MARKET OVERVIEW

The Global Electrically Conductive Foam market is an integral part of the electronics and electrical industries combined. It manufactures and sells specially designed foams that can conduct electricity to guarantee optimum performance and safety for any electronic device. The foams are used to shield sensitive components from electromagnetic interference and electrostatic discharge, which extends the lifespan and improves reliability of an electronic product.

Electrically conductive foam has become very significant due to the uniqueness of some of its properties, which put flexibility, conductivity, and cushioning all in one material. These foams can be made from such materials as polyurethane or polyethylene impregnated with conductive fillers like carbon, metal-coated particles, or conductive polymers. This realizes a fine balance in electrical conductivity and mechanical resilience for such foam and makes it an extremely useful component in very many applications.

One major application of electrically conductive foam is in consumer electronics, which provides shielding for sensitive components in smartphones, tablets, and laptops. With the increasing miniaturization and complexity of electronic devices, there will only be a growing need for EMI shielding and ESD protection. Electrically Conductive Foam will thus be integral to the performance and safety of these devices by ensuring they do not malfunction from any electromagnetic interference or electrostatic discharge.

Demand for Electrically Conductive Foam is expected to grow in the automotive industry. The trend toward greater integration of electronic systems in today's vehicle—from ADAS to infotainment—bodes well for the demand for more and more robust EMI shielding solutions for all types of electronic components. Thus, intensive usage of electrically conductive foam will be required to reliably protect electronic components against hostile environmental conditions.

Beyond that, the telecommunications segment will lend further impetus to growth in the Global Electrically Conductive Foam market. With rapidly expanding 5G networks and a proliferation of connected devices, the need for effective EMI shielding solutions will become even more acute. Electrically Conductive Foam will be used to protect complex electronic systems at the heart of telecommunications infrastructure and ensure uninterrupted and reliable connectivity.

Electrically Conductive Foam in the medical sector will find an outlet in cushioning sensitive electronic apparatuses like diagnostic devices, monitoring systems, and therapeutic machines. These foams will turn out to be very instrumental in ensuring that medical equipment works with precision and reliability; this is critical to the safety of the patients and effective dispensation of health care.

Electrically Conductive Foam will increasingly find its place at work in the aerospace and defense sectors. These are industries where the use of electronic systems is exposed to very extreme conditions and heavy performance standards. Electrically Conductive Foam will provide protection for the reliable operation of key electronic parts in aircraft, satellite, and defense systems.

As technology advances and further sophisticated electronic devices and systems become in demand, so will the Global Electrically Conductive Foam market. With continuous innovation in material science and manufacturing processes, newer and more effective Electrically Conductive Foams will be developed, making them more cost-efficient and thus more adoptable across industries.

The Global Electrically Conductive Foam market has been and will continue to be one of the most energetic and vital sectors within the electronics and electrical industries. With the advancement in technology, their importance will increase in the near future due to increasing demand for EMI shielding and ESD protection for a wide variety of applications. This market will be marked by continuous innovation and adaptation to the changing needs of the industries it serves in the future.

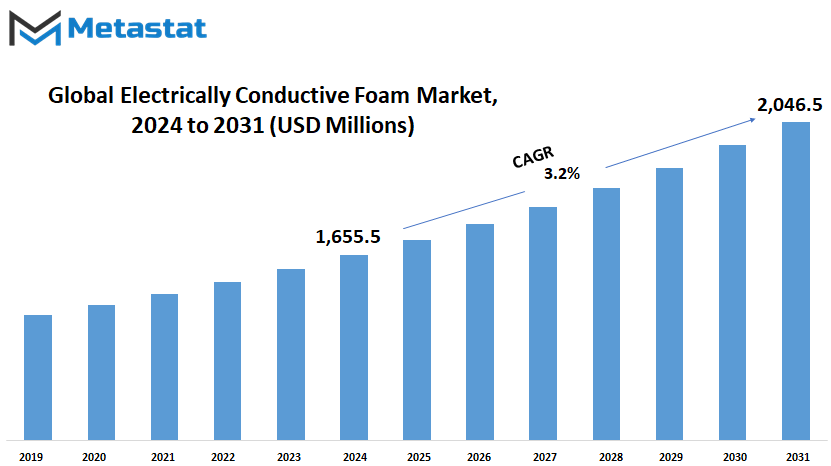

Global Electrically Conductive Foam market is estimated to reach $2,046.5 Million by 2031; growing at a CAGR of 3.2% from 2024 to 2031.

GROWTH FACTORS

The factors are going to have huge growth in the market for Global Electrically Conductive Foam. Major drivers include increasing demand for lightweight and flexible materials in extensive industries, chiefly bundle with most electronic and automobile sectors. Innovation is happening tremendously in those sectors, so the demand for a material that gives freedom and, at the same time, offers resilient building will keep on increasing. This will become particularly important in applications requiring EMI shielding and dissipation of static charges in sensitive electronic equipment.

Highest of the production costs relate to the manufacturing of electrically conductive foam, in which production cannot be scaled since it is required by more extensive mass-market applications. Yet another challenge is holding the lines of constant conductivity and durability at all times in different environmental conditions. All of this can moderate the growth of this market and widespread application of electrically conductive foam in various industries. Of course, among all these problems, some perspectives are very optimistic. Attractive innovative developments of manufacturing techniques and materials can greatly reduce production costs with excellent performance in the electrically conductive foam. Bettering in these aspects could achieve expansion and enlargement to the market with an increase in reach and application.

This is likely to drive growth and create lucrative opportunities within the years to come. The EMI shielding and static dissipation in contemporary electronic devices have become not only the trend of this century but also the shape of a requirement for further infrastructural development. The importance of effective solutions of shielding can only grow with the ever-increasing complexity and compactness of today's electronic devices.

Electrically conductive foam proves just the right solution, possessing flexibility but without giving up the protective properties needed in a modern electronic device. The next large growth drivers are the increasing adoption of electric vehicles and the advanced driver-assistance system in the automotive segment. Both of these require the utilization of greater amounts of electronic components in order to provide effective EMI shielding if they are to be reliable. As a result, this will be a class of lightweight materials that can provide such shielding, thereby maintaining high demand to continue aiding the electrically conductive foam market.

So, the outlook for the global electrically conductive foam market does look promising with a few troublesome areas. As the demand for new, flexible materials purposely for electronics and automotive applications together with EMI shielding and static dissipation requirements, will this market be. Further growth of the market will ultimately be seen provided the challenges of high production costs can be alignnd with uniform performance, which really makes huge opportunities when those mats of advancements and applications enter into general use across many industries.

This field advances not through improvements in the material itself, but in the development of new manufacturing techniques; many of the challenges that face the materials today are expected to decrease in impact as the technique advances.

MARKET SEGMENTATION

By Type

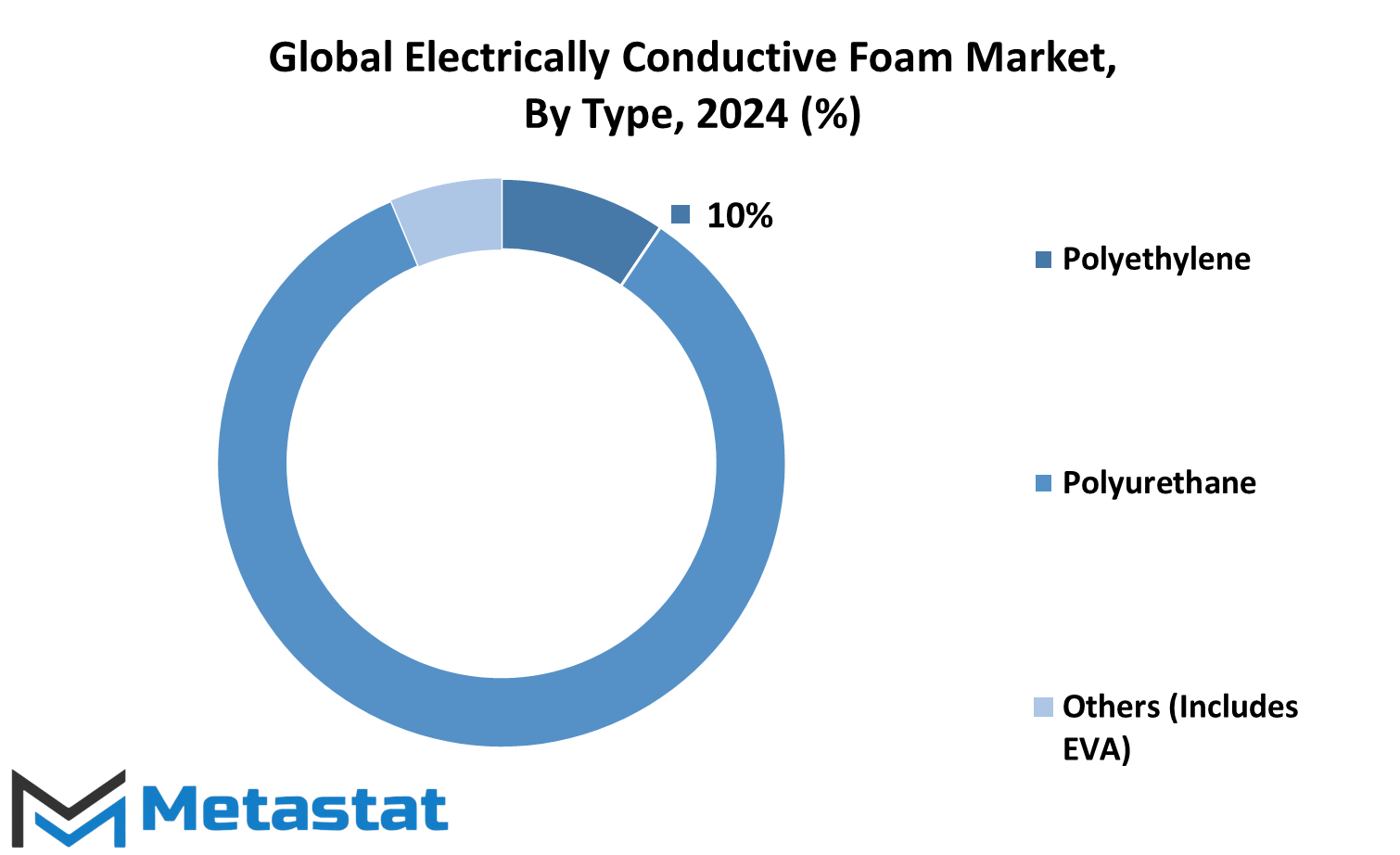

The Global Electrically Conductive Foam market has huge potential in the coming years. This market, segmented into types of polyurethane foam, silicone foam, and others, will rise with increased demand due to the need for efficient methods that control the problem of electromagnetic interference (EMI). With rapid technological development, the requirement regarding protection of the electronic device from EMI becomes of prime importance. It is in this context that electrically conductive foam assumes a very important place, enriched by outstanding conductivity and shielding characteristics. Among the major types, polyurethane foam will still gain widespread use in the near future, since it has versatility coupled with effectiveness.

There are manifold benefits for this type of foam, as it brings lightness and strength together with good conductivity. Therefore, the above-mentioned target applications fully fit for it, from consumer electronics to industrial equipment. Miniaturization is the trend for electronics; thus, there is growing demand for polyurethane foams in this sector, even more so since this will provide the required protection without remarkable additional weight or bulk. Another large segment is silicone foam, which would also show significant growth in the future. Because of its properties of high-temperature and toughness, the application of silicone foam in some extreme environments under such operation conditions is pretty wide.

Growth in the application industries of automotive and aerospace will drive demand for silicone foam, in whose applications the operating conditions are extremely difficult. This industry generates maximum demand because it has the ability to remain conductive while being flexible and resilient. Other kinds of conductive foams will also find market growth as research and development efforts are oriented toward improving their properties and applications. New innovations will bring foams with higher conductivity, improved durability, and efficient shielding into existence. This new frontier contains a great deal of opportunities in some of those emerging fields electric vehicles and renewable energy systems in areas where the component of EMI management is very significant.

In the near future, the Global Electrically Conductive Foam market will get impetus from the rising adoption of smart devices and the Internet of Things. As more and more devices are interconnected, the need for shielding from EMI will become critical. Electrically conductive foam will be of much essence in ensuring reliability and performance in those devices.

Moreover, raising awareness about the role of electromagnetic compatibility in the attainment of safe and functional performance of any electronic system will further fuel its growth. The Global Electrically Conductive Foam market makes its way to pound within a world full of challenges and opportunities that are technologically advanced. In other words, this improving market will support the evolution and reliability of future electronic devices and systems. The future of electronic technology is going to lean more on innovation and sustainability in ensuring that electrically conductive foam remains vital in the protection and performance of the same.

By Product Type

This duration, over the coming years, can be quite optimistic for the growth of the Global Electrically Conductive Foam marketplace. Of course, this will be due to the increasing demand in the sectors of the industry at electronics, automotive, and telecommunications. Electrically conductive foams are one of the principal drivers of EMI shielding for the trouble-free functioning of the electronic device.

As progress changes with a changing world, the requirement for effective EMI shielding will further scale up, thus developing new and improved variants of conductive foam. One of the major products to have hit the market is the conductive sponge. The foam is very flexible and it has very many uses. In the future, more advanced applications for conductive sponges will appear, especially in space-constrained, complicated electronic assemblies that need highly adaptable materials.

Another vital category is that of conductive sheets. Conductive sheets have many uses in several electronic component or electronic device productions. With electronic devices becoming ever more miniaturized, conductive sheets are assuredly to become even more indispensable. Their purpose will involve not just protecting the smaller and more intricate circuits, but ensuring the smaller and more intricate circuits remain intact and workable, predicted to become a portion of the mainstream market in the upcoming years.

This will stretch to the conductive tape market. Conductive tapes are applied easily and are always reliable. They become very essential in situations whereby efficient EMI shielding is realized alongside fast processes for that case. As industries seek a more automated and efficient production process, there will be the demand for conductive tapes. A principal role will be played by the tapes in maintaining production efficiency while making sure that electronic gadgets are EMI-shielded.

Another major component of the market is conductive gaskets; they are known to provide robust EMI shielding in enclosures and junctions. Since secure and reliable electronic systems are becoming a prime requirement, conductive gaskets will also experience a similar hike in demand in the coming years. Advancements in this category will normally be toward building more strength and efficiency into these gaskets to enable them to meet the dynamically changing requirements of different industries.

For example, Global Electrically Conductive Foam does not just offer these several specific products attuned to certain needs and applications; the company offers them continuously. In fact, the continuous innovation and introduction of groundbreaking electrically conductive foam products is another reason why this market would become very exciting in the future.

The Global Electrically Conductive Foam market will exponentially increase in the future with an increase in demand for EMI shielding solutions across sectors. Diversifying further will be the innovations into conductive sponge, conductive sheets, conductive tapes, and conductive gaskets to be at a par with key solutions needed for serial technological innovations in the near future.

By Application

Looking ahead, the global electrically conductive foam market is going to increase drastically. Indeed, with its applications across varied industries, this market has scope for newer inventions that can offer better performance in their respective fields.

Electrically conductive foam is intended for preventing electromagnetic interference and grounding solutions. In the modern world, surrounded by electronic devices, this has become very important. Good quality EMI shielding has become critical as technology improves. The versatility and significance it has gained from its application in I/O Shield and Non-shear Standard Connectors, EMI Shielding, Electrical Grounding, Automotive, Consumer Electronics, Aerospace, Medical, and many more have made it of significant growing importance.

In the automotive industry, electrically conductive foam will be very competitive in terms of ensuring that cars on the road are both safe and efficient. Effective EMI shielding against the ensuing interference with sensitive electronic systems brought about by electric and autonomous vehicles coming into the market will be realized with greater importance. This market presents a position to address such demands by providing advanced materials that secure vehicle safety and performance.

Another huge area of application lies within the consumer electronics sector, in which electrically conductive foam will find their usage enhanced. The more compact and powerful devices become, the more risks of electromagnetic interference are associated with them. This foam will help in mitigating such issues so that the devices function optimally without compromising on high performance or safety concerns. Steadily increasing miniaturization of electronic components drives the demand for new shielding solutions and hence gives further impetus to this market.

Advanced properties of electrically conductive foam will soon serve the aerospace sector by helping to sustain the integrity of communication systems and electronic controls critical to safe and efficient operations. Therefore, the demand for EMI shielding is expected to increase further as technology advances in the aerospace sector and forms the basis for market growth.

Electrically conductive foam in the medical domain will provide a way to ensure medical devices work correctly something of extremely high importance both for the safety of patients and the effectiveness of treatments. On the other hand, an increasing reliance on electronic devices in healthcare is boosting demand for materials capable of providing robust EMI shielding and grounding solutions.

By End-user

The market of electrically conductive foam is going to witness the bright growth in the Global market. It's primarily driven into interface growth from the various end-user industries, some of which include electronics, automobiles, aerospace, and healthcare, among other packaging sectors. The overall bond demand is exponentially increasing and trying to meet the effective shielding solution. Hence, highly popular are foams exhibiting brilliant performances of electrical conductivity and cushionability.

Meanwhile, the pharmaceuticals and food processing industries also offer an important site for the use of conductive foam to protect sensors from being upset by EMI or to be shielded from static electricity as the case may be. The resulting demand in the wake of more and more devices coming into the marketplace from the cover list of electronics, for suitable EMI shielding materials, will finally also lead to one that requires electrically conductive foam. On the other hand, innovation in consumer electronics combined with the ongoing trend to miniaturize devices secures that this one market segment will always remain high. Another key end-user of the sector is the automotive industry.

The increasing percentage of electric and self-driving vehicles will force efficient and reliable EMI shielding against interference in automotive electronics. The electronically conductive foam will provide protection to the electronic control units, sensors, and all other varieties of applied important elements of such cars. Demand for conductive foams on broad terms will rise as the automotive sector moves toward vehicles that are highly advanced and connected. The possibility of an electrically conductive foam to be majorly utilized will also correspond to the reliability and safety of aircraft electronics. Presently, the aerospace industry makes use of advanced electronic systems in matters of communication, navigation, and control.

The use of conductive foam will help in the protection of these systems from EMI. This will aid in making aircraft operations safer and more efficient. High-quality conductive foam solutions will continue to be in demand. That can be done by electrically conductive foam, which can be of great use in healthcare as well. Currently utilizing such foam in medical equipment, the said medical gadgets include imaging machines, patient monitoring systems, among others, where effective EMI and RF shielding is vital so that the gadgets work with required accuracy and reliability. This need will increase appreciably, with sensitive electronic medical devices needing to be properly shielded from EM interference and the continued proliferation of healthcare technologies.

Other broad application areas of electrically conductive foam will be in the field of packaging. Growing requirements for protecting sensitive electronic components during storage and transportation will nowadays increase demand for conductive foam in the packaging industry. This type of foam offers excellent cushioning and EMI shielding against shocks to ensure that electronic products reach their destinations without any damage.

The Global Electrically Conductive Foam market would grow faster compared to other end-user industries. In addition, with the overall enhancement of the electronics technology, the need for efficient EMI shielding solutions would increase manifold, thereby acting as a driver for the electrically conductive foam.

The Electrically Conductive Foam market will continue its dynamics through innovation as many diversified requirements come from various industries. A promising Electrically Conductive Foam market in future seemed to be evident with developing strides for improvement and adoption growing in several sectors.

REGIONAL ANALYSIS

Appreciable growth in the global electrically conductive foam market will be witnessed over the following few years, with the augmentation being driven through the varied regional dynamics. North America is expected to drive the market of these foams, as technological advancements in the region are taking place and key manufacturers of these products are located in the US, Canada, and Mexico. These countries are investing a huge amount in research and development in discovering new applications of electrically conductive foam for serving the electronic and automobile industries. This will be complemented by a rise in demand for high-performance materials in these industries.

The market has other major contributors to growth in the UK, Germany, France, and Italy in Europe. The regional market will witness a high demand for electrically conductive foam due to growing environmental concerns, with a focus on sustainability, and the region's wide application in EMI shielding and static control. The European market will continue to be important due to its well-built industrial base and interest in technological progress.

The fastest growing will be the Asia-Pacific, including its principal countries, India, China, Japan, and South Korea, due also to industrialization, urbanization, and increasing disposable income. Industrialization and urbanization are rising furiously. In fact, by input and modernization of infrastructure, China and India are leading, which will require more advanced materials. This, moreover, will be underpinned by the boom in electronics in the region, and the automotive sector will grow.

South America is also expected to showcase growth, with countries such as Brazil and Argentina registering slow growth in comparison to other regions; still, demand for electrically conductive foam will receive a positive fillip from economic development and greater investments in the manufacturing sector. The growing adoption of advanced technologies by industries, such as electronics and automotive, will benefit the market. The increase in industrial activities and investments made in various infrastructure projects will drive further market growth in the Middle East and Africa.

Global Cooperation Council countries, Egypt, and South Africa are high in strategic initiatives among the countries to diversify their economic structures away from an over-reliance on the oil sector and are, therefore, appropriately positioned for leading growth. This will create a demand for the electrically conductive foam, thereby enhancing it for the purpose of construction and electronics in such regions. This is one area where the global electrically conductive foam market will blossom with the development in technology due to rising demand from various industries. Development and innovation in these regions would provide an increasing rate of adoption, thus keeping the overall market graph of electrically conductive moving in an upward direction and proving significant presence in the future of material science and engineering.

COMPETITIVE PLAYERS

The Global Electrically Conductive Foam market is all set for a dynamic future, powered and shot into orbit by technological advancements and increasing demand from sundry industries. This market commands a lot of attention, since it plays a vital role in shielding sensitive electronic components from electromagnetic interference. Some of the key players involved in the production of this industry include Laird, Kitagawa GmbH, Foamtech Corporation, Rogers Corporation, Kemtron, Seiren Co, Schlegel, Holland Shielding Systems, Ghiringhelli Mario, Kingbali, Shenzhen HFC Shielding Products Co, Suzhou Sinkery Electronic Technology Co, Quality Foam Packaging, Pro-Pack Materials Correct Products, EG Electronics, Zotefoams, MTC, and Adaptivation. In doing so, they are constantly upgrading their products to compete with each other in the market.

As the electronics sector grows, the Electrically Conductive Foam market would grow in the process. The growing usage of electronic devices in daily life will drive demand for effective shielding solutions that ensure device functionality without interference. This demand will drive companies to enhance their products and make them efficient and reliable. Further, growth in IoT and smart devices will add to this market, as these technologies fundamentally rely on signal integrity and low interference.

In the next few years, sustainability will be the prime factor that will drive the Electrically Conductive Foam market. Most probably, companies will be oriented to ecofriendly material development without loss in performance. This green trend will satisfy not only the regulatory but also the growing consumer demand for 'green' products. The innovations in this area will be key to winning market share and competitive advantage.

It will also be characterized by the growing trend of product customization. Enterprises will have to offer products that can be personalized for potential customers working in industries like automotive, aerospace, and telecommunications that require unique solutions. This agility will enable companies to meet diversified requirements and grow in the market by attracting more customers.

Basically, the competitive landscape of the Electrically Conductive Foam market will be shaped by strategic partnerships and collaborations. This would amount to companies forming alliances that help leverage each other's competencies for driving some amount of innovation and expansion of their product lines. The alliances will, therefore, become very important for survival in a rapidly changing market. Moreover, mergers and acquisitions will play an important role as firms look to enhance their market presence and capabilities.

The future for the Global Electrically Conductive Foam market is quite promising and full of endless potentials for increased growth and innovation. Key players will invest in sustainability, customization, and strategic collaborations to remain at the leading edge with a competitive advantage. Increasing demand for reliable and efficient shielding solutions fuels this market on its journey to greater heights, driven by advanced technologies and electronics use in daily life.

Electrically Conductive Foam Market Key Segments:

By Type

- Polyurethane Foam

- Silicone Foam

- Others

By Product Type

- Conductive Sponge

- Conductive Sheet

- Conductive Tape

- Conductive Gasket

- Others

By Application

- I/O Shield

- Non-shear Standard Connectors

- EMI Shielding

- Electrical Grounding

- Automotive

- Consumer Electronics

- Aerospace

- Medical

- Others

By End-user

- Electronics

- Automotive

- Aerospace

- Healthcare

- Packaging

- Others

Key Global Electrically Conductive Foam Industry Players

- Laird

- Kitagawa GmbH

- Foamtech Corporation

- Rogers Corporation

- Kemtron

- Seiren Co

- Schlegel

- Holland Shielding Systems

- Ghiringhelli Mario

- Kingbali

- Shenzhen HFC Shielding Products Co

- Suzhou Sinkery Electronic Technology Co

- Quality Foam Packaging

- Pro-Pack Materials

- Correct Products

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252