MARKET OVERVIEW

The Dry Cleaning (Gas Chemical Etch) Equipment Market serves as the backbone of the textile and industrial sectors. Dry cleaning, a process integral to preserving the quality of textiles and critical manufacturing components, relies heavily on gas chemical etch equipment, which makes this market a vital contributor to several industries.

To understand the Dry Cleaning (Gas Chemical Etch) Equipment Market, it is imperative to appreciate its historical development. The practice of dry cleaning dates back centuries, but the transformation into a highly specialized industry gained momentum in the 20th century with the introduction of innovative equipment. Previously, solvents such as kerosene were used, but technological advancements have since paved the way for safer, more efficient methods using specialized machinery.

The Dry Cleaning (Gas Chemical Etch) Equipment Market is characterized by a range of dynamic factors that influence its growth. At the heart of this market are the cutting-edge machines designed to clean fabrics and delicate components using gas chemical etching methods. These machines rely on a precise combination of chemicals, heat, and pressure to effectively remove contaminants, oils, and dirt. The market's growth is closely linked to advancements in technology, as manufacturers continually develop more energy-efficient, eco-friendly, and automated equipment to meet evolving consumer demands.

A closer examination of the Dry Cleaning (Gas Chemical Etch) Equipment Market reveals several key segments. First and foremost, there are residential dry cleaning machines, designed for personal use, which are compact and efficient. These machines cater to individuals who value the convenience of at-home dry cleaning. On the other end of the spectrum are commercial dry cleaning machines, which are larger, capable of handling significant workloads, and often used by professional dry cleaning businesses. Additionally, industrial dry cleaning equipment is critical in sectors such as aerospace and electronics manufacturing, where precision cleaning is paramount to product quality and safety.

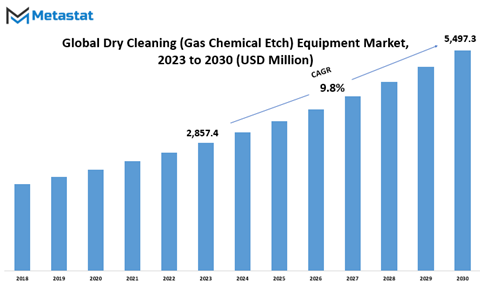

Global Dry Cleaning (Gas Chemical Etch) Equipment market is estimated to reach $5,497.3 Million by 2030; growing at a CAGR of 9.8% from 2023 to 2030.

GROWTH FACTORS

The Dry Cleaning (Gas Chemical Etch) Equipment Market is experiencing a significant upswing driven by the surging demand for advanced semiconductor devices and electronics that require higher precision and performance. This increasing need for technological excellence has paved the way for a thriving market. Moreover, the emphasis on contamination control in manufacturing processes has become imperative to ensure product quality and reliability.

One of the primary driving forces behind the growth of the Dry Cleaning Equipment Market is the escalating demand for more advanced and precise semiconductor devices and electronic components. These devices, which are the backbone of modern technology, require exacting manufacturing processes to meet the increasingly sophisticated needs of consumers. As a result, the market for dry cleaning equipment, which is a critical component in the semiconductor manufacturing process, has seen a surge in demand.

The manufacturing of these high-tech devices requires an environment with minimal levels of contamination. Even the tiniest impurity can lead to defects or malfunctions in these devices. Dry cleaning equipment plays a vital role in removing such impurities, thereby ensuring the quality and reliability of the final product. This stringent quality control requirement has contributed significantly to the market's growth.

However, it's not all smooth sailing for the Dry Cleaning Equipment Market. The high capital investment necessary for procuring and maintaining dry cleaning equipment presents a significant challenge for both new entrants and existing businesses. The specialized nature of this equipment, as well as the need for cutting-edge technology, drives up the initial costs. Businesses must be willing to make substantial financial investments to enter or expand within this market.

MARKET SEGMENTATION

By Operation Mode

The Dry Cleaning (Gas Chemical Etch) Equipment Market can be dissected into different operation modes. In 2022, the Automatic segment raked in a substantial value of 1080 USD Million. This signifies a considerable market presence and highlights the significance of automation in the industry.

On the other hand, the Semi-Automatic segment, which is another operational mode in the Dry Cleaning Equipment Market, also had a noteworthy value in 2022. It was evaluated at 937.3 USD Million. This shows that there is a substantial demand for semi-automated systems, which might be preferred by some businesses for various reasons.

The Manual segment, the third operational mode in this market, secured a value of 598.9 USD Million in 2022. While it's not as substantial as the automatic and semi-automatic segments, it still represents a significant portion of the market, indicating that there's a demand for manual systems in the dry cleaning industry.

These three segments, Automatic, Semi-Automatic, and Manual, cater to diverse preferences and requirements within the Dry Cleaning (Gas Chemical Etch) Equipment Market. The variances in their values in 2022 reflect the dynamic nature of this industry, where businesses have options to choose the operation mode that best suits their needs.

By Wafer Size

The Dry Cleaning (Gas Chemical Etch) Equipment Market is a dynamic and evolving industry that plays a significant role in the manufacturing of semiconductors. This market is primarily categorized by the size of the wafers it handles, which are essential components in semiconductor production. In 2022, the market was divided into three main segments based on wafer size: Less than 150 mm, 200 mm, and 300 mm.

The Less than 150 mm segment of the Dry Cleaning (Gas Chemical Etch) Equipment Market held a value of 454.5 million US dollars in 2022. This segment caters to the processing needs of smaller wafers, which are commonly used in older semiconductor technologies or for specialized applications.

Moving on to the 200 mm segment, it boasted a value of 749.4 million US dollars in 2022. These Dry Cleaning (Gas Chemical Etch) Equipment units are designed to handle wafers with a 200 mm diameter, making them suitable for a wide range of semiconductor production processes.

The 300 mm segment, with a value of 1,412.3 million US dollars in 2022, represents the high end of wafer size. These equipment units are geared towards advanced semiconductor manufacturing, as larger wafers offer greater efficiency and economies of scale.

Each of these wafer size segments has its own set of requirements and challenges. The Less than 150 mm segment may cater to niche markets with specialized needs, while the 200 mm and 300 mm segments serve broader and more demanding semiconductor production.

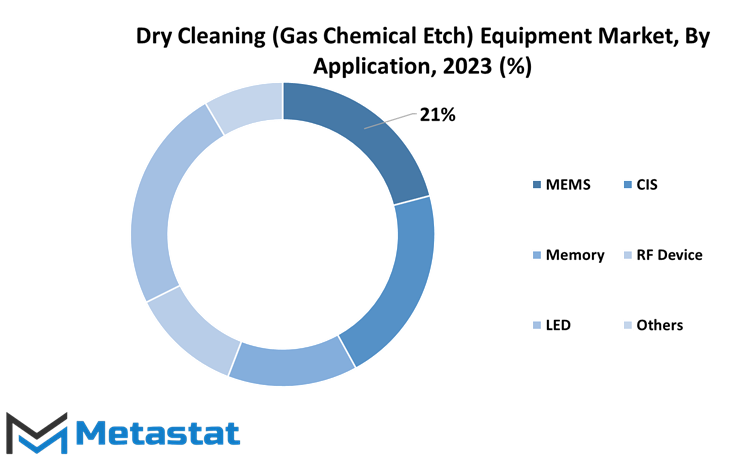

By Application

The Dry Cleaning (Gas Chemical Etch) Equipment Market is segmented based on its application into several categories. These categories include MEMS, CIS, Memory, RF Device, LED, and Others. In this essay, we will delve into the significance of these applications in the market.

MEMS, which stands for Micro-Electro-Mechanical Systems, play a pivotal role in various industries. They consist of tiny mechanical and electrical components that can be found in devices like accelerometers, gyroscopes, and pressure sensors. These components are crucial in the development of smartphones, automotive airbags, and medical devices. The Dry Cleaning Equipment Market caters to the needs of these MEMS devices by providing a precise and efficient cleaning process.

Next, the market serves the CIS, or Complementary Metal-Oxide-Semiconductor Image Sensors, sector. These sensors are vital components in digital cameras, smartphones, and other imaging devices. The demand for high-quality imaging is ever-increasing, and the Dry Cleaning Equipment Market ensures that CIS devices remain clean and fully functional, contributing to the production of sharp and clear images.

The Memory application within the market is also of great significance. It involves the cleaning of memory chips used in various electronic devices, including computers, smartphones, and gaming consoles. Clean memory chips are essential for the smooth operation of these devices, ensuring data storage and retrieval is efficient and reliable.

Furthermore, the RF Device application focuses on Radio Frequency devices, which are integral in wireless communication systems. These devices enable wireless connectivity in our everyday lives, from Wi-Fi routers to mobile phones. The Dry Cleaning Equipment Market ensures that RF Devices are free from contaminants and particles that could disrupt their functionality, ultimately improving the quality and reliability of wireless communication.

LEDs, or Light Emitting Diodes, represent another important segment of the market. LEDs are widely used in lighting solutions, displays, and indicators. Keeping LED surfaces clean is crucial for maintaining their luminous efficiency and extending their lifespan. The Dry Cleaning Equipment Market plays a vital role in supporting the LED industry by providing effective cleaning solutions.

The Others category encompasses a variety of applications not mentioned specifically. This catch-all category highlights the versatility of dry cleaning equipment. It can be used in diverse industries where precision cleaning is required, demonstrating the adaptability and wide-reaching impact of this technology.

REGIONAL ANALYSIS

The Dry Cleaning (Gas Chemical Etch) Equipment Market can be understood through an exploration of its geographical divisions, with a specific focus on North America and Europe. These two regions play a pivotal role in shaping the landscape of this industry.

In North America, the Dry Cleaning (Gas Chemical Etch) Equipment market showcases a robust presence. The demand for such equipment in this region is fueled by a growing consciousness about environmental concerns and the need for more sustainable and eco-friendly dry cleaning processes. Moreover, consumers in North America appreciate the convenience and efficiency of gas chemical etch equipment, making it a favorable choice for businesses in the dry cleaning industry. As a result, the market for these machines is on an upward trajectory, and companies are continually investing in research and development to enhance the performance and energy efficiency of their equipment.

Europe, on the other hand, presents a slightly different scenario. European market for Dry Cleaning (Gas Chemical Etch) Equipment is influenced by a combination of factors. The European market values quality and precision in dry cleaning processes. The gas chemical etch equipment aligns well with these expectations as it offers a high level of accuracy and cleanliness. European customers prefer dry cleaning methods that preserve the integrity of their fabrics, and gas chemical etch equipment excels in this aspect.

In both North America and Europe, the Dry Cleaning (Gas Chemical Etch) Equipment Market is evolving steadily. Market players are investing in innovative technologies and methods to further improve the efficiency and environmental friendliness of these machines. Additionally, regulations and standards are playing a significant role in shaping the market, as there is an increasing focus on reducing the environmental impact of dry cleaning processes.

As we delve deeper into this market, it's evident that the geographical divide reflects varying consumer preferences and priorities. North America leans towards eco-friendliness and efficiency, while Europe emphasizes precision and quality. These differences provide a dynamic backdrop for the global Dry Cleaning (Gas Chemical Etch) Equipment Market, making it an exciting arena for both businesses and consumers.

COMPETITIVE PLAYERS

The Dry Cleaning (Gas Chemical Etch) Equipment Market involves the production and distribution of specialized machinery used in the dry cleaning process. This industry is driven by the need for efficient and environmentally friendly cleaning methods in various sectors. Two major players in this market are TES Co., Ltd. and Applied Materials. TES Co., Ltd. and Applied Materials are significant contributors to the Dry Cleaning Equipment industry. These companies play a pivotal role in developing and providing the necessary equipment for gas chemical etching in dry cleaning operations.

Dry cleaning, as a method of cleaning, has gained popularity due to its effectiveness in removing stains and dirt from clothing and textiles. The process involves specialized equipment and chemicals that don't require water, hence the term dry cleaning. This is especially useful for fabrics that are sensitive to water or prone to shrinking when exposed to moisture.

TES Co., Ltd. has established itself as a prominent player in the dry cleaning equipment market. They offer a range of cutting-edge equipment designed to meet the growing demands of the industry. TES Co., Ltd.'s focus on innovation has led to the development of more efficient and eco-friendly machines, which are highly sought after by dry cleaning businesses.

Applied Materials, another key player in the industry, has a strong presence in the market, offering a diverse range of equipment catering to different needs in dry cleaning processes. Their products are designed to provide cost-effective solutions while maintaining high-quality cleaning standards. Their contribution to the industry has made them a name to reckon with.

The Dry Cleaning Equipment Market has witnessed substantial growth in recent years, thanks to the advancements in technology and a growing awareness of environmental concerns. Dry cleaning equipment manufacturers, like TES Co., Ltd. and Applied Materials, are continuously working on refining and expanding their product offerings to meet the evolving needs of the market.

Dry Cleaning (Gas Chemical Etch) Equipment Market Key Segments:

By Operation Mode

- Automatic

- Semi-Automatic

- Manual

By Wafer Size

- Less than 150 mm

- 200 mm

- 300 mm

By Application

- MEMS

- CIS

- Memory

- RF Device

- LED

- Others

Key Global Dry Cleaning (Gas Chemical Etch) Equipment Industry Players

- TES Co., Ltd.

- Applied Materials, Inc.

- Tokyo Electron Ltd.

- Lam Research Corporation

- Shibaura Mechatronics Corporation

- Veeco Instruments Inc.

- CVD Equipment Corporation

- ASML

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252