MARKET OVERVIEW

The global curved surface printer market is a sector that is moving into a world where innovation is not a competitive edge but a requirement. This subsection of industrial printing is breaking through the limits of conventional surfaces, into areas that defy planar norms and standard machinery. As technology developers and manufacturers increasingly focus on solutions that can handle intricate designs, the curved surface printing industry will keep expanding the boundaries of what machines should be able to do. Differently from conventional printing technologies, this business works on the periphery of personalized demand, necessitating precision, ruggedness, and flexibility in applications that will probably require further customization in the coming years.

Moving forward, the global curved surface printer market will not simply react to increasing demand for product differentiation it will shape the way established and new brands convey identity through non-linear surfaces. The path will tend to pick up in sectors such as consumer electronics, automotive, cosmetic packaging, and sports equipment, where appearance determines consumer acceptance. With increasingly demanding aesthetic and functional needs, the demand for printing on contoured, cylindrical, or irregular surfaces will create prospects for solutions that marry design agility with technical toughness. The market will not be limited to printing static images but will evolve eventually into a platform that facilitates dynamic, multi-dimensional brand experiences.

Much of the future for this industry will depend on how well it can marry automation, software savvy, and innovative ink technologies. Unlike flat surface printing, curved substrates tend to need recalibrated positioning, accuracy registration, and pressure management, all requiring smarter hardware-software interfaces. This industry will increasingly rely on technologies that bridge the space between imagination and mechanical implementation. Software with 3D surface mapping, variable data printing, and adaptive calibration will be more normal in the future. This revolution will not only transform machine operation but also how operators, designers, and engineers interact through production processes.

As the global curved surface printer market continues to mature, environmental stewardship will no longer be an afterthought. The composition of materials, energy usage patterns, and recyclability of inks will come under greater scrutiny by regulators and customers. Green practices, previously seen as a value-added attribute, will become minimum requirements in the near future. The sector will have to transition away from one-time use parts and high-polluting solvents, opening a new age of environmentally friendly innovation without compromising performance.

Essentially, the global curved surface printer market future is not about keeping pace with demand it will be anticipating it. Choices today will determine how flexible, innovative, and sustainable this industry will be tomorrow. Instead of being niched out, it is set to grow into larger industries just realizing how big curved surface potential can be. This evolving journey presumes that the market will not just grow but also restructure the paradigms of industrial design and consumer engagement.

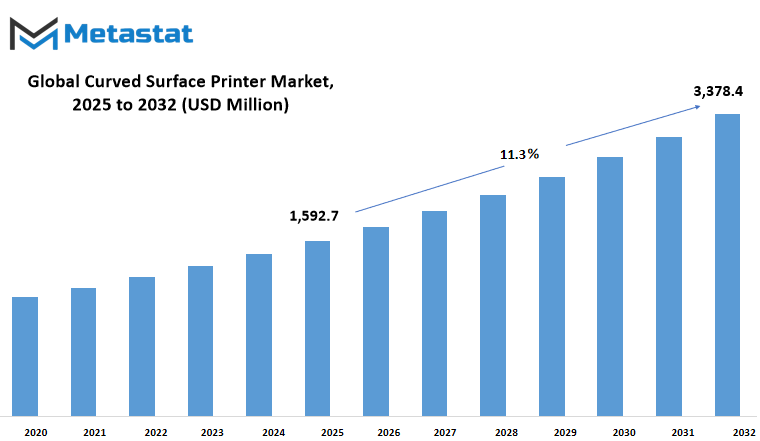

Global curved surface printer market is estimated to reach $3,378.4 Million by 2032; growing at a CAGR of 11.3% from 2025 to 2032.

GROWTH FACTORS

The global curved surface printer market is on the rise as increasing numbers of companies seek innovative means to beautify their products. Among the significant drivers fueling this development is the heightening demand for customized print on objects that are not flat such as bottles, helmets, and other irregularly shaped products. This movement away from flat printing to bespoke designs on intricate surfaces is particularly fashionable in branding and promotional exercises. Firms desire their logos, slogans, and designs to be unique, and curved surface printing allows that to happen with more flexibility and individuality.

In addition to personalization, the quick growth of the packaging and promotional product markets is also playing a significant role. Businesses globally are driving demand for aesthetically pleasing packaging that will differentiate them on retail shelves. From limited-edition beverage cans to exclusive merchandise, businesses are now opting for curved printing to enhance the visual impact as well as value of products. As marketing teams work harder to capture consumer attention, such specialized printing has become a valuable tool in their strategy.

But the path isn't entirely smooth for the global curved surface printer market. A major hurdle is the high setup cost. In many small companies or startups, the initial investment in curved surface printers proves to be a big deterrent. Such machines not only demand finances but also a specific location and maintenance assistance, which can be difficult for smaller companies to handle. Therefore, take-up of this technology is restricted to those who have enough capital and long-term vision.

Another challenge is finding trained professionals. Working with curved surface printers is not as simple as working with legacy flatbed printers. It requires one to know how materials will respond when printed on a non-flat plane, and how to set parameters for precision and longevity. Alas, there aren't enough qualified operators to go around, and this lack of expertise can delay a project or drive up the cost of doing business for companies that are trying to keep pace with orders.

Nevertheless, the future is promising. The expansion of 3D object printing into sectors such as automotive and consumer products is opening up new opportunities for curved surface printing to flourish. Consider dashboards, gear knobs, or cosmetic containers products where branding on the surface can impact significantly. As these industries begin to find new ways to marry design and functionality, demand for sophisticated surface printing is likely to increase.

More encouraging, though, is the advancement in printing technology itself. New printing equipment is being engineered that will print quicker, with increased resolution, and with greater accuracy even on very curved surfaces. These improvements may reduce costs in the long run and invite more companies to enter the market. With more improved tools and increased interest from several industries, the global curved surface printer market is likely to open up interesting opportunities in the future.

MARKET SEGMENTATION

By Product Type

The global curved surface printer market is experiencing visible change as companies are seeking new approach of printing on different-than-flat, curved, or unusual surfaces. This is substantially encouraged with the aid of the accelerated call for for personalization and individualization in industries which includes packaging, automotive, cosmetics, and client electronics. Brands now not locate widespread labels and flat prints proper. Rather, they preference hanging, complete-surface prints that talk for themselves and interact with their clients on a extra personal level. It is that this call for that has driven the development of curved floor printing technology that promise now not most effective accuracy but also layout flexibility.

Among the present sorts of products, inkjet printers have made a main leap forward, representing $933.Eight million in cost. Their reputation is because of their flexibility, value-effectiveness, and ability for printing in first-rate shade on a huge range of curved surfaces. Though the laser printer and thermal printer additionally percentage space inside the global curved surface printer market, the inkjet gadget remains desired for responsibilities calling for shiny colour and exact layout, especially in package printing and uniqueness merchandising. These printers have the capability to paintings with various shapes and materials, which makes them a legitimate option for organizations that need to increase their innovative attain.

As generation keeps advancing, these printers becomes more efficient and cheap. Companies will probably deal with improving ink adhesion, print pace, and help for various substances to fulfill clients' rising demands. This will simplify the use of curved surface printers for businesses not only for bulk orders, but also for smaller, customized orders a burgeoning category in markets that are moving to tailor to customization. The potential for innovation is high, and the industry will continue to adapt both to creative demands and to operations needs with wiser, more elegant printing solutions.

By Application

The global curved surface printer market is experiencing a visible change, driven by increasing requirements for customization and high-definition printing in various industries. The technology allows for printing directly onto objects with non-planar shapes, which is a best fit for materials that cannot be printed by employing conventional flat-surface printers. As businesses hold to prioritize emblem photograph and style, curved floor printers are increasingly being applied. Businesses everywhere in the international are actively looking for these solutions to address evolving customer needs for visually appealing, custom designed products.

For the beverage enterprise, curved surface printers are being applied on merchandise like tumblers, bottles, and different vessels. These products are usually integrated into branding efforts or employed for promotional uses. Having the capacity to print vivid, enduring designs on cylindrical or curved beverage boxes allows corporations to advantage a aggressive gain. Whether it is a water bottle or a espresso tumbler manufactured from stainless steel, the stop product embodies a easy, expert look that makes a distinction. The ease and accuracy of curved printing also minimize waste and labor, adding to its increasing popularity in the segment.

Packaging is also a sector where this printing technology has great potential. As brands are competing to design unboxing moments that are remembered, being able to print straight onto containers or irregularly shaped packaging materials is a game-changer. Conventional flat printing processes tend to need labels or shrink wraps, but curved printers eliminate that extra process. That not only saves time in production but also produces more resilient and visually continuity packaging, which is appealing to business and consumers alike.

In the automobile sector, customization and branding have increased considerably, and curved surface printers are fulfilling these needs. Whether dashboard parts, gear knobs, or outer accessories, vendors are utilizing this technology to apply fine details and logos with precision. The automobile industry treasures precision, and curved printers offer that without sacrificing speed. Since more and more companies are now interested in providing customized solutions to consumers, this process of printing is going to become increasingly prevalent in the production of vehicles.

Curved surface printing also finds applications in the electronics sector, particularly for manufacturing devices such as earbuds, wearable technology, and control panels. Several of these products feature rounded surfaces that demand direct printing to ensure functionality and aesthetic quality. Customers look for smooth, compact electronic devices with pleasing finishes, and curved surface printing enables that. With miniaturization trends not slowing down, having dependable and flexible printing methods will be critical for manufacturers in this category.

Medical equipment, in many cases constructed with non-planar surfaces and rigorous durability requirements, represents another field where this printing process is called upon. From surgical tools to medical monitoring devices, permanent and readable labelling is paramount in terms of safety and compliance. Curved surface printing provides healthcare manufacturers with the ability to place necessary information directly onto instruments or devices without sacrificing cleanliness or functionality. As this industry keeps on expanding and developing with the help of technology, the demand for clean, accurate, and quick printing solutions will continue to rise.

Outside of these broad categories, other markets are embracing curved surface printing for products that don't lend themselves to traditional printing configurations. From sporting equipment to home furnishings and promotion items, applications are varied. Companies who used to have to spend hours hand-decorating have access now to automated systems that provide consistent, high-quality output.

With the growing awareness of this method of printing and advances in technology, the global curved surface printer market will continue to grow. Various uses are propelling it in diverse manners, creating a market that is increasingly gaining strength. It might be for household products or industrial purposes, but the functional benefits of curved surface printing are more apparent with every passing year.

By End-User

The global curved surface printer market is slowly emerging as a promising field of innovation, driven by increasing demand for personalized and esthetically pleasing products. Such printing technology enables the ability to print directly on non-flat surfaces, like bottles, helmets, and other curved products. With personalization becoming an increasing trend in various sectors, this type of printing has come to stand out as it can produce high-quality designs without the constraints of conventional flatbed technologies. Companies are now realizing the efficiency and aesthetic appeal of curved surface printing, particularly as consumers become more interested in bespoke designs for their daily products.

In the manufacturing industry, curved surface printing is coming into focus for its property to print straight onto industrial equipment, parts, and branded components. Unlike conventional labeling, it produces a more professional finish without the need for adhesive substances. Manufacturers that handle high-volume production find curved printing particularly helpful for branding and marking that can withstand wear and tear. This is not just an economical approach but also aids in ensuring uniformity on mass-produced items.

Retail companies have also utilized curved surface printers to enhance product display and branding. From special edition packaging to giveaway merchandise, the technology allows retailers to produce visually distinctive products that are evident on store shelves. With customers disturbing extra personalization, mainly in beauty, liquids, and lifestyle products, this printing technique profits an advantage through imparting pretty saturated, durable prints on merchandise with non-planar surfaces. Brands are tending more in the direction of modern packaging as a method of affecting buying decisions, and curved floor printing fits ideally into that approach.

Within the healthcare sector, this type of printing plays a more utilitarian function. Curved surface printing is applied to print on medical devices, containers, and tools of irregular shape directly. Such items usually must be labeled for safety, dosage, and identification, and text and symbol printed durability is paramount. Printing by curved surface provides consistent results that cannot smudge or peel easily, even with heavy usage or exposure to sanitizing chemicals. The precision to print clearly on small and irregular surfaces finds special application in settings where accuracy is crucial.

Other industries are beginning to discover the possibilities of this technology. From interior design to sports, curved surface printing brings added value by rendering products more aesthetically appealing and brand-focused. Its ease to conform across different materials plastic, metal, glass makes it a desirable choice for companies looking for innovative solutions without sacrificing strength. The increasing interest across these disparate fields indicates that this market will continue to build momentum as businesses seek smarter means of uniting aesthetics and function.

On the whole, the global curved surface printer market is broadening its horizons by providing functional and innovative solutions that cater to the requirements of various industries. With increasing enterprises in search of techniques to enhance branding, product customization, and process efficiency, this printing method is poised to take a more assertive role in dictating the manner in which products are perceived and experienced.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,592.7 million |

|

Market Size by 2032 |

$3,378.4 Million |

|

Growth Rate from 2025 to 2032 |

11.3% |

|

Base Year |

2024 |

|

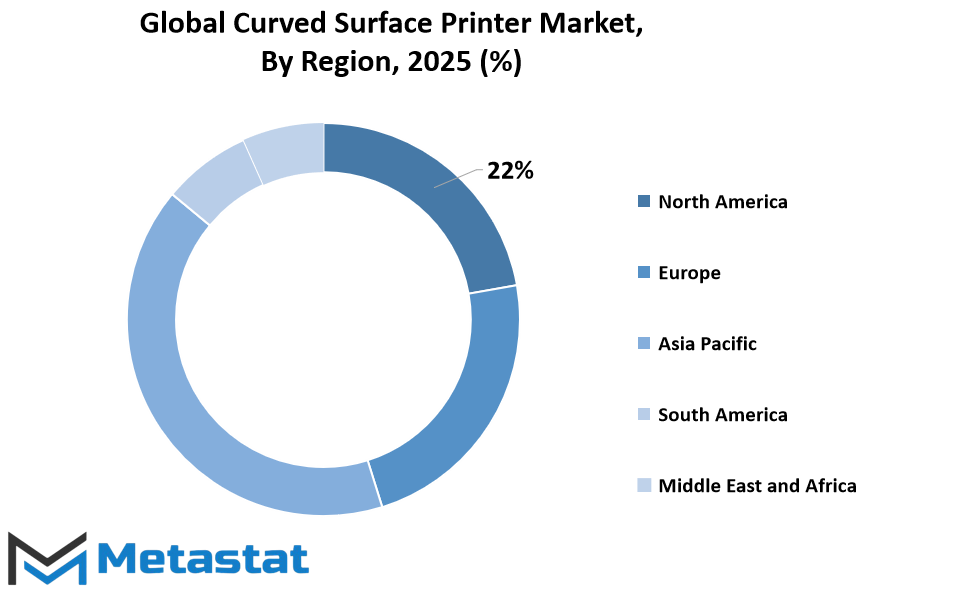

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global curved surface printer market keeps expanding as businesses aim to find improved means of personalizing and ornamenting items that are not flat. The printers have been of use in various industries, such as packaging, consumer electronics, and advertising specialties. As organizations try to find innovative means of differentiating themselves visually, the market for curved surface printing has been increasing consistently. This increasing demand is influenced in part by regional market trends, each with their own pace and inclination.

Geographically, in North America, it is segmented by the United States, Canada, and Mexico. Of these, the U.S. plays a major role with its robust manufacturing sector and technologically adept consumer base. Firms here are likely to embrace new print technologies promptly, especially for marketing and branding purposes. Canada and Mexico follow similarly, with manufacturers employing curved surface printers to cater to domestic as well as cross-border requirements.

Europe has a broad span of growth, such as the UK, Germany, France, Italy, and the Rest of Europe. Germany's established production base and Italy's artistic industries drive the uptake of these printers. In France and the UK, the popularity of high-end customization has motivated companies in cosmetics, drinks, and fashion accessories to try out curved surface designs. Other regions in Europe also drive the growth of the global curved surface printer market, albeit smaller in scale.

In Asia-Pacific, the geography comprises India, China, Japan, South Korea, and the Rest of Asia-Pacific. China is characterized by volume of production, whereas Japan and South Korea pay greater emphasis to technology advancements and innovation. India's emerging manufacturing hub and increased appetite for customized products have also presented new opportunities. The future is likely to remain intensely competitive as businesses seek to cut costs while enhancing design flexibility.

South America comprises Brazil, Argentina, and the Rest of South America. The major curved surface printer market here is Brazil, which is aided by the increasing demand for local branding and export-grade packaging. Argentina and the rest of the countries in the region are starting to follow suit, particularly where food, beverage, and household product lines are expanding. While adoption may be slower than in other areas, awareness of the advantages that these printers provide is increasing.

The Middle East & Africa segment is broken down into GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa. Investment in retail and hospitality in the GCC Countries has driven interest in product customization, particularly for promotional products and souvenirs. Egypt and South Africa exhibit potential, particularly in small-scale manufacturing and local artisanship. Region-wide, as more companies venture into branding outside of flat surfaces, curved surface printing will increasingly be included in regular manufacturing processes.

Different regions have individual patterns of demand and industrial focus. While others prioritize volume, others prioritize design and brand building. As this technology continues to validate its utility, more industries in all regions will embrace it, further influencing the future of customized and curved surface printing globally.

COMPETITIVE PLAYERS

The global curved surface printer market is heading for an era driven by innovation and accuracy. These printers, famous for their capability to print on non-flat objects like bottles, helmets, and other 3D items, are gaining greater significance in various industries. From promotional products to product packaging, curved surface printing is proving crucial in establishing brand differentiation. What was once a specialist service is now becoming a necessity, courtesy of increased demand for bespoke and attractive products. As companies seek to provide more bespoke experiences, curved surface printing is making it easy for them to do so with both speed and effectiveness.

In the last few years, technological advancements have made such printers more dependable and affordable. The emphasis has turned towards better print quality, minimizing waste, and user-friendliness. Businesses utilizing curved surface printers no longer need to use heavy manual work or several machines for one product. A single printer is capable of processing an extensive range of forms and materials. Such versatility is catching the eye of industries like cosmetics, food and beverages, medicines, and electronics. With product looks more becoming an influence on consumer purchase, being able to print directly onto curved items lends value that other flat-surface printers simply can't provide.

The other reason for the momentum of the global curved surface printer market is the increasing need for eco-friendly and on-demand production. The curved surface printers reduce waste by printing on products directly without the use of additional packaging or labels. This strategy comes in favor of more sustainable production, one that several companies are now focusing on. With environmental issues escalating, printing options that cut down waste while still providing top-notch visuals are increasing in popularity. This trend is not only fueled by legislation, but also by evolving consumer values.

The sector itself has a diverse set of businesses, each with its own capabilities to offer. Major players dominating the trends of the curved surface printer market are Mimaki Engineering Co., Ltd., Seiko Epson Corporation, Inkcups Now Corporation, and LSINC Corporation. Others like Anker Innovations Technology Co., Ltd (eufyMake), Canon Inc., OKI Data Corporation, and Roland DG Corporation remain pivotal in making advancements to limits. Veteran companies such as Ricoh Company, Ltd., Konica Minolta, Inc., Brother Industries, Ltd., Mutoh Holdings Co., Ltd., and Kornit Digital Ltd. are also working to create high-speed, high-quality solutions. Groundbreakers such as Electronics for Imaging, Inc. (EFI), FUJIFILM Holdings Corporation, ColDesi Incorporated, and SwissQprint AG continue to work towards providing machines capable of handling both creative and commercial expectations.

In the future, the curved surface printer market will only see more expansion as businesses from various industries adopt personalization and digital printing. With technology advancing, these printers will be even more efficient and versatile to accommodate new uses. This market will continue to advance because of the demand for items that are perceived as personal, visually unique, and sustainable. With so many leaders in the field so heavily invested in next-generation solutions, the future of curved surface printing is full of promise and purpose.

Curved Surface Printer Market Key Segments:

By Product Type

- Inkjet Printers

- Laser Printers

- Thermal Printers

By Application

- Tumblers, Bottles, and Other Drinkware

- Packaging

- Automotive

- Electronics

- Medical Devices

- Others

By End-User

- Manufacturing

- Retail

- Healthcare

- Others

Key Global Curved Surface Printer Industry Players

- Mimaki Engineering Co., Ltd.

- Seiko Epson Corporation

- Inkcups Now Corporation

- LSINC Corporation

- Anker Innovations Technology Co., Ltd (eufyMake)

- Canon Inc.

- OKI Data Corporation

- Roland DG Corporation

- Ricoh Company, Ltd.

- Konica Minolta, Inc.

- Brother Industries, Ltd.

- Mutoh Holdings Co., Ltd.

- Kornit Digital Ltd.

- Electronics for Imaging, Inc. (EFI)

- FUJIFILM Holdings Corporation

- ColDesi Incorporated

- SwissQprint AG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252