MARKET OVERVIEW

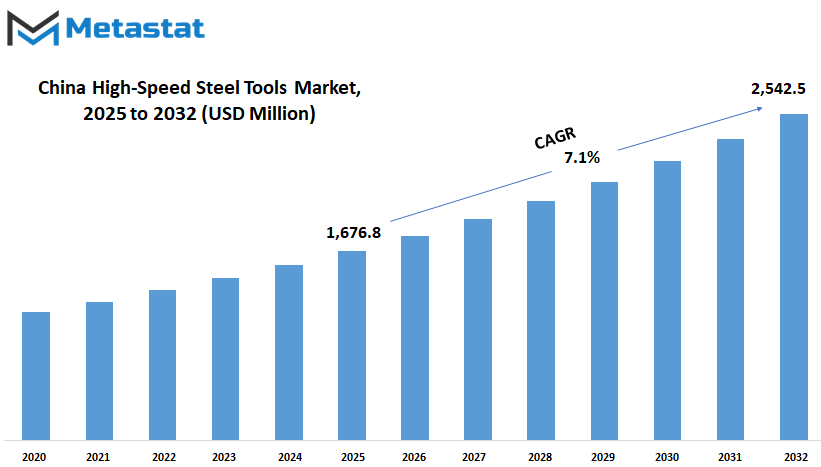

China High-Speed Steel Tools market is estimated to reach $2,542.5 Million by 2032; growing at a CAGR of 7.1% from 2025 to 2032.

The China High-Speed Steel Tools Market plays a key role in the manufacture and machining industries by providing cutting and drilling solutions for many applications. High-speed steel (HSS) tools are widely accepted for being some of the toughest and most heat-resistant tools that hold their sharpness even in the worst conditions. Thus, this market shall continue to play a significant role in metalworking, construction, and automotive manufacturing as industry sectors demand efficiency and precision.

The China High-Speed Steel Tools market is meant for high-speed machining of hard materials with cutting instruments. They are unique in lathe operations, milling, drilling, and shaping, which require a very high degree of precision and hardness and are widely used. Manufacturing companies operating in this sector would be expected to further refine alloys on application of promising developments in metallurgical techniques for improvement in performance and long life. Heavy-duty machining industries would continue to rely on high-speed steel tools due to their economical price and reliability in high-temperature environments.

Adoption of modern manufacturing plants will create the developments in the China High-Speed Steel Tools market as automation and precision engineering become mainstream in the industry today. Performance consistency under high-stressed conditions will trigger improvements in modern tool coatings, material compositions, and advanced methods of production. High-speed steel tools are rugged and can often be reused, but that will not hinder them from becoming obsolete when new cutting technologies are invented. Such factories and workshops, which are usually in search of solutions that would complement efficiency and durability, would keep this market fundamental in industrial growth.

Heat treating innovations will be the spearhead in product development within the China High-Speed Steel Tools market. Most manufacturing industries would only be interested in making tools that provide or could handle more vigorous applications, while manufacturers will be refining their hardening techniques for the improvement of wear resistance and thermal stability. With advances in powder metallurgy, producers will be able to manufacture high-speed steel tools with grain structures designed for optimum performance and prolonged life. These improvements will facilitate the production and application of intricate machining, enhancing productivity in metal shaping and cutting processes.

High-speed steel has these guarantees, and industries will continue to use such tools. From aerospace engineering to infrastructure development, the needs of machining will change over time, and accordingly, tools will be adopted for better cutting speed and defense against mechanical load. The China High-Speed Steel Tools market will serve those industries that make products at a cost while taking no less effort in efficiency in the reliability of tools. This would be the way for manufacturers to invest further in research into refining the microstructure of these tools.

Supply chain improvements and availability of raw materials would also bring forces to play in the China High-Speed Steel Tools market. The market has seen innovations in manufacturing methodologies aimed at enhancing production efficiency without compromising quality. The trend towards sustainability will enhance the initiatives toward the optimization of high-speed steel tools' recyclability with the intention of minimizing material wastage and maximizing resource utilization. The factories and machining centers that require these tools are mainly oriented toward availability and performance, thereby underlining the market relevance within precision manufacturing.

Future coating developments will also have their bearing on the market for high-speed steel tools in China. The depositing of titanium and/or ceramic coatings would improve the cutting efficiency by reducing friction and enhancing wear resistance. This evolution guarantees the high-speed steel tools be competitive in the market within which tool life and performance take priority considerations. Continuous innovation has to conform to the dynamic evolution of machining needs and will thus continually strengthen the position of this market in the industrial production processes.

GROWTH FACTORS

The China High-Speed Steel Tools market will be shaped by technological developments. Inventions within the steel manufacturing process will also develop tools that have better durability, heat resistivity, and cost-effectiveness. The firms are now working on enhancing the composition of high-speed steels to increase strength and performance in extreme conditions. High-speed steel tools will gradually become more durable and efficient due to continuing developments in manufacturing methods, thus making them a choice for various industries. China, meanwhile, enjoys the competitive edge in the export markets through the supply of high-quality tools at fairly affordable market prices that attract buyers from different regions.

The forecast for high-speed steel appliances in China suggests increasing demand with the industrial expansions and modernization taking place. The high-speed steel material is vitally needed since industries such as automotive, aerospace, and construction put huge demands on a highly flexible and durable cutting tool. Manufacturers search for production efficiency along with various other ways, of which the advanced tools are a major contributor to ensure precision and speed. Thus, the amplified need for high-performance machines in these sectors will increase the demand for high-speed steel tools, thereby enhancing China's position as one of the major suppliers.

Yet internal growth opportunities will be countered by fierce competition among the suppliers in China. Pricing pressures affecting profit margins arise from the presence of numerous manufacturers producing nearly identical tools. These are companies that will need to find differentiation through superior quality or custom solutions, or betterupon service offerings. Moreover, market saturation will limit growth, making a focus on continual improvement and innovation key to business survival. A concerted effort toward research and development would allow manufacturers to produce tools with advanced coatings producing better wear resistance and longer life, keeping them ahead of the competition.

An additional feature that will shape the industry's future will be obligatory consideration to environmental issues. Steel production, resource- and energy-consuming, has, therefore, seen increasing regulatory frame currently turned into strictly regulatory consideration; therefore, companies should adopt a cleaner and far more sustainable manufacturing process within these environmentally complace. Nevertheless, the industry will keep a balance between meeting the growing production demand and its environmental responsibility for long-term growth.

Expansion opportunities in the China High-Speed Steel Tools market will arise from investment and technological advancement. Enhanced infrastructure and refined production processes will ensure better product quality and competitiveness through these advancements. Innovations inbound automation and digitalization will greatly aid the production process by making manufacturing more precise and cheaper. The greater the world industry demands the sky-high productivity, more important is the role of China in supplying high-speed steel tools, as it is becoming an opportunity for sustained market growth.

MARKET SEGMENTATION

By Type

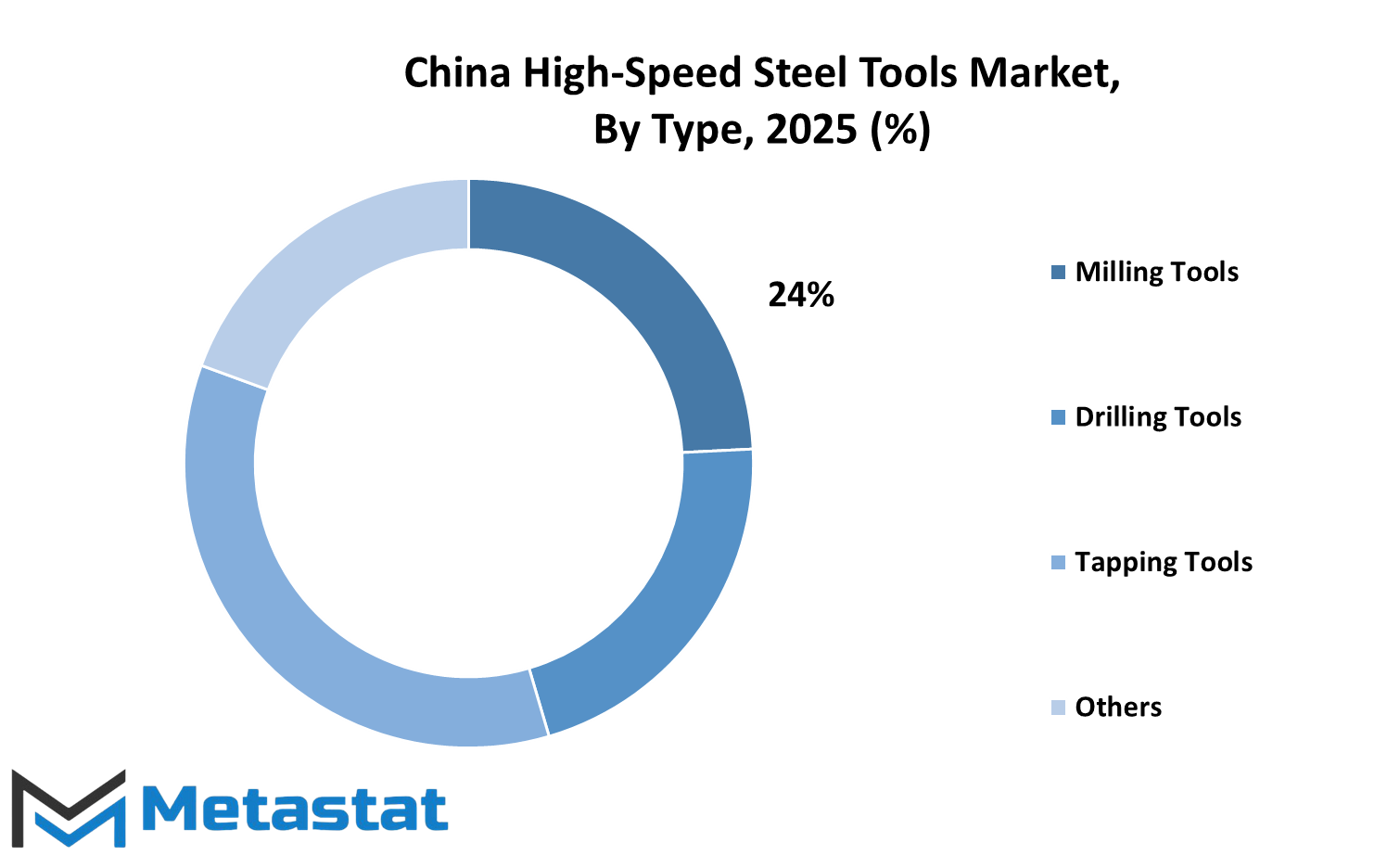

Demand in China for high-speed steel tools will keep rising as industries continue to look for reliable and durable cutting solutions. With advances in manufacturing and the need for even greater efficiency, steel tools will remain indispensable to many important industries. Thus, companies are focusing on tool performance enhancement with new materials that provide better heat resistance and longevity so that industries can cut costs while producing with accuracy and quality.

There will be a much greater focus on designs and technologies in the China high-speed steel tools market. Milling tools will be much more advanced, with faster cutting speeds but the same accuracy. New coatings and geometries would be developed for drilling tools, improving wear resistance and usability. Advancements in tapping tools can be expected to assist better in the smooth threading process with less wear on tools. Additional high-speed steel tools will be designed according to industry needs, predominantly for customized cases.

As industries grow, manufacturers will introduce tools for both conventional machining and automatic machining. The trend for smart manufacturing will also affect tool development and create high-speed steel tools working with digital systems. Such usage would allow monitoring of tool performance in real-time, leading to adjustments to improve productivity. All these developments toward increasing AI and automation in production facilities will also act in favor of creating and keeping the future market, where tools will have to respond to very fast and complex working processes.

The market rivalry will drive companies to test new manufacturing systems. Some firms will upgrade material composition to render tools more resistant to extreme states, while others will perfect coatings to enhance cutting efficiency. Retention of sharpness for a more extended period is expected to be a decisive factor in the prospects of these products among the automotive, aerospace, and heavy machinery industries.

Sustainability will be another way that this market will shape itself. The producers of high-speed steel will will thus think of ways to make the high-speed steel tools environmentally friendly in its production; recycling and reconditioning would be carried out to a great extent for the worn-out tools so that waste can be diminished while performance requirements are met.

With continuous advancements in technology and industrial processes, high-speed steel tools in China will remain an important tool of manufacturing. The development of more efficient, durable, and adaptable tools will allow businesses to survive in competition and satisfy modern production requirements. The market will respond with solutions that are increasingly pushing the limits of the working capabilities of these tools, whenever new challenges arise.

By End-user

The demands of high-speed steel tools will soar in China with the advancement of the industry in manufacturing initiatives. Organizations continually pursue technology improvements and precision tools that create durable and efficient tools that give long-term commitments to provide flexibility and reliability to withstand high temperatures during machining processes. There will also be an increase in the use of high-speed steel tools in various industries because they are not reliable; they offer reliability-long service life and withstands high temperatures during machining. The demand for high-quality cutting and drilling tools will continue increasing with the growing industries including automotive, aircraft, oil and gas, machinery, and shipbuilding.

The modernization in the China High-Speed Steel Tools market will mainly result from automation and smart manufacturing. Factories are now gradually transitioning to efficient production lines, and the demand for these machines will start going up when "high speed" becomes associated with precision. The automobile sector is and should be a dominant user; the main objective of automakers is producing more while still adhering to stricter quality criteria. "Emerging markets will thus require sleek tools that will accommodate specialized materials that electric vehicles will be built with," pointed out the industry expert who wished to remain anonymous.

Again, the aircraft industry will be another crucial player in how this market scenario will pan out. These days, when the aircraft manufacturers are looking for means to manufacture fuel-efficient craft, there's a trend toward the use of stronger, lighter materials, which in turn requires cutting tools that would keep sharpness and accuracy under very severe conditions. Comparable is drilling and extraction processes in which the oil and gas industry also relies on these tools. This is because of their durability and resistance to extreme environment conditions. This is also one major industry that will remain a constant contributor to this sector due to the fact that automation keeps on changing production facilities. They need tools that will be able to support high-speed operations without compromising their efficiency.

Discipline shipbuilding has also been mentioned as one of the portfolios that would impact the China High-Speed Steel Tools market. with global trade up and running, the world now requires big boats and specialized ships. And that requires high-performance tools with an ability to perform precise machining on tougher materials. Other industries that are going to generate significant demand include construction and manufacturing heavy equipment as they call for tools capable of doing complicated cutting and shaping.

Future advances will try to improve tool coatings by reducing wear and enhancing the cutting speed without compromising the quality. In research and development, manufacturers will invest on understanding and developing the tools that may offer the extended life and enhanced efficient usage. With growing industries modernizing, demands for high-speed steel tools are likely to remain strong and shape the market footprint for years to come. With innovations and adaptability in mind, firms will succeed winners, ensuring that the industry gets what it wants in terms of how its trend within the industries keeps evolving.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$ 1,676.8 Million |

|

Market Size by 2032 |

$2,542.5 Million |

|

Growth Rate from 2025 to 2032 |

7.1% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

COMPETITIVE PLAYERS

As industries in China head toward advanced manufacturing and precision engineering, the market for high-speed steel tools will witness continued growth. These tools are critical in machining and metalworking operations in all industrial environments where high durability and efficiency are required. The focus of manufacturers will be on enhancing tool performance through continuous developments in material technology and advanced production techniques so that the tools are capable of being subjected to high temperatures and immense workload while maintaining precision.

Going forward, the market for China High-Speed Steel Tools will see growing usage of innovative coatings and improved compositions of steel that had elevated wear resistance and extended tool life. Cutting tool industries such as those in aerospace, automotive, and heavy machinery manufacturing will require more efficient cutting tools to sustain the demands of high-speed production lines. As these areas will push the manufacturers to explore the further hardening of tools with maintained toughness to put up with very demanding applications, companies will invest energy into researching the development of tools for less energy consumption and shorter machining time for cost-effective operations.

Competition among key players will thus intensify as the market expects differentiation of products. The leading manufacturers such as China Yongbao, Fushun Special Steel Co., Ltd., and Dongbei Special Steel Group Co., Ltd. have already acquired a strong foothold and will continue to build on their already strong position through innovation. Other companies like Dalian BaoSteel Metallurgy Group Co., Ltd. and ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE will develop their product range in line with varied industries. It is this competition that will lay the pathway for tool improvement in efficiency, quality, and customization for more reliable options sought by various industries for upgrading their manufacturing functions.

Meanwhile, other members such as Zhuzhou OBT Carbide Tools Co. Ltd., Dongbei Group Special Steel and Shandong Honsiron Machinery Parts Co. Ltd. will have a pivotal role in forming the market while specializing their lines in precision tooling and specialty applications. The issuance of high-performance tools for specialized tasks will now be guaranteed. On the other hand, Changzhou Lihao Tools Co., Ltd., Union Hardware, Zhejiang Zhenyue Tools Co., Ltd., and Chengdu Karve Precision Machinery Co. Ltd. would work on addressing affordability without sacrificing quality. Such efforts will gain the high-speed steel tools access to a church customer base.

The increasing demand for high-performance tools will prompt manufacturers to continuously refine their operations and bring forth solutions aimed at productivity enhancement. Material science, automation, and sustainability will forge the cutting tools of the future for this market empowered by increased availability to demand now placed on modern manufacturing.

China High-Speed Steel Tools Market Key Segments:

By Type

- Milling

- Drilling

- Tapping

- Others

By End-user

- Automobile Industry

- Aircraft Industry

- Oil & Gas Industry

- Machinery Industry

- Shipping Building Industry

- Others

Key China High-Speed Steel Tools Industry Players

- China Yongbao

- Fushun Special Steel Co., Ltd.

- Daye Special Steel Co., Ltd.

- Dalian BaoSteel Metallurgy Group Co., Ltd.

- ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE

- Zhuzhou OBT Carbide tools Co., Ltd.

- Dongbei Special Steel Group Co., Ltd.

- Shandong Honsiron Machinery Parts Co., Ltd

- Changzhou Lihao Tools Co., Ltd.

- Union Hardware

- Zhejiang Zhenyue Tools Co., Ltd

- Chengdu Karve Precision Machinery Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383