MARKET OVERVIEW

The global digital manufacturing market is changing the way the production process works for industries. This very industry, based on cutting-edge technologies, will continue to metamorphose traditional methods of manufacturing to ultimately increase efficiency and flexibility as well as innovation. digital manufacturing utilizes advanced digital tools and systems to improve and streamline design, production, and delivery of products. This change is not incremental but a paradigm shift reshaping manufacturing practices around the world.

In essence, digital manufacturing combines all these technologies such as artificial intelligence, IoT, big data analytics to form a seamless, connected production environment. Hence, it would allow real-time monitoring and regulation of all production processes, thus making them optimized and minimizing losses due to downtime. More importantly, digital twins – virtual copies of physical assets – that can be utilized to experiment and test processes in a virtual setup prior to being implemented on the shop floor; this not only lessens risks but also accelerates the cycle of development, thus leading to faster time-to-market for products. Again, the global digital manufacturing market incorporates some aspect of supply chain management.

A digital tool enhances visibility and transparency in the chains. It helps directly to improve demand forecasting, inventory management, and logistics planning. Manufacturers through this can reduce wastes, save on costs, and eventually improve their supply chain efficiency. On top of these aspects, blockchain technology is integrated to ensure traceability and authenticity of products involved in the chain. Customization and personalization are key drivers today, with digital manufacturing right at the heart of this trend. Advanced software and automation help manufacturers produce customized products in volume to meet one individual's specific needs and preferences. That is where traditional mass customization really stops, unlocking new business models and revenue streams for benefits to both customers and companies. Environmental effects of manufacturing processes on the increased level and have drawn the attention of Global digital manufacturing to the need for their inclusion.

digital manufacturing makes better use of resources, reduces the amount of generated waste and the consumption of energy; provides opportunities for the development of sustainable products using materials and processes. As stringent environmental regulations and the demands of consumers for greener products have become a significant challenge to face by industries across the world, it is in this context that digital manufacturing stands out in supporting such initiatives. Workforce transformation forms another integral part of the global digital manufacturing market. Novel job roles are being created as well as a new demand for new skill sets due to the adoption of digital technologies. It is investing in workforce training and upskilling to ensure that manufacturers have the capability to handle the intricacies of digital tools and systems.

In other words, workforce development has been seen as critical in maximizing the benefits of digital manufacturing in any business; otherwise, it would be difficult to maintain competitiveness in the marketplace. This trend will continue in the near term due to persistent technical development and the change in market dynamics. The global digital manufacturing market would continue to attract more manufacturers adopting digital solutions to improve their manufacturing capability, increase efficiency, and cater to consumers' demand for customized and sustainable products. As such, the global digital manufacturing market will play an important role in shaping the future of manufacturing, bringing innovation, and contributing to global economic growth. The global digital manufacturing market develops transformation in the manufacturing industries through the incorporation of advanced technologies and digital tools. As such, this will result in better efficiency, flexibility, and innovation toward efficiently solving some of the key issues: supply chain management, customization, sustainability, and workforce development. Since the market is yet to develop, it will redefine practices of manufacturing and drive future growth and development in the industry.

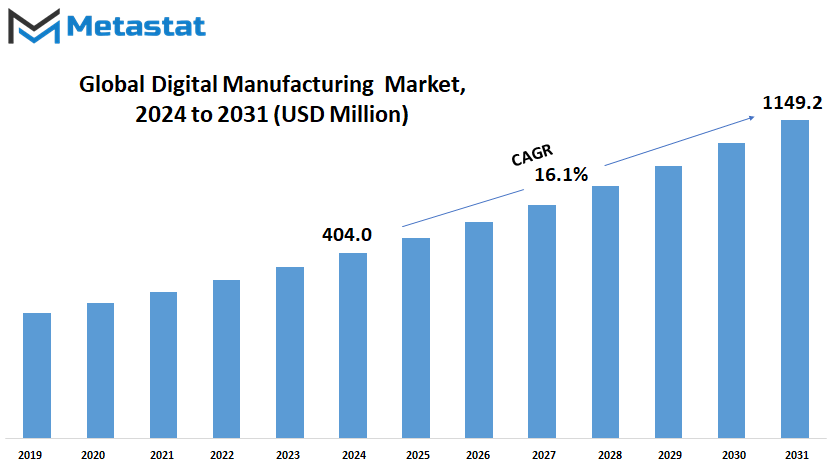

Global digital manufacturing market is estimated to reach $1149.2 Million by 2031; growing at a CAGR of 16.1% from 2024 to 2031.

GROWTH FACTORS

The digital manufacturing wave, coming to create an attractive wave that transformed the industrial world with unprecedented efficiency and innovation. As one watches on, globalization coupled with technological advancements promises to take the global digital manufacturing market to levels of spectacular growth, well-defined by confluences of factors promising to redefine even the way we look at, perceive, and conduct manufacturing operations.

Industry 4.0 and IoT technologies spearhead this revolution. These cutting-edge technologies have made connectivity unparalleled, enabled comprehensive data exchange, and made real-time monitoring possible. This results in a streamlined process, optimized resource utilization, increased productivity, cost-effectiveness, and operational excellence.

The increasing demands for high-performance and low-cost production processes also spurred the incorporation of digital manufacturing solutions. In a highly competitive global marketplace, one of the ways by which businesses get into mainstream competition is through waste reduction, minimizing chances of scheduled downtime, and maximizing output quality. digital manufacturing techniques, such as virtual simulations, predictive maintenance, and automated quality control, have proven indispensable in achieving these objectives, making them a very attractive proposition for forward-thinking enterprises.

That being said, there are possible difficulties in adoption. The associated installation and implementation costs for such technologies present a barrier to adoption, especially in smaller organizations or industries whose involvement is a concern. In such interconnected systems, potential cybersecurity and data privacy issues cannot be overlooked, as their reliance on data for these manufacturing systems may allow cause for breach and vulnerability.

On the other hand, vast scope is expected in the near future for growth in the global digital manufacturing market as the adoption pace of artificial intelligence and machine learning enhances. This promising technology can allow technological changes through predictive analytics, self-optimizing systems, and intelligent decision-making capabilities for processes to change the game around manufacturing. In a future that's destined to be led by digital manufacturing, manufacturers embracing these innovative solutions will unlock new domains of efficiency, quality, and profitability.

That's why the global market for digital manufacturing should grow dramatically-from that intersection of Industry 4.0 and IoT, as well as emerging technologies such as AI and ML. The potential benefits in efficiency, cost-effectiveness, and competitiveness make it too compelling to ignore all the challenges ahead. The uptake of digital manufacturing solutions will likely increase in the future as business leaders continue to encourage innovations and adapt to the high demands of this dynamic industrial landscape.

MARKET SEGMENTATION

By Component

The world of manufacturing is all set to undergo a digital transformation with positive vibes in the future. global digital manufacturing market growth prospects are tremendous and will continue into the future since this market streamlines cutting-edge technology application into traditional manufacturing processes.

Hardware, from advanced sensors and robotics to additive manufacturing machines and industrial computers will enable digitization in manufacturing. But the spine of such intelligent systems will be the software. Decisions will be made on advanced algorithms, machine learning models, and simulations, leveraging responsive manufacturer offers for market demands. One can imagine a world where the virtual twin of the product and process can be tested and optimized in simulation to make sure that there is waste elimination and maximum productivity in the factory floor.

But the true power of digital manufacturing will come from its ability to integrate services. The data analysts, cybersecurity experts, and cloud computing engineers will help manufacturers and these businesses collaborate to extract valuable insights and protect sensitive information.

As we take the new digital journey, innovation will lead the march toward a world where digital manufacturing is a leader, relentlessly pushing towards excellence. Hardware, software, and services will converge to open up a world where manufacturing less becomes the process and more of an art form, where efficiency meets sustainability and where the boundaries of possible and impossible blur all the time.

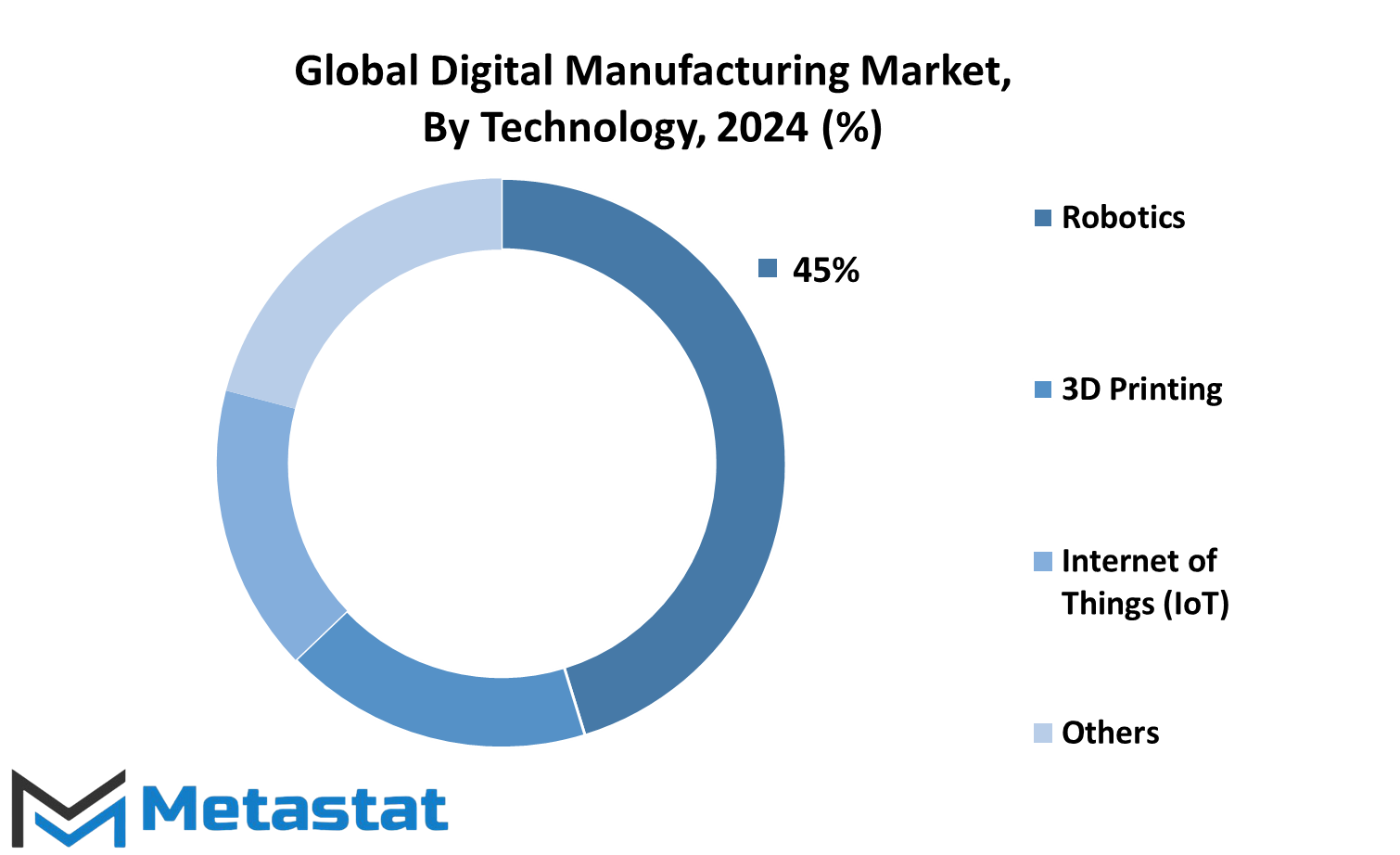

By Technology

digital manufacturing is changing the scenario of making goods by leaps and bounds. It is bringing about a new era of efficiency, customization, and innovation while constructing and remodeling each other. As the age-old adage goes, "A new day comes with its new advantages." The right that is bestowed upon this planet in this fashioning process is undergoing tremendous growth in the wake of advances in the development of globally available new technologies like robotics, 3D printing, and the IoT.

Robotics serves as the backbone of digital manufacturing and makes production lines around the world entirely new products. Advanced robots that perform highly sophisticated movement can execute long processes with more accuracy and precision, doing that without an iota of errors or inaccuracies; thus, causing more output. These automated systems are not only efficient but also quality, hence allowing manufacturers to meet the increasing demands of consumers.

This is 3D printing, which used to be one niche technology but is now revolutionizing the way digital manufacturing is done. It gives the ability to produce complex geometries and intricate designs that cannot be created with conventional methods. Its possibilities for customization, rapid prototyping, and on-time production have helped to push up unique products desired by individuals with personalized preferences.

The Internet of Things is extremely significant in digital manufacturing. This will give connectivity and data exchange among machines, systems, and processes in digital manufacturing. IoT ensures that real-time information is collected and then analyzed to make improvements for operations, predict when maintenance should be undertaken, and it takes informed action based on actionable insights.

Other technologies that could shape the future of digital manufacturing in the coming years include the use of augmented and virtual realities. AR and VR applications could offer a more realistic means of virtual simulation for training purposes and remote collaboration. This kind of applications helps streamline processes generally, though improving work safety and productivity.

It is going to be an innovation-driven, endlessly efficient future of the global digital manufacturing market. The competitive advantage for those producers employing such technologies will be in quicker quality production, at lower costs, and flexibility in responding to emerging requirements of the global digital manufacturing market.

The robotics, 3D printing, IoT, and other futuristic technologies will converge to redefine the boundaries of manufacturing in this dynamic landscape that encourages imagination and innovation.

By Application

The global digital manufacturing market represents an era of production processes much more advanced, in terms of their concepts and methods of implementing ideas about making goods, than previous generations of manufacturing. This revolutionary approach incorporates cutting-edge solutions so that virtual simulation of things, data analytics, and sophisticated automation can be very well combined to optimize or smooth out most manufacturing processes.

The future of digital manufacturing may simply see factories as a highly smart and connected ecosystem. Indeed, every step - whether from designing and prototyping or quality control to logistics - will be guided by advanced algorithms. Beyond that, AI and machine learning come to the forefront in predictive maintenance, real-time optimization, and instantaneous responsiveness to shifting market demands.

It would be a revolution in the automobile and transportation sectors of digital manufacturing. People would get their customized cars, according to individual requirements, through flexible production lines. Additive manufacturing, or 3D printing, would target producing complex components with unparalleled precision and minimal waste.

The aerospace and defense sectors will embrace digital manufacturing in terms of light weight and high-performance material properties along with geometric complexities. Virtual testing and simulation will only cut out the need for a physical prototype, thereby reducing the development cycle without compromising on safety standards.

Consumer electronics has always been a fast-moving area. digital manufacturing will once again enable it to be agile and responsive to changing market conditions-by which I mean the length of the product cycle and the speed at which consumer feedback can be incorporated into the product design.

The industrial machines are going to be fundamentally changed because, when they produce items, they will combine with humans. The intelligent machines will produce a more harmonious collaboration and thus provide well-timed increases in productivity and safety and enhancements to quality control. Predictive maintenance algorithms will reduce downtime and ensure the operation runs efficiently and without interruption.

As we march into the future, digital manufacturing will remain a big part of it; a process set on fire by ever-advancing technologies and relentless optimization. The lines between the physical and digital worlds will blur, and in its wake, a world will be fashioned whose creativity, efficiency, and sustainability are perfectly knitted to define the world around us.

By Process Type

The global digital manufacturing market in a vital way because digital processes are being opened up to the whole world as regards what a manufacturer may do digitally. digital manufacturing is such a significant phenomenon cutting across different age groups and geographic divides in that digital manufacturing has its core among an amalgamated complex of state-of-the-art technologies applied to redefine the designing, simulating, and realization of products.

At its core, the global digital manufacturing market the group of computer-aided processes throughout every phase of a product's lifecycle. Computer-Based Designing forms one of the three main pillars here, wherein powerful software is devoted to conceptualizing product designs and refining the designs with unparalleled precision and creativity on part of the designers, mainly by entertaining and performing iterative refinements to reach the end result for the designer's vision.

Supporting the design stage is Computer-Based Simulation, a virtual prototype-testing facility where manufacturers can validate the performance of their product, identify potential problems, and make the necessary adjustments before committing to prototyping it physically. By simulating real-world conditions, manufacturers are able to reduce risks, keep costs at bay during the development phase, and actually hasten time-to-market.

Computer 3D Visualization is also part of the key component, bringing life to digital designs with highly realistic renderings. The visualization supports stakeholder cooperation, which enables teams to understand and improve a design from diverse directions before it is brought into real life.

Analytics is quite crucial in digital manufacturing. It enables informed decision-making through the power of data. Manufacturers gather data at various stages of the manufacturing process and analyze that to make informed decisions regarding production efficiency, quality control, or emerging trends and optimize their decisions accordingly.

These represent the basic processes in digital manufacturing; however, the world does not stand still, as there is an ever-changing wave of new advanced techniques. Going from additive manufacturing to industrial Internet of Things (IIoT), the future promises even greater integration of digital technologies and even more significant change from how products are conceived, produced, and delivered to the consumer.

As the world accepts the digital age, it's digital manufacturing in innovation when manufacturers shine a beacon light at precision, efficiency, and agility in designing, simulating, and producing- more than at any other time in history. Here is the proof of humanity's never-ending quest for more-progress how the fronts of what then thought possible are constantly stretched and re-put on the map.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$404.0 billion |

|

Market Size by 2031 |

$1149.2 billion |

|

Growth Rate from 2024 to 2031 |

16.1% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global digital manufacturing market is changing the industrial canvas, which is being carved into new shapes with the lightest touches of the most advanced technologies that hit the market. Regional dynamics loom large in shaping the future course of this far-reaching change. Look ahead.

North America is the birthplace of innovative digital manufacturing adoption. With a tech-friendly workforce and sound infrastructure, this region saw significant adoption of new technologies, such as additive manufacturing, industrial automation, and data analytics. Here, big corporations and start-ups alike are making the most of these opportunities to optimize operations, improve product quality, and generate savings.

Europe, possessing a rich industrial heritage, is only marginally behind. Industry 4.0 initiatives have driven investments in digital manufacturing solutions in the key industries-automotive, aerospace, and machinery. Germany and the UK have led the charge for more avant-garde applications, including digital twins and intelligent management of the supply chain.

The region has been witnessing a multiplication of digital manufacturing, primarily because of the powerhouse economies such as China, Japan, and South Korea. With an extensive infrastructure put in place and an emerging consumer market, this region is leveraging the strengths of digital technologies to optimize production, cut costs, and hence meet changing consumer needs.

Not to conclude that South America is currently in some form of digital revolution, but it is definitely embracing the revolution of the global digital manufacturing market. Brazil is heavily investing in smart factories and using data-driven insights to make the most out of productivity in order to compete at a global level.

Although both regions are highly diversified in their industrial landscapes, the strategic importance of digital manufacturing is being realized in the Middle East and Africa. Of course, such initiatives are helping usher in a much more digitally enabled manufacturing ecosystem through improvements related to skills development and infrastructure upgrades as well as public-private partnerships.

Constant future development of the global digital manufacturing market depends on regional partnerships and knowledge sharing-collaboration, technology transfer, and the best practice exchange for a stronger, interlinked, and more effective manufacturing system of innovation and economic growth across all regions.

COMPETITIVE PLAYERS

With the digital revolution now bringing in this unprecedented era of transformation, modern manufacturing today is ahead of its game. Sticking out at the front are a set of competitive players bringing innovation to the global digital manufacturing market. Companies with vision have used the power of cutting-edge technologies in shaping the design, production, and delivery of their products.

By the near future, one would be able to envision a world where the lines between the real and virtual worlds blur seamlessly. The biggest driving forces behind this change are leaders such as Siemens AG, TATA Consultancy Services Limited, Dassault Systèmes, Autodesk Inc., SAP SE, and PTC Inc. Among these innovators, the development of software solutions, and pertinent cloud computing along with intricate data analytics would prove vital in enhancing manufacturing processes to deliver unprecedented efficiency to the sector.

Imagine factories in which intelligent machines interact perfectly with human operators to optimize cycles of production or reduce waste. Imagine designers and engineers sharing and interacting with virtual models to iterate and refine designs before building the first physical model. Imagine supply chains that are perfectly integrated, so their parts could track and adjust minute by minute, in real time, to accommodate fluctuating the global digital manufacturing market demands.

It is not a dream future for the distant, but an unfolding reality that is becoming increasingly fast. Organizations such as Cogiscan, Mitsubishi Electric Automation, Inc., Fujitsu Limited, and Metal Worm are innovating in the use of leading-edge technologies to reimagine what is possible in the manufacturing business world. Advanced robotics and automation systems, 3D printing, and augmented reality applications are making companies powerhouses of transformation.

But beyond the technological change, it represents a deep-seated cultural shift-from a culture in which collaboration, agility, and continuous improvement are deeply ingrained in the fabric of manufacturing operations themselves. And these companies will be some of the first to realize enormous opportunities; their products will be delivered faster than ever before with unprecedented precision and quality.

Digital Manufacturing Market Key Segments:

By Component

- Hardware

- Software

- Services

By Technology

- Robotics

- 3D Printing

- Internet of Things (IoT)

- Others

By Application

- Automotive and Transportation

- Aerospace and Defense

- Consumer Electronics

- Industrial Machinery

- Others

By Process Type

- Computer-Based Designing

- Computer-Based Simulation

- Computer 3D Visualization

- Analytics

- Others

Key Global Digital Manufacturing Industry Players

- Siemens AG

- TATA Consultancy Services Limited

- Dassault Systèmes

- Autodesk Inc.

- SAP SE

- PTC Inc.

- Cogiscan

- Mitsubishi Electric Automation, Inc.

- Fujitsu Limited

- Metal Worm

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383