MARKET OVERVIEW

The Global EDM Wire market and industry is a niche segment of the advanced manufacturing sector, primarily serving the precision engineering requirements of different industries. EDM wire, an essential part of wire-cut EDM machines, is crucial for processes that demand extreme accuracy and detail. This market is influenced by the demand for specialized tools that can cut intricate tasks on hard-to-machine materials like titanium, tungsten carbide, and hardened steel. The Global EDM Wire market will continue to be an important link in industries where precision is critical.

EDM wire is mainly used in industries like aerospace, automotive, electronics, and medical device manufacturing. Its importance lies in its ability to produce high-precision results where traditional machining methods fail. These wires serve as cutting tools, where electrical discharges are used to erode material to create shapes with very tight tolerances. With the focus of industries on efficiency and precision in production, demand for reliable EDM wire will increase, and this market will become an important part of advanced manufacturing.

The Global EDM Wire market is very wide-ranging, covering all kinds of wires, including brass, zinc-coated, and copper-based. Each of the types has its specific benefits, which are suitable for individual industrial applications. For example, brass wires are often preferred for their conductivity and tensile strength, and coated wires help improve the machining efficiency by reducing electrode wear. With its high range of diversity, the market fulfills multiple technical requirements and, consequently, spreads to a more diverse industry.

Developments in the material sciences and production technologies will, therefore have a lot of influence in the Global EDM Wire market. As the need for closer tolerances and better finishes increases among the producers, performance characteristics in wires will keep on rising, and, therefore, new developments of wire composition, coatings, and diameters will foster a competitive industry. So, this type of change will make the market well aligned with evolving requirements of high precision manufacturing.

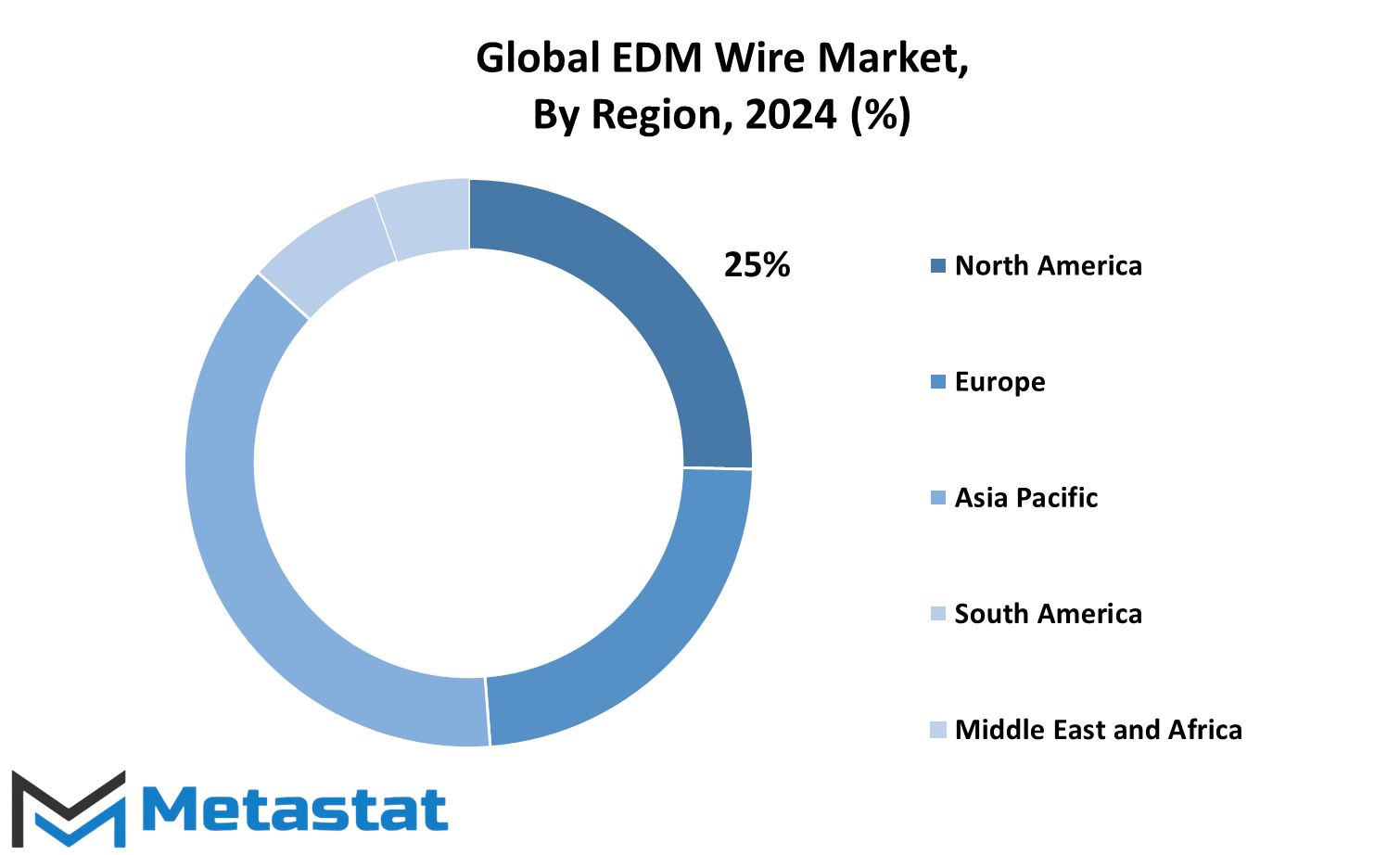

Geographically, the Global EDM Wire market covers key industrial regions across North America, Europe, and Asia-Pacific. The same is a hotbed of aerospace and automotive manufacturing and will be the primary location of growth for wire EDM due to the high dependence on wire EDM technology by those industries. Emerging markets would also see growth in demand as local manufacturing sectors continue to adopt advanced machining techniques to meet global standards. This geographic diversity underlines the fact that EDM wire technology is used widely and is of global importance.

The competitive nature of the market, as well, will come under transformation through this phenomenon of high-quality, low prices delivered by the manufacturers, leading to high production facilities and optimized supply chain. Some collaborations are most likely likely to emerge from EDM machine manufacturers and wire suppliers companies that deliver the end solutions for the industry to realize full compatibility in optimal output performance.

The Global EDM Wire market and its industry stand at the top of precision manufacturing, catering to the critical needs of industries that demand accuracy and efficiency. As technology evolves and industrial demands change, so will this market, remaining relevant in a world of precision-driven solutions. Its importance in modern manufacturing practice endures and promises further progress into the future.

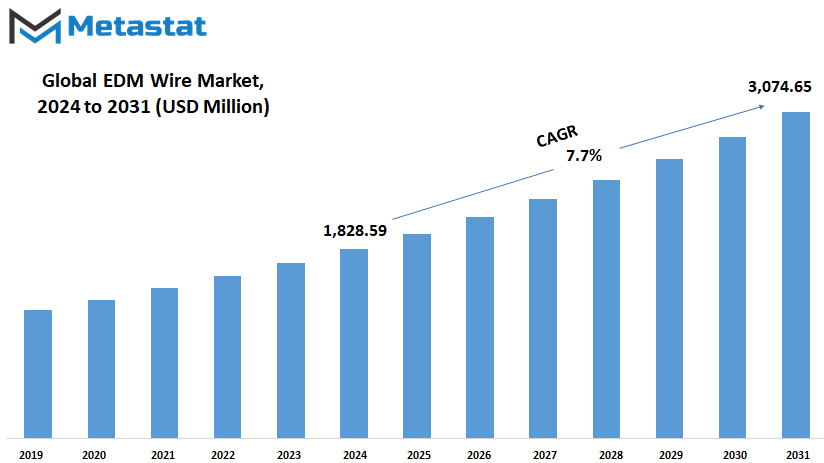

Global EDM Wire market is estimated to reach $3,074.65 Million by 2031; growing at a CAGR of 7.7% from 2024 to 2031.

GROWTH FACTORS

The Global EDM Wire market has grown over the years with this trend likely to persist in the future. As industries increase the demand for high-quality and precision machining products, EDM wire will form a key component in such a move. Several reasons are attributed to this growth pattern, and they are poised to change the future shape of the market.

The growth driver of high-precision and complex parts is increasing demand in industries like automotive, aerospace, and electronics. Such industries need EDM technology to create intricate parts with a high degree of accuracy. As manufacturing processes advance, so will the demand for materials like EDM wire that have better performance and efficiency. This will be a driving requirement for the better EDM wires with quality, which ensures that more precision machining is produced.

Another prime driver for the Global EDM Wire market is technological advancement in the EDM machines and equipment associated with it. With progress in EDM technology, new machines that emphasize high speed, higher accuracy, and energy conservation are being developed. These advancements will open up new avenues for the application of EDM wire in industries that demand high-performance cutting tools and parts. Moreover, the demand for EDM wires that work well with automated systems will also be enhanced due to the increased focus on automation in manufacturing processes.

The trend toward reducing the environmental impact of manufacturing processes is also responsible for the growth of the EDM wire market. The industry is growing to include more eco-friendly practices in its work, like recyclable material usage and reducing waste. The manufacturers are designing wires with superior performance along with being sustainable and energy-efficient. As the awareness of the world grows with respect to environmental issues, demand for green solutions in manufacturing will give a push to the market for eco-friendly EDM wires.

Furthermore, the increased demand for custom parts and additive manufacturing will add fuel to the EDM wire. Industries are becoming specialized and are requiring wires that can operate in a specific condition. With the increasing demand for wires to operate in such conditions, especially with complex and high-precision components, EDM wire is going to become a fundamental part of the manufacturing processes in the future.

MARKET SEGMENTATION

By Wire Type

The global EDM wire market has been developed over the years through different technological advancements. Since the different industries have become interested in precision manufacturing, EDM wire becomes an important aspect in these processes, like Electrical Discharge Machining (EDM). The market remains diverse and expands significantly because of the major emphasis given to the wire types. Different EDM wire includes non-coated, coated, and hybrid wires that play their unique roles in the manufacturing landscape.

Non-coated wire, especially brass wire, is widely used because of its excellent conductivity and cutting capabilities. Brass wire is known for delivering precise cuts, which makes it the preferred choice in industries that require high-quality outcomes in metalworking. Going forward, we are likely to see this sector sustain its demand because of the efficiency and cost-effectiveness of the product. In relation to the changing methods of manufacturing, brass wire would continue to be used as it is simple and reliable, thus satisfying the demands of the industry, while giving consistent results with very little maintenance.

Coated wire, which includes products such as zinc-coated and tin-coated wire, is gaining prominence. The coatings on these wires add protection against corrosion and enhance the general performance of the wire in different environments. For instance, zinc-coated wire is known for its durability and resistance to wear and therefore is suitable for applications requiring extended service life and high performance. Tin-coated wire provides additional lubrication, which helps reduce friction and enhance the overall cutting precision. These wires are bound to find increased demand due to the industry's quest for wires that can endure even tougher conditions, offering higher performance and a longer lifespan in EDM processes.

A recent development on the market is the hybrid wire, made from various materials combined together to reap the benefits of each of the materials involved. This type of wire is increasingly being recognized with its ability to offer both the durability of coated wire and the electrical conductivity of non-coated wire. Hybrid wire may soon be more in demand as industries search for versatile solutions that offer performance and cost-efficiency. The possibility of combining materials means that hybrid wires can cater to lots of requirements, thereby improving the EDM machining process altogether.

The future of the global EDM wire market is promising, as industries are moving forward with more advanced manufacturing techniques. The demand for high-performance wires will only increase from here. With developments in wire types such as non-coated, coated, and hybrid options, the market will continue to grow and evolve, providing solutions that meet the ever-changing needs of manufacturing processes all over the world. With advancing technology, these types of wires will play an increasingly vital role in the precision engineering sector.

By End User

In the coming years, the Global EDM Wire market is likely to witness growth because most of the industries of various sectors have begun to embrace advanced manufacturing techniques. EDM wire plays a crucial role in precision cutting, which is required in several high-demand industries. With increasing demands for more efficient and accurate production methods, EDM wire will probably see increasing demand in the future. In fact, segmentation into the end user accounts for the biggest share for it, Automotive, Aerospace & Defense, Electronics, Medical Devices and Other categories. Automobile makers must continue developing increasingly complicated and feature-intensive designs in light of advanced technology usage.

Precision machining and parts tailored to customer needs and specs will make up in an edmy market demand in EDM wires for automotive. EDM wire is critical in manufacturing parts including engine components, gears, and intricate molds, that are integral to the automobile manufacturing industry. With the growing trend of electric vehicles, manufacturers will be requiring even more specialized and precise components, which further expands the requirement for EDM wire.

The Aerospace and Defense sector is another considerable contributor to the Global EDM Wire market. Specialized machinery that can produce complex, high-quality parts is required to produce highly precise parts for aircraft, spacecraft, and defense equipment. EDM wire is essential in producing parts like turbine blades, gear parts, and structural components that need to meet stringent safety and performance standards. This factor can make the use of EDM wire increasingly necessary as technology becomes more advanced and the need for even more complex aerospace and defense products is developed.

The demand of the electronics industry is another key driver of EDM wire demand. The trend to miniaturize electronic equipment is continuously increasing, coupled with the production of complex electronic products; hence, the demand to precisely machine components such as connectors, switches, and circuit boards will increase. EDM wire is crucial for processes that call for such precision and, therefore, is a fundamental tool used in electronics production. The further growth of the global market for EDM wire will be exponential with the advancement of technology that requires high-quality electronic components.

Med devices are also another area where EDM wire will be used much more with time. In fact, the rising needs of minimally invasive surgery and custom implants would mandate a specific precision in the manufacture of medical instruments and devices. As the industry continues to advance into highly sophisticated devices, it’s evident that EDM wire has become a fundamental source of producing these components precisely as needed for the manufacture of these products with medical standards.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$1,828.59 million |

|

Market Size by 2031 |

$3,074.65 Million |

|

Growth Rate from 2024 to 2031 |

7.7% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The EDM Wire market is segmented across various geographies, which are characterized by different facets and growth prospects. It has been established that regional distribution in the EDM Wire market brings forth the differential demands as well as supply dynamics in every part of the world. North America stands as an important region in the EDM Wire market, backed by high technological infrastructure and strong manufacturing capabilities in countries such as the U.S., Canada, and Mexico. The U.S. is also one of the largest economies in the world and has a high likelihood of dominating the market as it maintains its emphasis on innovation as well as demand for precision manufacturing.

Europe is another giant region. It includes many industrialized powerhouses like the UK, Germany, France, and Italy. These countries have a long history of engineering excellence, especially in sectors like automotive, aerospace, and precision engineering, which are very EDM-intensive. Demand for EDM Wire in these regions is likely to increase as industries continue to adopt automation and advanced manufacturing techniques. Moreover, countries in Europe are now becoming more concerned with low production costs and high-quality output, due to which EDM Wire has become inevitable in the manufacturing process.

Asia-Pacific is the largest and fastest-growing region of EDM Wire. The industrial center of the region remains China, Japan, South Korea, and India. With booming manufacturing industries, these countries have seen rising demand for EDM Wire. China, for example is the leading manufacturing country that significantly contributes to the world EDM Wire market through vast production and significant industrial demands.

Japan with technological developments continues to innovate in terms of precision machining that drives growth in the EDM Wire industry. India, with its fast-growing industrial sector, is also expected to have a growth in demand due to the increasing numbers of small and medium-sized enterprises embracing advanced manufacturing processes.

Gradual improvements in the manufacturing sector of countries like Brazil and Argentina are going to help the EDM wire market in South America remain steady. The market still has a lot of potential in terms of growth, as local industries become more aware of the benefits offered by electrical discharge machining.

The Middle East and Africa also hold growth prospects for the EDM Wire market. Though less mature than the industries of North America or Europe, the region has industrial giants such as the UAE, Saudi Arabia, Egypt, and South Africa that are increasing their production bases. The rise of manufacturing hubs in these regions, driven by a push for diversification away from traditional oil industries, will likely lead to increased demand for high-precision tools such as EDM Wire.

Overall, growth in the global EDM Wire market is expected to be experienced across all regions, with each region contributing differently based on its industrial development, technological advancements, and market demands. Demand is expected to increase further due to rising requirements for precision and efficiency in numerous processes of manufacturing.

COMPETITIVE PLAYERS

The Global EDM Wire market has emerged as one of the crucial elements within the industrial manufacturing industry. Further advancement in technology will definitely drive this market with growth potential, because EDM Wire finds extensive usage in many applications, including precision machining and high-accuracy manufacturing. Some key players have so far defined the market while each contributes to the further expansion of this market. Companies such as Thermocompact and Sumitomo Electric Industries Ltd., Tamra Dhatu, and Sodick Co., Ltd. appear to be in the spearhead of technology development pertaining to EDM wire. Firms that have a specialty for innovation, with being able to provide for all the growing needs of their high-quality precise EDM wires.

Thermocompact is one such company appreciated for its state-of-art manufacturing processes, which focus on delivering premium performance in wire cutting applications. Meanwhile, Sumitomo Electric Industries Ltd., one of the largest names in the world wire market, continues to solidify its position with high-tech production and environmentally friendly processes. As the market continues forward, these companies, and others like Senor Metals Pvt. Ltd., YUANG HSIAN METAL INDUSTRIAL CORP., and Boway Group, will probably continue their pursuit of high-quality products that will continue to satisfy the growing demands of industries, including aerospace, automotive, and electronics.

Companies such as Novotec BV, Oki Electric Cable Co. Ltd, and Opecmade Inc. also cannot be ruled out in this context. Such firms have really made their marks by focusing on particular needs in the market for enhancing their products. It is whether the improvement has been done in terms of wire consistency, durability, or cutting efficiency, the companies keep improving themselves to keep up with the competitive edge of a highly demanding market. Additionally, firms like Berkenhoff GmbH and J. G. Dahmen GmbH & Co. KG are particularly noted for their expertise in precision and customization, catering to sectors where high levels of accuracy are paramount.

Looking ahead, the Global EDM Wire market will witness intense competition among these key players. As industries demand more precise and reliable wire for their production processes, these companies will spend on research and development to provide even more advanced solutions. Automation, improved quality control, and better cost efficiency will be the keys that shape the future of EDM wire manufacturing. With the growing demand for precision everywhere, the future market seems to be moving more towards environmentally friendly and high-performance material applications, driven both by technical progress and the expectations of consumers.

EDM Wire Market Key Segments:

By Wire Type

- Non-coated Wire (Brass)

- Coated Wire (zinc-coated, tin-coated, etc.)

- Hybrid Wire (Combination of materials)

By End User

- Automotive

- Aerospace & Defense

- Electronics

- Medical Devices

- Others

Key Global EDM Wire Industry Players

- Thermocompact

- Sumitomo Electric Industries Ltd.

- Tamra Dhatu

- Sodick Co., Ltd.

- Senor Metals Pvt. Ltd

- YUANG HSIAN METAL INDUSTRIAL CORP.

- Boway Group

- Novotec BV.

- Oki Electric Cable Co.Ltd

- Opecmade Inc.

- Berkenhoff GmbH

- J. G. Dahmen GmbH & Co. KG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252