MARKET OVERVIEW

In the vast expanse of industrial landscapes, the China High Speed Steels market emerges as a significant player, shaping the trajectory of its industry. Within this sector, high-speed steels (HSS) occupy a pivotal position, characterized by their exceptional hardness, wear resistance, and heat resistance properties. As technology continues to advance, the demand for high-performance materials intensifies, propelling the growth of the HSS market in China.

The China High Speed Steels market is distinguished by a diverse array of applications across various sectors. From automotive to aerospace, from manufacturing to construction, the versatility of HSS finds application in cutting tools, drill bits, machining components, and more. With the relentless pursuit of efficiency and productivity, industries are increasingly turning to HSS to meet the demands of modern manufacturing processes.

One of the defining features of the China High Speed Steels market is its commitment to innovation and research. As industries evolve and challenges emerge, the market responds with new formulations, alloys, and processing techniques to enhance the performance of HSS. This continuous innovation ensures that China remains at the forefront of the global HSS market, catering to the ever-changing needs of industries worldwide.

Furthermore, the China High Speed Steels market is characterized by robust infrastructure and manufacturing capabilities. With state-of-the-art facilities and a skilled workforce, China boasts a competitive edge in HSS production. The country's ability to scale production efficiently and cost-effectively positions it as a formidable player in the global market.

Looking ahead, the China High Speed Steels market is poised for significant growth and expansion. As industries continue to demand higher performance materials, the market will witness increased investments in research and development, driving innovation and pushing the boundaries of HSS capabilities. Moreover, with the rise of automation and Industry 4.0, the demand for precision-engineered components will soar, further fueling the demand for high-speed steels.

The China High Speed Steels market stands as a dynamic and thriving industry, propelled by innovation, infrastructure, and evolving industrial demands. With its versatile applications, commitment to research, and robust manufacturing capabilities, China is poised to play a leading role in shaping the future of the global HSS market. As industries embrace new technologies and push the boundaries of performance, the China High Speed Steels market will continue to evolve, driving progress and innovation in the industrial landscape.

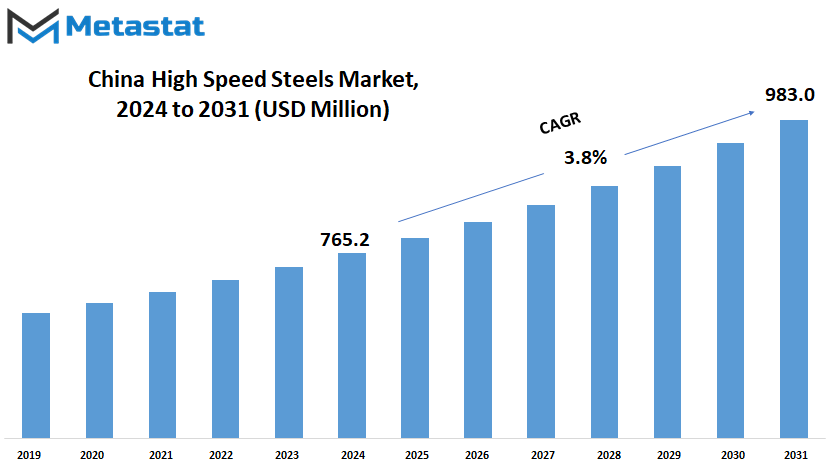

China High Speed Steels market is estimated to reach $983.0 Million by 2031; growing at a CAGR of 3.8% from 2024 to 2031.

GROWTH FACTORS

The growth of China high speed steels market is propelled by various factors that shape its trajectory. One significant driver is the increasing demand for high-speed steel tools across diverse manufacturing sectors like automotive, aerospace, and construction. This demand surge propels the market forward, indicating a promising outlook for China's production of high-speed steels.

Moreover, advancements in technology within the steel manufacturing sector play a pivotal role in fostering growth. Continuous innovations in manufacturing processes have led to the creation of high-quality, cost-effective high-speed steel products. These technological advancements not only enhance the quality of the products but also make them more accessible to a wider range of consumers.

However, despite these promising factors, the market is not without its challenges. Intense competition among various suppliers of high-speed steels within China has led to pricing pressures and market saturation. This competitive landscape poses a hurdle to the sustained growth of China's high-speed steel industry.

Additionally, environmental and regulatory challenges pose constraints on production and export capabilities. Stringent regulations regarding emissions control and compliance with quality standards add complexity to the manufacturing process and may impede market growth.

Nevertheless, there are opportunities for expansion and enhancement within the Chinese high-speed steel market. Investments in research and development, infrastructure, and technological capabilities offer avenues for improving product quality, fostering innovation, and enhancing competitiveness in the domestic marketplace. These opportunities pave the way for continued growth and evolution within China's high-speed steel industry in the years to come.

The growth of China's high-speed steels market is driven by a combination of demand from key manufacturing sectors, technological advancements, and opportunities for expansion. While challenges such as intense competition and regulatory hurdles exist, strategic investments and innovations present avenues for overcoming these obstacles and ensuring sustained growth in the future.

MARKET SEGMENTATION

By Type

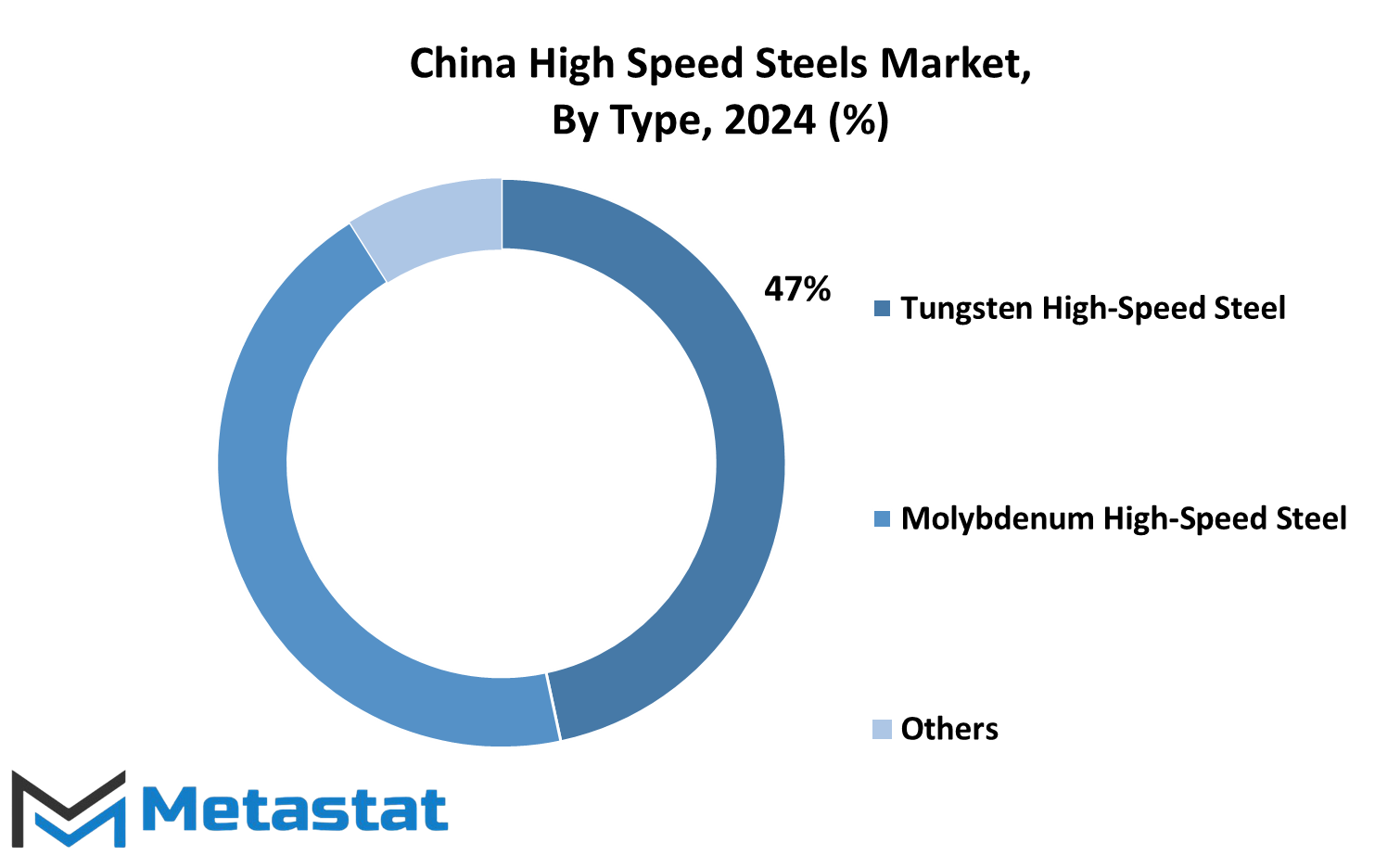

The Chinese high-speed steel market, categorized by type, includes tungsten high-speed steel, molybdenum high-speed steel, cobalt high-speed steel, and others. This segmentation reflects the diverse materials used in manufacturing high-speed steel products. Tungsten high-speed steel, known for its hardness and resistance to wear, will likely continue to dominate the market due to its favorable properties. Molybdenum high-speed steel, valued for its high-temperature strength and toughness, will also play a significant role in the market. Cobalt high-speed steel, with its excellent heat resistance and hardness, will find applications in specialized industries. Additionally, other types of high-speed steel will contribute to the market, each offering unique characteristics suited to specific manufacturing needs.

The future of the Chinese high-speed steel market will be influenced by various factors, including technological advancements, market demand, and regulatory policies. Technological innovations will drive the development of new and improved high-speed steel formulations, enhancing performance and expanding applications. With increasing demand for high-speed steel in industries such as automotive, aerospace, and manufacturing, the market will experience steady growth. Moreover, stringent regulations aimed at ensuring product quality and environmental sustainability will shape the market landscape, encouraging manufacturers to adopt sustainable practices and produce high-quality steel products.

As the Chinese economy continues to grow and industrialize, the demand for high-speed steel will rise, driven by the need for efficient and cost-effective manufacturing solutions. High-speed steel tools and components will play a crucial role in enhancing productivity, precision, and reliability across various industries, driving further demand growth. Additionally, advancements in additive manufacturing and other production technologies will enable the fabrication of complex high-speed steel parts with unprecedented precision and efficiency, further fueling market expansion.

Globalization and international trade will also impact the Chinese high-speed steel market, creating both opportunities and challenges for market players. Increasing competition from foreign manufacturers and fluctuations in raw material prices will require domestic companies to innovate and adapt to changing market dynamics. Collaboration and partnerships with international counterparts will become essential for accessing new markets and technologies, ensuring the competitiveness of Chinese high-speed steel products on the global stage.

By Grade

China's high-speed steel market is segmented by grade, with notable categories including M Grade, T Grade, and Advance Grade. These grades determine the steel's specific properties and performance characteristics, catering to diverse application needs.

The M Grade high-speed steel stands out for its balanced composition, offering a blend of toughness, hardness, and wear resistance. It finds extensive use in cutting tools, drills, and machining applications where reliability and precision are paramount. As manufacturing technologies advance, the demand for M Grade high-speed steel is expected to soar, driven by the growing need for high-performance tooling solutions.

T Grade high-speed steel, on the other hand, is renowned for its superior thermal stability and heat resistance. This grade excels in high-temperature applications, such as metal forging and die casting, where tools are subjected to extreme heat and stress. With the continuous expansion of industries requiring thermal processing capabilities, the T Grade high-speed steel market is poised for sustained growth, driven by the demand for durable and heat-resistant tooling materials.

Advance Grade high-speed steel represents the pinnacle of technological innovation in the industry. Characterized by enhanced performance metrics, including hardness, wear resistance, and cutting edge retention, Advance Grade steel pushes the boundaries of what's achievable in machining and tooling applications. As industries embrace automation and precision engineering, the demand for Advance Grade high-speed steel will surge, fueled by the need for cutting-edge tooling solutions that can deliver unparalleled performance and productivity.

By Production Method

China's high-speed steel market, a key component of its industrial landscape, is characterized by diverse production methods. Conventional HSS, the traditional method, relies on established techniques to craft high-quality steel. However, as technology progresses, newer methods have emerged, reshaping the market landscape.

Powder Metallurgy (PM) HSS represents a significant advancement in steel production. This method involves the consolidation of fine metal powders to create superior steel products. By utilizing finely ground powders, PM HSS enhances the uniformity and purity of the steel, resulting in improved performance and durability. As China continues to invest in research and development, PM HSS is poised to play an increasingly prominent role in the market.

Another innovative approach is Spray Forming (SF) HSS, which utilizes a spray deposition process to manufacture steel. By atomizing molten metal and rapidly cooling it, SF HSS achieves precise control over the microstructure of the steel, enhancing its mechanical properties and overall performance. This method offers unique advantages in terms of efficiency and versatility, making it an attractive option for manufacturers in China's high-speed steel market.

As China embraces these advanced production methods, the competitive landscape of the high-speed steel market is undergoing a transformation. Traditional methods coexist with cutting-edge techniques, offering a range of options for manufacturers and consumers alike. This diversification not only fosters innovation but also drives growth and sustainability in the industry.

By End User

The Chinese high-speed steel market is segmented by end users into several sectors, including automotive, manufacturing, aerospace, mechanical engineering, construction, and others. Each sector plays a crucial role in driving the demand for high-speed steel in China.

In the automotive sector, high-speed steel is widely used for various applications such as cutting tools, dies, and molds. With the continuous advancement in automotive technology, the demand for high-speed steel is expected to increase further as manufacturers seek materials with superior durability and performance to meet the demands of modern vehicles.

Similarly, in the manufacturing industry, high-speed steel finds extensive usage in cutting and shaping tools due to its excellent wear resistance and toughness. As China continues to be a global manufacturing hub, the demand for high-speed steel in this sector will remain robust, driven by the need for efficient and reliable machining processes.

The aerospace industry is another significant end user of high-speed steel in China. High-speed steel is utilized in the production of critical components such as turbine blades, drills, and reamers, where precision and durability are paramount. With the rapid growth of the aerospace sector in China, particularly in the commercial aviation segment, the demand for high-speed steel is poised to surge in the coming years.

Mechanical engineering encompasses a wide range of applications, including machinery manufacturing, tool and die making, and precision engineering. High-speed steel plays a vital role in this sector, offering superior performance and longevity in demanding operating conditions. As China continues to invest in infrastructure development and industrial automation, the demand for high-speed steel in mechanical engineering applications is expected to witness sustained growth.

The construction industry also presents opportunities for the high-speed steel market in China. High-speed steel is used in the fabrication of cutting tools for construction machinery, as well as in the production of components for building materials and structural elements. As urbanization and infrastructure projects continue to expand across China, the demand for high-speed steel in the construction sector will remain buoyant.

Besides these key sectors, high-speed steel also finds applications in various other industries such as mining, energy, and consumer goods manufacturing. Overall, the China high-speed steel market is poised for steady growth driven by the diverse needs of end users across multiple sectors. As China embraces technological advancements and industrial innovation, the demand for high-speed steel will continue to grow, offering ample opportunities for market players to capitalize on emerging trends and applications.

COMPETITIVE PLAYERS

In the vast landscape of the High-Speed Steels market in China, several notable contenders emerge, each vying for a significant share of the industry pie. Among these competitive players are names like Dalian Special Steel Products Co., Ltd., Jiangsu Tiangong Tools Company Limited, Fushun Special Steel Co., Ltd., and Daye Special Steel Co., Ltd. These companies, with their robust presence and expertise, are poised to shape the trajectory of the market in the coming years.

Dalian Special Steel Products Co., Ltd., for instance, stands out with its commitment to innovation and quality. Leveraging advanced technologies and a skilled workforce, the company is primed to meet the evolving demands of customers and stay ahead in the competitive landscape.

Similarly, Jiangsu Tiangong Tools Company Limited brings to the table a wealth of experience and a diverse portfolio of high-speed steel products. With a focus on customer satisfaction and continuous improvement, the company is well-positioned to capitalize on emerging opportunities and maintain its competitive edge.

Fushun Special Steel Co., Ltd., known for its cutting-edge research and development initiatives, is another key player in the market. By investing in research and forging strategic partnerships, the company aims to develop innovative solutions that will cater to the evolving needs of industries reliant on high-speed steels.

Daye Special Steel Co., Ltd., with its strong emphasis on quality control and customer-centric approach, also commands a significant presence in the competitive landscape. By prioritizing customer feedback and market insights, the company is poised to adapt swiftly to changing dynamics and cement its position as a market leader.

In addition to these formidable players, other notable contenders such as Dongbei Special Steel Group International Trade Co., Ltd., Shougang, Shenzhen Haoyuan Special Steel Co., Ltd., and Changshu Fengyang Special Steel Co., Ltd., are actively shaping the competitive landscape with their unique strengths and strategic initiatives.

As the High-Speed Steels market in China continues to evolve, these competitive players will play a pivotal role in driving innovation, fostering growth, and meeting the diverse needs of customers across various industries. With their unwavering commitment to excellence and relentless pursuit of success, they are poised to chart new territories and redefine the benchmarks of success in the ever-evolving landscape of high-speed steels.

Chine High Speed Steels Market Key Segments:

By Type

- Tungsten High Speed Steel

- Molybdenum High Speed Steel

- Cobalt High Speed Steel

- Others

By Grade

- M Grade

- T Grade

- Advance Grade

By Production Method

- Conventional HSS

- Powder Metallurgy (PM) HSS

- Spray Forming (SF) HSS

By End User

- Automotive

- Manufacturing

- Aerospace

- Mechanical Engineering

- Construction

- Others

Key China High Speed Steels Industry Players

- Dalian Special Steel Products Co., Ltd.

- Jiangsu Tiangong Tools Company Limited

- Fushun Special Steel Co., Ltd.

- Daye Special Steel Co., Ltd.

- Dongbei Special Steel Group International Trade Co., Ltd.

- shougang

- Shenzhen Haoyuan Special Steel Co.,Ltd

- Changshu Fengyang Special Steel Co., Ltd

- Sandvik Materials Technology (Wuxi) Co., Ltd.

- Bohler Edelstahl China Co., Ltd.

- Wuhan Iron and Steel Group Corporation

- Rizhao Iron and Steel Group Co., Ltd.

- Jianlong Group (Chengdu) Special Steel Co., Ltd.

- Baosteel Group Corporation

- Maanshan Iron & Steel Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383