MARKET OVERVIEW

The global automotive plastics market is expected to continue its significant transformation in the coming years, as the demand for lighter and more fuel-efficient vehicles continues to rise. Highly critical in the manufacturing of a vehicle, this industry will see increased innovations as automakers push for advanced materials that do not only meet standards for safety and performance but also sustainably meet these goals.

With the industry now embracing new materials, plastics will increasingly play important roles in designing vehicles. Advanced polymer-based materials, thermoplastic elastomers, polycarbonates, and high-performance composites from automotive manufacturers are expected to create a wide array of functional applications. These would provide a combined strength of strength, flexibility, and lightweight qualities to optimize fuel efficiency while allowing structural integrity to be maintained.

The automotive plastics industry is likely to change as companies seek ways these materials can help them meet the global environmental standards. Plastic parts will be part of the strategies that reduce carbon footprints, and car manufacturers will adopt approaches that encourage the use of recycled and recyclable materials in vehicle production. Hence, the design and engineering processes will have to be developed with an aim toward getting the plastics-interlaced vehicles which can achieve high recyclability without compromising their performance. Consequently, improvements in the recycling of automotive plastics will be required, with higher efficiency and scalability.

The consumer expectations are going to shift as well. The more environmentally friendly the buyer is, the greater their demands on automakers during the production process of automobiles using sustainable materials are likely to be. Consequently, there will be a growing need for green plastic materials such as bioplastics to produce the automobiles that may appeal to this fast-growing environmentalist consumer category.

On the technological front, it is expected to grow with the introduction of smart plastics in the automotive industry. These novel materials will have sensor-embedded and self-healing properties, which enhance the safety and performance features of vehicles. Plastics that will connect new technologies in dashboard interfaces, seating components, and exterior body panels make automobiles more intelligent and connected. This integration would allow for real-time monitoring and adaptation of vehicle systems with a higher degree of safety and performance.

Future of global automotive plastics market Specialization of material on basis of type of vehicles, including the rise of Electric vehicles and requirements specific to this, for instance, lighter-weight plastics, designed for better energy storage efficiency, as the more a vehicle is lightweight, the more its battery lasts. In similar fashion, the Autonomous Vehicle might demand unique plastic usage in support systems with sensor wiring, communication technology.

As this happens, however, the market will also face a number of issues, specifically regarding the scale and complexity involved in scaling up sustainable practices in the supply chain. As the demand for automotive plastics increases, companies will need to find new, innovative ways to maintain efficiency in the supply chain while the growing demand requires increasing sustainable production.

As the integration of smart and sustainable materials continues to grow, plastics will be an integral part of future generations of vehicles, addressing the emergent needs of manufacturers as well as users. Of course, the global automotive plastics market will occupy a central place in shaping the future of the automotive industry.

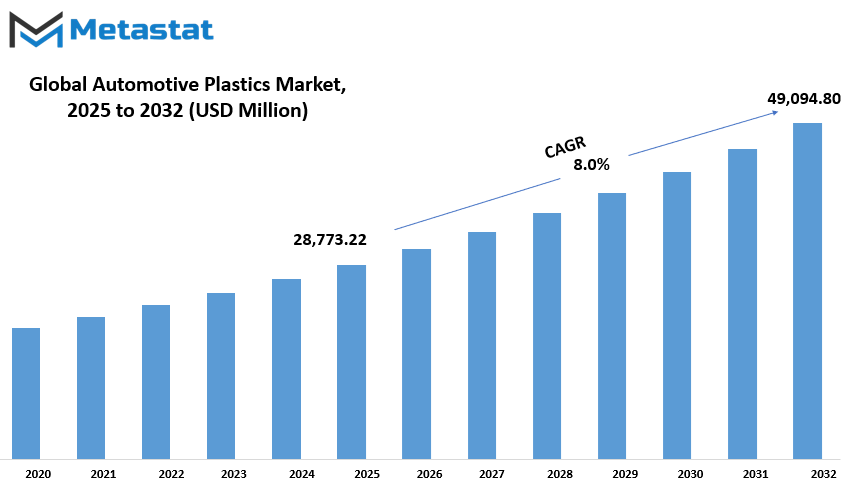

Global automotive plastics market is estimated to reach $49,094.80 Million by 2032; growing at a CAGR of 8.0% from 2025 to 2032.

GROWTH FACTORS

The global automotive plastics market is growing very significantly. Lightweight materials are presently becoming popular in the quest to reduce fuel consumption. Electric vehicles and hybrid vehicles are also increasing in use. Automakers have been under undue pressure regarding "how much to cut in terms of fuel consumption, and how much in terms of reducing carbon emissions," and lightweight materials such as plastics have been needed in their quest.

These materials help decrease the overall weight of vehicles, further increasing fuel economy and reducing environmental impact from transportation. Apart from the pressure of increased fuel efficiency, growing demand for electric and hybrid vehicles increases the demand for automotive plastics. Electric and hybrid vehicles require advanced lightweight components to enhance the performance of batteries and extend driving range. It is, therefore, a chance for the automotive plastics industry to expand and grow.

However, despite its market growth potential, several things may hinder its progress. One major challenge is the cyclic instability of raw materials, especially oil, which affects the plastics production cost. The cyclic instability of oil prices directly results in costs that may be passed on to manufacturers, ultimately impacting automotive plastics affordability and profitability.

The recycling of automotive plastics is also another challenge. The problem is yet to be resolved by the industry of effective and efficient recycling of plastic materials that are used in vehicles. There are cases when significant portions of automotive plastics could not be recycled, leading to environmental concerns. The buildup of plastic waste in ecosystems could potentially cause harm to these areas. Governments and consumers demand more green solutions for which the automotive industries need to seek a way out.

Nevertheless, growth opportunities remain massive in the Global Automotive Plastics market. As mentioned earlier, a significant growing opportunity is about the demand of sustainable and recyclable automotive plastics. Consumers, along with producers, are concentrating increasingly on sustainable productions, thereby resulting in demand for eco-friendly material. With growing innovation by developing recyclable and sustainable plastic materials, this would be more valuable for producers and will drive up the volume in the short-term. Such a scenario would increasingly be looking for plastics that are lightweight and environmentally responsible. In this light, the demand for automotive plastics is sure to remain the promise of this market for several coming years.

MARKET SEGMENTATION

Type of Plastics

The automotive industry has developed significantly with time, with one of the most significant changes being the general acceptance of the use of plastics in the vehicle manufacturing process. Plastics possess durability and lightness and are relatively inexpensive than other materials; thus, their application can occur at various stages in automobiles. As fuel consumption and environmental aspects continue to demand attention, plastics are becoming vital in the automobile industry.

The global automotive plastics market is continually on an upsurge with the growing requirement for lighter materials that assist in the increase of fuel efficiency and decrease in emissions. Automakers always look for better vehicle performance in a manner where it will remain affordable. The use of plastics in several types of components, such as interior and exterior parts, under-the-hood applications, and electrical components, makes it an ideal solution.

Various kinds of plastics are employed in the global automotive plastics market for different purposes. Among those, Polypropylene (PP) has the largest part of around $9,593.60 million. It is widely used because of its excellent resistance properties towards chemicals, lightweight body, and low cost compared to other plastics. Polyurethane (PU) is another important plastic because it is extensively used because of its flexibility and permanence for seating and insulation, respectively. Polyethylene is valued for toughness and is also used in fuel tanks and protective coverings.

Polyvinyl Chloride (PVC) is widely applied in vehicle interiors, as they are durable, yet cost-effective. The acrylonitrile butadiene styrene is chosen on account of the strength and the impact resistance it possesses, due to which there is a higher use of acrylonitrile butadiene styrene in dashboards and other structural components. The requirements of designing and performance specific usage are covered through specialized plastics. The necessity of sustainability in automotive plastics market also increases in today's context. Manufacturers now started investing into biodegradable and recyclable plastics to minimize the environmental footprints. As governments become stricter on pollution and waste, the industry has moved towards greener options without compromise on quality and efficiency.

In addition, technology is driving the future of automotive plastics. The innovations in polymer science have resulted in the creation of high-performance materials that confer enhanced safety, comfort, and durability properties. As such, they also impact improvements in aerodynamics, noise reduction, and lifetimes of vehicles.

It is quite visible that the growth in demand of lightweight and energy-efficient vehicles leads to an automobile industry which extensively uses plastics in their manufacturing, and therefore the global automotive plastics market is expected to move ahead with its research and developments as the cars become efficient and cost-effective for the environment.

By Vehicle Type

The global automotive plastics market grows because manufacturers continue to seek alternative materials that not only enhance performance and efficiency in vehicles but make them more environmentally friendly. Here, plastics really become very significant in modern productions since it really addresses a large need for something lighter but not weaker. In this way, it helps a vehicle to lighten up overall while consuming less fuel and producing much less carbon. Plastics are now very important in the automotive industry because the market is moving towards designing environmentally friendly vehicles and consumer demand for durability and safety. The global automotive plastics market is categorized into vehicle types: passenger vehicles, commercial vehicles, electric vehicles (EVs), hybrid vehicles, and others.

Passenger vehicles are very significant because of their high volume production and consumers' demand for light and fuel-efficient cars. Plastics are incorporated into various components of the vehicle's interior, exterior, and under-the-hood to give aesthetic appeal and performance in vehicles. Commercial vehicles also benefit from plastic components through fuel efficiency and cost-cutting on maintenance.

The logistics and transportation industries opt for such commercial vehicles. Further still, the growth of electric vehicles and hybrid vehicles increased demand for automotive plastics. These vehicles heavily depend on light weight to make up for battery weight and push out driving ranges. Plastics are used in casings, interior panels, and aerodynamic designs to improve the performance of batteries. Governments all over the world encourage electric mobility by incentives and policies; the manufacturers go innovative with new plastics materials with features of heat resistance, impact strength, and recyclability. With advancements in plastic technology, new advanced materials develop a high-performance polymer resistant to extreme temperature stresses and mechanical stresses.

The most used materials in this regard include polypropylene, polycarbonate, and polyamide. These are known to exhibit strength, flexibility, and resistance to corrosion. Of late, there has been an interest in recycled and bio-based plastics because the industry is moving toward sustainability. Eco-friendly materials are increasingly being used by automakers to meet global initiatives aimed at reducing environmental impact.

Even with the benefits, the global automotive plastics market has concerns regarding recycling and disposal. Waste management of plastic remains an issue; hence, better recycling technologies and biodegradable materials are researched. Industry leaders have been considering closed-loop recycling systems that enable the reuse of plastics in manufacturing, thus lessening dependence on virgin materials.

As technological developments continue with a rising trend in sustainability, this market for automobile plastics will continue to rise highly in the near future. Adaptation in the auto industry towards changing customers' preferences and upgrading regulatory requirements would be the leading plastic innovations, while design and production of vehicles would be efficiency, safety, and environmental friendliness.

By Process

The global automotive plastics market has recorded a rapid growth trend in the last few years because of the high demand of lightweight and durable materials in the automotive world. Plastics are an integral part in the manufacturing of modern automobiles since it provides the benefits of weight reduction, better fuel economy, and design flexibility. Since auto manufacturers emphasize both the considerations regarding environmental regulations and vehicle performance, the plastics usage in automobiles is under constant expansion.

Some of the main drivers in this market are the increasing need for fuel-efficient vehicles. This is attained through lighter materials, which diminish the overall weight of the vehicle, thus increasing fuel efficiency and reducing emissions. A strict regulation of emissions by governments around the world forces manufacturers to use lightweight materials like plastics. In addition, the rise of electric vehicles has further accelerated the demand for these materials, as reducing weight is essential for maximizing battery efficiency. The global automotive plastics market is categorized based on different processes used in manufacturing.

Injection molding, blow molding, and thermoforming are the primary techniques employed to shape plastic components for vehicles. Injection molding can be widely offered because it easily produces complex geometries with extreme precision and precision. This would be ideal to make interior as well as exterior parts, in which dashboards, bumpers, and even door panels all fall into line. Blow molding is commonly adopted for hollow plastics such as those for fuel tanks and air ducts. Due to this particular technique, there is a means of producing extremely lightweight yet the strength of their parts that goes well with all industry standards.

Another important process is thermoforming, which is used to produce large plastic panels and protective covers. It heats up a plastic sheet until it is flexible, and then shapes it using a mold. This process is useful in the production of trunk liners, interior trims, and other structural parts. Besides being light in weight, automotive plastics also provide enhanced durability and resistance to corrosion, which makes them more favorable for the vehicle manufacturers. The plastic components do not rust; thus, their usages extend the life of many automotive parts.

Secondly, plastics offer greater design freedom. With this comes the opportunity for car manufacturers to have innovative, yet pleasingly designed automobiles. Just as sustainability grows in importance, so does the use of recycled and bio-based plastics. Most companies are now investing in environmental-friendly alternatives that suit performance standards. With technology progressing further ahead, the global automotive plastics market will evolve by bringing out new innovations and concepts. Plastics will remain vital in the future of automobiles, with a strong focus on lightweight materials, fuel efficiency, and sustainability.

By Application

As vehicle manufacturers increase production of lighter and more fuel-efficient vehicles to enhance performance with minimum emissions, demand for plastics globally in the automobile industry has dramatically increased. Some of the reasons for their usage include their ability to reduce weight, flexibility in designs as and when required, and also greater durability. As the demand for electric vehicles and sustainability increases constantly, in the near future, the utilization of plastics in the automobile sector will increase more. Fuel efficiency is a strong driving factor in the global automotive plastics market.

One of the significant reasons is that lighter vehicles consume lesser fuel, therefore lesser carbon emissions. Historically, steel and aluminum have been the traditional metals used. They are slowly being replaced with high-performance plastics that don't compromise on strength but dramatically reduce weight. Not only do they help achieve tight environmental standards but also optimize overall vehicle performance. The surge in electric vehicle production has created an added requirement for novel materials that provide increased energy efficiency without a sacrifice to safety. The global automotive plastics market is categorized by application into four main segments: Interior, Exterior, Under Bonnet, and Others. Interior applications include dashboard components, door panels, and seating elements, where plastics provide comfort, durability, and a stylish finish.

The exterior segment covers parts like bumpers, grilles, and lighting systems, where impact resistance and aesthetic appeal are essential. Bonnet applications feature heat resistance and chemical stability advanced plastic with regards to components that can include: engines, battery housings, fuel systems. In "Others", several small elements add functionality to vehicles while supporting their overall performance. Sustainability is the key driver in terms of market growth. Bio-based and recyclable plastics are a focus area for manufacturers in meeting global environmental concerns. Demand for eco-friendly material is prompting the development of innovations in polymer technology, with plastics being produced for the automotive industry that are both high strength, lightweight, and recyclable.

Challenges remain for the global automotive plastics market despite all the advantages that it presents. Growing concerns over waste and the low recyclability rate of plastics lead to strict policies on material use. However, studies are in place to better improve recyclability and minimize impacts on the environment. Advances in technology and ever-tightening regulations will, therefore, define the future role of plastics in the automotive sector. The role of automotive plastics will remain important for the vehicle-manufacturing sector in terms of efficiency, sustainability, and innovation as the automobile industry emphasizes the three dimensions.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$28,773.22 million |

|

Market Size by 2032 |

$45,773.88 Million |

|

Growth Rate from 2024 to 2031 |

8.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global automotive plastics market is rising due to high demand for material that weighs lesser to increase higher fuel efficiency as well as lessen carbon emission. Companies are under pressure to engineer high-performance plastic with durability and flexibility along with low price tags. Its use areas range between interior and exterior parts, including under-hood components, to electrical systems, which is no longer possible in the construction of a contemporary car.

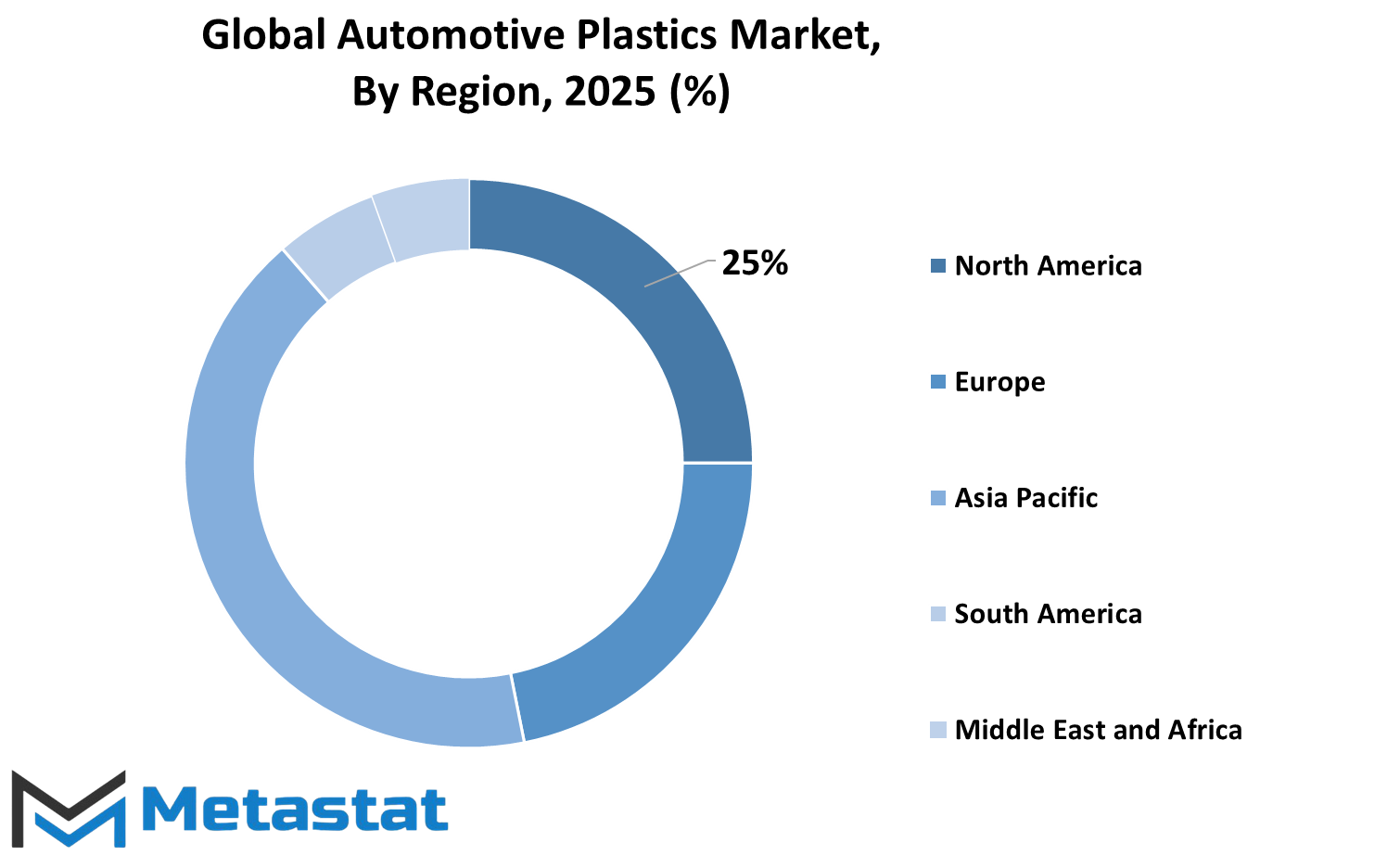

Geographically, it is segmented as North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. North America contains the U.S., Canada, and Mexico while Europe contains UK, Germany, France, Italy, and the Rest of Europe. Asia-Pacific contains India, China, Japan, South Korea, and the Rest of Asia-Pacific. South America is further divided into three groups: Brazil, Argentina, and Rest of South America. Middle East & Africa is also divided into four groups: GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa. Each market has its specific set of opportunities and challenges that vary from regions like growth in industries, governmental regulations, and technological influences.

In North America, environmental regulations have become quite strict and there has been an uptrend in electric vehicle usage. Here, a matured automobile industry prevails, and all leading manufacturers have invested in the research process for the development of new plastic solutions. The country holds the major market share; followed by Canada and Mexico where automobile production has also increased lately.

Today, Europe becomes a home to the giant automakers of the world and pushes the demand for sustainable and lightweight materials within their production. Some of the major contributors to the global automotive plastics market come from Germany, being one of the world's largest automobile manufacturers, France, Italy, and the UK. Automotive plastics development companies are highly focused on sustainability and fuel efficiency.

Asia-Pacific is the region where growth has been the most aggressive, spurred by the rapidly growing vehicle manufacturing sectors in China, India, and Japan. High-speed urbanization and an increased disposable income generate demand for passenger vehicles, and consequently for more advanced plastics. South Korean technology innovations solidify the position of the region.

Steady growth is experienced in South America, mainly in Brazil and Argentina, as the automotive industry grows. Economic fluctuations and regulatory policies affect market dynamics. In the Middle East & Africa, infrastructure development and rising vehicle demand in GCC Countries, Egypt, and South Africa provide support for growth.

The global automotive plastics market continues to evolve due to technological advancement and environmental concerns. Manufacturers are now expected to create more eco-friendly and high-performance plastics to suit future demands.

COMPETITIVE PLAYERS

The global automotive plastics market is growing as lightweight and fuel-efficient vehicles are increasingly in demand. Automakers have resorted to improving on fuel economy and reducing emission, making plastics essential material for vehicle manufacturers. These materials provide not only lightweight properties but also durability, corrosion resistance, and design flexibility, adding more versatile usage in all automotive applications. Plastics are used for everything from interior components to exterior body panels in modern vehicle design.

Several factors are driving demand for the global automotive plastics market. One key reason is the shift toward electric vehicles. Manufacturers of EVs are looking to improve battery efficiency and extend driving range, which has made weight reduction a priority. The plastics achieve this by replacing the conventional heavy material such as metal. Moreover, severe regulations and rules in regard to the emission of carbon into the atmosphere have forced vehicle producers to use lightweight materials. These regulations also enhanced the demand for car plastics.

Plastics in a vehicle do not only cut the weight of a vehicle but are also being utilized for improving the safety features, comfort level, and beauty. High performance polymers can be seen as parts of an airbag, seat belts, or bumpers. The usage in interior sections such as dashboard, door panel, and seat helps achieve an appealing and neat appearance while keeping durability in place. Impact resistance, moisture, and chemical resistance can also be significantly enhanced using plastics, increasing the lifetime of car components.

The industry in question, however, has its bag of negatives. First and foremost is environmental impact. More than ever, since sustainability took center stage, plastic waste and recycling processes have been worried over. Automakers and material manufacturers are now investing in research and development of recyclable and bio-based plastics that can reduce environmental footprints while maintaining performance standards. Another factor that is gaining momentum is the circular economy initiative, which encourages the reuse and recycling of plastic components.

BASF SE, SABIC, Covestro AG, Dow Inc., Exxon Mobil Corporation, LANXESS AG, LG Chem, Evonik Industries AG, DSM Engineering, LyondellBasell Industries Holdings B.V., Asahi Kasei Corporation, and Borealis AG are some of the majors of global automotive plastics market. And these companies continuously work in developing advanced materials as per the needs of the automobile industry.

The automobile sector will continue innovating, and plastics become a part of manufacturing in the near future to support this effort. Future developments in such a manner will emphasize 'sustainability' and 'performance' to make automotive plastics contribute to an efficient and environment-friendly transportation sector.

Automotive Plastics Market Key Segments:

By Type of Plastics

- Polypropylene (PP)

- Polyurethane (PU)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Butadiene Styrene (ABS)

- Others

By Vehicle Type

- Passenger Vehicles

- Commercial Vehicles

- Electric Vehicles (EVs)

- Hybrid Vehicles

- Others

By Process

- Injection Molding

- Blow Molding

- Thermoforming

By Application

- Interior

- Exterior

- Under Bonnet

- Others

Key Global Automotive Plastics Industry Players

- BASF SE

- SABIC

- Covestro AG

- Dow Inc.

- Exxon Mobil Corporation

- LANXESS AG

- LG Chem

- Evonik Industries AG

- DSM Engineering

- LyondellBasell Industries Holdings B.V.

- Asahi Kasei Corporation

- Borealis AG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383