MARKET OVERVIEW

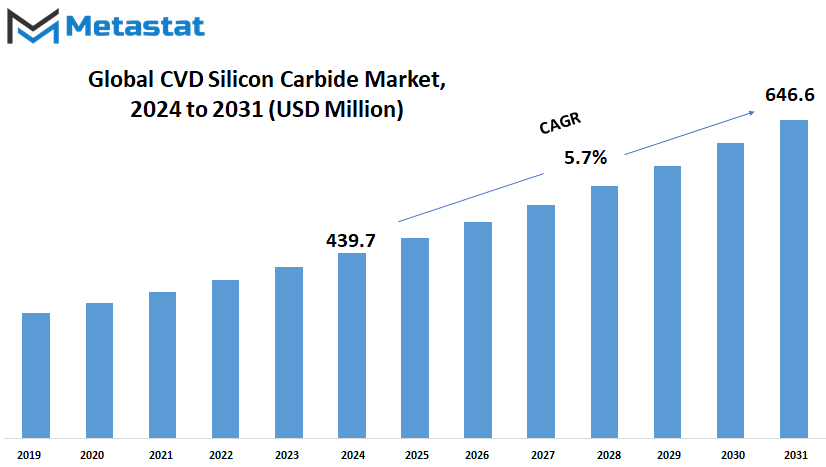

Global CVD Silicon Carbide market is estimated to reach $646.6 Million by 2031; growing at a CAGR of 5.7% from 2024 to 2031.

The Global CVD Silicon Carbide market stands at the forefront of technological advancement within the semiconductor industry. CVD (Chemical Vapor Deposition) Silicon Carbide, a cutting-edge material known for its exceptional thermal conductivity, superior mechanical strength, and high-temperature stability, has garnered significant attention across various sectors. This market caters to a diverse array of industries, ranging from automotive and aerospace to electronics and energy.

In the coming years, the Global CVD Silicon Carbide market is poised to witness remarkable growth, fueled by increasing demand for efficient power devices, robust electronic components, and durable materials capable of withstanding harsh operating conditions. The semiconductor industry, in particular, will play a pivotal role in driving the adoption of CVD Silicon Carbide, as manufacturers seek to enhance the performance and reliability of their products.

Furthermore, the automotive sector is expected to emerge as a key contributor to market expansion. With the growing trend towards electric vehicles (EVs) and the push for energy-efficient transportation solutions, there is a rising need for advanced power electronics and lightweight materials. CVD Silicon Carbide offers a compelling solution, enabling the development of high-performance EV powertrains and battery systems that deliver greater efficiency and extended range.

Moreover, the aerospace industry presents promising opportunities for CVD Silicon Carbide applications. As aircraft manufacturers strive to improve fuel efficiency, reduce emissions, and enhance overall performance, they are turning to advanced materials capable of withstanding extreme temperatures and corrosive environments. CVD Silicon Carbide, renowned for its exceptional thermal and mechanical properties, is increasingly being integrated into aircraft components, such as turbine engine parts and structural elements, to achieve these objectives.

In electronics, the demand for CVD Silicon Carbide is driven by the need for high-power, high-frequency devices used in telecommunications, industrial automation, and renewable energy systems. As the Internet of Things (IoT) continues to proliferate, there is a growing requirement for semiconductors capable of handling increased data processing and transmission speeds. CVD Silicon Carbide, with its superior electrical properties and reliability, is poised to meet these evolving demands and enable the next generation of connected devices and infrastructure.

Furthermore, the energy sector represents a significant growth opportunity for the Global CVD Silicon Carbide market. With the ongoing transition towards renewable energy sources and the need to improve the efficiency of power generation and distribution systems, there is a rising demand for advanced materials that can withstand high temperatures and harsh operating conditions. CVD Silicon Carbide, with its excellent thermal conductivity and chemical inertness, is well-suited for applications such as solar power inverters, power grid components, and energy storage systems.

The Global CVD Silicon Carbide market is poised for substantial growth across various industries in the coming years. As technological advancements continue to drive innovation and address emerging challenges, CVD Silicon Carbide will play an increasingly integral role in shaping the future of semiconductor manufacturing and enabling transformative applications across diverse sectors.

GROWTH FACTORS

The Global Chemical Vapor Deposition (CVD) Silicon Carbide market is witnessing a surge in demand driven by the need for high-performance materials with exceptional thermal conductivity, chemical resistance, and mechanical strength. This demand is particularly pronounced in the electronic and aerospace sectors, where such materials are indispensable. Additionally, the increasing adoption of CVD silicon carbide for the production of advanced semiconductor devices, power electronics, and high-temperature components is further propelling market growth.

However, despite these promising prospects, there are challenges that could impede the widespread adoption of CVD silicon carbide. One such challenge is the high production costs associated with its manufacturing processes. This cost factor may deter its use in industries where cost sensitivity is paramount. Moreover, there are technical hurdles to overcome, particularly in achieving uniform thickness and ensuring high-quality crystal structure during the CVD deposition process. These challenges pose potential barriers to the market's expansion.

Nevertheless, there is reason for optimism as technological advancements and process optimizations in CVD manufacturing techniques are on the horizon. These advancements hold the promise of improving production efficiency, reducing costs, and enhancing the overall quality of CVD silicon carbide materials. As these innovations continue to unfold, they will open up lucrative opportunities for the market in the years to come.

While the Global CVD Silicon Carbide market faces challenges such as high production costs and technical complexities, its growth trajectory remains promising. The increasing demand for high-performance materials in key industries, coupled with ongoing advancements in manufacturing processes, will undoubtedly shape the market's evolution in the future. As stakeholders continue to invest in research and development, the outlook for CVD silicon carbide remains bright, with opportunities for both innovation and market expansion on the horizon.

MARKET SEGMENTATION

By Type

The Global CVD Silicon Carbide market is a dynamic landscape with various segments catering to different needs and applications. One of the key segments is categorized by type, which includes High Resistivity Grade, Middle Resistivity Grade, and Low Resistivity Grade silicon carbide.

High Resistivity Grade silicon carbide is anticipated to play a crucial role in industries where high levels of resistance to electrical conductivity are required. This type of silicon carbide will find applications in sectors like electronics, where precision and reliability are paramount. Additionally, its use in power electronics, telecommunications, and automotive sectors is expected to grow steadily

Middle Resistivity Grade silicon carbide, on the other hand, fills the niche for applications that require moderate levels of resistivity. It strikes a balance between the high and low resistivity grades, making it suitable for a wide range of applications. Industries such as aerospace, defense, and medical devices may benefit from the versatility and reliability offered by this grade of silicon carbide.

Low Resistivity Grade silicon carbide is poised to meet the needs of industries where low levels of resistance to electrical conductivity are essential. This grade of silicon carbide will find applications in power distribution systems, renewable energy technologies, and high-power electronics. Its ability to efficiently conduct electricity while maintaining stability makes it an attractive option for industries looking to optimize performance and reliability.

In the coming years, advancements in materials science and manufacturing processes will drive innovation in the Global CVD Silicon Carbide market. New applications and industries will emerge, creating opportunities for growth and expansion. As the demand for high-performance materials continues to rise, silicon carbide will play an increasingly vital role in shaping the future of various industries.

The Global CVD Silicon Carbide market's segmentation by type, including High Resistivity Grade, Middle Resistivity Grade, and Low Resistivity Grade, reflects the diverse needs and applications of silicon carbide across different industries. As technology continues to evolve, these segments will continue to evolve and adapt to meet the changing demands of the market.

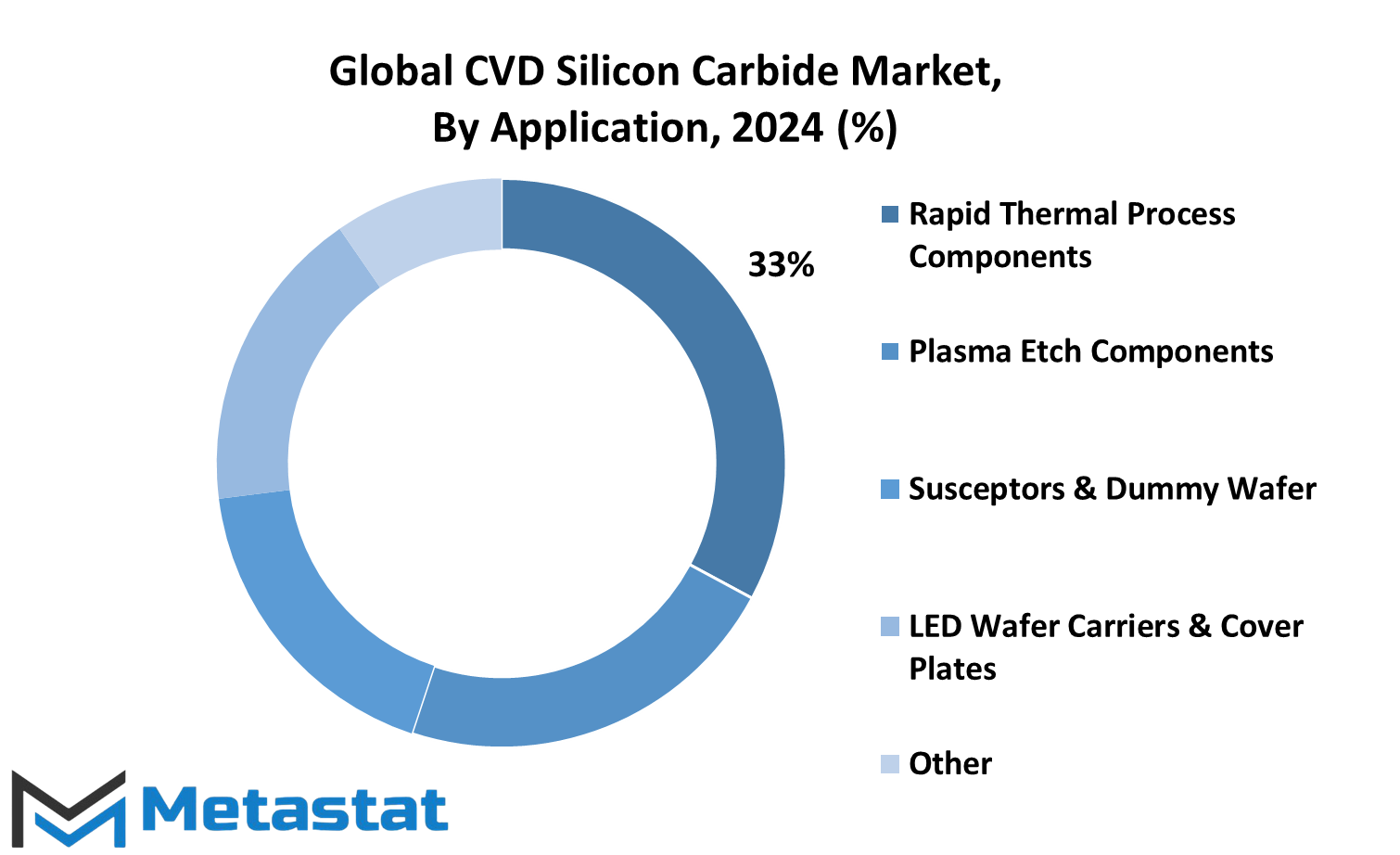

By Application

The Global CVD Silicon Carbide market is witnessing significant growth, with various applications driving its expansion. Among these applications, Rapid Thermal Process Components, Plasma Etch Components, Susceptors & Dummy Wafer, LED Wafer Carriers & Cover Plates, and Others are prominent.

Rapid Thermal Process Components play a crucial role in semiconductor manufacturing processes. They facilitate rapid heating and cooling of wafers, ensuring efficient production. As technology advances, the demand for these components will likely increase, driven by the need for faster processing times and higher yields.

Plasma Etch Components are essential for etching precise patterns on semiconductor wafers. This process is integral to the fabrication of microchips and other electronic devices. As the demand for smaller and more powerful electronic components continues to rise, the market for Plasma Etch Components will expand accordingly.

Susceptors & Dummy Wafers are utilized in various thermal processing applications, including chemical vapor deposition (CVD) processes. These components help maintain temperature uniformity and promote efficient heat transfer during semiconductor fabrication. With the continued development of advanced manufacturing techniques, the demand for Susceptors & Dummy Wafers will likely grow.

LED Wafer Carriers & Cover Plates are essential components in the production of light-emitting diodes (LEDs). These carriers provide support and protection for LED wafers during processing, ensuring high-quality output. As the demand for energy-efficient lighting solutions increases, the market for LED Wafer Carriers & Cover Plates will see sustained growth.

Additionally, the market encompasses other applications that contribute to the overall growth of the CVD Silicon Carbide market. These applications may include specialty components for specific industries or emerging technologies that utilize CVD Silicon Carbide materials.

The Global CVD Silicon Carbide market is experiencing robust growth, fueled by diverse applications such as Rapid Thermal Process Components, Plasma Etch Components, Susceptors & Dummy Wafer, LED Wafer Carriers & Cover Plates, and Others. As technology progresses, these applications will play an increasingly vital role in shaping the future of the semiconductor and electronics industries.

REGIONAL ANALYSIS

The global market for CVD Silicon Carbide is analyzed on a regional basis, considering various geographical areas: North America, Europe, Asia-Pacific, South America, and Middle East & Africa.

In North America, the market is segmented into the United States, Canada, and Mexico. Similarly, Europe comprises the United Kingdom, Germany, France, Italy, and the rest of Europe. Asia-Pacific includes India, China, Japan, South Korea, and the rest of Asia-Pacific. South America is represented by Brazil, Argentina, and the rest of South America. Lastly, the Middle East & Africa region encompasses GCC Countries, Egypt, South Africa, and the rest of Middle East & Africa.

Each region is unique in terms of its market dynamics, influenced by factors such as economic development, technological advancement, regulatory frameworks, and consumer preferences. For instance, North America and Europe are typically characterized by mature markets with established industries and stringent regulations, while Asia-Pacific, particularly countries like China and India, are experiencing rapid industrialization and urbanization, driving demand for advanced materials like CVD Silicon Carbide.

Moreover, regional variations in manufacturing capabilities, infrastructure, and investment climate also play a significant role in shaping market trends. For example, countries with robust semiconductor and electronics industries, such as South Korea and Japan, are likely to witness higher adoption of CVD Silicon Carbide for various applications, including power electronics, automotive, and aerospace.

Additionally, geopolitical factors and trade policies can impact market dynamics by influencing supply chains, pricing strategies, and market access. The ongoing trade tensions between the United States and China, for instance, have implications for companies operating in the Asia-Pacific region, leading to diversification strategies and reshoring initiatives.

Furthermore, cultural factors and societal trends may influence consumer preferences and adoption rates for CVD Silicon Carbide products. For instance, growing environmental awareness and concerns about energy efficiency may drive demand for eco-friendly materials and technologies across regions, impacting the market for CVD Silicon Carbide in applications such as renewable energy and electric vehicles.

The regional analysis of the global CVD Silicon Carbide market provides valuable insights into the diverse factors shaping market dynamics across different geographical areas. Understanding these regional nuances is essential for businesses to devise effective strategies and capitalize on emerging opportunities in the ever-changing landscape of the global market.

COMPETITIVE PLAYERS

In the dynamic landscape of the global CVD Silicon Carbide market, several key players are making significant strides to maintain their competitive edge. These players are essential drivers of innovation and progress within the industry, each bringing their unique expertise and capabilities to the table.

Tokai Carbon, Morgan Advanced Materials, Ferrotec, SGL Carbon, CoorsTek, Dow, AGC, SKC Solmics, Ortech Inc., Insaco Inc, Saint, Toyo Tanso, Mersen, CVD Equipment Corporation, Xycarb Ceramics B.V., and NOVASiC are among the prominent names shaping the future of CVD Silicon Carbide technology.

Tokai Carbon, with its extensive experience and technological prowess, continues to set benchmarks in the market. Morgan Advanced Materials, known for its innovative solutions and commitment to quality, remains a formidable force driving progress in the industry.

Ferrotec, SGL Carbon, and CoorsTek are also playing pivotal roles with their cutting-edge technologies and relentless focus on research and development. These companies are at the forefront of advancing CVD Silicon Carbide applications across various sectors, from electronics to automotive and aerospace.

Dow, AGC, SKC Solmics, and Ortech Inc. are leveraging their expertise to address emerging market demands and enhance product performance. Their commitment to sustainability and efficiency is reshaping the industry landscape and driving sustainable growth.

Insaco Inc, Saint, Toyo Tanso, and Mersen are renowned for their precision engineering and innovative solutions. Their contributions to the market are driving efficiency, reliability, and performance improvements, catering to the evolving needs of customers worldwide.

CVD Equipment Corporation, Xycarb Ceramics B.V., and NOVASiC are pioneering advancements in CVD Silicon Carbide manufacturing processes and equipment. Their focus on technological innovation and collaboration is accelerating the pace of development and opening up new possibilities for the industry.

In the coming years, these key players will continue to shape the global CVD Silicon Carbide market through their innovation, collaboration, and commitment to excellence. As technology evolves and market dynamics shift, their collective efforts will drive progress and unlock new opportunities for growth and advancement in the industry.

CVD Silicon Carbide Market Key Segments:

By Type

- High Resistivity Grade

- Middle Resistivity Grade

- Low Resistivity Grade

By Application

- Rapid Thermal Process Components

- Plasma Etch Components

- Susceptors & Dummy Wafer

- LED Wafer Carriers & Cover Plates

- Others

Key Global CVD Silicon Carbide Industry Players

- Tokai Carbon

- Morgan Advanced Materials

- Ferrotec

- SGL Carbon

- CoorsTek

- Dow

- AGC

- SKC Solmics

- Ortech, Inc.

- Insaco Inc

- Saint

- Toyo Tanso

- Mersen

- CVD Equipment Corporation

- Xycarb Ceramics B.V.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383