Sep 02, 2025

A global fall protection & confined space rescue equipment market report from Metastat Insight presents a story unveiling the dynamic evolution of protective solutions intended to save lives within dangerous working environments. An outlook founded on fourteen years of on-the-ground experience anchors the tone in the real world, avoiding generic abstractions to provide a story influenced by first-hand observation and immersion.

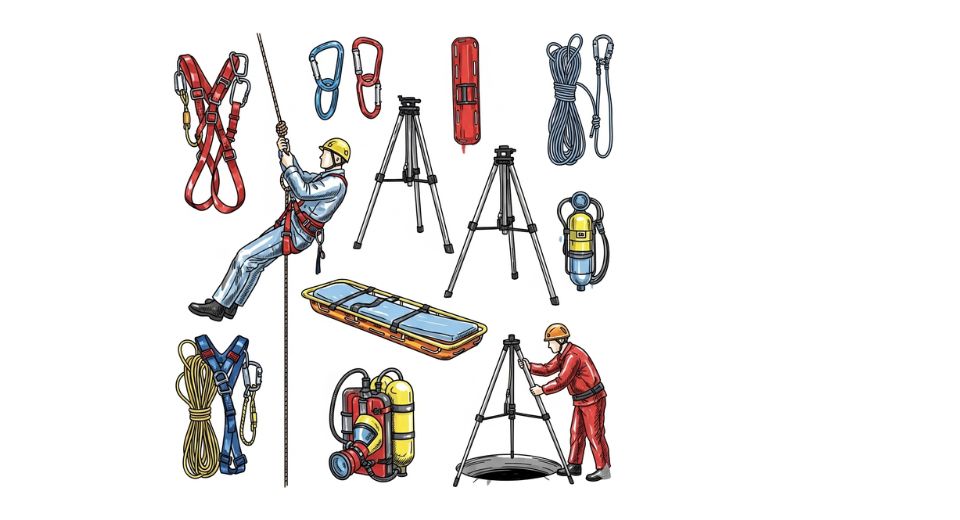

In industrial environments where heights and confined spaces overlap with day-to-day operations, safety equipment becomes silent sentinels whose worth is established by design, dependability, and faith from people. Stories from the field are woven where lifesaving harnesses and breathing-supplied tools encounter the harsh realities of application under stress, juxtaposing theoretical blueprint against actual use under duress. The performance ethos under pressure sets the stage not as a dry technical abstraction but as an unfolding dialogue between tools and the professionals who count on them when every moment matters. Shifting changes in material and assembly disclose a quiet revolution.

Composition of fibers changes, creating lightweight but resilient assemblies. Points of connection are refined to facilitate engagement under gloved hands and poor light, simplifying actions where careless fumbling becomes hazard. Rapid-donning equipment evolves from novelty to essential interface, smoothing passage from routine work to rescue mode. Testimony of tough on-site testing hints at the fine line between success and failure, recorded not on charts but in pulse-slowing instants when a worker gains confidence in gear and safety marshals note steadiness of breath. Changes in manufacturing ideology reverberate along supply chains. Suppliers used to batch large-scale production under general blueprints.

Today, feedback loops carry end-user input from far-flung project locations on different continents, prompting micro-adjustments. Fabric weaves adjust for abrasion buried deep underground; breathing gear adjusts valve positions after rescue simulations in weightless conditions. These fine details come from dialogue and not committee, delivered in anecdotes traded over coffee at job-site trailers. End users become ad-hoc co-conspirators. Employee unions and safety inspectors pass on issues that shift designers out of box-checking and into problem-solving. One anecdote remains: a crew responsible for dusty shafts discovered that screen visibility was diminished under particulate-filled air. Refinement ensued, not as checkbox adherence but as reaction to lived experiment. In low-visibility areas, glowing stitching and touch codes etched direction where vision failed, converting passive gear into an active interface.

Training modules conform to gear transmutation. Teachers of confined-space procedures combine physical simulation with equipment acclimation, providing users with muscular memory for putting on in limited stalls, conducting rescue lines through narrow hatches, and positioning breathing systems in spatially limited rescue pods. The learning environment surpasses drills it becomes a rehearsal wherein drills reflect the close-quarter truth and equipment smiles at practice rather than surprise. Worldwide visibility of safety requirements speeds up through online storytelling. Footage from remote construction shafts or deep wells makes its way instantly to design review panels.

Engineers identify endurance defects; site managers celebrate harness comfort for entire shifts. Collaborative video fosters sympathy: a design team in one time zone witnesses how a rescue system crouches under low-roof conditions thousands of miles away, and modifications accommodate local ergonomic requirements. The hardware evolves in appearance and ability, driven less by designations and more by communal visual evidence. The convergence of safety and culture underlines the narrative. Government directives set minimum performance, but welfare culture shapes how rigor goes beyond minimum. Stories carry weight: supervisors insist on quick checks, not just because rules require but because firsthand recollection reminds them how a colleague bypassed gear for speed and paid dearly.

That connective memory elevates equipment from compliance item to trusted colleague, defined by how often it fights against chance and wins. Future-oriented design responds to behaviour seen in real-time. Reports from current user logs inform material treatments that withstand contaminants introduced in chemical-laden ingress. Rescue kits transform from rigid packs to modular rigs that break down neatly throughout vessel compartments, allowing for quicker entry. There are no bullet points to record these transformations; instead, evolution is a sequence of subtle refinements shared through regular feedback and casual critique, informing the equipment path. Wrapping up with reflection on the product from Metastat Insight, a global fall protection & confined space rescue equipment market report produced by that think tank leads back to the beginning.

A passionate synthesis born of fourteen years' expertise takes in the subtle dance between equipment, mundane danger, and human determination. Reality-based advancements, pulled from corridors and shafts, lighthouses and rigs, uncover safer workplaces crafted not in quantities but in narratives of endurance and design that reacts where life hangs in the balance.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479