MARKET OVERVIEW

The Global Electrical Discharge Machine (EDM) market, along with the EDM industry, presents a significant portion of modern manufacturing processes through some of the finest machining possibilities for hard metals and complex shapes. Top-of-the-line advance non-traditional machining revolves around electrical discharges or sparks to shape a material that otherwise proves difficult for conventional methods to cut. EDM technology has achieved enormous importance on account of its performance with outstanding accuracy and surface quality in industries, such as aerospace, automotive, electronics, and healthcare.

The Global Electrical Discharge Machine (EDM) market will now be on the rise in terms of having its additional reach and applications as the demand for high-performance and complex part systems continues to grow. Unlike traditional machining processes on hard materials such as titanium and hardened steel, mechanical stress is not introduced, but rather controlled electrical sparks that erode material from the workpiece shape it for intricate and precise shaping. This makes it conclusive for applications requiring precise tolerances and complex geometries.

This market covers various kinds of EDM machines, which include wire EDM, sinker EDM, and fast hole drilling EDM, to suit specific manufacturing needs. Wire EDM is used largely to produce extremely complex contours and fine detail and is thus mainly preferred for making components of very high precision. Sinker EDM excels, in fact, at producing molds and dies with very intricate cavities, promising flexibility all through design and shape. Fast hole drilling EDM directly answers the requirement for speed and accuracy in the creation of holes in hard materials and is typically used for applications in the aerospace and medical fields.

In terms of geography, the Global Electrical Discharge Machine (EDM) market will widely be embraced across regions as a result of having gained momentum on industrialization and increased investment into high-precision manufacturing. This effort will be also supported by key players in the industry seeking to develop new and innovative EDM solutions for productivity increases, as well as reductions in operational costs and improvement in machining accuracy. Lastly, as the advancement in technology continues, the incorporation of automation and smart manufacturing practices will keep redefining the EDM processes, making them more efficient and adaptable.

Moreover, research development activities will grow further over the future period optimally to refine EDM technologies and wider applications. Enhanced features will probably include highly integrated software support, real-time monitoring, and predictive maintenance, which will help ensure consistent performance and minimum downtime. Such innovations will also strengthen the position of the EDM industry in meeting modern manufacturing accommodate changing newer demands.

The Global Electrical Discharge Machine (EDM) market would be one that keeps on bringing into manufacturing technology the consistency of unparalleled precision and wild versatility. Great progress will be made by the industry when it meets the complex challenge of machining and producing high-quality outcomes in a multitude of areas. Moreover, as the field of technological progress continues to develop and the demands for precision engineering continue to rise, the EDM machines would be a solid frontier of advanced manufacturing, whether globally or locally.

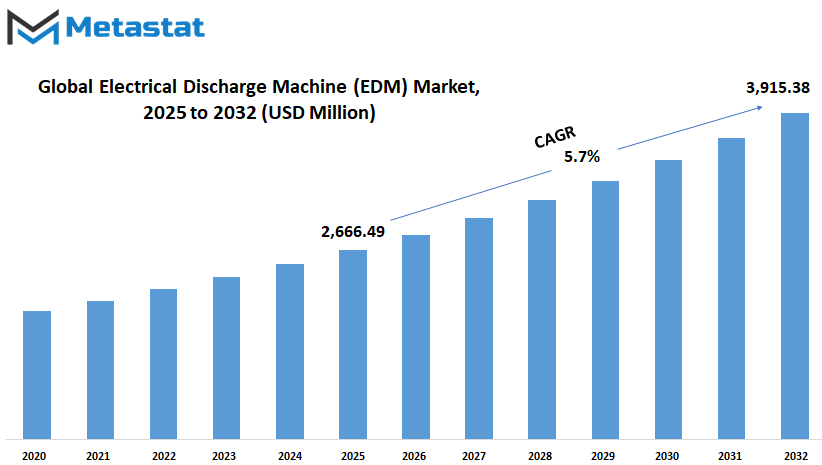

Global Electrical Discharge Machine (EDM) market is estimated to reach $3,915.38 Million by 2032; growing at a CAGR of 5.7% from 2025 to 2032.

GROWTH FACTORS

Over these years, the global Electrical Discharge Machine (EDM) market has lined up to grow significantly over the years concerning technology advancement and increasing requirement for high-precision components among different industries. The demands for machines with higher precision and detail will continue as manufacturing processes advance. EDM machines can shape hard metals and complicated materials at very high precision. They've gotten newer importance in the aerospace, automotive, and electronics industries, where even the slightest difference can make a whole lot of difference in performance and quality.

Another key factor driving the expansion of the Global Electrical Discharge Machine (EDM) market is the ongoing advancements in EDM technology. Manufacturers are investing heavily in research and improvements to production efficiency, accuracy, speed, etc. Some innovations include improvements in automation, electrode materials, and control systems of operations, which render EDM machines to be quite reliable and user-friendly. These not only save time during production but help in reducing the chances of errors, thus making the machines attractive for companies that want to keep an esteemed quality.

Increasing demand for high-precision components is another key driver of growth. Such industries include the manufacture of medical devices, aerospace, and electronics; they all impose exact dimensions on their parts along with a flawless finish. Destructive testing and condition monitoring through what is the refined functionality of EDM machines indicate proficiency in manufacturing; especially, with hard or heat-resistant materials that are much harder to shape by traditional methods.

Implying that as the market grows for devices that need to be miniaturized and further efficient, there is bound to be an increase in demand for these intricate yet precise parts, hence the increasing proliferation of this technology going forward.

Yet, with all these promising factors comes a few problems that have been identified, which might slow the growth of the Global Electrical Discharge Machine (EDM) market. Initial high costs associated with EDM machines are one of the most prohibitive portions in developing nations concerning SMEs.

The considerable budget required for the procurement of machine and maintenance, in addition to skills development to train operators on proper use and maintenance of EDMs for short to medium-term runs, is a disadvantage to this technology. Also available are alternative machining technologies like laser cutting and CNC milling which give another list of choices to manufacturers that may in some cases be more affordable depending on use.

But with the expansion of the medical device manufacturing sector, the future of the EDM market is still bright. As technology advances in healthcare, the demand will increase for the sophisticated medical instruments and implants that will need exact specifications. EDM machines will serve as good candidates for manufacturing these delicate and intricate components, making them a necessity in future medical devices to come.

The Global Electrical Discharge Machine (EDM) market is expected to continue its growth streak in the years ahead. The market is meant for steady and continuous growth, courtesy of many technological improvements, which together with the growing demand for precision manufacturing will keep boosting the demand for EDM in major segments of production. However, overcoming cost challenges and competing technologies will be essential but with the added opportunities posed by such sectors as healthcare and electronics, the future looks bright for EDM technology across the world.

MARKET SEGMENTATION

By Type

The Global Electrical Discharge Machine (EDM) market is further segmented by types that are each meant for particular applications in manufacturing. The Die Sinking EDM is mostly used for creating complex cavities and shapes for moulds and dies, thereby considered highly indispensable for industries demanding accurate and detailed designs. The requirement of these accurate and fine moulds shall only increase in response to the advanced manufacturing industry, and therefore, demand for Die Sinking EDM will also increase.

Small Hole Drilling EDM has the advantage of drilling tiny, precise holes in very hard materials which traditional drilling methods find difficult. This technology proves to be indispensable in industries such as aerospace and electronics, where the most diminutive components are held to intolerance level standards. With advancing technology and miniaturization, the demand for small precise parts will become more prominent, thus putting Small Hole Drilling EDM on the map.

Wire Cutting EDM specializes in producing intricate shapes and fine detailing with much precision. It has rightly earned an important position in industries that also demand the making of high-precision parts with very tight tolerances. As demand continues to grow for specialized high-end machinery, Wire Cutting EDM shall remain central to the arms of manufacturers for the perfection of their products.

Thus, the Global Electrical Discharge Machine (EDM) market will continue to broaden as industries are increasingly tending toward sophisticated and efficient manufacturing processes. On the other side of the spectrum, new technologies and the discovery of new families of materials will constantly challenge EDM machines to enhance themselves further into the peak of advanced machinery in current production. Essentially, due to their unique capabilities and growing significance, EDM machines will go a long way in shaping the future of manufacturing.

By Application

There is going to be a very large changing and growing Global Electrical Discharge Machine (EDM) market in the years to come. As industries continue to explore advances in manufacturing technologies, EDM machines will receive the attention they deserve for their speed and precision. EDM machines use electrical sparks to form hard materials, thereby allowing complex parts to be made highly accurately. The upcoming years may see an increase in demand for EDM machines due to the technological advancements that will require progressive manufacturing methods in various industries.

The worldwide electrical discharge machine market is driven by their diverse applications. Technology will increasingly be used in security related sectors. In this area, the demand for precision and reliability is high, and production of top quality components for advanced security systems would depend on EDM machines. The future evolution of security needs will show an increasing number of applications of EDM in the manufacture of sophisticated parts. Since EDM can manufacture interlacing designs with the exact specifications, EDM becomes an important tool in the development of next-generation security technologies.

EDM technology is being adopted for container manufacturing in addition to the other applications. High durability and precise geometry of containers can be achieved with machining tools that can effectively machine very hard materials and complex shapes. EDM machines provide the necessary accuracy to manufacture such products of high quality. Even though this translates into a positive view of the growth in trade and logistics on a global level, it will also mean increased demand for scenarios where advanced manufacturing options such as EDM will be even more sought after.

Another new innovative application of EDM technology is in portable classrooms. Also, there is an increasing demand for using space efficiently and deploying it quickly in education, which causes an increase in need for portable classrooms. The manufacture of structural components and specialty parts for the mobile classroom will depend significantly on EDM processing. As education systems worldwide look for adaptable flexible solutions, the more use of EDM machines will likely see in this sector in the future.

Aside from these core applications, there are many other applications for EDM machines. The obtainment of highly specialized industrial parts, the combination of the general processes with prototype production, and, in general, the versatility of EDM technology will add great value to a large number of industries. Increased advanced manufacturing techniques will only increase the importance of improving the demand for precision tools such as EDM.

The future foresees even brighter prospects for the Global Electrical Discharge Machine (EDM) market as it prepares to scale up advancements in technology as well as demand from various sectors. In manufacturing, with its capacity to deliver high precision and efficiency, this technology will continue taking significant strides toward shaping the future of manufacturing. The innovations that will occur with time to come with the industries will progressively emphasize the great importance of EDM in producing high-quality and reliable components.

By Industry

The Global Electrical Discharge Machine (EDM) market is poised for considerable growth in the upcoming years, propelled by increasing application inclination towards precision manufacturing and technological advancements. EDM technology has widely impacted the industries requiring high accuracy and complex shaping of materials. As these industries are increasingly transforming via automation and digitalization, the acceptance of EDM machines seems to rise, which will become a very prominent tool for production processes. In other words, industries worldwide are adopting EDM solutions to keep pace with their changing needs, thus providing efficiency, quality, and precision.

Manufacturing stands as a principal driver propelling growth in the Global Electrical Discharge Machine (EDM) market. Increasing demand for intricate and precise constructs poses high reliance on manufacturers involving EDM technology to produce high-value products, maintaining exceptional accuracy. With increasing automation and other smart manufacturing interventions, EDM machines will rise further in performance and sophistication, quickening production times and lowering costsworthiness in the industry.

The ED market also has big opportunities lying ahead in the healthcare sector. Manufacturers of medical devices need tools that can produce components with extreme precision and reliability. EDM technology is well-suited for making surgical instruments, implants, and special equipment with fine details and high accuracy. With healthcare advances being made in personalized medicine and minimally invasive procedures, demand for custom-made, expertly engineered devices is bound to increase. This creates a considerable opportunity for EDM machines to carve a niche in medical manufacturing.

In the Food and Beverage industry, EDM machines are used to manufacture specialized equipment and parts needed in fully automated production lines. As the industry puts focus on efficiency and hygiene, such precision tools are essentials that guarantee product quality and meet regulatory standards. With EDM technology, machinery parts are created possessing smooth finishes and accurate dimensions, thus greatly minimizing risks for contamination and enhancing production efficiencies.

EDM technology also finds a niche in the construction sector, aiding in creating durable, precisely shaped components for heavy machinery and infrastructure project requirements. With increasing spacious urbanization and new sustainable construction practices, this industry will require high-quality parts that will be consistent and strong, as produced by EDM machines.

Very specialized tools and equipment used in drug manufacturing and packaging are produced by pharmaceutical companies through EDM machines. More precision-engineered components will be needed in production due to the growth of the sector in view of new medical revelations and treatments. In fact, EDM technology is set to become a big asset for pharmaceutical production.

The Global Electrical Discharge Machine (EDM) market is, therefore, well poised for steady growth as industries evolve and experiment with advanced technologies. The innovations in the design of EDM machines, their software capabilities, and automation will be a further boost to their applications in all these diverse fields and thus ensure their relevance in industrial processes in the future.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,666.49 million |

|

Market Size by 2032 |

$3,915.38 Million |

|

Growth Rate from 2025 to 2032 |

5.7% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

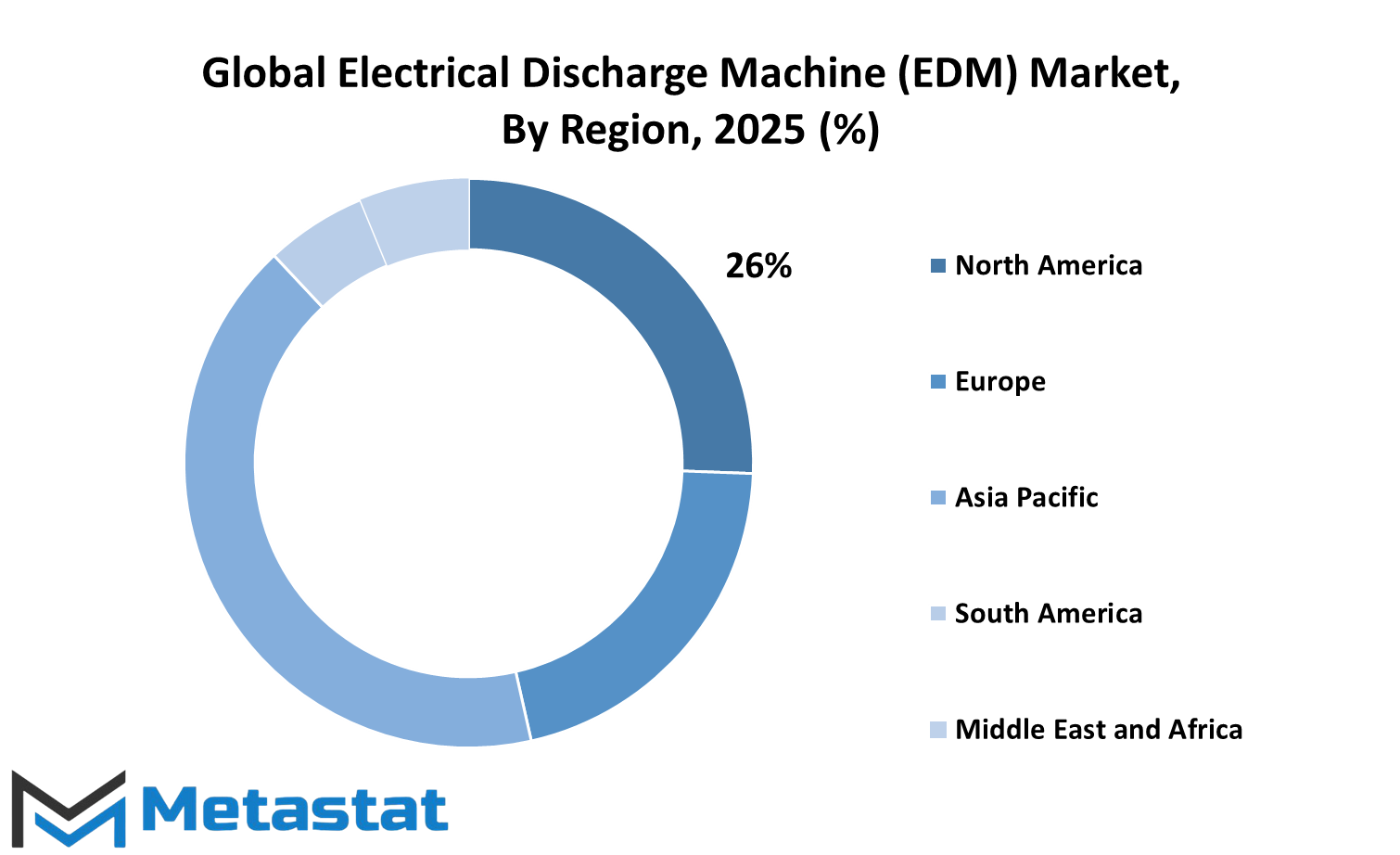

Future trends promise development in the International Electric Discharge Machine (EDM) market. Future growth will be in response to increased demand for new-age manufacturing technologies across the world. EDM will be at the heart of generating further modern manufacturing. Regional analysis provides a deeper understanding of how different parts of the world contribute to and benefit from this progressively evolving markets.

Steady growth is what can be expected for the North America region, which includes the United States, Canada, and Mexico, owing to the technological advances within the region and higher adoption of manufacturing automation. In this regard, the U.S. dominates as a major player, supported by large investments in industrial development and presence of many well-established high technology companies. High demand for precision tooling, such as EDM, is also seen in both countries through their growing automotive and aerospace industries.

Europe shapes the market by the manufacturing strength of countries like the UK, Germany, France, and Italy. Advanced technology is highly adopted in Germany, a nation of engineering excellence, where the UK and France are expanding their ability to establish an industrial presence. Keeping up with that spirit, Italy also retains its competitive stance with its state-of-art know-how in high-quality manufacturing, while the rest of Europe backs the growth of the market through its commitment to technological advancement and industrial efficiency.

The future of the Global EDM market seems more brighter in Asia-Pacific, as a result of the rapid industrialization and technological growth in countries like China, India, Japan, and South Korea. Manufacturing in China remains among the largest in the world, while constant investing in advanced machinery keeps fuelling further demand for EDM machines. India's growing push to be a global manufacturing hub further adds to its expansion. On the other hand, Japan and South Korea remain key players who are pushing the agenda of EDM technology toward new frontiers because of their innovative targets and high-quality production.

The South American potential markets are Brazil and Argentina, where gradual modernizations are being made in the manufacturing sector. These countries are expected to attract a larger market for EDM as they invest further into automation and advanced machinery. The rest of the region seems promising, showing increased interest in the growth and modernization of industries.

Countries such as the GCC nations, Egypt, and South Africa support the market in the Middle East and Africa. The GCC countries, spurred into diversification from oil, now focus on investment in advanced manufacturing technologies. The growth of the industrial sector of South Africa continues, while Egypt is slowly adapting to modern methods of production.

Changing from time to time with respect to the Global Electrical Discharge Machines (EDM) market, each of the continent contributions would be shaping at different stages of the future trajectory of the market. With technological advancement and need for precision in manufacturing, the market is meant to grow significantly worldwide in the future.

COMPETITIVE PLAYERS

The market is already known to be a very promising one for future years. Advances in the area of manufacturing technologies are redefining almost every aspect of precision and hence pushing up demands for EDM in modern applications. EDM, an industrial tool that can be easily incorporated and coupled with excellent accuracy in shaping hard materials, has become obligatory at the present time to meet production needs. Evolution of the industrial processes continues to open avenues for economically improved methods of production, and in this regard, EDM machines are expected to become more popular. This growth will provide new opportunities for longstanding companies as well as newer entries into the space.

Strong competition within the market due to these factors motivates the very future of the market. Such global players such as Mitsubishi Electric Corporation, Makino Milling Machine Co., Ltd., and Sodick Co., Ltd. Are recognized worldwide for their innovation in EDM technology. The intensity in development activities, therefore, guarantees the introduction of even more sophisticated and efficient machines that will meet the emerging demands of the industries. Some other names that take an important part in meeting the standards of high quality and performance among them are GF Machining Solutions, FANUC Corporation, and CHMER EDM.

In addition to these well-established names, there are also a broad array of other manufacturers who take up market status for more of the diversity and competition in the industry. ONA Electroerosión S.A., Kent CNC, Seibu Electric & Machinery Co., and Excetek Technologies Co. have altogether different solutions for all types of industries. Knuth Machine Tools, Beaumont Machine, and Accutex Technologies Co., Ltd. Add to the market offer of different EDM systems, each designed for a specific application. This multitude of competitors will always keep driving improvement and feature innovation.

Indeed, as the technology advances, so does the Global Electrical Discharge Machine (EDM) market, which is expected to gradually move toward an automated but efficient system. By and large, the application of smart technology and, supposedly, some artificial intelligence in EDM machines should further enhance precision, minimize human intervention, and cut down errors. Companies such as NovaTech International, Belmont Equipment & Technologies, as well as Proterial, Ltd. Are expected to concentrate on these innovations, thus keeping their products in the running category of market trends.

The growth of this market would, therefore, be supplemented by the regional players, such as Brother Industries, Ltd., Novick Digital Equipment Co. LTD, and Yihawjet Enterprises Co., Ltd., providing such localized features and specific solutions. MaxSee Industry Co., Ltd. And JOEMARS MACHINERY & ELECTRIC INDUSTRIAL CO., LTDs also build this dynamic environment by providing specialized equipment under specific niches.

With a strong lineup of competitive players and ongoing technological advancements, the future of the Global Electrical Discharge Machine (EDM) market looks promising; industries requiring precision combined with efficiency and innovation will expand its demand at a great pace in the EDM systems and hence shape the future of modern manufacturing.

Electrical Discharge Machine (EDM) Market Key Segments:

By Type

- Die Sinking EDM

- Small Hole Drilling EDM

- Wire Cutting EDM

By Application

- Security

- Containers

- Portable Classrooms

- Others

By Industry Vertical

- Food & Beverages

- Pharmaceuticals

- Manufacturing

- Healthcare

- Construction

- Others

Key Global Electrical Discharge Machine (EDM) Industry Players

- Mitsubishi Electric Corporation

- Makino Milling Machine Co., Ltd.

- Sodick Co., Ltd.

- GF Machining Solutions

- FANUC Corporation

- CHMER EDM

- ONA Electroerosión S.A.

- Kent CNC

- Seibu Electric & Machinery Co.

- Excetek Technologies Co., Ltd.

- Knuth Machine Tools

- Beaumont Machine

- Accutex Technologies Co., Ltd.

- NovaTech International

- Belmont Equipment & Technologies

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252