May 23, 2025

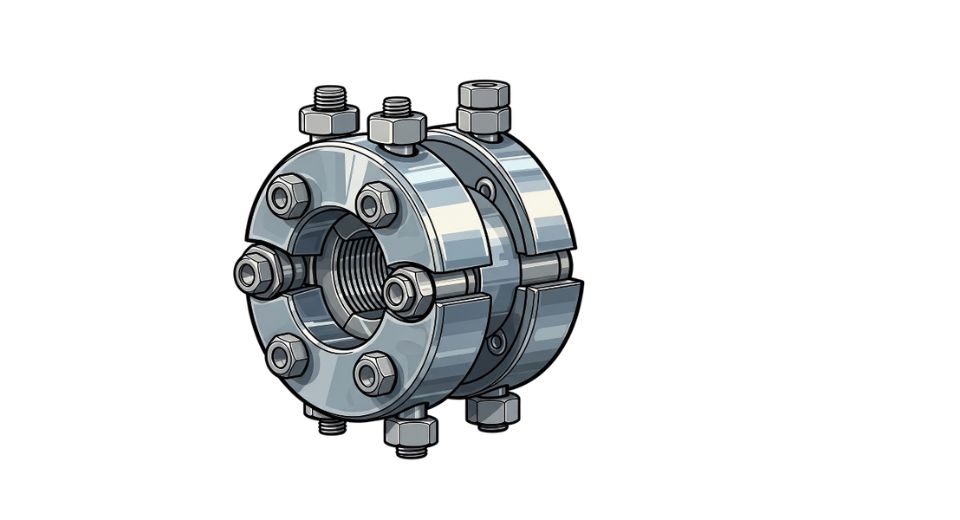

The latest release by Metastat Insight illuminates the evolving structure and multifaceted nature of the global industrial coupling market, offering a close-up examination of how machinery and mechanical equipment across sectors are transforming to meet emerging demands. In the mechanical universe, couplings play a unobtrusive yet essential role in bridging rotating shafts and transferring torque efficiently and accurately. Their purpose, though simple at the outset, grows more complicated as industries demand greater reliability, customization, and constancy in ever-more varied operating environments. The role of couplings ranges across sectors as disparate as manufacturing, energy, mining, transportation, and marine, where continuous operation and mechanical alignment are not merely desirable, but imperative.

As mechanical systems have grown in complexity, so has the coupling's role in them. The selection of coupling type whether flexible, rigid, or fluid has come to respond to an individual system's character and operating conditions. It is not unusual for designers and engineers to collaborate with manufacturers to customise couplings to exact load conditions, alignment tolerances, and vibration management. This has created a wider emphasis on coupling design parameters, putting more demands on materials and precision manufacturing processes. Over the last few years, this has created growing emphasis on areas such as torsional stiffness, backlash protection, and thermal efficiency. Consequently, the global industrial coupling market has become an industry where high-precision engineering converges with operational need and innovation usually exists in the minutest of details.

What distinguishes this market is the very technical environment in which it has developed, one that is fueled not by fleeting fads but by the inherent mechanical requirements of industrial-scale operations. Not only is there a need for high-performance couplings but also for those that prove to be long-lived, low-maintenance, and easily integrated with older or new systems. Consequently, producers are often tasked with the challenge of building components within tighter and tighter mechanical tolerances while delivering durability under hostile conditions whether high temperature, corrosive environments, or high-speed use. This requirement for great tolerance to operating stress has led manufacturers to try out innovative alloys, composite materials, and precision machining procedures.

One more factor that continues to impact this industry is the emphasis on operational efficiency. While timing couplings in themselves are not the subject of timing couplings in most industrial conversations, their failure can result in costly downtime, equipment destruction, and safety issues. The need for high reliability has driven continuing improvements in predictive maintenance and condition monitoring. Some producers have started integrating smart sensors into coupling systems so that torque loads, misalignment, and vibration can be monitored. These are not technology niceties they are reacting to the industrial world's larger goal of minimizing unexpected downtime and maximizing uptime. Thus, the global industrial coupling market is becoming quietly aligned with the larger trend toward intelligent industrial systems.

Geographical differences also have a significant influence on the formation of this market. Various regions have different preferences based on industry density, regulatory conditions, and even weather conditions. Where heavy industry like mining and energy extraction predominate, couplings tend to need to operate in harsh, rugged environments. Urbanized areas with sophisticated automation technologies, however, require small, optimized couplings with applications for robotics, packaging machines, and precision equipment. This variation in demand has pushed suppliers to keep portfolios broad and to provide localised industry-specific customization choices. Supply chain resilience has also become even more important, leading firms to look at more localised models of production and partnerships for guaranteed delivery and supply.

There is a transformation going on in some segments of the Global Industrial Coupling industry as mergers, collaborations, and acquisitions reshape the industry rivalry. The bigger players are looking to diversify their portfolios by taking in companies with specialized or complementary technologies. This consolidation can spur innovation but also raises the bar for the small players, who must continue to differentiate themselves on the basis of niche capabilities, delivery speed, or better customer service. Having both global behemoths and local specialists contributes a level of competitive dynamism to this market, wherein technical expertise and responsiveness are the norms for establishing market leadership.

Technical support and training are becoming more and more integral parts of customer care in this business. Most clients anticipate more than the provision of components; they anticipate consultation on selection, installation, and lifecycle upkeep. This has prompted coupling manufacturers to engage in closer relationships with their customers, providing customized advice that extends beyond the catalog. The increased focus on technical competence and after-sales service demonstrates an overarching appreciation that industrial couplings, though not the most noticeable component of equipment, can make a dramatic difference in system operation and lifespan.

The in-depth insights provided in the global industrial coupling market Report by Metastat Insight provide an insight into the manner in which this sector continues to establish new avenues through specific engineering, material science, and operational accuracy. The incremental, at times unsung developments observed in this market highlight the criticality of coupling systems in a wide range of industries. As engineers, manufacturers, and industrial operators continue to rely on these components, the need for performance, customization, and durability guarantees that the market is an arena for strategic thinking and serious innovation. The future of industrial equipment, in so many respects, will depend on the strength and reliability of these silent connectors that make the mechanical universe go round.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479