MARKET OVERVIEW

The global fire-retardant fabric market will undergo a transformation that reaches a long way past its immediate enterprise confines. Traditionally utilized in protecting garb and safety gear, fire-retardant fabric are set to steer sectors previously untouched by way of such specialized textiles. As rules tighten and patron cognizance grows, the application of those fabric will no longer be restrained to firefighting or business workwear. Instead, future innovation will result in broader, surprising integrations across structure, customer electronics, or even interior design.

What lies beforehand for the industry isn't merely an expansion of its customer base however a whole rethinking of how fire safety is approached in present day existence. Smart homes and buildings will call for textiles that offer extra than simply basic hearth resistance. Designers and engineers will an increasing number of are searching for out substances that assist each function and form. Fire-retardant curtains, upholstery, and insulation fabrics turns into fashionable functions in sustainable architecture. This shift will now not be driven solely by using compliance but by using a deeper commitment to integrating safety into aesthetic and environmental priorities.

Beyond construction, the amusement and sports sectors will in all likelihood witness an infusion of advanced fire-retardant fabrics. Costumes and degree setups in movie, theater, and live activities will evolve to consist of textiles that provide safety with out compromising overall performance or visible appeal. In intense sports activities, the demand for lighter but long lasting fire-resistant gear will affect how clothes are engineered. These changes receiver's merely cater to experts.

Another measurement on the way to emerge is the use of fireplace-retardant fabrics in virtual and digital products. As devices grow to be greater compact and effective, the chance of warmth-associated incidents will upward thrust. Manufacturers will start to line electronic additives and wearable tech with skinny, breathable hearth-retardant materials which could resist higher temperatures without degrading. The global fire-retardant fabric market will serve as a foundational element on this defensive approach, paving the manner for textiles to end up active members in tech safety.

Moreover, the sustainability conversation will push the fireplace-retardant fabric enterprise to innovate beyond chemical remedies. In the approaching years, natural and recycled fibers with inherent hearth resistance will possibly be advanced. This shift will not simplest reduce environmental effect however additionally redefine how consumers and manufacturers understand the category. Instead of viewing hearth-retardant fabrics as area of interest or commercial, they will be seen as flexible and crucial.

As the road between protection and every day consolation keeps to blur, the global fire-retardant fabric market could be poised to behave as a silent but effective contributor to evolving design requirements, consumer expectancies, and cross-enterprise answers. It will no longer be a static enterprise defined by way of beyond programs, but a dynamic force that quietly reshapes the manner human beings revel in safety in both normal and awesome settings.

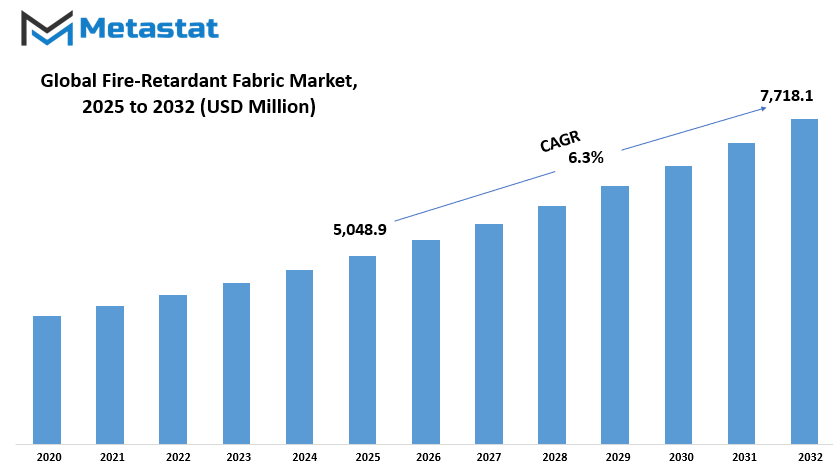

Global fire-retardant fabric market is estimated to reach $7,718.1 Million by 2032; growing at a CAGR of 6.3% from 2025 to 2032.

GROWTH FACTORS

The global fire-retardant fabric market is steadily gaining significance as protection standards emerge as greater crucial throughout industries. With growing guidelines targeted on fireplace prevention in workplaces, factories, and public homes, the demand for substances that could sluggish or prevent the spread of fireplace is at the upward thrust. Industries including oil and gasoline, creation, transportation, and manufacturing are now prioritizing defensive fabrics to make certain worker and infrastructure safety. This shift isn't just about compliance however also approximately reducing threat and liability. The growing use of hearth-retardant fabric in uniforms, upholstery, curtains, and different crucial areas highlights how essential those materials have become.

A key issue helping this marketplace develop is the rising want inside military and protection operations. Fire-retardant fabric are extensively utilized in protecting gear, tents, and other system in which exposure to excessive temperatures or open flames is a challenge. The army requires materials that could face up to severe environments, and hearth resistance is a critical characteristic. As worldwide defense budgets growth and safety will become a top priority, the demand for such specialized fabrics keeps to develop. In addition, the economic and home sectors also are adopting fireplace-retardant textiles for protection purposes, in addition helping market increase.

However, now not the entirety works in want of this marketplace. One principal undertaking is the high production value. The technique of creating fabrics proof against hearth usually entails pricey chemical remedies or advanced fibers, which provides to the very last product's rate. This makes it difficult for a few producers, mainly smaller ones, to undertake those materials on a big scale. Another problem is the lack of know-how in many growing regions. In places where protection requirements are nevertheless evolving or no longer strictly enforced, human beings and organizations won't see the cost of making an investment in fire-retardant fabrics, despite the fact that they provide lengthy-time period advantages.

Despite those hurdles, the marketplace also gives promising possibilities. One of the maximum interesting regions is the development of green and sustainable fireplace-retardant fabrics. With growing environmental worries, companies are seeking out ways to create safer textiles with out counting on harmful chemical substances. This opens up new opportunities for innovation and appeals to both purchasers and regulators. The car and aerospace sectors are also starting to contain greater hearth-retardant materials into their designs, pushed by the need for protection and compliance with global standards. These advancements recommend sturdy destiny boom for the marketplace.

MARKET SEGMENTATION

By Type

The global fire-retardant fabric market will hold to gain importance in industries in which protection is a concern. This fabric is specially designed to withstand ignition and save you the unfold of flames. Its role will grow considerably in sectors like defense, aerospace, creation, transportation, and oil & gas, wherein fire safety will never be elective. These fabric are frequently used to make defensive apparel, upholstery, curtains, and different substances that could otherwise seize hearth quick. The market will be pushed by protection rules and increasing recognition of the dangers of hearth-associated injuries.

There are primary kinds in the market: Inherent Fire-Retardant Fabric and Treated Fire-Retardant Fabric. Inherent fabrics are made with fibers that naturally withstand fire. These fabric will retain their hearth-retardant homes even after repeated washing and wear, making them more long lasting ultimately. The global fire-retardant fabric market value of this section is projected to attain $1872.6 million. On the opposite hand, treated fire-retardant fabrics are made through applying a chemical remedy to in any other case flammable textiles. These fabric are more cost-effective however might lose their hearth-resistant excellent over time, specifically if not treated consistent with right care instructions.

One cause for the steady call for will be strict fireplace protection requirements across public areas, work environments, and transportation structures. Countries round the arena will retain updating their constructing codes and industrial protection regulations, making the use of hearth-retardant materials greater commonplace. For example, in high-danger places of work like welding shops or chemical plants, employees want gear in an effort to shield them from sparks and flames. The growing variety of such facilities will contribute to growing call for.

At the identical time, the marketplace will face a few challenges. The cost of manufacturing, specially for inherently hearth-retardant fabric, is high. Also, some treated fabrics can improve environmental concerns due to the chemicals used. There might be growing pressure to locate more secure, green treatments that don't compromise hearth resistance. However, this can also bring possibilities for organizations that spend money on sustainable era.

As industries prioritize each safety and environmental duty, the fireplace-retardant cloth marketplace will no longer simplest expand however additionally shift towards extra long lasting, reusable, and sustainable answers. Manufacturers who reply early to those changes will probable lead the way in shaping the future of this important enterprise.

By Fabric Type

The global fire-retardant fabric market will preserve to draw attention across numerous industries because of its significance in ensuring safety and assembly strict regulatory standards. One of the most practical approaches to classify the marketplace is by way of material kind, which includes coated fabrics and spun bond material. Each kind has a selected characteristic and reason, catering to unique industry needs which includes creation, army, transportation, and home furniture.

Coated fabric will continue to be extensively used due to the introduced layer of protection they provide. These fabric are generally dealt with fireplace-retardant chemical substances that improve their resistance to flames. The coating no longer only boosts their durability but additionally ensures that the fabric can withstand excessive temperatures for a longer time. This nice makes lined fabric an ideal preference for packages where protection is a pinnacle concern, inclusive of firefighting suits, commercial uniforms, and delivery seating. As industries like aviation and automobile preserve to prioritize passenger protection, using lined fabrics will in all likelihood come to be even more commonplace.

On the opposite hand, spunbond material may also maintain a robust role in the marketplace. This fabric type is produced thru a way that bonds the fibers together the use of warmth, giving it a completely unique energy and lightweight nature. It is specially famous in sectors that require a stability of safety and comfort. For example, it will be used in protective clothing for workers who require mobility without compromising safety. Spunbond clothing will also show increasing interest in household items and curtains, where fire safety is required, but with focus on cost -effective solutions.

The manufacturers will continue to focus on increasing both essential features such as breathing and comfortable compromise both fabric type fire fighting properties. As consumers and businesses are more aware of the risks and safety rules of fire, the demand for these clothes will increase. Additionally, technical improvement in cloth treatment will lead to reducing environmental concerns, which will play an important role in market development.

Both coated fabrics and spoonbond fabric will play an important role in the future of the global fire-retardant fabric market. Their personal benefits will ensure that they remain relevant to various requirements, help industries meet safety standards, while keeping in mind the cost and functionality. Since security is a major concern around the world, the importance of choosing the right fire-holding clothes will continue to increase.

By Application

The global fire-retardant fabric market, when viewed through its application lens, presents a landscape that will continue to move to the side of the security-conscious areas. In major applications, protective fabrics hold a strong position. This section will play a major role in demand for industries such as oil and gas, military, fire fighting, and manufacturing, which focuses on the activist security. These clothes are used in clothes that will help reduce the severity of injuries caused by heat or flames. As the industries become more regulated and the standard become tightened, the use of fire fighting protective clothing will probably not be important but necessary. Employers will continue to invest in these solutions to complete the security protocol and protect their workforce.

In household items, fire-retardant fabrics will be found in products such as curtains, upholstery and beds. This application will mainly increase due to the increasing awareness between the owners of the house and the dangers of the fire. Fire safety rules in hotels, hospitals and even residential complexes will contribute to the increasing use of such materials. These clothes will provide additional protection without design or comfortable compromise. Since consumers are more concerned with both safety and style, fabric manufacturers will need to balance aesthetics with functionality.

Public utilities will also represent an important area where the use of fire-secure fabric will be more common. These include areas such as transport, electricity and water services, where any fire outbreak can cause mass damage. In these areas, workers often face risks that require clothes made from materials that slow down or resist flames. Growing infrastructure projects worldwide will also increase the demand for better security gear in utility services.

Industrial use of fire fighting clothing will further expand in factories, warehouses and chemical processing plants. Here, accidental fire is often high due to machinery, chemicals and other volatile materials. These clothes will be used to create a safe environment in workwear, machine cover and even wall coverings or division. Industry will prefer these clothes to avoid operations downtime and meet legal requirements.

Each application shows a clear reason that fire-retardant fabric will not only be relevant, but will increase in importance. The future of this market lies in how well these materials will suit various environment, which provide protection without renunciation or abandoning efficiency.

By End User

The global fire-retardant fabric market, when studied by the end user, shows a wide and practical range of applications. This material is used in industries where protection is necessary for safety and protection from flames. In the main end users, the oil and gas fields will continue to lead due to their high -risk environment. In this area, workers are constantly exposed to flammable substances, and therefore fire-driving fabrics and equipment are not optional-they are important. These clothes will be essential in protective gear, which will help reduce the risk of burns and injuries. Similarly, a steady demand for these clothes will appear in the construction sector, especially in areas where welding, grind, or electrical work is being done. Construction workers, such as oil and gas, require durable clothing that can oppose the dangers of the fire and provide extra time in emergency situations.

Manufacturing and mining industries will also maintain strong use of fire fighting clothing. In manufacturing, especially in factories that deal with heat-based procedures or flammable materials, the need for fire protection is created in the daily routine. The mining industry, which involves consistent contact for underground work and combustible dust, will rely on these clothes for safety. Chemical plant, where there is a continuous risk of fire due to chemical reactions or leakage, will remain a major final user. Here, fire-retardant fabric will help prevent accidents from being fatal. Fabrics are designed to oppose ignition and prevent fire spread, which is important in the environment that handles dangerous substances daily.

The transport sector is another important final user. In railway, aviation, and even motor vehicle production, safety rules will require the use of fire fighting clothing in both employee uniform and internal content. Similarly, in military and defense areas, where uniforms, tents and gears are often exposed to tablets, explosions or extreme temperatures, fire resistant fabric is a requirement. These materials will help protect personnel in dangerous missions and training operations.

Finally, the "other" category includes small scale applications such as fire fighting, electrical work and even some areas of the hospitality industry where kitchen safety matters. In all these sections, the use of fire fighting fabric will be inspired by a shared requirement: to protect people from the dangers of fire in the atmosphere where a spark can change everything.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$5,048.9 million |

|

Market Size by 2032 |

$7,718.1 Million |

|

Growth Rate from 2025 to 2032 |

6.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

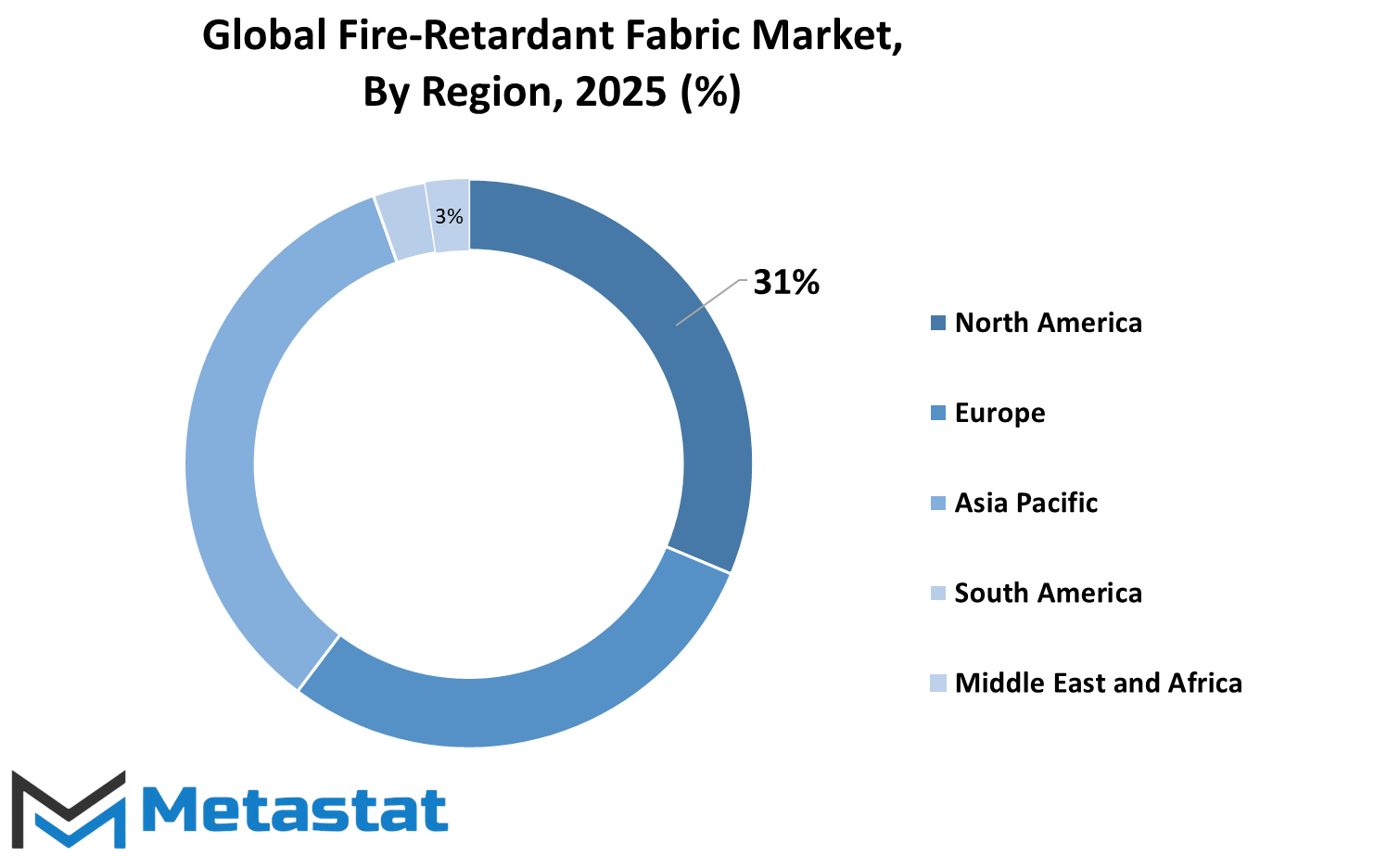

REGIONAL ANALYSIS

The global fire-retardant fabric market is broadly fragmented on geographical areas, each with its own industrial setup, safety rules and manufacturing powers that shape the demand for such clothing. North America plays a major role in this market, especially with the United States, Canada and Mexico. U.S. Security leads to protocols and fire safety compliance, which will continue to promote the need for fire fighting clothing in industries such as construction, oil and gas and defense. The Canadian worker follows a uniform trend with increasing attention to protection and public safety, while the expansion of Mexico will probably add overall demand in the region.

In Europe, the fire-retardant fabric market is supported by strict rules and high awareness about fire safety. Countries like UK, Germany, France and Italy have established strong guidelines that require the use of protective clothing and fire-safe materials in public and private places. These rules will support stable demand. The strong industrial landscape and infrastructure of Germany will also focus on the use of fabric on the infrastructure and energy areas. For the rest of Europe, countries trying to improve growing construction projects and safety standards will contribute to the development of the market in this part of the continent.

Asia-Pacific is expected to show the fastest growth in the market due to increasing construction activities, rapid industrial development, and awareness about workplace safety. India, China, Japan and South Korea are the major markets within the region. India and China, with their large population and growing urban centers, will see an increase in the need for fire-safe construction materials and protective clothing. Japan and South Korea will maintain their demand for focusing their focus on technology and safety compliance, being a highly industrial nation.

In South America, Brazil and Argentina are leading the demand for fire fighting clothes. Along with construction activities, Brazilian oil and gas sector will insist on safety upgradation, while Argentina's industrial growth will also contribute. The rest of South America will gradually increase as the fire safety awareness increases. Meanwhile, the Middle East and Africa will also have capacity due to increase in investment in oil, gas and construction projects. GCC country, Egypt and South Africa are the main contributors. Since these areas continue to develop their infrastructure and implement safety rules, the use of fire fighting fabric will be more widespread.

COMPETITIVE PLAYERS

The global fire-retardant fabric market will continue to be fashioned with the aid of the growing call for more advantageous safety throughout various industries. Fire-retardant fabrics are designed to face up to ignition and prevent the spread of flames, making them critical for environments in which fireplace risks are a consistent situation. These fabrics are commonly used in industries such as oil and gas, defense, mining, construction, aviation, or even public shipping. The want for progressed worker safety will push industries to undertake better protecting apparel and fixtures, using the call for hearth-retardant materials. The use of such fabrics isn't restrained to workwear; they'll also be used an increasing number of in residential and business settings wherein fire protection standards have become greater stringent.

The global fire-retardant fabric market will benefit from the growing awareness of place of job protection policies. Governments and global bodies will implement legal guidelines requiring using protecting apparel, especially in sectors wherein workers face excessive dangers. This will push businesses to supply top notch fire-retardant textiles to comply with safety standards. The continuous improvement of fabric that not most effective face up to fire however additionally stay light-weight, breathable, and cushty can be a key element of their adoption. Comfort turns into just as vital as safety, specially in industries wherein employees need to wear such clothing for extended hours. This shift in desire will inspire manufacturers to innovate and offer progressed textile solutions.

Key players within the global fire-retardant fabric market consisting of PBI Performance Products, Inc., TenCate Protective Fabrics, Glen Raven, Inc., Lenzing AG, Westex, Delcotex Delius Techtex GmbH & Co. KG, Shandong Yulong Textile Co., Ltd., Herculite, Inc., Charles Parsons & Co. Pty Ltd, Carrington Textiles Ltd, DuPont de Nemours, Inc., 3M Company, Teijin Limited, Milliken & Company, W. L. Gore & Associates, Inc., and Kaneka Corporation will retain to steer the path of the market. These groups will recognition on growing textiles that meet new protection policies and cater to a much broader range of applications. Investments in studies and development will result in cloth improvements that offer higher flame resistance, sturdiness, and comfort. Collaborations and partnerships among these players and give up-use industries will help in addressing unique needs, improving product performance, and increasing the marketplace attain.

As safety standards tighten and consumer focus grows, the demand for fireplace-retardant fabric will boom regularly. The global fire-retardant fabric market will circulate in the direction of greater sustainable, excessive-overall performance materials that serve both commercial and home purposes without compromising comfort or compliance.

Fire-Retardant Fabric Market Key Segments:

By Type

- Inherent Fire-Retardant Fabric

- Treated Fire-Retardant Fabric

By Fabric Type

- Coated Fabrics

- Spunbond Fabrics

By Application

- Protective Clothing

- Home Furnishings

- Public Utilities

- Industrial

By End User

- Oil & Gas

- Construction

- Manufacturing

- Mining

- Chemicals

- Transportation

- Military & Defense

- Other

Key Global Fire-Retardant Fabric Industry Players

- PBI Performance Products, Inc.

- TenCate Protective Fabrics

- Glen Raven, Inc.

- Lenzing AG

- Westex

- Delcotex Delius Techtex GmbH & Co. KG

- Shandong Yulong Textile Co., Ltd.

- Herculite, Inc.

- Charles Parsons & Co. Pty Ltd

- Carrington Textiles Ltd

- DuPont de Nemours, Inc.

- 3M Company

- Teijin Limited

- Milliken & Company

- W. L. Gore & Associates, Inc.

- Kaneka Corporation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252