May 29, 2025

The latest publication by Metastat Insight provides an in-depth examination of the Global PVC Market that highlights the trends, advancements, and evolutions that defined the industry over the years. Polyvinyl chloride, commonly referred to as PVC, has been a leading product in a wide variety of industrial and commercial uses for a long time. Its versatility and properties have made it a go-to material in construction, packaging, automotive parts, and consumer products. The history of PVC has not been one of linear events but rather of constant interaction among technology, manufacturing processes, and demands of use. Every industry using PVC has evolved its own requirements and standards, resulting in a rich tapestry of both complexity and potential.

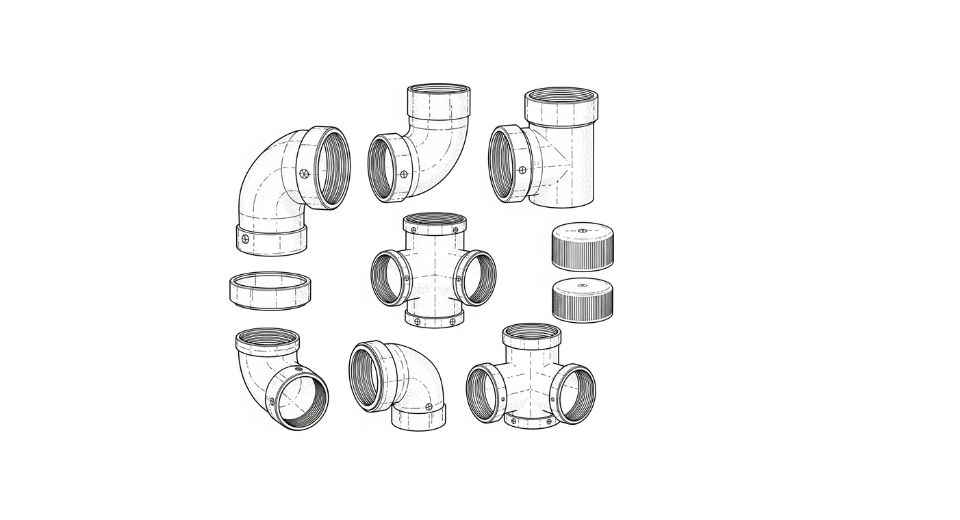

One of the impressive aspects of the Global PVC Market is its ability to diversify and adjust to many uses without compromising on its fundamental identity. Whether applied in flexible films or rigid pipes, the performance and structural properties of PVC make it suitable for a broad range of utility. This capability to satisfy unique technical requirements, while being cost-effective, has enabled it to maintain a robust presence despite alternatives. Suppliers continue to collaborate closely with industry players to narrow product specifications and meet changing demands. The versatility of PVC to operate effectively under different conditions without compromising on durability is one reason why it remains a key player in sectors.

In building, for example, PVC use has moved beyond traditional piping and cabling to window frames, door frames, and floors. Such uses require materials that not only withstand pressure but which are also visually and design flexible. The visual flexibility of PVC, along with its durability, has enabled it to be shaped into functional and attractive forms. In addition, the ease of logistics in shipping and installing PVC-based products lends itself to its extensive application in urban development as well as in infrastructure. Each of these uses demonstrates a careful balance of material properties with everyday, real-world requirements.

Packaging has also been one place where PVC's flexibility is well demonstrated. Its capability to create films and containers that can securely hold and protect products has made it a popular option among manufacturers and retailers. The clarity, strength, and workability of PVC allow it to address specific packaging requirements in food, pharmaceuticals, and industrial products. Manufacturers are constantly looking for means to maximize PVC for protective features without adding excess weight or volume. By so doing, they preserve the balance between function and efficiency that users require. These qualities underpin the long-term currency of PVC in a business always on the lookout for innovation without sacrifice to reliability.

Within transport, PVC is applied in a range of interior and exterior items, such as dashboards, trim, and cable insulation. These applications underscore not merely strength as a material property but also priorities in comfort, safety, and durability. The PVC acceptance by the automotive industry has been fostered by its ability to be engineered into specific textures and finishes that meet performance and aesthetic requirements. The material must satisfy stringent regulatory and safety requirements, which has driven continuous development in the areas of product formulations and production processes. As manufacturers strive to achieve these standards, they persist in calling attention to the singular combination of versatility and performance provided by PVC.

At a production level, production of PVC has been significantly refined over the years. Improved processing equipment and formulations have enabled manufacturers to improve consistency while reducing waste. Coordination between up-stream suppliers and down-stream users has become more critical in backing the supply chain. This constant liaison ensures that levels of production are compatible with application requirements, preventing bottlenecks and ensuring product availability. Although the technology of PVC manufacture is technical, the larger market environment is one of co-ordination and responsiveness to one another. All players along the supply chain contribute to framing the direction and stability of the Global PVC Market.

The demands of the environment have led the industry to research responsible production and disposal habits. As concern about material effects has grown worldwide, PVC producers and consumers have reacted by investing in better recycling technologies and more sustainable feedstocks. The life cycle of PVC products is now being considered from a more complete perspective, with consideration of not only near-term performance but also end-of-use designs. This focus on material flow helps ensure that the industry stays abreast of environmental and regulatory requirements without losing performance or accessibility. These activities are part of a larger trend within materials science that balances both innovation and responsibility.

During its course, PVC has shown an extraordinary ability to accommodate diverse and shifting conditions. Its resilience is not only based on technical capability but also in how it meets the changing requirements of industries that depend on reliable materials. The Global PVC Market, as discussed in the new report by Metastat Insight, reveals a multifaceted and nuanced image of how a single material can impact so many aspects of contemporary life. From the infrastructure to packaging, and from interior fittings in vehicles to domestic fittings, the use of PVC evidences a collective confidence in its attributes. As the industry strives to improve its processes and push its boundaries, PVC is a pillar in material planning and application design, tracking a path that is dynamic and rooted in practical use.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479