Global Calcined Bauxite Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global calcined bauxite market will start its progress tracing its roots to the early 20th century when bauxite began being tested as a raw material by industry uses. Refractory manufacture initially generated a need for bauxite with steel and glass plants requiring high-temperature endurance. Europe and North America initiated small-scale operations, with basic calcination processes and few export channels. In the mid-20th century, mechanical kilns and improvements in purification techniques allowed for improved quality calcined bauxite, and their usage was expanded to abrasives and ceramics industries.

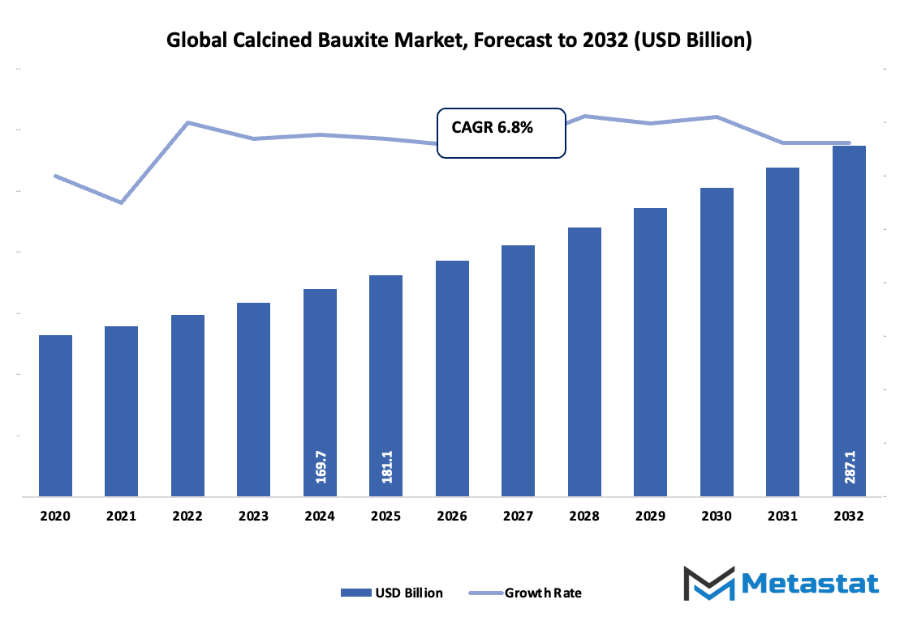

- Global calcined bauxite market size of approximately USD 181.1 million in 2025 and expected to grow at a CAGR of about 6.8% between 2032, with an estimated potential to reach more than USD 287.1 million.

- Refractory Grade has a market share of nearly 66.8%, leading innovation and expanding applications through intense research.

- Principle growth drivers: Growth in demand from the steel and refractory industries, Increased use in abrasives and high-temperature industrial processes

- Opportunities include: Developing environmentally friendly and high-performance calcined bauxite products for cutting-edge industrial applications

- Principle insight: The market will continue to grow exponentially in value in the next decade with strong growth prospects.

- In the later half of the 20th century, the global market for calcined bauxite will continue to expand with the assistance of the reconstruction era and increasing demands for industrial infrastructure.

The 1970s were a threshold period when Asian economies began exploiting bauxite reserves, rearranging supply lines and providing competitive prices. At the same time, regulatory changes as far as environment protection is concerned will influence methods of production, and producers will be compelled to move towards using cleaner, energy-efficient calcination processes. These changes will increasingly reshape the market's profile towards suppliers capable of offering more stringent emission levels without any degradation of product quality. Customer needs will increasingly shift towards proprietary grades of calcined bauxite for novel applications. In refractory linings, for instance, higher alumina content and lower impurities will become critical, while in abrasives, consistency of the particles will be what determines product performance.

Enhanced milling, sorting, and heat treatment technologies will improve the consistency and reliability of the products, positioning the world calcined bauxite market for broader industrial application. Meanwhile, developing markets will begin seeking local sources of calcined bauxite in order to reduce dependency on imports, propelling regional production centers. The global market for calcined bauxite in the future will be guided on a course by processing technology, use diversification, and environmental protection. With increasing automated operations being integrated, precision thermal control being applied, and new bauxite sources being explored, the industry will redefine the limits of efficiency and excellence. The market will find itself moving more towards more sustainable practices, juggling industrial needs with regulatory needs, to supply the growing need for high-performance, customized calcined bauxite products in industry segments.

Market Segments The global calcined bauxite market is mainly segmented by Grade, Application, End-user Industry, By Grade is sub-divided into: Refractory Grade: Refractory grade bauxite is used to a large extent for high-temperature purposes since it will not deteriorate at elevated temperatures. It is hence essential to industries that require heat-resistant materials such as steelmaking and cement manufacturing.

Market Segments

The global calcined bauxite market is mainly classified based on Grade, Application, End-user Industry, .

By Grade is further segmented into:

- Refractory Grade: Refractory grade bauxite is used to a large extent for high-temperature purposes since it will not deteriorate at elevated temperatures. It is hence essential to industries that require heat-resistant materials such as steelmaking and cement manufacturing. The global market for refractory grade Calcined Bauxite is expected to grow moderately due to the ongoing demand from industry.

- Abrasive Grade: Abrasive grade bauxite is utilized in the production of materials which have the ability to grind, polish, or clean other surfaces. Its strength and hardness render it ideally suited for application in sandblasting, grinding wheels, and other abrasives. The market for Calcined Bauxite globally will see consistent growth driven by its effectiveness in the manufacture of long-wearing abrasive products.

- Other: This refers to bauxite used in applications other than in refractory or abrasives. It may include unusual industrial applications or lower-volume applications in the manufacturing process. The global calcined bauxite market will continue to expand as industries explore alternative uses and develop new products.

By Application the market is divided into:

- Refractory Materials: Calcined bauxite finds its key application in the manufacturing of refractory materials utilized in furnaces, kilns, and other thermal applications. Its resistance to thermal shock provides such materials with stability as well as a long lifetime. Ongoing demand within heat-resistant applications will be backed by the global calcined bauxite market.

- Cement: Calcined bauxite is utilized in the cement sector for product quality improvement along with heat and wear resistance. It converts the cement mixes to be stronger and more resilient through the addition of it. The market will expand due to increased construction activity as well as infrastructure growth leading to increased cement production across the globe.

- Abrasive products: Calcined bauxite is an essential raw material to produce abrasives for grinding, polishing, and cleaning. The hardness prevents the inefficient processing of the material and surface treatment. market will increase as industry maintenance and production increasingly depend upon quality abrasive products.

- Pavement & Flooring: Bauxite is employed to enhance the toughness and durability of flooring and roads. Its incorporation brings wear and hard condition resistance. The market will experience consistent growth as urbanization and infrastructure call for more resistant paving material.

- Others: This application category includes uses outside the major industries, such as specialized industrial processes and laboratory. Industrial demand and technological development will drive this segment's influence on the global calcined bauxite market, enabling growth in the long term.

By End-user Industry the market is further divided into:

- Steel Industry: Calcined bauxite is essential in steel production for lining furnaces and producing heat-resistant components. Its high melting point ensures safe and efficient operations. The global calcined bauxite market will expand with growth in steel manufacturing and increasing demand for durable, heat-resistant materials.

- Petroleum Industry: In petroleum, calcined bauxite is used in catalysts and refinery processes, improving efficiency and performance. The market will see growth as energy production and refining activities continue to develop worldwide.

- Construction: Construction industries rely on calcined bauxite for durable building materials, including cement and flooring solutions. Its properties enhance strength and longevity. The market will grow steadily with rising infrastructure projects and urban development.

- Manufacturing: Manufacturing sectors use calcined bauxite in various processes to improve product quality and durability. Its role in producing abrasives, refractories, and specialty materials drives demand. The market will benefit from expanding manufacturing operations across multiple regions.

- Other: This includes industries not explicitly mentioned, which use calcined bauxite in smaller-scale or niche applications. Innovation and industrial requirements will shape this segment’s growth within the global calcined bauxite market.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$181.1 Million |

|

Market Size by 2032 |

$287.1 Million |

|

Growth Rate from 2025 to 2032 |

6.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

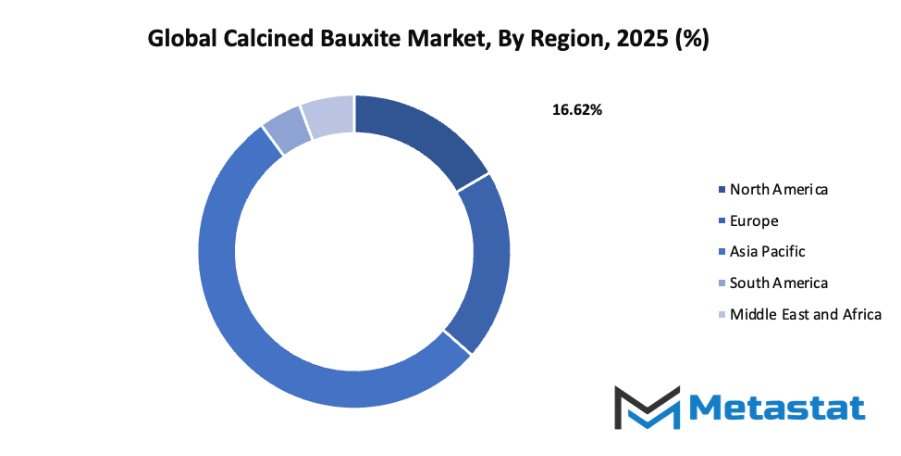

By Region:

- Based on geography, the global calcined bauxite market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Growing demand from the refractory and steel industries: The global calcined bauxite market will experience strong growth due to rising requirements in the refractory and steel industries. These industries rely on high-quality calcined bauxite to withstand extreme temperatures and maintain structural integrity, which will drive consistent demand over time.

- Increasing applications in abrasives and high-temperature industrial processes: The use of calcined bauxite in abrasives and various high-temperature industrial processes will continue to expand. Its properties make it suitable for grinding, polishing, and other industrial operations, contributing significantly to the growth of the global calcined bauxite market.

Challenges and Opportunities

- High production and processing costs: High costs associated with production and processing will remain a key challenge in the global calcined bauxite market. Extracting, calcining, and refining the material requires energy-intensive processes, which can limit profitability and slow market expansion if not managed efficiently.

- Environmental concerns related to mining and calcination processes: Mining and calcination processes have significant environmental impacts, including air and water pollution. Addressing these environmental concerns will be critical for sustainable growth, as industries and governments increasingly focus on reducing the ecological footprint of raw material extraction and processing.

Opportunities

- Development of eco-friendly and high-performance calcined bauxite products for advanced industrial applications: There is a growing opportunity to develop eco-friendly and high-performance calcined bauxite products. Such innovations will meet industry demands for sustainable and efficient materials, enhancing the global calcined bauxite market and supporting long-term industrial applications.

Competitive Landscape & Strategic Insights

The global calcined bauxite market is shaped by a combination of long-established international companies and emerging regional players, creating a competitive landscape that will continue to evolve over the coming years. Established industry leaders bring experience, scale, and advanced production capabilities, which will help set benchmarks for quality, efficiency, and sustainability. At the same time, regional competitors are likely to introduce innovative approaches and flexible strategies, enabling faster adaptation to local demands and emerging market trends. This balance between large-scale producers and smaller regional firms will drive the market toward more efficient and sustainable practices, as each player strives to gain a competitive edge.

Important competitors in the market include Sinocean Industrial Limited, Bosai Minerals Group Guyana Inc., Henan Qingjiang Industrial Co., Ltd, Plomp Mineral Services BV, Alchemy Mineral LLC, EKC.AG, Great Lakes Minerals, LLC, LKAB, Artha Mineral Resources, Royal Mineral, CIMSA, and GNPGraystar. Each of these companies brings unique strengths and capabilities to the industry. While international leaders will continue to dominate global supply chains, regional competitors will focus on specialized products, customer-specific solutions, and local partnerships. Over time, this dynamic will encourage collaboration, technology sharing, and new investment in production methods that increase efficiency and reduce environmental impact.

Looking toward the future, the Calcined Bauxite market will likely experience significant technological advancements. Automation, digital monitoring, and energy-efficient processing methods will become more common, allowing companies to optimize production while reducing costs. Sustainability will also play a critical role, as demand for environmentally responsible materials continues to rise. Companies that can balance productivity with sustainable practices will be positioned for long-term success, while those slow to adapt may face challenges in maintaining market share. The combination of global reach and regional agility will make the industry more resilient, capable of responding to changes in demand, raw material availability, and regulatory requirements.

Market size is forecast to rise from USD 181.1 million in 2025 to over USD 287.1 million by 2032. Calcined Bauxite will maintain dominance but face growing competition from emerging formats.

The global calcined bauxite market is poised for continued growth as new technologies, regional innovations, and strategic collaborations reshape the industry. Both established international companies and emerging regional competitors will influence the direction of production, investment, and sustainability efforts. As the market evolves, it will become increasingly competitive, with innovation and adaptability serving as the keys to long-term success in the years ahead.

Report Coverage

This research report categorizes the Calcined Bauxite market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Calcined Bauxite market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Calcined Bauxite market.

Calcined Bauxite Market Key Segments:

By Grade

- Refractory Grade

- Abrasive Grade

- Other

By Application

- Refractory Materials

- Cement

- Abrasives

- Pavement & Flooring

- Other

By End-user Industry

- Steel Industry

- Petroleum Industry

- Construction

- Manufacturing

- Other

Key Global Calcined Bauxite Industry Players

- Sinocean Industrial Limited

- Bosai Minerals Group Guyana Inc.

- Henan Qingjiang Industrial Co., Ltd

- Plomp Mineral Services BV

- Alchemy Mineral LLC

- EKC.AG

- Great Lakes Minerals, LLC

- LKAB

- Artha Mineral Resources

- Royal Mineral

- CIMSA

- GNPGraystar

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383