MARKET OVERVIEW

The Global Hammer Mill market will have a transformation in these coming years from the comprehension of industries throughout the world about their primary role in the processing of materials in different sectors. Hammer mills have long been recognized as standard equipment for the reduction of coarse material to smaller sizes. They have attained their important position in industries such as agriculture, pharmaceuticals, and recycling. Due to rising requirements for affordable yet high-performance milling solutions, the industry would hence benefit from much innovation in technologies making these mills highly adaptable to contemporary demands.

Another area denoting the transformation of the future of amalgamation in the hammer mill will be automating AI into production streams to maximize production efficiencies. This innovation will also be the key to improving super-accurate control over the milling procedure to minimize wastage and maximize yield. With sensors and smart technologies integrated for efficient operation, mills shall have the capability of real-time Performance Monitoring and Performance Improvement through parallel adjustments. This will also enhance safety standards where mechanization would help to eliminate attendance in dangerous environments.

The recent years will increasingly account for sustainability in the Global Hammer Mill market. Manufacturers are likely to manufacture eco-friendly machines with the intention of conserving energy and lowering carbon footprints. Improvement in the spheres of material science will enable the production of durable hammer mills that can last long and withstand repairs. This shift towards more sustainable practices is likely to be propelled by an increase in environmental awareness and regulatory pressure aimed at curbing emissions from industrial set-ups. The integration of renewable energy sources for operating mills, such as solar power or wind power, shall likewise be on the basic agenda and attest to these claims of greenness.

Geographically speaking, the Hammer Mills Global shall witness growth from developing economies where industrialization is spreading in a rapid fashion. There shall be a great concerted increase in demand for hammer mills from the countries of Asia, Africa, and Latin America, as new industries sprout while traditional sectors are being modernized. Such a regional migration would compel manufacturers to systematically adjust their products to meet the specific needs and requirements that are unique in each market. Specializing hammer mills for particular applications like food processing, biomass grinding, or waste management will become an approach for companies to expand their footprint within these areas.

As further development of the market progresses, additional development of hammer mills for the next generation will be much aided by cooperation among manufacturers, research Institutions, and end-users. Knowledge will pass freely among these entities and advanced technology will be born to meet the many and varying needs of industries all over the world.

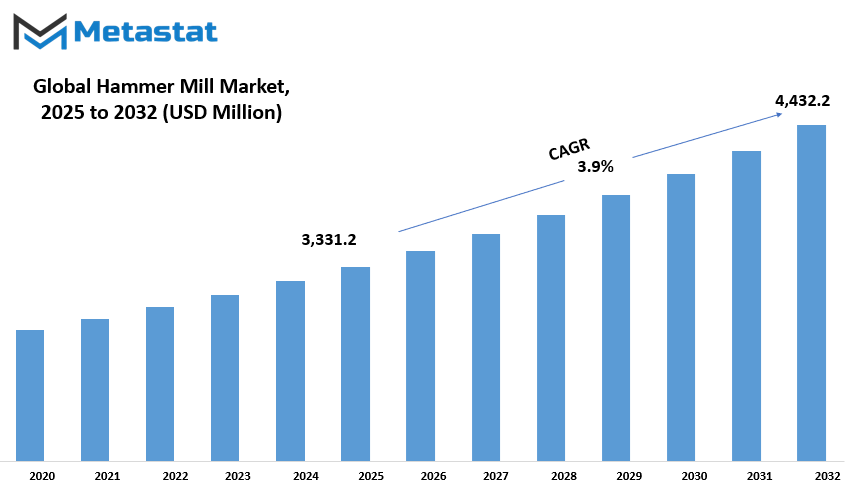

Global Hammer Mill market is estimated to reach $4,432.2 Million by 2032; growing at a CAGR of 3.9% from 2025 to 2032.

GROWTH FACTORS

The global hammer mill market is marked by burgeoning growth on account of a number of factors and opportunities but faced with a few challenges on the way. Much of the hammer mill demand can be ascribed to the quest for efficient yet speedy grinding processes in industries requiring the capacity to work on various materials-from grains to metals in agriculture, food processing, and the mining industries. Hammer mills are, in fact, able to process huge quantities of material in a short time frame, hence are very much in demand in those industries where productivity matters the most. Their variable application, ease of operation, and economy have thus made them an indispensable element in many manufacturing processes.

Advancement in the technology of hammer mill plays an important role in this growth. There is much ongoing improvement by the manufacturers to enhance the performance and productivity of these machines through improved motor efficiency and precision grinding among others. This, therefore, means that an increase in productivity in various industries translates to decreased operational costs and more output. These innovations also provide for the reliability of the machine, which is extremely important for companies needing dependable and consistent results.

Despite being the growth drivers, there exist some restraining factors for the hammer mill market. Among these, the most prominent one is the extensive maintenance costs involved with the hammer mill machinery. Although the machines perform their work well, maintaining and repairing them can be very costly if they are frequently used in harsh environments. This raises the operational cost of industries that count so much on these machines. Other constraints are the stringent harassment laws against the environment; all these are now greatly affecting the manufacturing processes. With governments worldwide slowly tightening regulations on emissions and waste, manufacturers must therefore match the equipment with these rules, adding to their operational complexity and cost.

Nonetheless, the hammer mill market remains rife with numerous growth opportunities. Noteworthy among these opportunities is increased adoption of hammer mills in food processing and agriculture. As these industries expand, the demand for high-performing and efficient grinding equipment becomes more pressing. This demand is served by solutions that hammer mills provide for the processing needs of these industries that require a high degree of quality in a cost-effective manner. The other growth opportunity that continues to grow is the need for energy-efficient and sustainable grinding equipment. With increasing environmental concerns, companies are looking toward machines that consume less energy and generate less waste. Such trends create room for innovation, and this is where opportunities are availed for the hammer mill toward harnessing the development of energy-efficient machines.

MARKET SEGMENTATION

By Type

The global hammer mill market is seen to be growing widely due to the variety of applications in different fields. A hammer mill is a machine whose purpose is to crush, grind, or shred material into smaller pieces and is popularly in demand in agriculture, mining, recycling, etc. The market may be classified into several categories, each with its own specifics toward the needs or material involved.

The Full Circle Screen hammer mill would be among the most prominent segments of this market, expected to account for market revenues of $1,064.9 million. The design of the Full Circle Screen hammer mill allows it to achieve incredibly high efficiency and more consistent and complete grinding than other hammer mills. It strikes an amazing balance between speed of processing and precision, thus being accepted by many industries.

Another major type is the Gravity Discharge hammer mill; this is used when processing the material without application of air pressure or other external force. The design thus enables free flow of the material and continuous smooth operation. The Gravity Discharge hammer mill suits those materials that are to be gently handled to maintain quality.

Horizontal In-Feed hammer mills are another class created for industries requiring a more controlled feed process. This class of hammer mill is especially advantageous in bulk material operations due to the leveling feed, thereby increasing milling efficiency.

Lump breakers hammer mill works on the principle of breaking big chunks of material to small manageable sizes. It is widely used in chemical processing and food industries, where uniformity in particle size determines the product's quality.

The pneumatic discharge hammer mill discharges ground material through airflow. Such a benefit, in some cul-de-sac, might also mean that space and efficiency in energy consumption are of prime considerations. The hammer mill is usually found in areas with conducive materials handling and transportation management.

Owing to the relentless demand for improved performance and flexibility in milling solutions, the hammer mill market is also set for expansion on a worldwide basis. Different designs of hammer mills are enabling industries to choose the right machinery for particular processing needs. Improved technology in the future will further enhance reliability, speed, and versatility for the hammer mill market.

By Capacity

The field saw growth steadily into a hammer mill market, which had been making gains on diverse and varied applications in the industries, such as agriculture, food processing, pharmaceuticals, and chemicals. Hammer mills are usually employed for pulverizing material, either grains, biomass, or chemicals, into smaller particles. They can process or convert huge quantities of raw materials within a very effective way, being used in almost every process of the industry.

According to the different weight capacity, the market segment is divided into different sub-categories based on output per hour, which include "Up to 1 Ton/hr." followed by "Up to 10 Units/hr." Each will represent a specific production capability class. While categorizing machines that operate in smaller-scale commercial businesses, others are intended for large-scale industrial tasks.

"Up to 1 Ton/hr." is generally good for small enterprises or companies where production requirements are limited. These hammer mills are usually applied in small food processing plants, research labs, or small farms. A larger capacity is coupled with a larger size and higher price. The "1-3 Tons/hr." class will be the one used for medium-sized operations that need high production but still fit into space and budget limits.

For even larger modes of industrial application come the "3-6 Tons/hr." and "6-10 Tons/hr." classes. Such machines are applied in larger food-processing units, in pharmaceutical and chemical manufacturing, where large quantities of materials must be ground or processed within a given time frame. At this level, hammer mills serve for high output and efficiency that matters to industries on a larger scale when high demand needs to be fulfilled.

Usually, the classes "10-50 Units/hr." and "50-150 Units/hr." are suited to operations in big factories and commercial operations, where capacity and performance are vital to ensure the smooth working of production lines. These hammer mills are built for heavy-duty applications and are designed to process large amounts of material in minimal time with equal importance, as is the case in industries that process animal feeds, biofuels, etc.

"150-300 Units/hr." and "Over 300 Units/hr." are located well beyond the top of the scale typically used in industries with tremendous production needs. In such cases, high-capacity hammer mills are appointed for large-scale operations in factories and are able to process vast quantities of material fairly quickly and efficiently. These mills are generally custom-built to respond to the demands raised by the most taxing production environments.

All in all, the Global Hammer Mill market extends across regions according to capacity: all segments are designed for a distinct production requirement. That ultimately makes hammer mills fit for versatility and efficiency across industries ranging from small to large-scale industrial operations. Understanding the range of capacities helps the company to select the hammer mill that best suits its needs.

By Application

The hammer mill market is an important global market encompassing different industries, whilst its applications also have a significant role in stipulating demand. Among others, there are many applications for the market to be bifurcated into, with three major classifications: fine milling, ultra-fine milling, and coarse milling. Each of these milling processes has its own purpose and serves a specific set of needs for several industries, such as food processing, pharmaceuticals, chemicals, and agriculture.

Hammer mills mostly find their applications in fine milling. Fine milling refers to the milling process whereby materials are reduced to a fine powder or much smaller particle sizes. It is critically important to industries that demand precision and high quality in their end products. Consider, for instance, fine milling within the food industry, whereby grains and other ingredients are processed into fine powder for baking, or in the pharmaceutical industry, where this milling technology is contraindicated if the active ingredients are not finely milled to be effective.

Ultra-fine milling further refines fine milling by producing an even smaller size of particles. This application is critical in industries where ultra-fine materials are needed for specialized applications such as production of fine powders used in cosmetics, advanced pharmaceuticals, or tailored coatings. High precision and control are paramount during the ultra-fine milling processes to guarantee fulfilment of the stringent specifications expected of such applications.

Coarse milling, however, is a process that is used when the resulting products do not have to be finely or ultra-finely processed. Here, the process deals with bulk materials, therefore reducing these materials into larger particle sizes. This form of milling is mainly used in agriculture, where it involves milling grains or other raw materials to coarser products such as animal feed or certain types of flour. Coarse milling is also applied during recycling, where plastics or wood are ground into larger chips for further processing or reuse.

The classification of the global hammer mill market into these three types is consistent with the divergent requirements and preferences from different industries. Quite simply, there is a trend towards the efficient design of raw materials, therefore hammer milling-on account of its application in fine, ultra-fine, and coarse milling-should see increased demand. These three applications play pivotal roles in improving productivity and ensuring that materials meet requisite specifications, thereby promoting the forward movement of industries throughout the world.

By End Use

The Hammer Mill market is rapidly growing across the globe, and several industries are taking advantage of the Hammer Mill in several applications. A Hammer can be defined as a type of mill that is essentially used to crush or grind. Hammer Mills really have an application across several sectors such as Agriculture, Food and Beverage, Metals and Mining, Energy and Power, Scrap Recycling, Chemicals, and Pharmaceuticals. Each of these industries uses Hammer Mills, in different ways, to meet their demands, such that their product meets the given specification.

Hammer Mills have great importance in agriculture since these are the machines used for feed ingredient processing, grain grinding, and animal feed formulation. Its ability to provide particle sizes that are beneficial to nutrition is of utmost importance in animal nutrition. These mills are also used for processing other crops for other food products that help meet global food requirements. Thus its flexible nature accommodates different agricultural applications; hence, Hammer Mills, through all these avenues, can enhance productivity in this sector.

For the food and beverage sector, Hammer Mills convert ingredients such as grain, nuts, and spices into fine powders. Milling processed food ingredients contributes significantly toward controlling the quality and the texture of food ingredients. The Hammer Mill, therefore, contributes to the thorough mixing of these powders and pastes for homogeneity of finished food products. The importance of Hammer Mills in maintaining uniformity and quality in milling flour, sugar, and spices helps in considering food safety and customer satisfaction.

Hammer Mills, cementing their importance in the mining and metals industry during ore grinding and mineral crushing, indeed mark the intersection of Hammer Mills. This way, the raw materials would be sized for quick metal extraction. Doing that enhances streamlined functions and efficiency within the mining value chain while failing to minimize waste. Mills also find applications for pulverizing coal, biomass, etc., for energy input in the energy generation sector. Their consistent working performance assures preparing required feed for energy production with the help of Hammer Mills.

In scrap recycling, a hammer mill is employed to shred larger qualities of scrap metal and supplies into smaller, readily handled materials, as soon as they arrive at the recycling facility. These smaller sizes are critical in recycling processes for the recovery of valuable metals and materials. This way, Hammer Mills are also used for grinding and blending materials in the chemical and pharmaceutical sectors so that the raw materials get processed into fine powders for formulations in these industries. This would lead to making many medicines and chemicals, using Hammer Mills to give precise and dependable outcomes.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3,331.2 million |

|

Market Size by 2032 |

$4,432.2 Million |

|

Growth Rate from 2025 to 2032 |

3.9% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

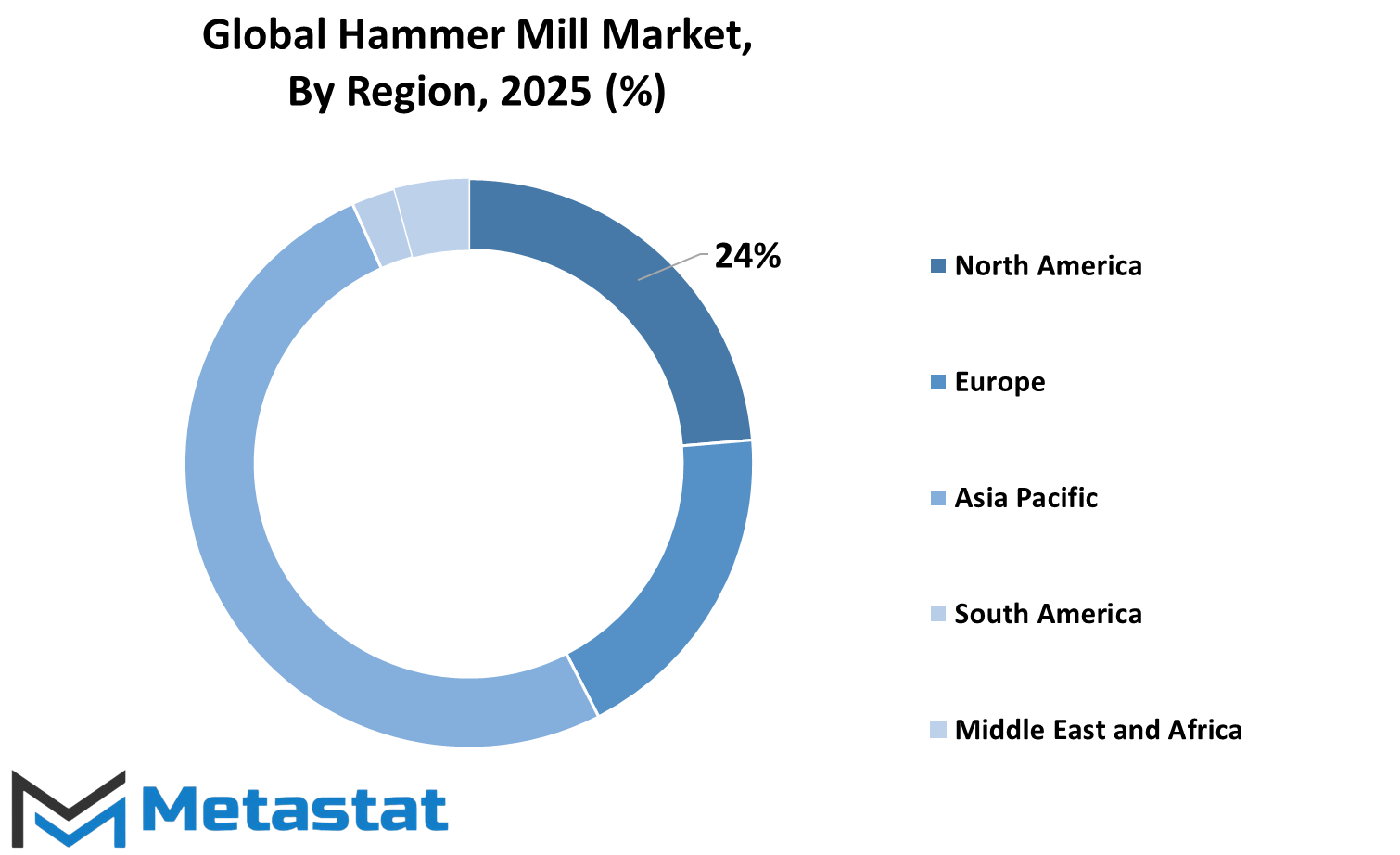

REGIONAL ANALYSIS

Every region of the world is again further separated by the different characteristics and demand patterns for the global hammer mill. North America, Europe, Asia-Pacific, South America, and North America, in North America, further divides between the United States, Canada, and Mexico, as each of these contributes their own portion towards overall hammer mills demand in different degrees. Whereas Europe includes countries like the United Kingdom, Germany, France, Italy, and various other European nations grouped as the Rest of Europe.

Countries like India, China, Japan, and South Korea are the major players in the Asia-Pacific hammer mill market segmentation, while the rest belong to the category Asia-Pacific: Rest. Most notably, growth in the next few years in this region will mainly be contributed by China and India due to increasing industrialization and a demand for efficient milling solutions.

Another critical market is South America, which consists of Brazil, Argentina, and all the others forming the Rest of South America. This area's demand has been carried from the growing agriculture and manufacturing sectors, with hammer mills being indispensable for processing fine products from raw materials.

The Middle East & Africa is another widely varied market. It can further classify into the GCC countries such as Saudi Arabia, the United Arab Emirates, Qatar, all other countries under these realms, and Egypt, South Africa, and the remaining areas of the Middle East & Africa. Hammer mills demand in such locations stems mainly from construction, agriculture, and mining industries.

The global Hammer Mill market has bases all of these and many more conditions as they relate to technological advances and regulatory modifications affecting each of the mentioned markets. Many opportunities will arise for manufacturers to cater to regional needs as they continue growing and evolving, which will mean more hammer mills are required. This demand will continue to come from the general need of different sectors such as agriculture, food processing, and manufacturing for better and more efficient milling solutions.

COMPETITIVE PLAYERS

Hammer Mill are now used for the grinding of several materials in fine powders or granules for different applications, rendering them versatile to comprehend. As industries continue to expand and innovate, the importance of mill equipment, which is reliable and efficient for performing the task, is becoming increasingly prominent. Hammer mill companies are in search of more efficient and cost-effective ways to process raw materials.

Abyss and Andritz, Bühler Group, Doppstadt-the hammer mill industry has all these players, with some even having devoted decades to providing the best machine work. They pride themselves on a hammer mill cataloged within the specification range from an industrial-scale processing system to a small specialized unit. According to Doppstadt, Andritz hammer mills have an ultra-strong construction, as they display different applications such as animal feed, biomass, and recycling.

Other names in this pertinent development towards a brand new breed of commercially viable milling solutions are Filtra Vibración, Bellmer GmbH, and even more dominant players in their own right-Hosokawa Micron Corp. While Filtra specializes in customized hammer mill solutions, Bellmer focuses on durable, premium quality equipment for the paper industry. On the other hand, Hosokawa Micron Corp is well known for its powder processing technology for pharmaceutical and food applications.

Kurimoto Ltd. and L.B. Bohle Maschinen & Verfahren GmbH are also major players that advance the pharmaceutical and chemical industries with grinding solutions in hammer mills. Both companies emphasize precision and reliability, which guarantees that their products will meet the high standard requirements of these industries. Lehrafuel, Manfredini & Schianchi, and the NETZSCH Group are other important players contributing to the hammer mill market with advanced machinery tailored to meet specific needs, from food processing to fine grinding of minerals.

Lessine SA, Perkin Elmer, Poittemill Forplex, and Prater Industries offer additional cost-effective and efficient milling options. Innovators such as Rasa Corporation, Sandvik AB, Schenck Process Holding GmbH, and Frewitt SA actively develop hammer mill technologies to ensure that customers enjoy access to the latest. With growing demand for hammer mills, these significant players will increasingly satisfy the needs of the industries located in the globe.

As demand for hammer mills continues unabated, technological advances coupled with heightened industrial demand propel the optimism of growth in the global hammer mill market.

Hammer Mill Market Key Segments:

By Type

- Full Circle Screen

- Gravity Discharge

- Horizontal In-Feed

- Lump Breaker

- Pneumatic Discharge

By Capacity

- Upto 1 Ton/hr.

- 1–3 Ton/hr.

- 3–6 Ton/hr

- 6-10 Ton/hr

- 10–50 Units/hr.

- 50–150 Units/hr.

- 150–300 Units/hr.

- Above 300 Units/hr.

By Application

- Fine Milling

- Ultra Fine Milling

- Coarse Milling

By End Use

- Agriculture

- Food & Beverages

- Metals & Mining

- Energy and Power

- Scrap Recycling

- Chemicals

- Pharmaceuticals

Key Global Hammer Mill Industry Players

- Andritz

- Bühler Group

- Doppstadt.

- Filtra Vibración

- Bellmer GmbH

- Hosokawa Micron Corp

- Kurimoto Ltd.

- L.B. Bohle Maschinen & Verfahren GmbH

- Lehrafuel

- Manfredini & Schianchi

- NETZSCH Group

- Lessine SA

- Perkin Elmer

- Poittemill Forplex

- Prater Industries

- Rasa Corporation

- Sandvik AB

- Schenck Process Holding GmbH

- Frewitt SA

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252