveness, reduce hard work fees, and make certain precision. Hydraulic cylinders play a crucial position in powering the motion of such machines, which makes them critical in those automated settings.

Despite the advantageous outlook, the marketplace does face some demanding situations. One of the common worries is the excessive protection associated with hydraulic structures. Over time, these additives are susceptible to wear and tear, frequently requiring regular inspection and renovation. There’s also the risk of fluid leakage, which now not handiest affects overall performance however can also reason protection and environmental worries. Additionally, the volatility in raw cloth fees—in particular metals utilized in production—can influence production fees, creating uncertainty for manufacturers and buyers alike.

That stated, the future holds promise. Innovation in smart hydraulic structures is already underway, with technology that allow for real-time monitoring, predictive protection, and far off manipulate. These enhancements goal to lessen downtime and make operations extra efficient. On pinnacle of that, the development of power-saving designs is addressing both overall performance and sustainability, which is turning into a growing priority for industries international. These advancements are predicted to open up new increase paths for the market within the coming years, making hydraulic cylinders greater adaptive and aligned with modern industrial desires.

MARKET SEGMENTATION

By Function

The global hydraulic cylinders market is seeing a consistent shift, pushed with the aid of technological modifications and growing use in extraordinary industries. Fundamentally, hydraulic cylinders are machines that appoint pressurized hydraulic fluid to generate linear force and motion, and they are essential additives in equipment that requires electricity, reliability, and accuracy. As industries attempt for automation and expanded mechanical performance, the demand for hydraulic systems has also expanded, therefore making such cylinders a critical issue of cutting-edge engineering.

Market-clever, the market is split consistent with how such cylinders paintings. One substantial phase is the Single Acting category, which accounted for an anticipated $12,768.15 million. This kind employs hydraulic stress in just one path, and a spring or different outside force to push the piston back to its unique role. These are usually hired in packages that entail a easy push or pull. By contrast, Double Acting cylinders exert hydraulic pressure in both guidelines, with greater manage and strength for programs that contain repeated lower back-and-forth motion. This makes them mainly best for industrial settings in which responsiveness and power are the maximum essential factors.

Sectors like manufacturing, mining, agriculture, and production retain to depend closely on hydraulic cylinder era to optimize their device and methods. Whether lifting heavy weights, driving earth-moving equipment, or using meeting strains, the versatility and strength of hydraulic cylinders offer undeniable blessings. As sustainability comes underneath the limelight, there's developing emphasis on cylinders that use much less, last longer, and are simple to preserve—attributes with a view to outline destiny increase within the enterprise.

With growing international infrastructure development and growing sophistication in machinery, the hydraulic cylinder enterprise will retain to develop in phrases of design and functionality. Both unmarried and double acting cylinders will coexist, depending at the precise operational requirements. The emphasis may be on maximizing overall performance with minimizing downtime and running costs.

By Product Type

The global hydraulic cylinders market is being driven by increasing demand for automated machinery, heavy equipment, and building solutions. Hydraulic cylinders are key elements that transform the fluid pressure into mechanical force and are used extensively across industries such as manufacturing, agriculture, aerospace, and mining. As industries push towards making processes more efficient and reliable, demand for high-performance hydraulic systems will keep increasing, propelling this market ahead. Companies also want components that are long-lasting and can withstand very heavy workloads, and hydraulic cylinders provide just that.

By product type, the market is segmented into a number of categories. Tie-rod cylinders are favored for their modularity and low maintenance requirements. They're usually selected in light to medium-duty applications where cost and space are major factors. Threaded cylinders, although not as prevalent, are selected due to their excellent sealing capacity, and thus they suit applications where leakage could cause operational failure or even safety issues.

Welded cylinders provide a more compact space and are commonly chosen for mobile machinery where space is restricted. Their assembly enables them to endure harsh environments and function consistently, thus becoming the choice in construction and agricultural machinery. Bolted or mill-type cylinders, however, are assembled for heavy-duty applications. They are normally found in industrial use with high pressure and heavy loads as the norm.

Telescoping cylinders are special because they extend in steps, making it possible to have a long stroke from a small unit. They are particularly valuable in dump trucks or in any situation where a large range of motion is needed within close limits. Other types of cylinders, which don't fit into the big two categories, also find important uses in niche markets. Their design tends to meet very specialized applications where generic alternatives won't work.

As companies move towards automation and intelligent machinery, the hydraulic cylinders market is going to be at the center. Energy-efficient systems and improved productivity will drive manufacturers to seek newer materials and newer design approaches. With each new improvement in equipment design, the call for precise, powerful, and reliable hydraulic movement gets even stronger.

By Bore Size

The global hydraulic cylinders market is experiencing regular increase fueled with the aid of demand in construction, mining, agriculture, and industrial automation. Hydraulic cylinders are an vital element in heavy equipment as they transform hydraulic energy into mechanical force and help in lifting, pushing, or pulling heavy masses. Their electricity, longevity, and performance lead them to a essential part of equipment together with excavators, loaders, cranes, and harvesters. As industries development toward automation and increased productiveness, hydraulic gadget utilization has come to be extra familiar, using the market similarly.

The global hydraulic cylinders market is segmented one manner thru bore size. Bore length is the inner diameter of the cylinder and substantially influences the performance, the weight capacity, and the use of the cylinder. The market is also segmented into four bore size levels: Less than 50mm, 51mm to 150mm, 151mm to 300mm, and More than 300mm. Each range serves the purpose of specific applications. Bore size ranges of less than 50mm are generally employed in smaller machinery where compactness and rapid response are essential. They are generally used in light-duty applications where precision is more needed than heavy-duty lifting.

Conversely, cylinders within the range of 51mm to 150mm are used extensively in mid-size machinery. The range is balanced between flexibility and strength and can be used for industrial applications and agricultural machinery that need a moderate amount of force. The range of 151mm to 300mm serves the needs of heavy-duty operations. Machinery engaged in construction projects on a large scale and mines often employs cylinders of this range so the machinery can be capable of withstanding high pressure and heavy loads.

The 300mm plus bore size segment supports heavy-duty, highly specialized, and industrial applications. Such cylinders are constructed to support excessive power and are used to operate under heavy load situations. Large-scale creation machinery, offshore structures, and positive mining systems make use of such cylinders for their heavy-obligation output and reliability in important programs.

As corporations maintain to require equipment capable of withstanding more force and functioning in challenging conditions, the demand for huge bore hydraulic cylinders will best growth. Yet compact and mid-length versions will nonetheless sustain robust demand as they may be flexible and green for quite a few smaller and mid-scale duties. The global hydraulic cylinders market will hold growing as equipment and device makers reply to evolving commercial needs and technological advancements.

By Application

The global hydraulic cylinders market is prompted through its substantial variety of applications, demonstrating the significance of these mechanical devices in diverse sectors. Essentially, a hydraulic cylinder operates on the principle of changing fluid electricity to mechanical force and linear movement. Such a easy yet powerful idea is relevant to severa industries, and this is the cause why demand for hydraulic cylinders stays regular.

One of the biggest software fields is cellular gadget, together with equipment for use in agriculture, construction, and cloth managing. These hydraulic cylinders are a important a part of operations that involve lifting, pushing, or pulling heavy loads with precision. Whether lifting a plow, elevating a crane arm, or shifting a forklift into role, hydraulic cylinders are at the back of it all. Their capability to carry out reliably beneath worrying situations and provide steady energy makes them a favourite within this market.

Industrial machinery is one of the maximum vital segments wherein hydraulic cylinders show their prowess. They discover huge software in manufacturing facility automation, presses, and assembly lines. In such setups, accuracy and ruggedness are crucial. Hydraulic cylinders allow tactics that need to run accurately with minimal room for mistakes, and that they help in reaching production objectives whilst maintaining maintenance necessities at a minimal.

In the Aerospace & Defense area, hydraulic cylinders are an vital part of important operations. Landing gear structures, cargo bay doorways, and missile launchers all depend on hydraulic motion for reliable operation. The device hired here desires to function without a hitch underneath monstrous strain, and hydraulic cylinders are designed to meet that assignment. Their strength transport capability in compact designs makes them advanced wherein area and weight are strictly managed.

The ocean industry also utilizes hydraulic cylinders to great advantage. From ship steering systems to stabilizers and winches, these systems ensure balance and control when on the ocean. The capability of these devices to withstand corrosion and high humidity environments is vital in these environments, where ordinary components would soon fail.

Mining is another industry where ruggedness and brute power are necessary. Heavy-duty equipment such as drills, loaders, and haul trucks rely on hydraulic cylinders to transfer tremendous load components. The abrasive, dusty environment and round-the-clock wear and tear necessitate equipment that will not fail readily. Hydraulic cylinders provide the ruggedness and brute power required to continue production without frequent stoppages.

Finally, there are others that don't fit into the common categories—those are classified under "Other." These would include such things as hydraulic amusement rides, medical devices, or custom industrial installations. Even in these special applications, these principles of force, motion, and control still hold.

Through all of these uses, what does not change is the need for effective, powerful, and reliable systems. The global hydraulic cylinders market will keep expanding, fueled by its versatility and the vital work that it does in contemporary machinery.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$17,320.96 million |

|

Market Size by 2032 |

$22,782.59 Million |

|

Growth Rate from 2025 to 2032 |

4.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

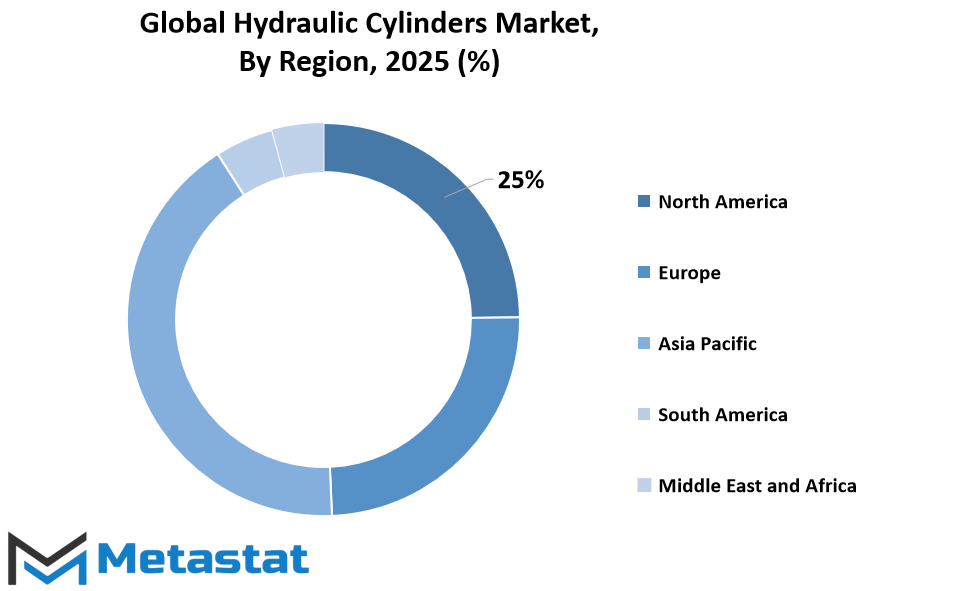

The global hydraulic cylinders market is influenced by differential regional needs, each determined by industrial development, infrastructure growth, and economic interests. Geographically, the market can be generally categorized into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each region has a distinct contribution, depending on its regional needs and technological developments.

In North America, the United States, Canada, and Mexico constitute the main markets. The U.S. is the leader here with robust investments in mining, construction, and agriculture sectors, which utilize hydraulic cylinders extensively. Canada comes a close second with its industries that are based on resources and machine upgrades. Mexico facilitates the regional growth through its growing manufacturing sector, which continues to implement hydraulic systems in favor of efficiency and performance.

On the other side of the Atlantic, Europe dominates this market. The UK, Germany, France, and Italy, together with the Rest of Europe, exhibit consistent demand. Germany, known for engineering and machinery manufacturing, owns a significant portion of it. France and Italy also drive growth in terms of automotive assembly and public infrastructure development. The rest of Europe also contributes to overall momentum as industries slowly transition to more mechanized systems driven by hydraulic components.

Asia-Pacific has the maximum potential for expansion, with India, China, Japan, South Korea, and the rest of the continent contributing actively. China is particularly distinct because of its colossal industrial output and government-supported infrastructure projects. India is racing ahead, fueled by its emphasis on industrialization and smart city growth. Japan and South Korea, with their cutting-edge manufacturing industries, maintain demand through innovation and precision-oriented applications. The wider area facilitates this growth as nations embrace new equipment in agriculture and construction.

In South America, Brazil and Argentina are the two biggest contributors to the hydraulic cylinders market. Brazil continues to see demand from agriculture and mining, both of which are major drivers in the region. Argentina has a similar trend, although on a smaller magnitude. Other regions of South America are slowly embracing new technologies, but their contribution is not significant compared to major regions.

Lastly, the Middle East & Africa provide steady prospects, particularly in the GCC nations, Egypt, South Africa, and the rest of the region. The GCC countries are spending on massive infrastructure and oil-related developments, where hydraulic equipment is crucial. Egypt and South Africa also indicate momentum, with construction and energy featuring prominently. Although the rest of the region is more diversified in industrial terms, active projects continue to underpin market presence. All regions have something unique to offer, and demand in these geographies mirrors not only industrial capacity but also the rate at which modern machinery is being adopted.

COMPETITIVE PLAYERS

The global hydraulic cylinders market is influenced by the dedication and innovation of a number of key players who have continued to shape it. Such entities, such as Van Halteren Technologies, Parker Hannifin, Eaton, SMC Corporation, Caterpillar, HYDAC, and Wipro Infrastructure Engineering, are renowned for their committed emphasis on quality, reliability, and performance. Their continued efforts benefit industries such as construction, agriculture, and manufacturing, whose operations hydraulic cylinders facilitate heavy loads and power various machines.

Hydraulic cylinders, while conceptually simple, are now at the forefront of contemporary mechanical systems. They are instrumental in assisting machinery in executing controlled linear movements with force and accuracy. In lifting construction equipment to driving manufacturing lines, these parts are ubiquitous. Those companies spearheading this industry know how essential durability and efficiency are in rigorous working conditions. This is the reason why companies such as Enerpac, Diamond Hydraulics, and Canara Hydraulics are continually striving to enhance the life span, safety, and productivity of these systems.

With more industries going modern and in search of greater automation, hydraulic cylinders are likely to become even more critical. Companies such as United Hydraulics, Hydratech Industries, Yuken Kogyo, and Komatsu are gearing up for this by making wiser designs and improving energy consumption. The industry also encompasses Hydroline Oy, Norrhydro, and Ligon Industries, which are all developing solutions to operate on a vast scale of applications—from miniature solutions on mobile machinery to giant operations in mining and defense.

Companies like Hunger Hydraulics and Liebherr provide added value through custom solutions specifically designed to meet particular requirements. With such a varied contribution, the market is not only competitive, but also one where there is a collective push to extend technical boundaries while keeping it realistic in terms of application.

What's so compelling about this space is that it is not only the quantity of the companies, but that each company tackles similar issues in a unique way. Whether it be material innovation, sophisticated control systems, or sustainable processes, these companies will continue to define the future of global hydraulic cylinders market.

Hydraulic Cylinders Market Key Segments:

By Function

- Single Acting

- Double Acting

By Product Type

- Tie-rod Cylinders

- Threaded Cylinders

- Welded Cylinders

- Bolted/Mill Type Cylinders

- Telescopic Cylinders

- Other Cylinders

By Bore Size

- Less than 50mm

- 51mm to 150mm

- 151mm to 300mm

- More than 300mm

By Application

- Mobile Equipment

- Industrial Equipment

- Aerospace & Defense

- Marine

- Mining

- Other

Key Global Hydraulic Cylinders Industry Players

- Van Halteren Technologies

- Parker Hannifin

- Eaton

- SMC Corporation

- Caterpillar

- HYDAC

- Wipro Infrastructure Engineering

- Enerpac

- Diamond Hydraulics

- Canara Hydraulics

- United Hydraulics

- Hydratech Industries

- Yuken Kogyo

- Komatsu

- Hydroline Oy

- Norrhydro

- Ligon Industries

- Hunger Hydraulics

- Liebherr

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252